Optical image capturing module

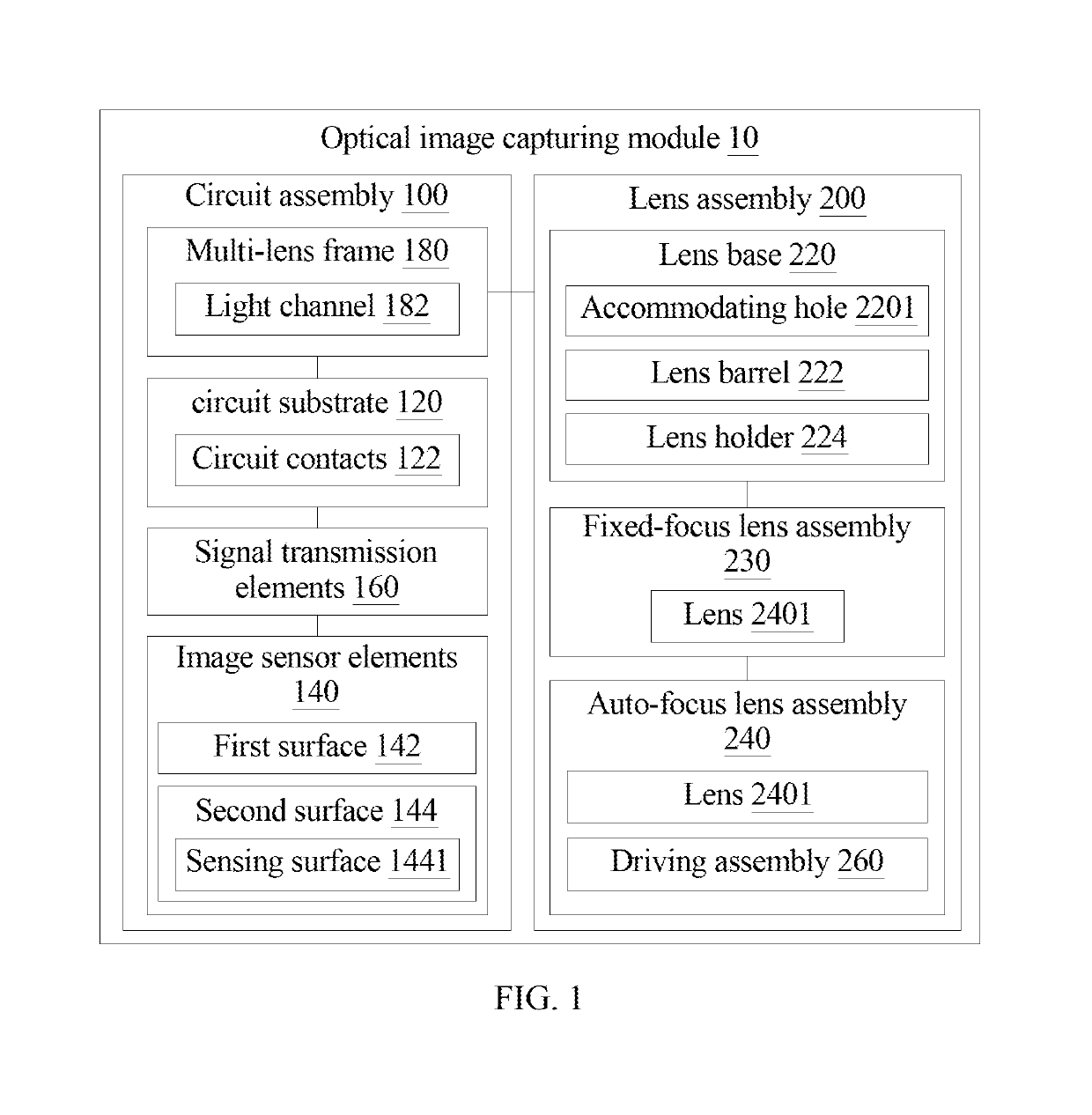

a technology of optical image and module, applied in the direction of camera filter, printer, camera focusing arrangement, etc., can solve the problems of difficult management of assembling and packaging quality of all components, many problems identified but not solved, etc., and achieve the effect of enhancing image quality and reducing the difficulty of light path regulating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first optical embodiment

The First Optical Embodiment

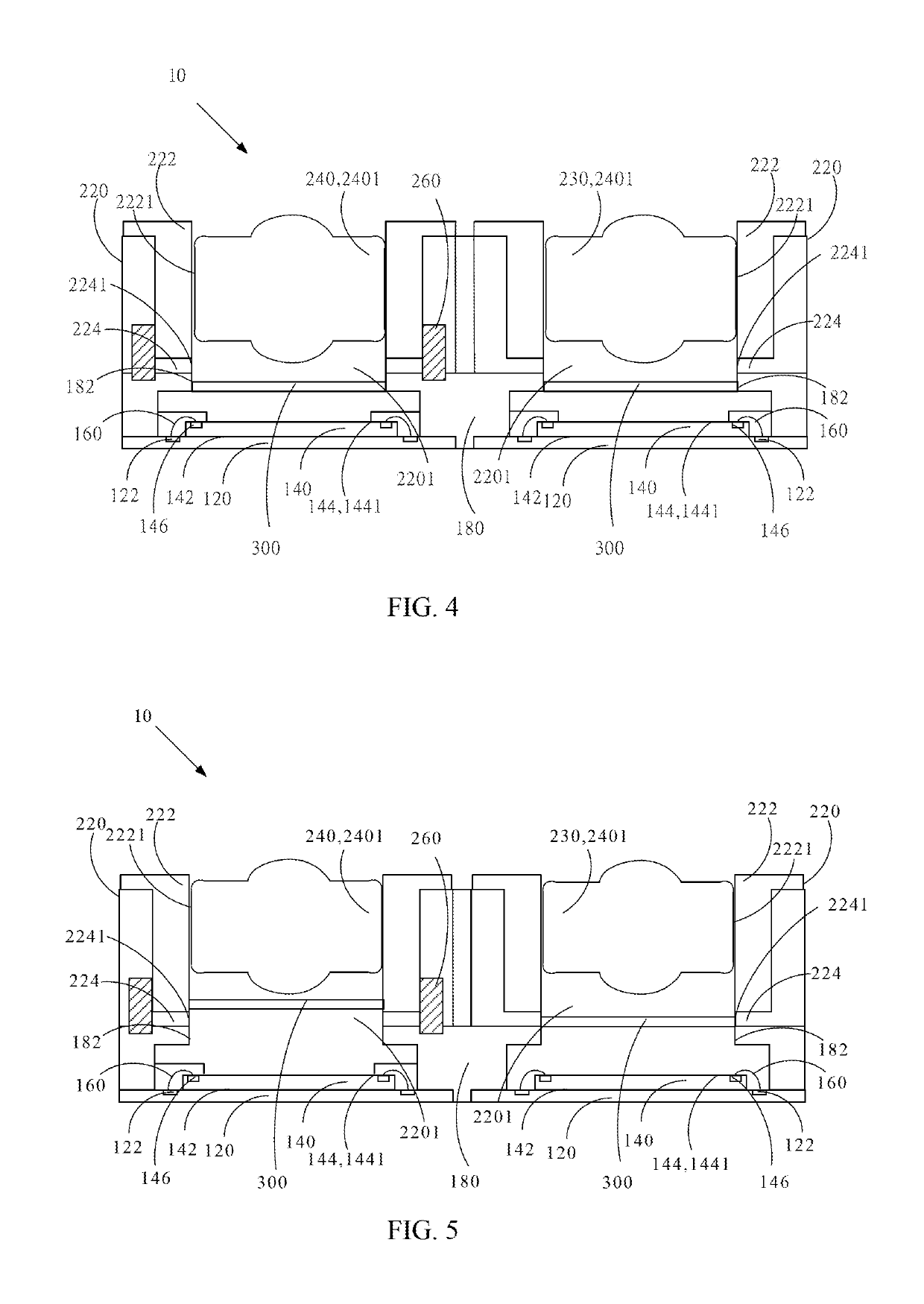

[0203]As shown in FIG. 21, the fixed-focus lens assembly 230 and the auto-focus lens assembly 240 include six lenses with refractive power, which are a first lens 2411, a second lens 2421, a third lens 2431, a four lens 2441, a fifth lens 2451, and a sixth lens 2461 sequentially displayed from an object side surface to an image side surface. The fixed-focus lens assembly 230 and the auto-focus lens assembly 240 satisfy the following condition: 0.1≤InTL / HOS≤0.95. Specifically, HOS is the distance from an object side surface of the first lens 2411 to the imaging surface on an optical axis. InTL is the distance on the optical axis from an object side surface of the first lens 2411 to an image side surface of the sixth lens 2461.

[0204]Please refer to FIG. 23 and FIG. 24. FIG. 23 is a schematic diagram of the optical image capturing module according to the first optical embodiment of the present invention. FIG. 24 is a curve diagram of spherical aberration, as...

second optical embodiment

The Second Optical Embodiment

[0268]As shown in FIG. 22, the fixed-focus lens assembly 230 and the auto-focus lens assembly 240 may include seven lenses 2401 with refractive power, which are a first lens 2411, a second lens 2421, a third lens 2431, a four lens 2441, a fifth lens 2451, a sixth lens 2461, and a seventh lens 2471 sequentially displayed from an object side surface to an image side surface. The fixed-focus lens assembly and the auto-focus lens assembly satisfy the following condition: 0.1≤InTL / HOS≤0.95. Specifically, HOS is the distance on the optical axis from an object side surface of the first lens 2411 to the image plane; InTL is the distance on the optical axis from an object side surface of the first lens 2411 to an image side surface of the seventh lens 2471.

[0269]Please refer to FIG. 25 and FIG. 26. FIG. 25 is a schematic diagram of the optical image capturing module according to the second optical embodiment of the present invention. FIG. 26 is a curve diagram of...

third optical embodiment

The Third Optical Embodiment

[0288]As shown inFIG. 21, the fixed-focus lens assembly 230 and the auto-focus lens assembly 240 include six lenses 2401 with refractive power, which are a first lens 2411, a second lens 2421, a third lens 2431, a four lens 2441, a fifth lens 2451, and a sixth lens 2461 sequentially displayed from an object side surface to an image side surface. The fixed-focus lens assembly 230 and the auto-focus lens assembly 240 satisfy the following condition: 0.1≤InTL / HOS≤0.95. Specifically, HOS is the distance from an object side surface of the first lens 2411 to the imaging surface on an optical axis. InTL is the distance on the optical axis from an object side surface of the first lens 2411 to an image side surface of the sixth lens 2461.

[0289]Please refer to FIG. 27 and FIG. 28. FIG. 27 is a schematic diagram of the optical image capturing module according to the third optical embodiment of the present invention. FIG. 28 is a curve diagram of spherical aberration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com