Air-permeable bottle and manufacturing process

A breathable bottle and bottle body technology, applied in the field of breathable bottles, can solve problems such as large limitations, unbalanced negative pressure concentration, and inability to fundamentally solve the problem of negative pressure, so as to prevent pollution, prevent water leakage, and achieve high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

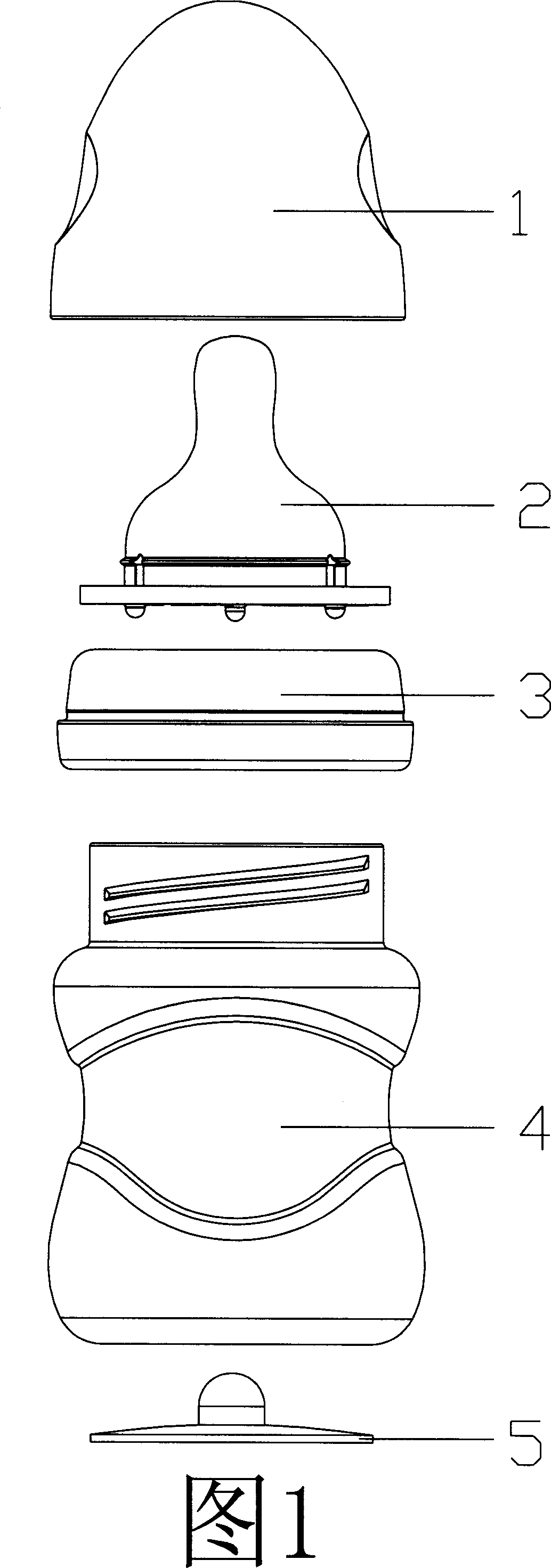

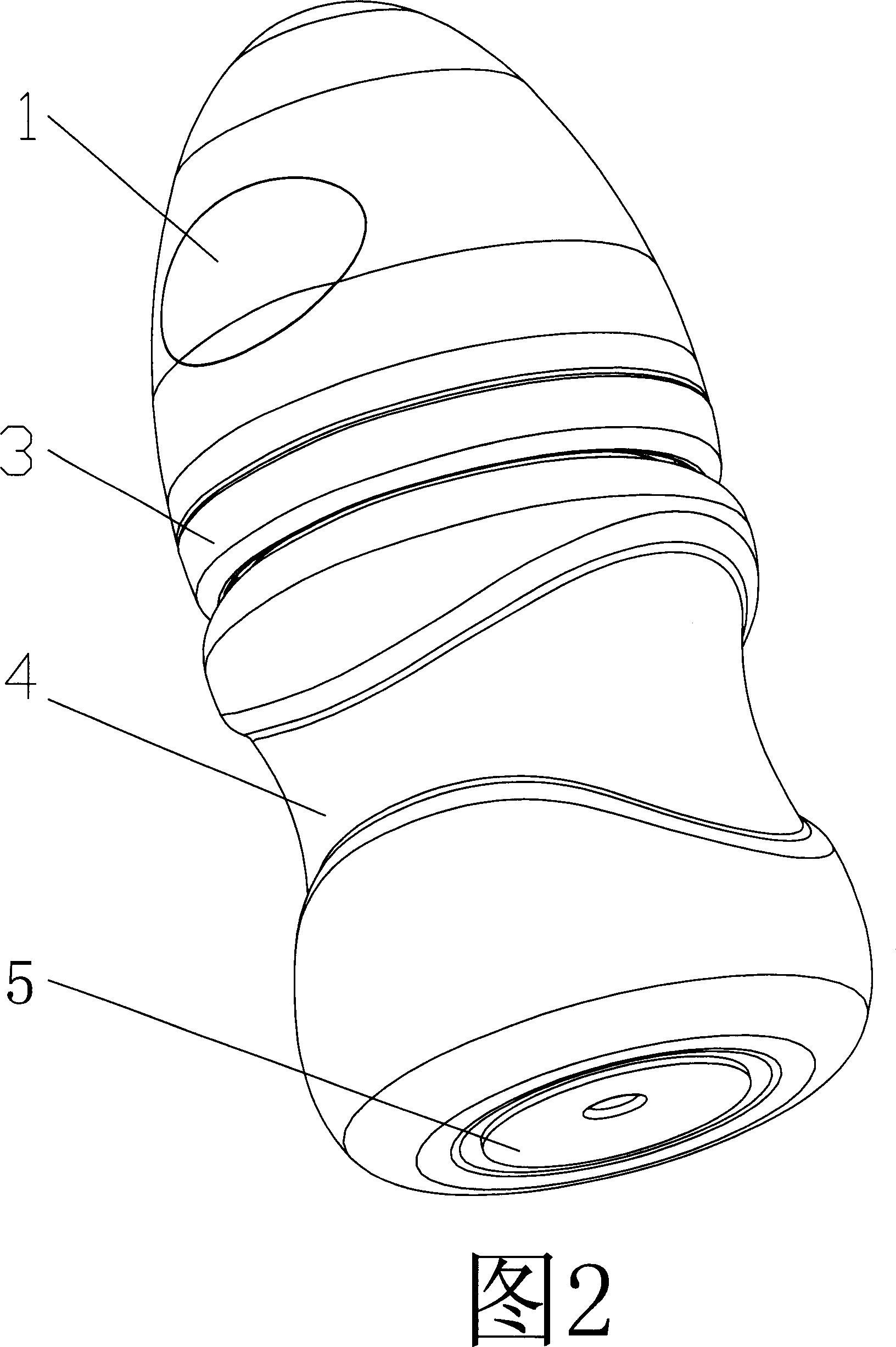

[0023] The present invention will be further detailed below in conjunction with the accompanying drawings:

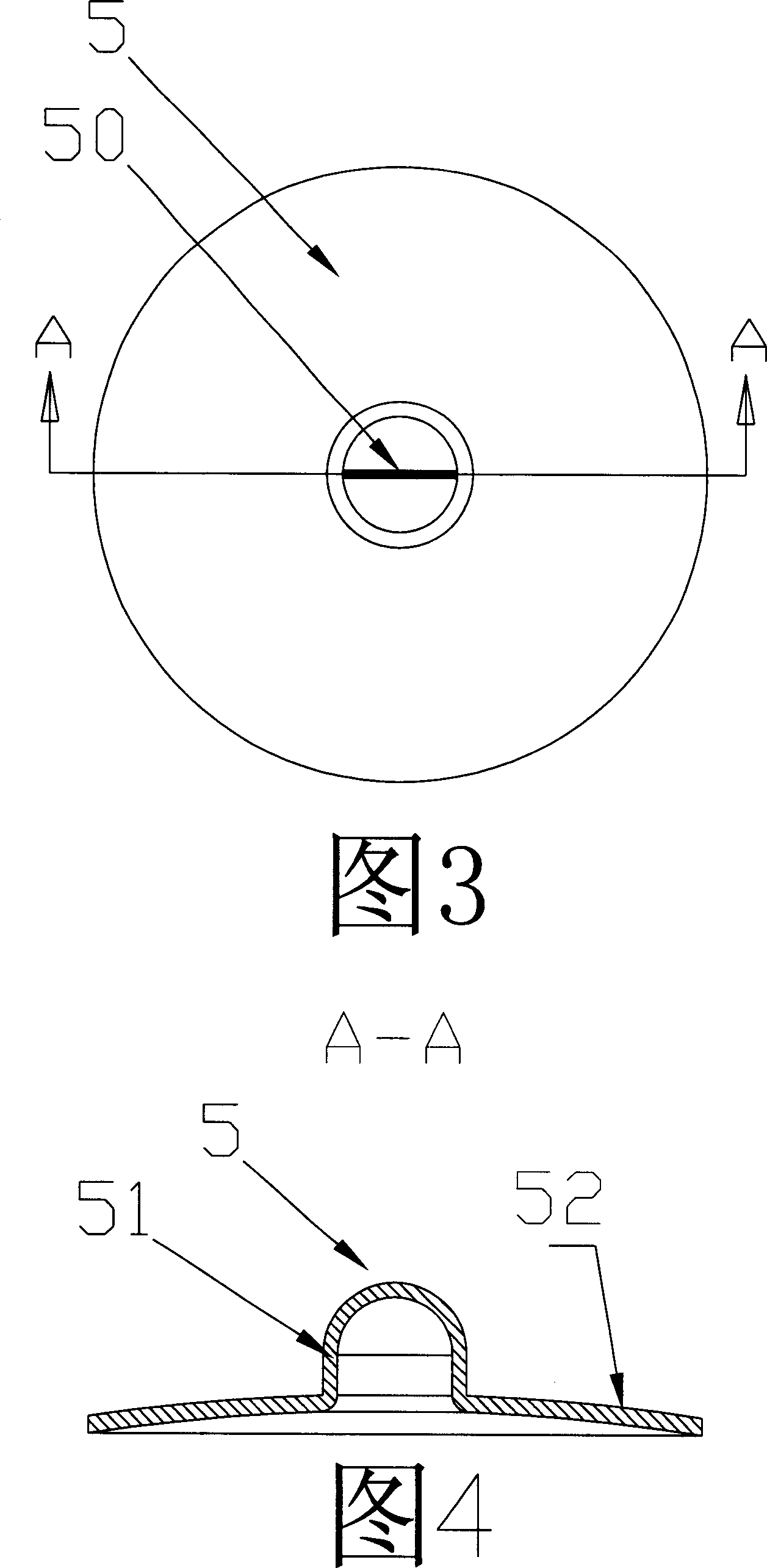

[0024] Please refer to the attached drawings, the structure of the breathable bottle: the open end of the breathable bottle body 4 is screwed with the rotating cover 3 of the built-in suction nozzle 2, and the transparent cover 1 that covers the suction nozzle 2 and is fastened to the rotating cover 3 is. There is an incision 50 in the middle, which can automatically supplement the pressure and ventilate the silicone breathable valve 5, which is coated on the bottom of the bottle. When the breathable bottle body 4 is squeezed by water pressure, it can effectively prevent the incision 50 from opening and causing water leakage and liquid Leaking from the bottom of the bottle. The silicone breathable valve 5 is composed of an annular edge 52 welded to the bottom of the bottle, a nipple-shaped wave point 51 protruding on the annular edge 52, and a breathable cut 50 on the wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com