Exhaust gas control system for internal combustion engine and control method for internal combustion engine

a control system and exhaust gas technology, applied in the direction of electric control, combustion engines, machines/engines, etc., can solve problems such as the inability to perform malfunction diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Hereinafter, a specific embodiment of the disclosure will be described based on the drawings. The dimensions, materials, shapes, relative arrangements, and the like of constituent parts described in the embodiments are not intended to limit the technical scope of the disclosure to these alone in particular as long as there are not specific statements.

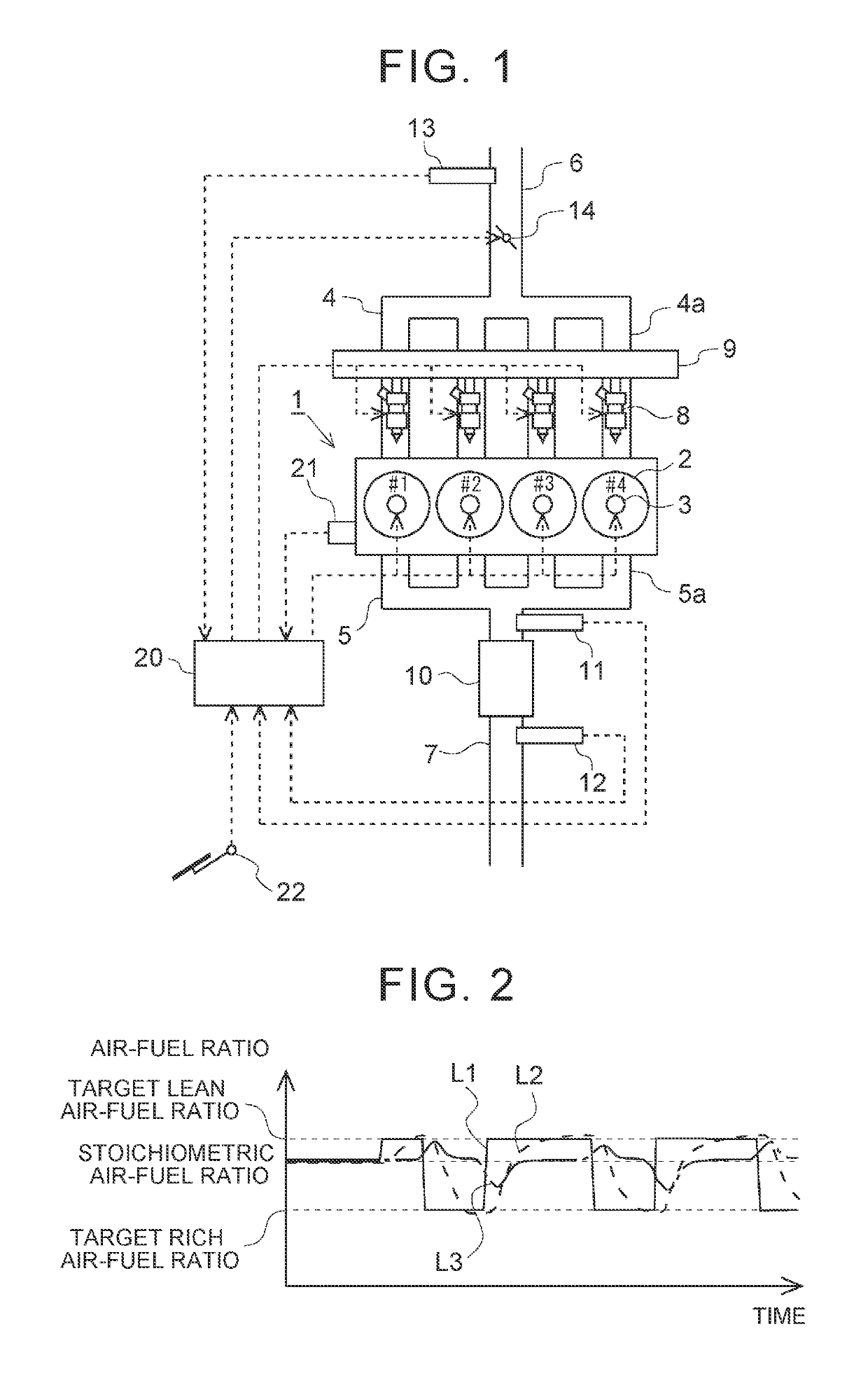

[0031]First, a first embodiment will be described. FIG. 1 is a diagram showing the schematic configuration of an internal combustion engine according to this embodiment and an intake and exhaust system thereof. An internal combustion engine 1 is a gasoline engine for vehicle drive. The internal combustion engine 1 is an in-line four-cylinder engine having four cylinders 2. Each cylinder 2 of the internal combustion engine 1 is provided with an ignition plug 3.

[0032]An intake manifold 4 and an exhaust manifold 5 are connected to the internal combustion engine 1. Then, each intake branch pipe 4a of the intake manifold 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com