High-thermal conductivity insulating paint and preparation method thereof

An insulating paint, high thermal conductivity technology, applied in coatings, fire retardant coatings, etc., can solve the problems of poor thermal conductivity of insulating paint, accelerated aging of insulating paint, etc., to increase thermal conductivity, improve thermal conductivity, and reduce hydrophilic groups. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

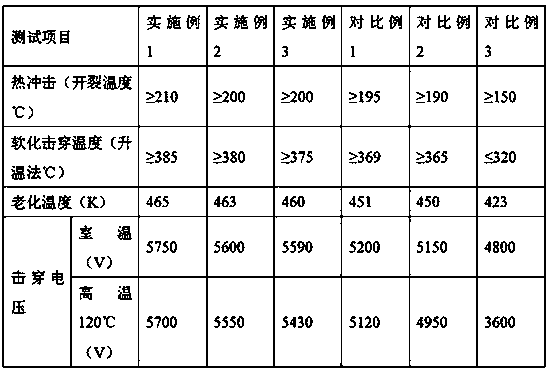

Examples

preparation example Construction

[0026] The preparation method of thermally conductive filler additive is:

[0027] (1) Take 4,4-dihydroxybiphenyl, add potassium carbonate at a mass ratio of 1~4:3~6, add benzyltriethylammonium chloride with 2~5% potassium carbonate mass, stir and mix for 30~40min, To obtain the mixture, take the mixture and add acetone according to the mass ratio of 1~5:10~20, raise the temperature to 55~60°C and stir and mix for 15~20min, to obtain the stirred mixture, take bromopropene and add acetone according to the mass ratio of 3~5:15~20, Stir and mix for 20-30 minutes to obtain a mixed solution;

[0028] (2) Take the mixed liquid and add it dropwise to the stirring mixture according to the mass ratio of 2~5:4~7, control the dropping time for 30~50min, keep it in an oil bath at 55~65°C for 18~24h, cool to room temperature, filter, Take the filtrate for rotary evaporation, take the rotary evaporator and add dichloromethane at a mass ratio of 3~5:8~10, then add 5~10% of the rotary evapor...

Embodiment 1

[0036] The preparation method of thermally conductive filler additive is:

[0037] (1) Take 4,4-dihydroxybiphenyl and add potassium carbonate at a mass ratio of 1:3, add benzyltriethylammonium chloride with a mass ratio of 2% of potassium carbonate, stir and mix for 30 minutes to obtain a mixture, and take the mixture according to the mass ratio Add acetone at a ratio of 1:10, heat up to 55°C and stir for 15 minutes to obtain a stirred mixture. Take bromopropene and add acetone at a mass ratio of 3:15, stir and mix for 20-30 minutes to obtain a mixed solution;

[0038] (2) Take the mixed solution and add it dropwise to the stirring mixture according to the mass ratio of 2:4, control the dropping time for 30 minutes, keep it in an oil bath at 55°C for 18 hours, cool to room temperature, filter, take the filtrate and rotary evaporate, and take the rotary evaporator according to Add dichloromethane at a mass ratio of 3:8, then add 20% hydrochloric acid with a mass fraction of 5% ...

Embodiment 2

[0046] The preparation method of thermally conductive filler additive is:

[0047] (1) Take 4,4-dihydroxybiphenyl, add potassium carbonate at a mass ratio of 2:5, add benzyltriethylammonium chloride with 4% potassium carbonate mass, stir and mix for 35 minutes to obtain a mixture, and take the mixture according to the mass ratio Add acetone at 4:150, heat up to 58°C and stir and mix for 18 minutes to obtain a stirred mixture. Take bromopropene and add acetone at a mass ratio of 4:18, stir and mix for 25 minutes to obtain a mixed solution;

[0048] (2) Take the mixed solution and add it dropwise to the stirring mixture according to the mass ratio of 4:5, control the dropping time for 40 minutes, keep it in an oil bath at 58°C for 22 hours, cool to room temperature, filter, take the filtrate and rotary evaporate, and take the rotary evaporator according to Add dichloromethane at a mass ratio of 4:9, then add 20% hydrochloric acid with a mass fraction of 8% of the rotary evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com