Ultrasonic transducer chip assembly, ultrasound probe, ultrasonic imaging system and ultrasound assembly and probe manufacturing methods

a technology of ultrasonic transducer and manufacturing method, which is applied in the direction of mechanical vibration separation, instruments, catheters, etc., can solve the problems of increasing the overall diameter of the ultrasound probe, rather cumbersome manufacturing such a probe, etc., and achieves a cost-effective and high-quality manufacturing process. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

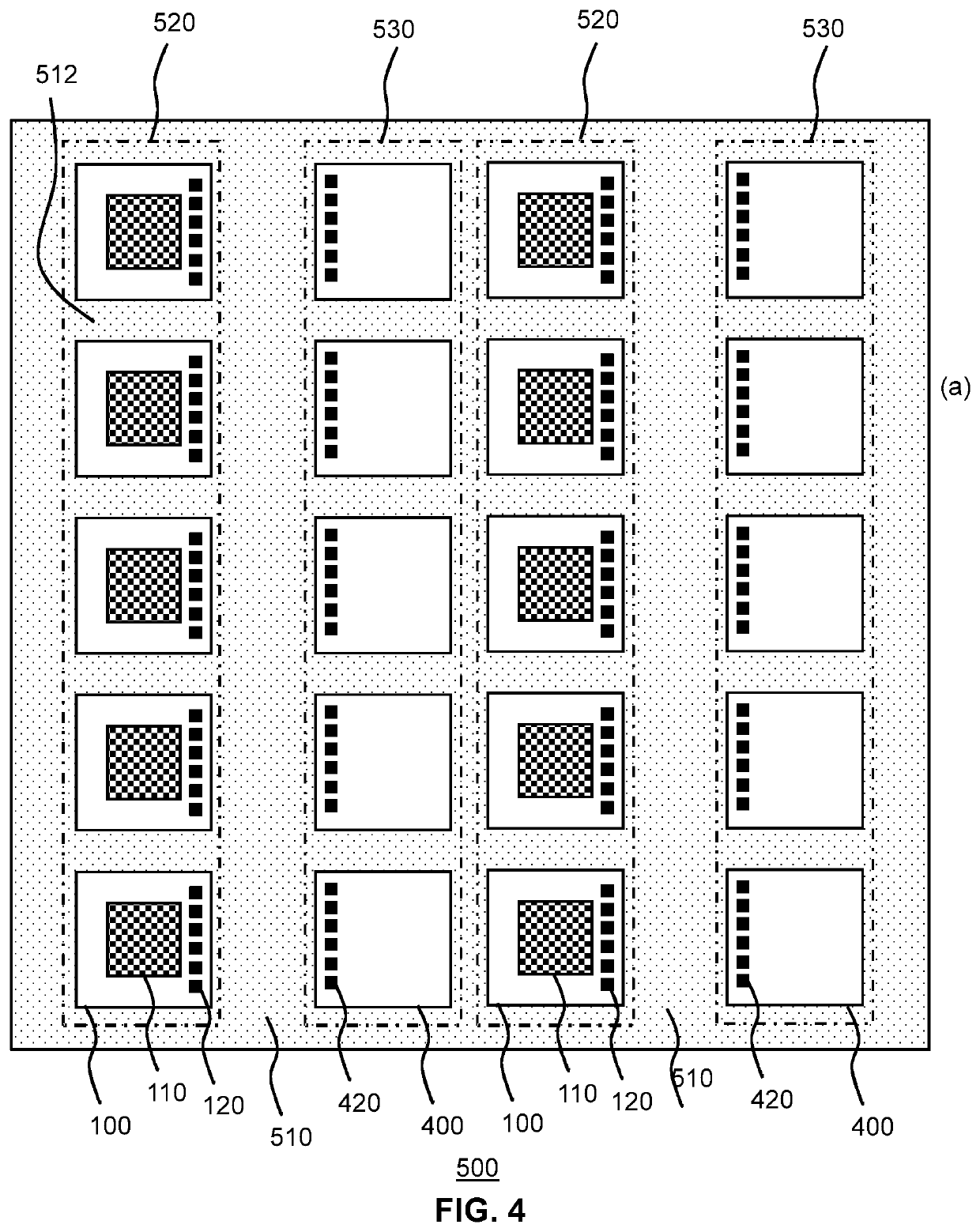

[0039]It should be understood that the Figures are merely schematic and are not drawn to scale. It should also be understood that the same reference numerals are used throughout the Figures to indicate the same or similar parts.

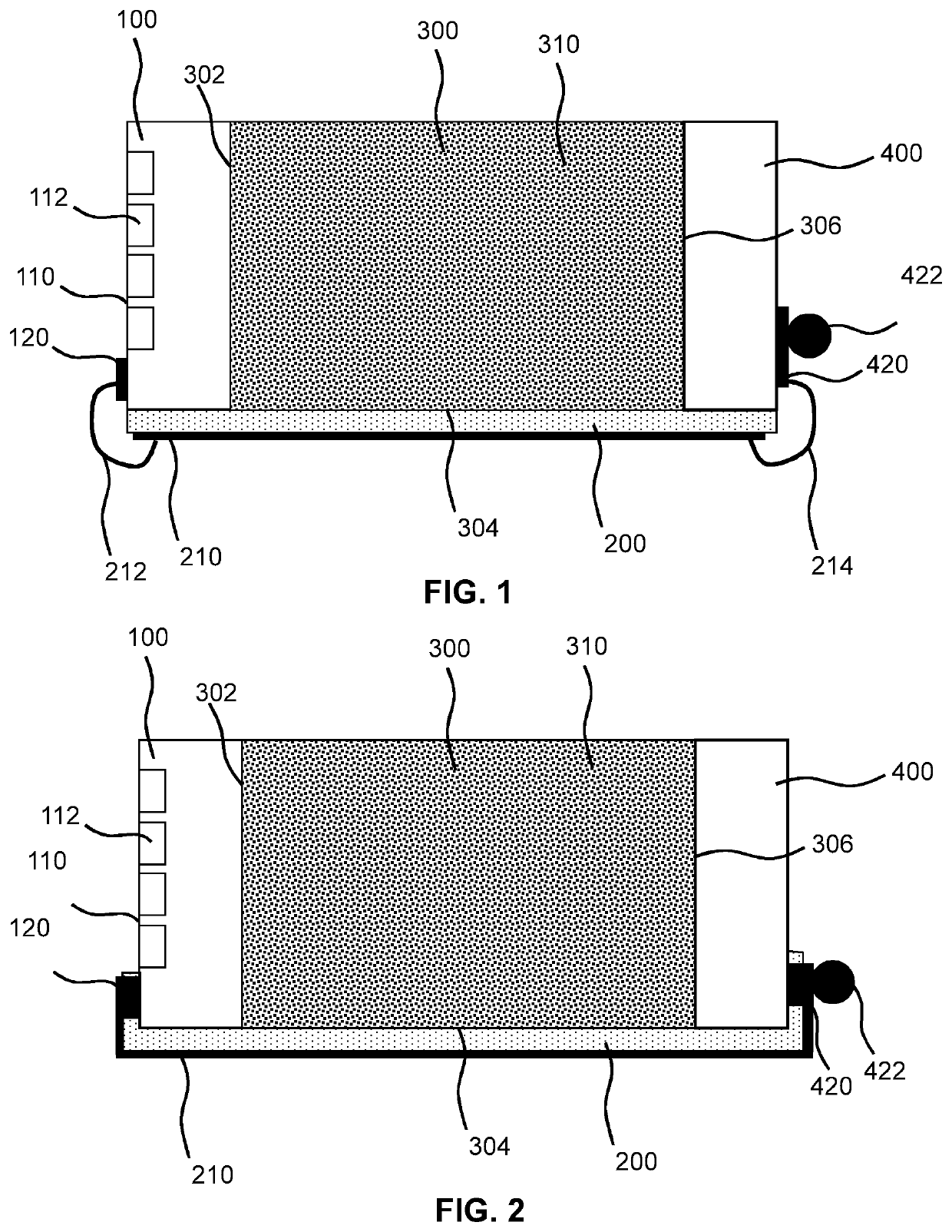

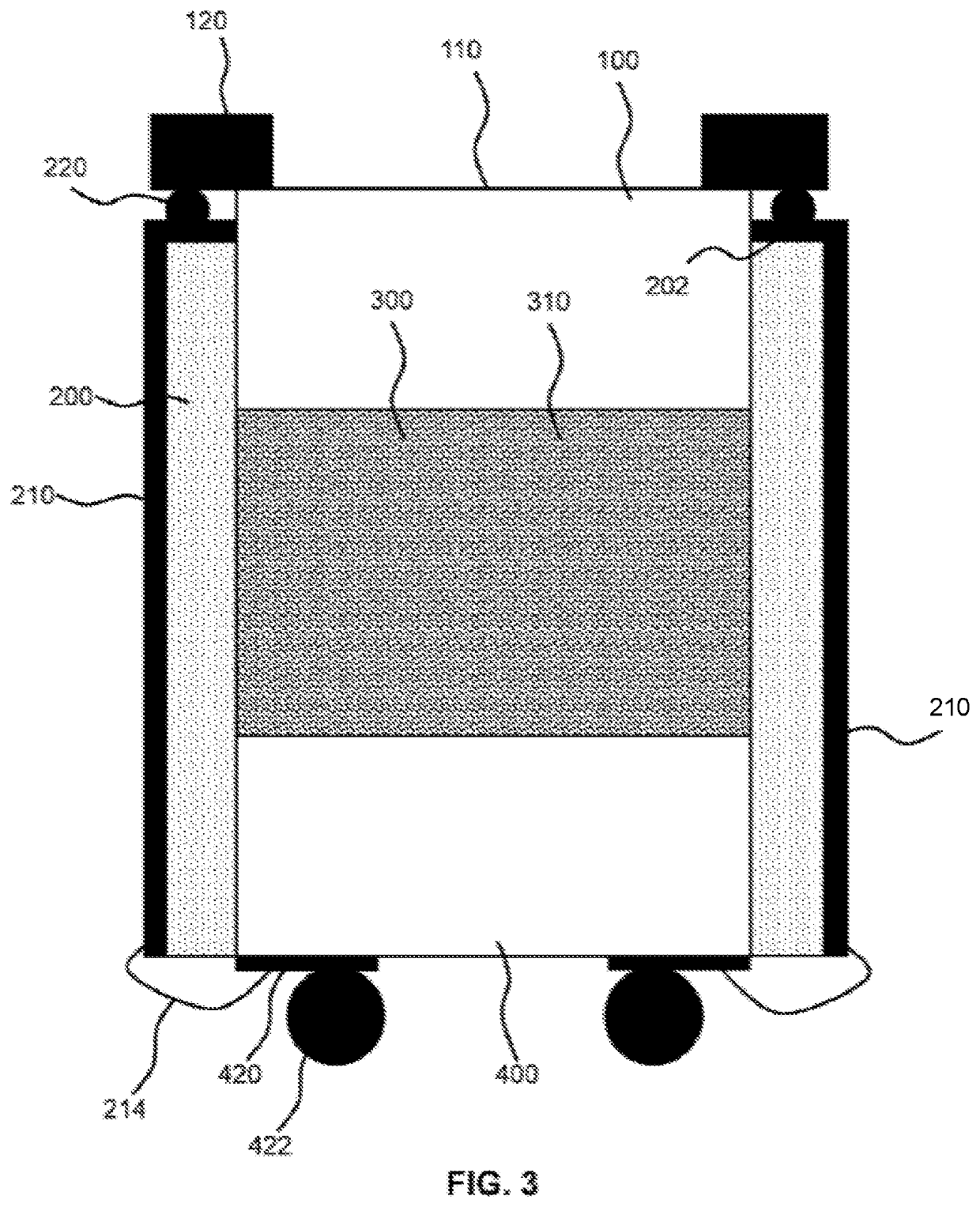

[0040]FIG. 1 schematically depicts an ultrasonic transducer assembly according to an embodiment of the present invention. The assembly comprises an ultrasonic transducer chip 100 having a major surface comprising an ultrasound transducer area 110, which typically comprises a plurality of transducer elements 112, such as CMUT or PZT elements. In a preferred embodiment, the major surface comprises an ultrasound transducer area 110 formed by a plurality of CMUT elements 112. The major surface further comprises a plurality of contacts 120, which may provide points of contact to the transducer elements 112 in any suitable manner as is well-known per se. Any suitable embodiment of such a transducer chip 100 may be chosen; it should be understood that embodiments of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com