Hologram screen and a method of producing the same

a technology of hologram screen and hologram light, which is applied in the field of hologram screen and a method of producing the same, can solve the problems of difficult preparation of very large hologram screen, poor image quality, and inability to reproduce uniformly the color of image light on all areas of the hologram screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0410] (First Embodiment)

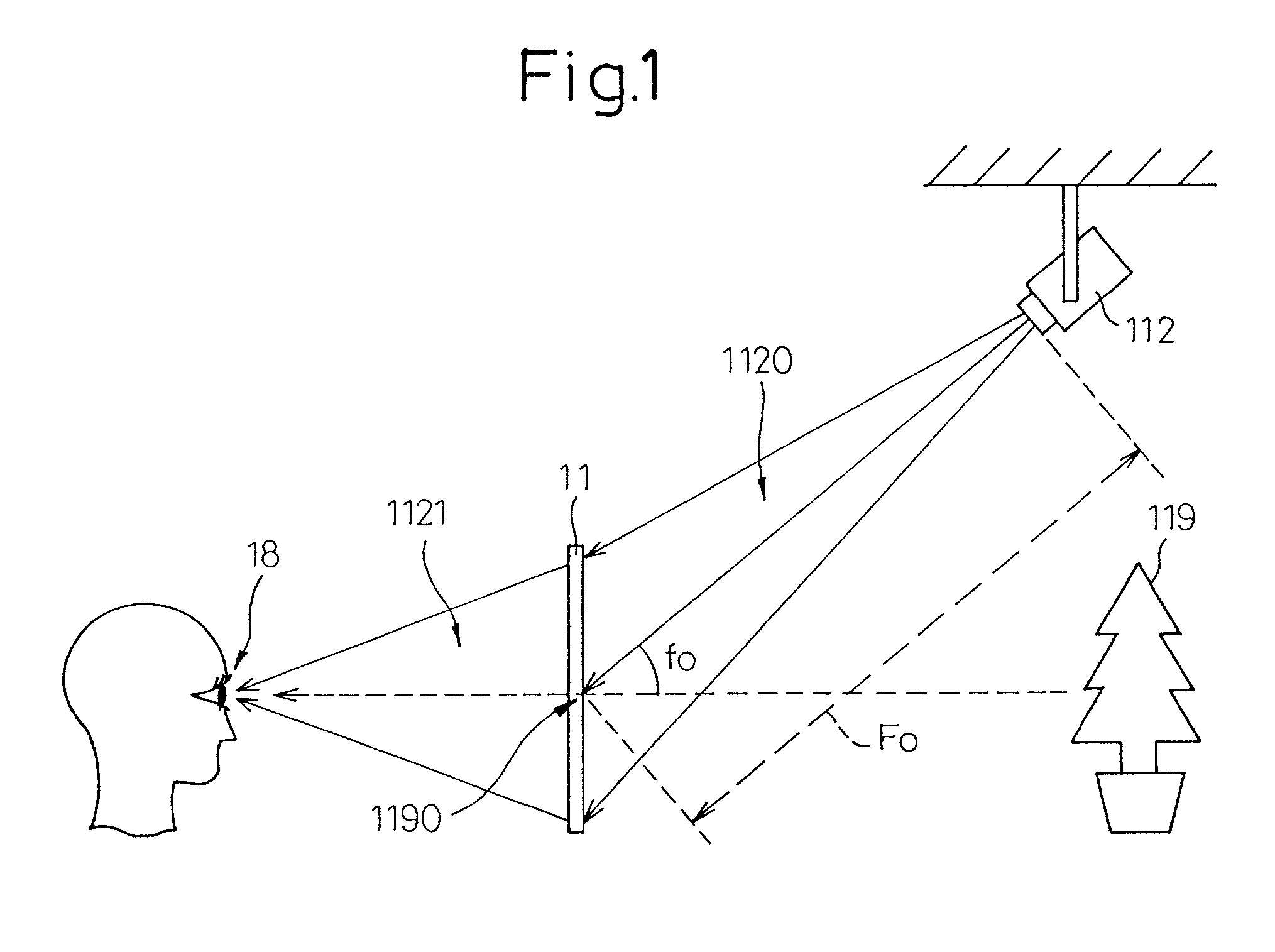

[0411] The first embodiment is explained in detail with reference to FIGS. 53 to 63. As shown in FIG. 56, the image light 331 from the image projector 22 is scattered and diffused on the hologram screen 31 so that it is possible to obtain the output light 332. As a result, the image is reproduced on the hologram screen 31. In this case, the half bandwidth of the hologram spectrum is 100 nm or more on the hologram screen (see FIG. 61).

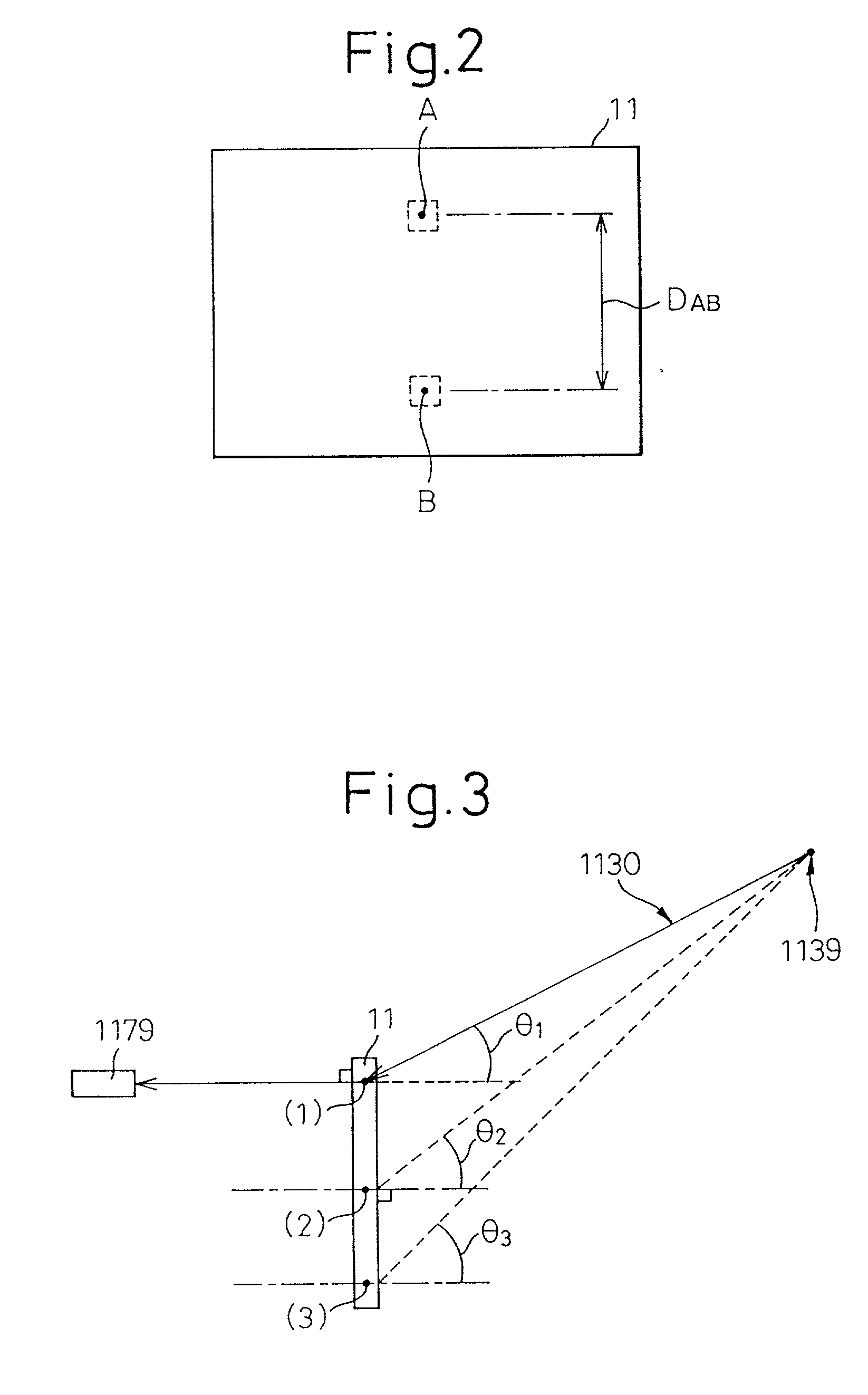

[0412] As shown in FIGS. 53 to 55, the hologram screen 31 is formed by the hologram element which is prepared by the interference fringe. That is, the diffusion light passing through the light diffusion body 3116 having the large light diffusion angle is used as the object light 3117, and the non-diffusion light is used as the reference light 3118. The object light 3117 and the reference light 3118 are irradiated onto the photosensitive material 3120 in order to form the interference fringe.

[0413] As shown in FIG. 56, the displa...

third embodiment

[0440] (Third Embodiment)

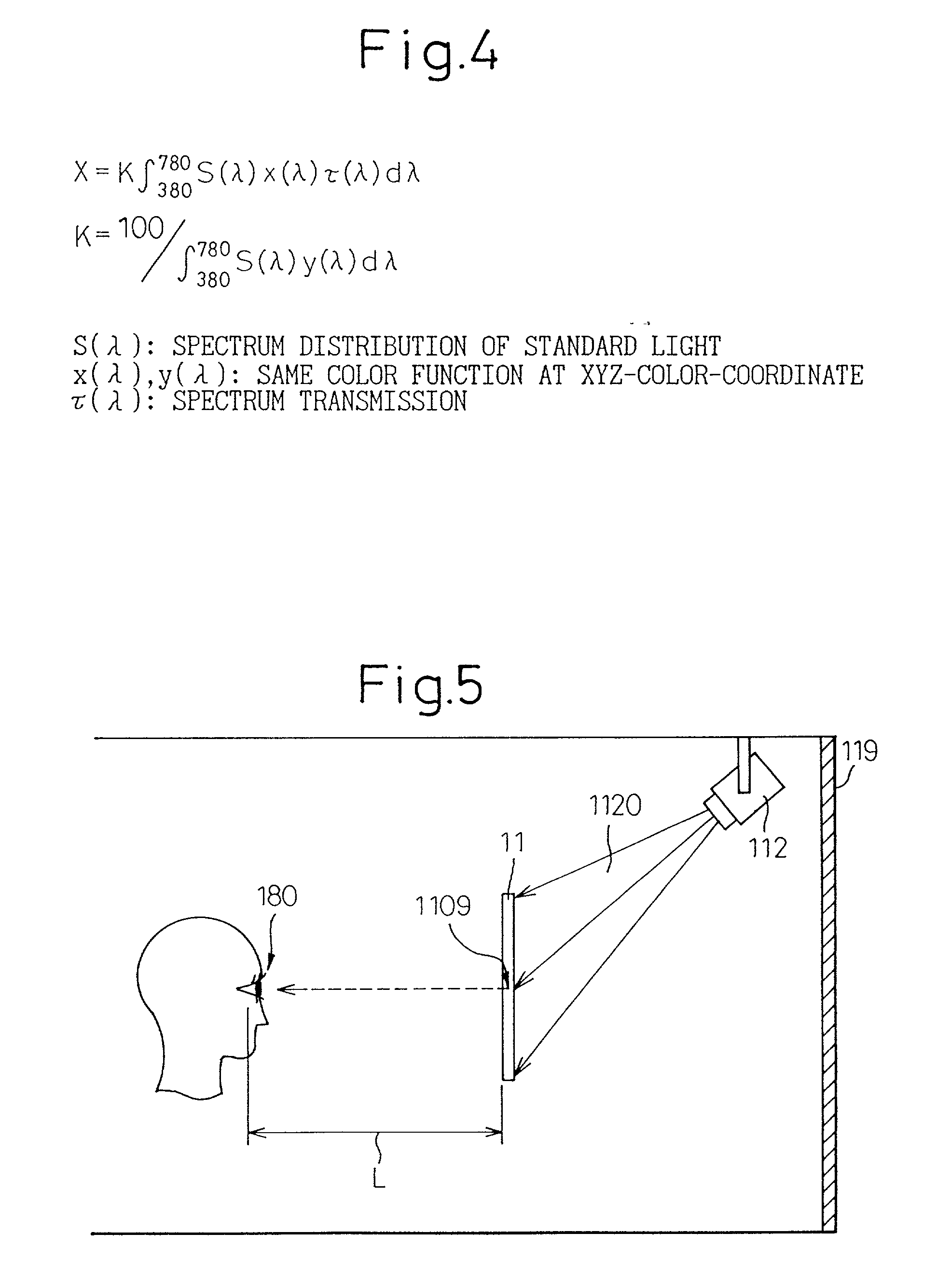

[0441] In the third embodiment, the intensity ratio R / O of the reference light (R) and the object light (O) is set to 0.1 to 30, and the reference light and the object light are irradiated on the photosensitive material in order to form the interference fringe on the hologram element. In this case, the half bandwidth of the hologram spectrum is 100 nm or more. The light diffusion body is formed by laminating four double-faced ground glasses. The intensity ratio R / O of the reference light and the object light is 3, and the incident angle .theta.r and the incident angle .theta.e are 30.degree.. As shown in FIG. 66, when the intensity ratio R / O is in the range of 0.1 to 30, the half bandwidth is 100 nm or more. It is obvious that the hologram element has the good color reappearance of the image.

fourth embodiment

[0442] (Fourth Embodiment)

[0443] In this embodiment, the peak wavelength of the hologram spectrum is either 525 nm or less, or 585 nm or more. The thickness of the photosensitive material (for example, the photopolymer made by Dupont Co.) is 6 .mu.m. The light diffusion body is formed by laminating three double-faced ground glasses, and the intensity ratio R / O of the reference light and the object light is 0.8, 3 and 5. Further, the incident angle .theta.r and the incident angle .theta.e are 30.degree..

[0444] As shown in FIG. 67, as well as the first embodiment, the intensity ratio R / O becomes large, the peak wavelength of the hologram is shifted to the short wavelength side. Further, the peak wavelength of the hologram spectrum is either 525 nm or less, or 585 nm or more. When the half bandwidth is 100 nm or more, particularly, when it is 140 nm or more, it is not necessary that the peak wavelength is 525 nm or less, or 585 nm or more. When the peak wavelength is either 525 nm or l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com