Charged particle beam device, optical device, irradiation method, diffraction grating system, and diffraction grating

a charge particle and beam technology, applied in the field of light beams, to achieve the effect of efficient observation, processing and energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

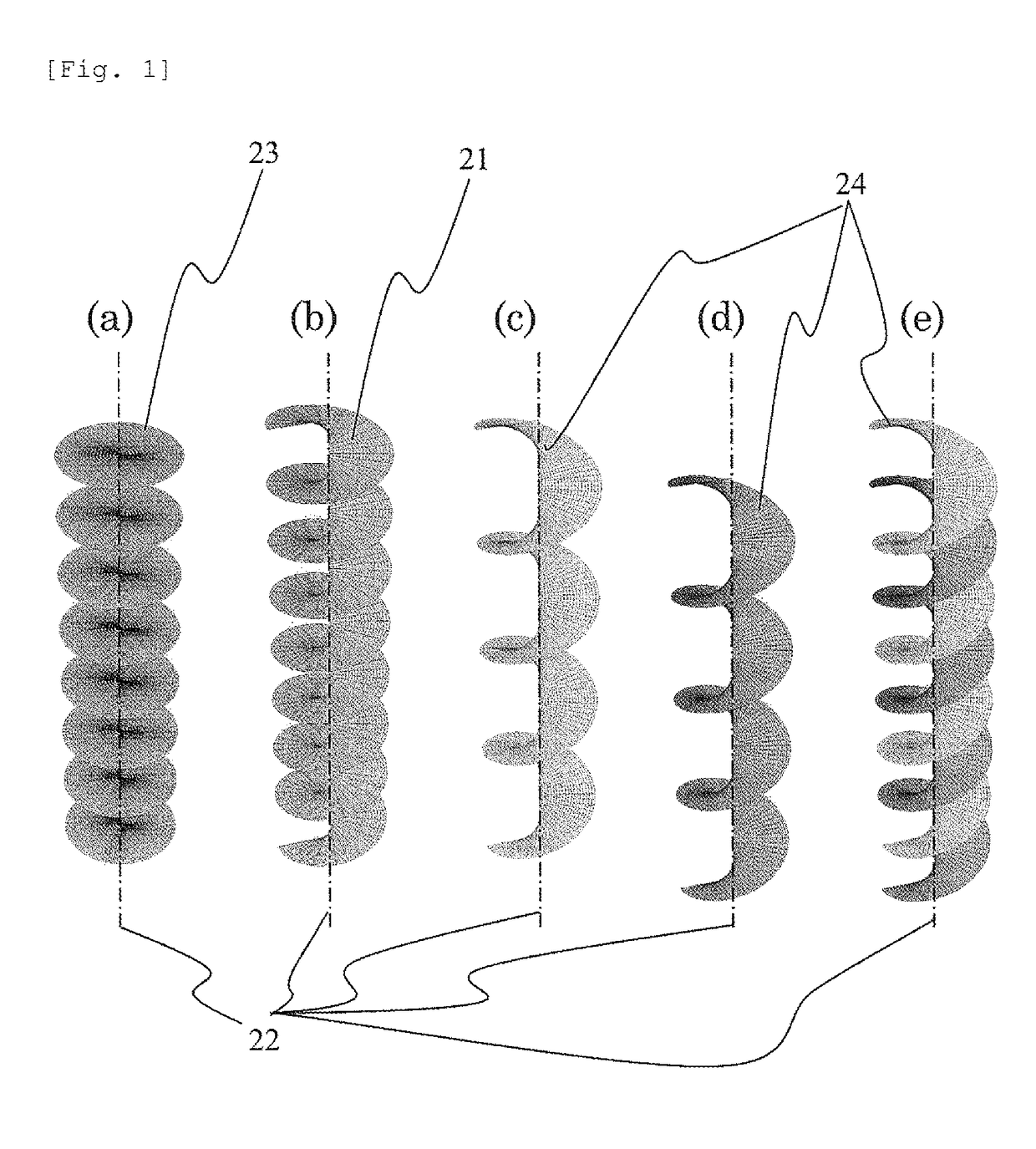

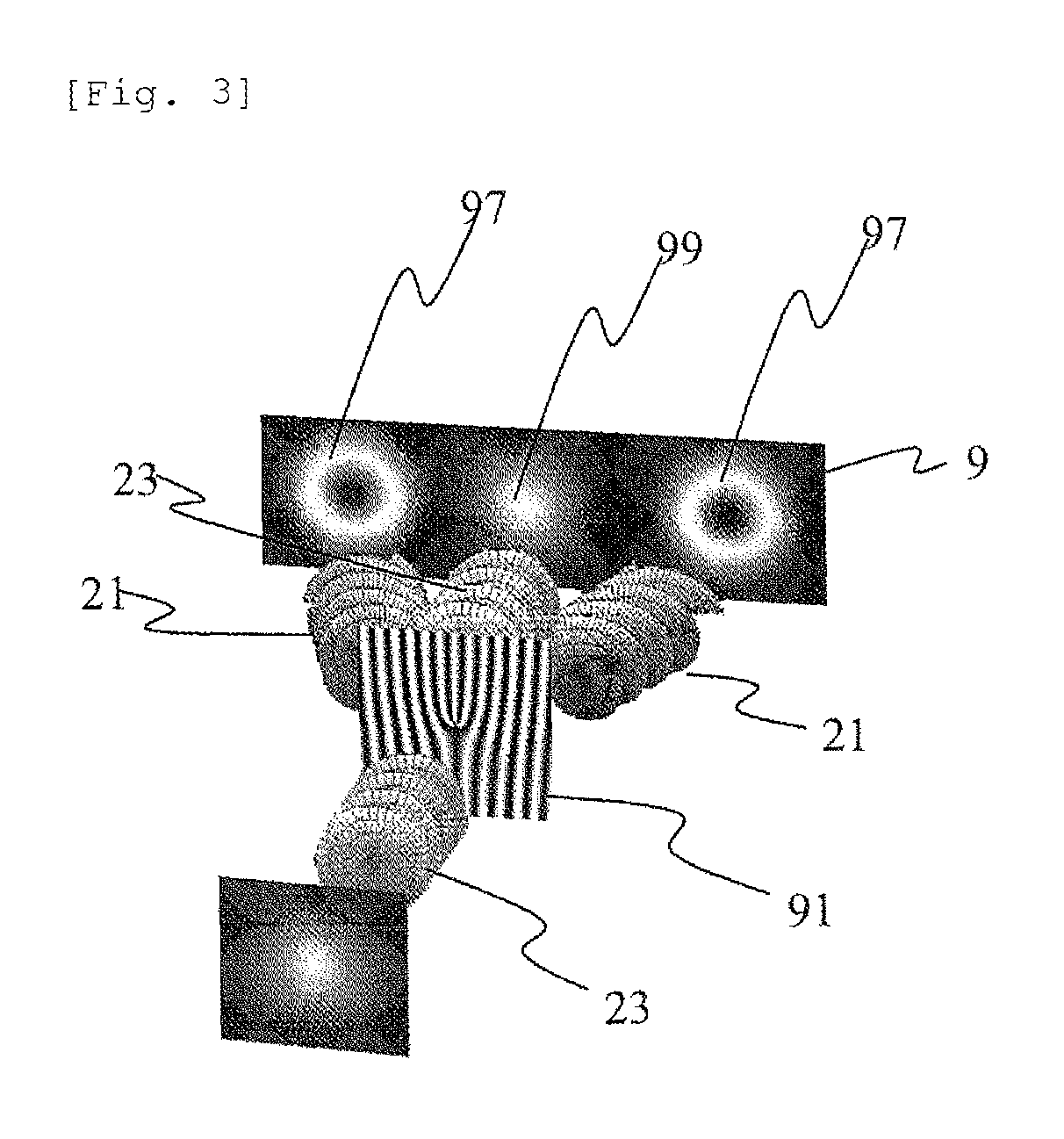

[0080]Example 1 for implementing the present invention is illustrated in FIG. 8. It has a configuration different from that illustrated in FIG. 3, and a diffraction grating 91 including the edge dislocation is irradiated with a plane wave 23 passes through the diffraction grating and thereafter forms a spiral wave 21 as a diffraction wave. However, the opening shape 81 of the diffraction grating 91 including the edge dislocation has a shape as an arrowhead (hereinafter, referred to as an arrowhead shape), and as illustrated in FIGS. 7a-7e, the arrowhead shape is reflected in the shape of annular diffraction spots 97. Moreover, the shape is a diffraction pattern in which annular diffraction spots 97 are rotated (here, rotated by 90 degree) to the left and right of the orientation indicating the diffraction spot 99 of a transmitted wave is in clock / counter clockwise directions respectively.

[0081]It is possible to make a predetermined spiral wave 21 by spatially separating one of the a...

example 2

[0085]Example 2 for implementing the present invention will be described with reference to FIG. 11A and FIG. 11B. FIG. 11A is an example of a diffraction grating system in which the diffraction grating 91 and the opener 83 are formed into a different structure. The opening shape 81 is a part of the opener 83. A state is illustrated in which the opener 83 is disposed adjacent to the upper part of the diffraction grating 91 (the grating outer shape is rectangular) with a third-order edge dislocation, but the upper and lower relationship between the diffraction grating and the opener, and the mutual distance are not limited to the configuration of FIGS. 11A and 11B. The relative positions of the diffraction grating and the opener may be changeable in the horizontal direction and the vertical direction. In other words, the positions of the diffraction grating 91 and the opener 83 may be changed.

[0086]FIG. 11B illustrates the shape without rotational symmetry (that is, having a single ro...

example 3

[0090]FIG. 12 illustrates Example 3 for implementing the present invention. FIG. 12 illustrates a case where a part of a closed curve defining the opening shape 81 of the opener 83 illustrated in FIG. 11 is irradiated with light beams or particle beams that irradiate a circular area. In the example of FIG. 12, the opening shape 81 of the light beams or the particle beams passing through the diffraction grating system becomes an irradiated area of the opening portion of the opener 83 as a result.

[0091]Accordingly, it is indicated that it is possible to realize the control equivalent to Example 2, not only by changing the shape of the opener 83, but also changing the irradiation area of the irradiation optical system and the irradiation intensity of the light beam or the particle beam (in other words, by deflecting the optical axis and converging beams by the lens).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com