Polyimide film

a polyimide film and film technology, applied in the field of polyimide film, can solve the problems of difficult film support only through fixtures or pins, high production equipment of bi-axial stretch technique, and inconvenient maintenance, and achieve excellent young's modulus and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

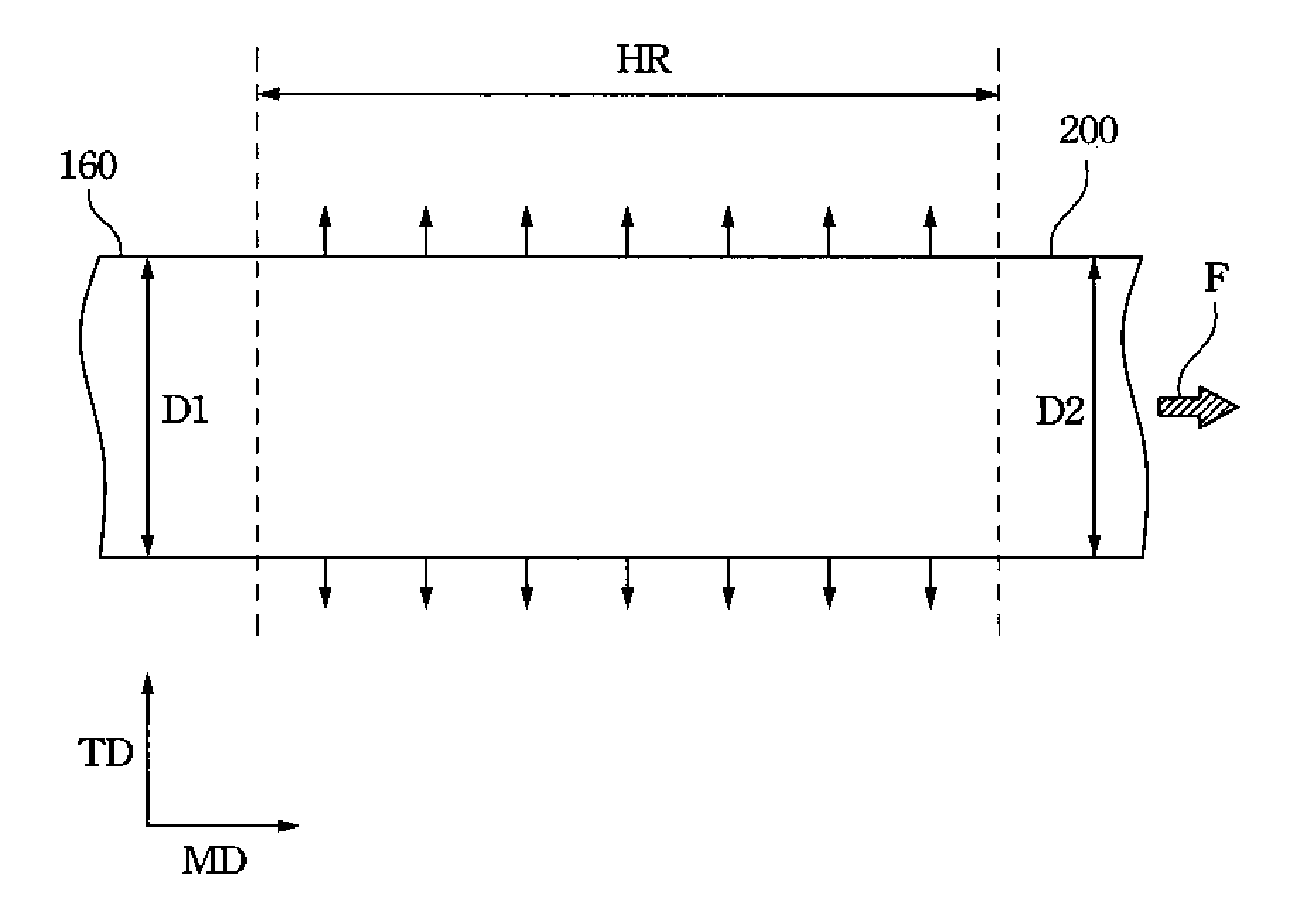

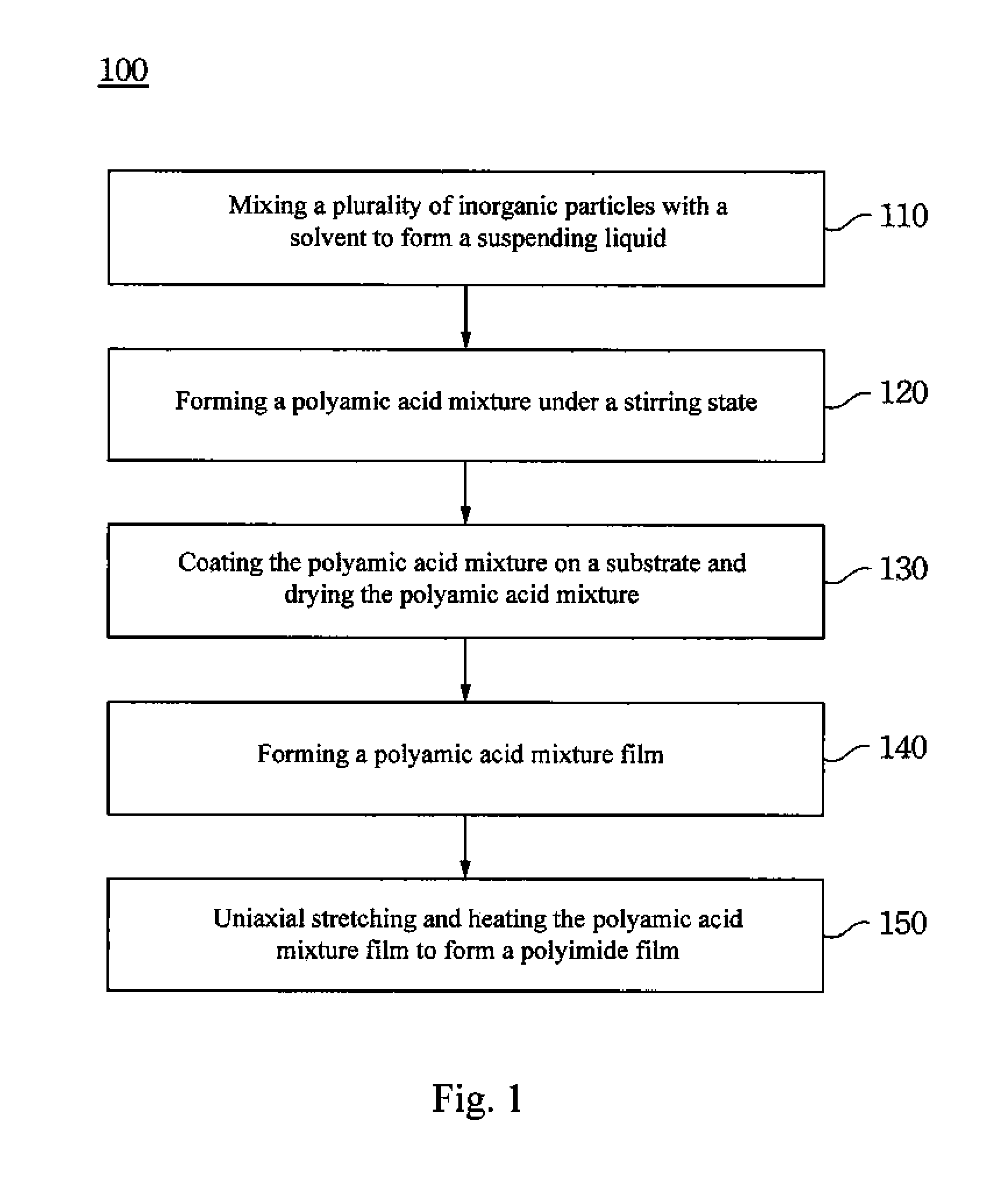

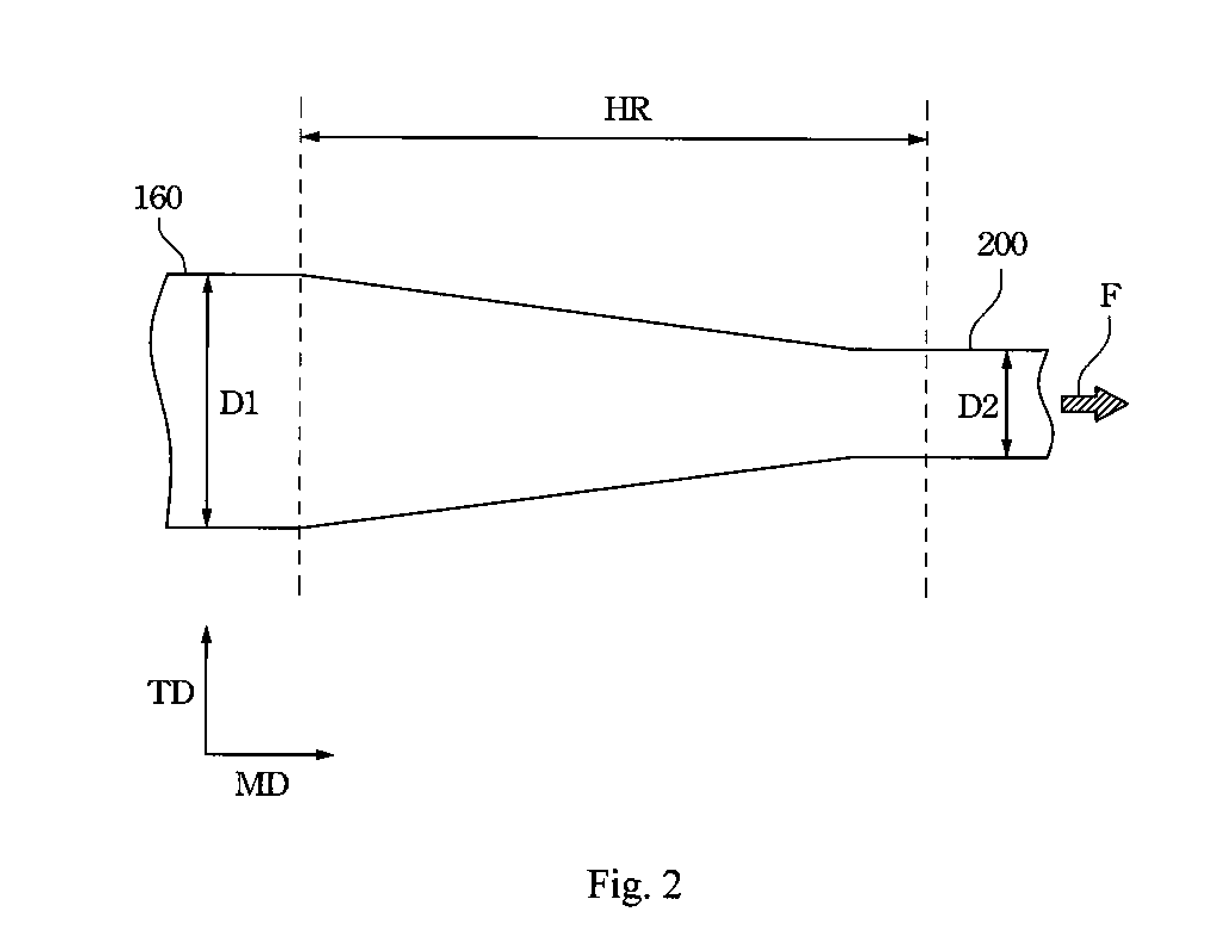

Method used

Image

Examples

embodiments

[0059]The following embodiments are used for illustrating specific aspects of the present disclosure in details, so that those of ordinary skills in the art of the present disclosure can implement the present disclosure. The following embodiments are not intended to limit the present disclosure.

embodiment 1

[0074]6.98 Kg silicon dioxide powder was added into a solvent of 79.07 Kg Dimethylacetamide (DMAC) with continuous stirring to make the silicon dioxide powder suspend in the DMAC solvent. The particle size of the above silicon dioxide powder was about 1-3 μm. Thereafter, 6.71 Kg ODA was added and dissolved. Afterwards, PDMA was slowly added and stirred for 6 h to perform a polymerization reaction and thus obtaining a polyamic acid solution. The temperature of the above reaction was controlled at 20-30° C.

[0075]It should be noted that since the polymerization reaction was performed with continuous stirring, the silicon dioxide powder was evenly distributed in the polyamic acid solution instead of being precipitated. After the polymerization reaction was completed, the polyamic acid solution has a certain viscosity, so that even when the stirring was stopped, the silicon dioxide powder was not precipitated in a short time by gravity. Furthermore, since in this embodiment, silicon diox...

embodiment 2

[0081]Compared with the embodiment 1, this embodiment mainly changes the adding amount of the silicon dioxide powder. The steps are illustrated in details as follows. 5.66 Kg silicon dioxide powder was added into a solvent of 80.19 Kg DMAC with continuous stirring to make the silicon dioxide powder suspend in the DMAC solvent. The particle size of the above silicon dioxide powder was about 1-3 μm. Thereafter, 6.81 Kg ODA was added and dissolved. Afterwards, PDMA was slowly added and stirred for 6 h to perform a polymerization reaction and thus obtained a polyamic acid solution. The temperature of the above reaction was controlled at 20-30° C. The subsequent steps are the same as these described in embodiment 1. In this embodiment, the weight percentage of the silicon dioxide powder in the polyimide film was about 28.6%.

[0082]In the embodiment 2, the resulted polyimide film was about 50 μm in thickness. The thermal expansion coefficient of the resulted polyimide film at the MD direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com