Locking mechanism for electric appliance

A technology of locking mechanism and tripping mechanism, applied in the direction of protection switch operation/release mechanism, circuit, electric switch, etc. The effect of small complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

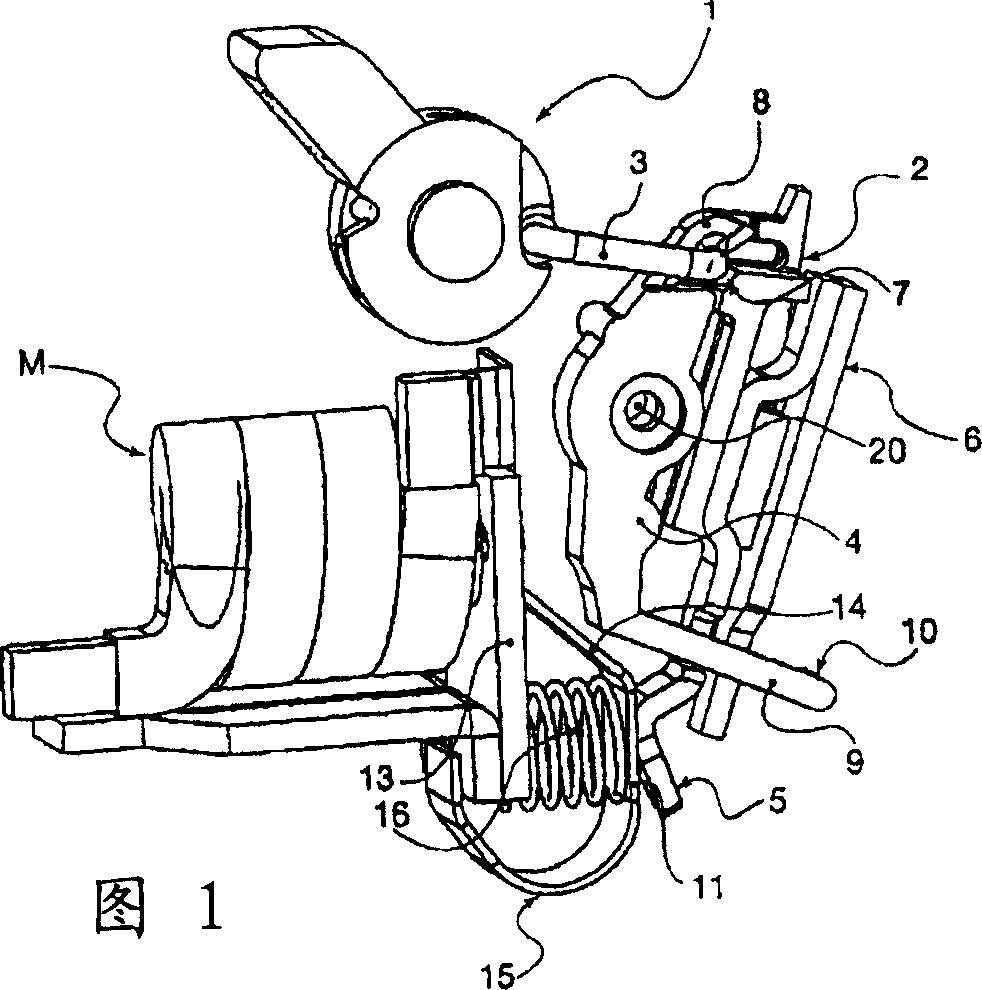

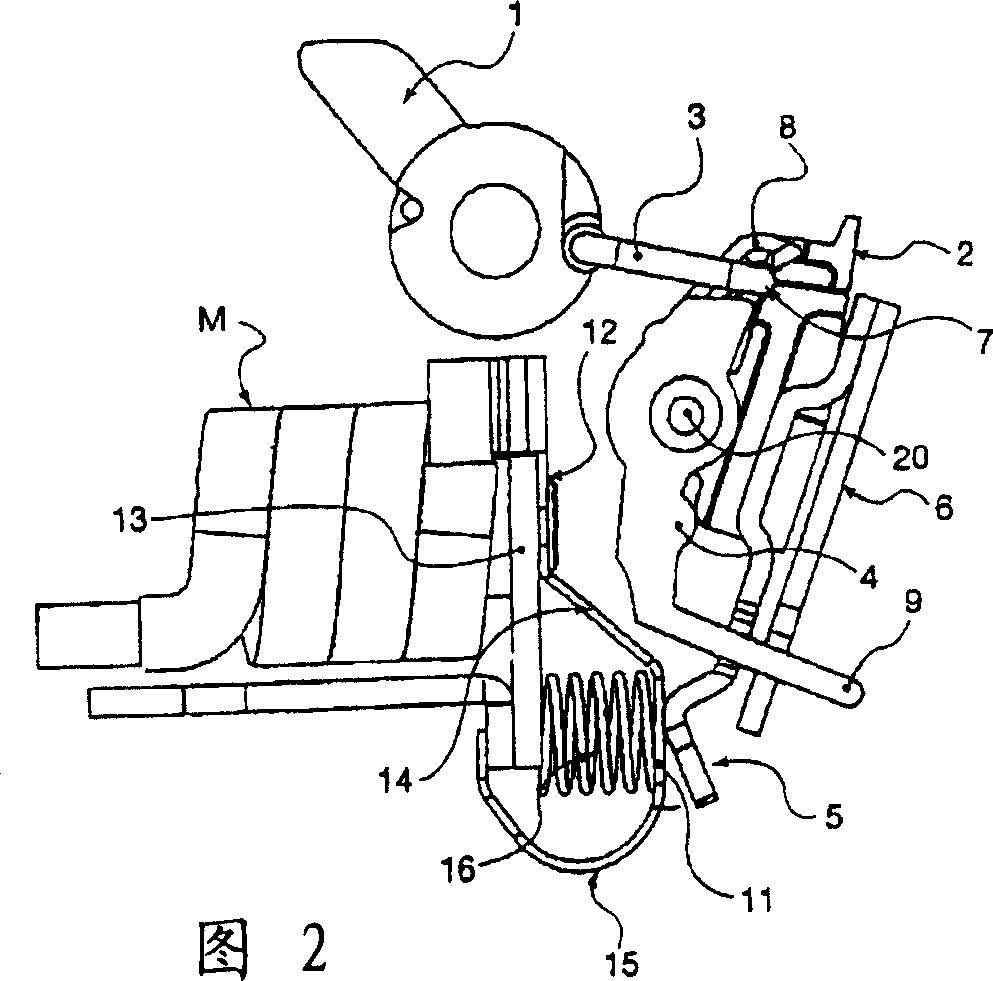

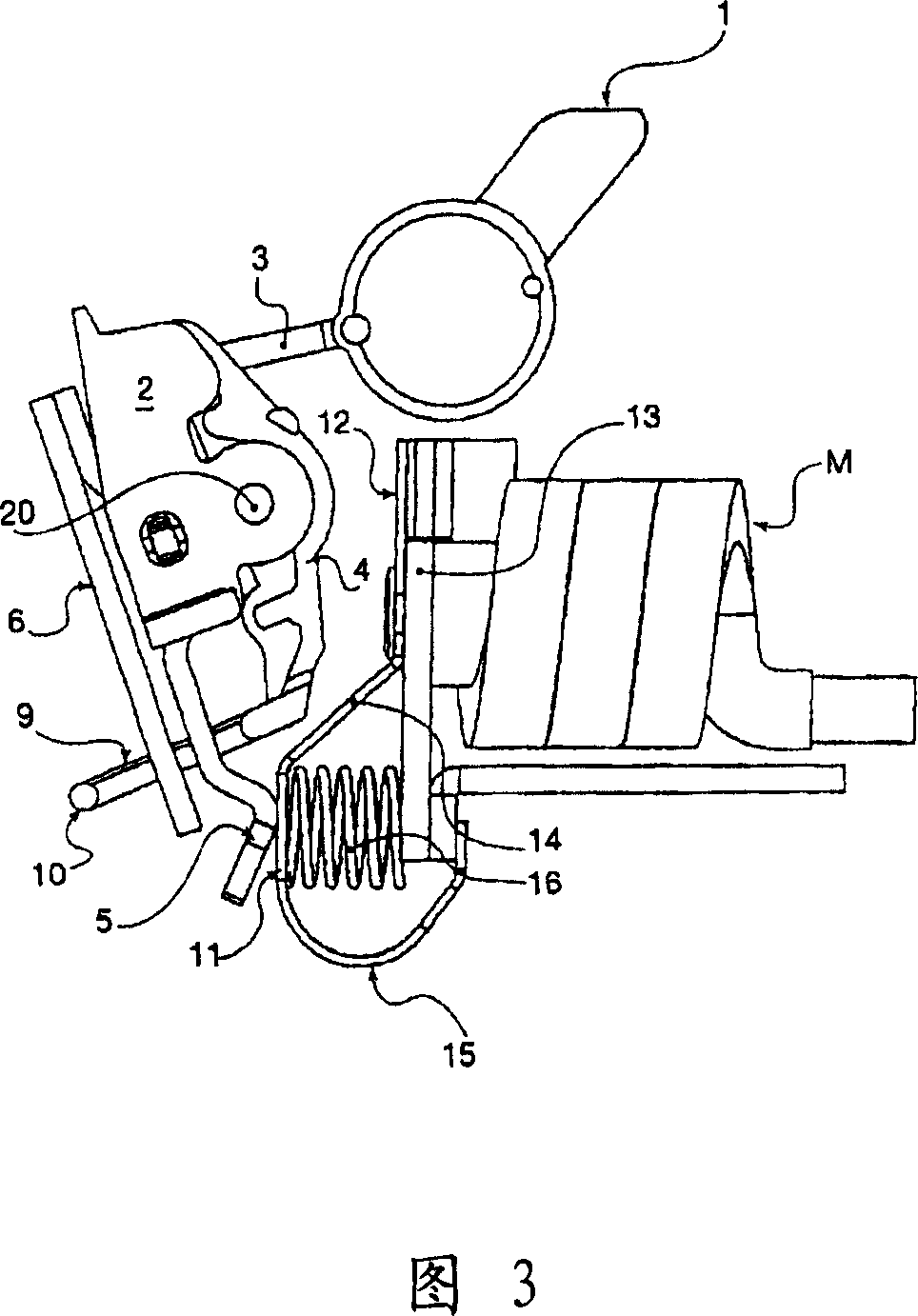

[0031] As shown in the figure, the control mechanism of an electrical appliance, such as a differential circuit breaker or a differential switch, is composed of a joystick 1 that is freely rotatable relative to the junction box of the electrical appliance, and its rotational movement is transmitted through a connecting rod 3 to a A movable component of the contact base 2.

[0032] The contact holder 2 itself is free to rotate about an axis relative to the junction box of the electrical appliance (not shown), and in the event of an abnormal operation of the circuit on which said electrical appliance is installed, a tripping mechanism 4 comes into play, also pivoting about said axis .

[0033] A movable contact 5 is fixed rigidly to the contact base 2 . According to one possibility, a bimetallic element 6 is also fixed rigidly to said movable contact 5 .

[0034] In general, it is known that the assembly works as a crank linkage in such a way that when the control mechanism 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com