Heater control apparatus for exhaust gas sensor

a technology of exhaust gas sensor and control apparatus, which is applied in the direction of electric control, machines/engines, instruments, etc., can solve the problems of burning troubles of heaters or driving elements, the voltage of charging generators might increase, and the inability to avoid burning problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

[0021] First Embodiment

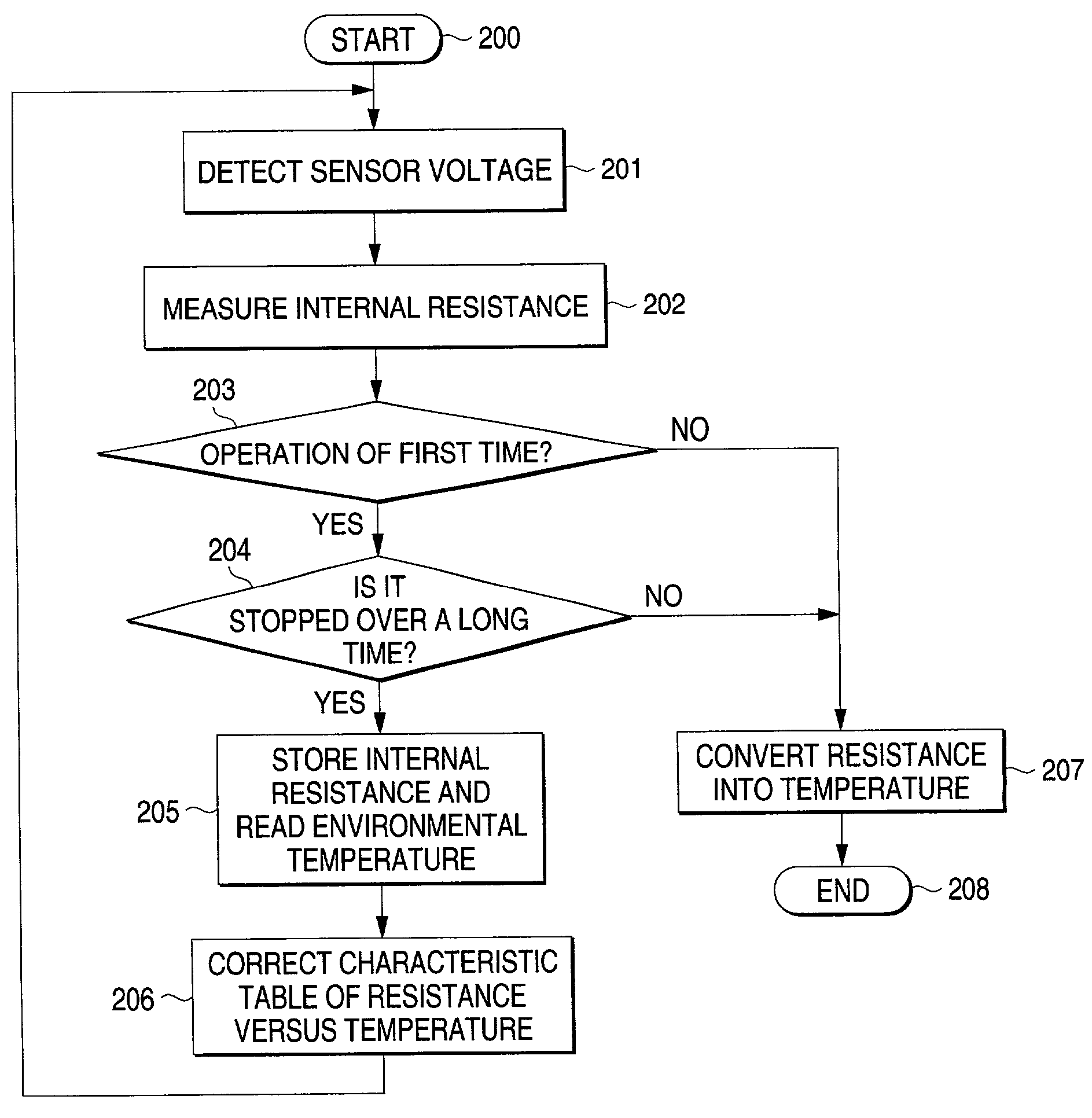

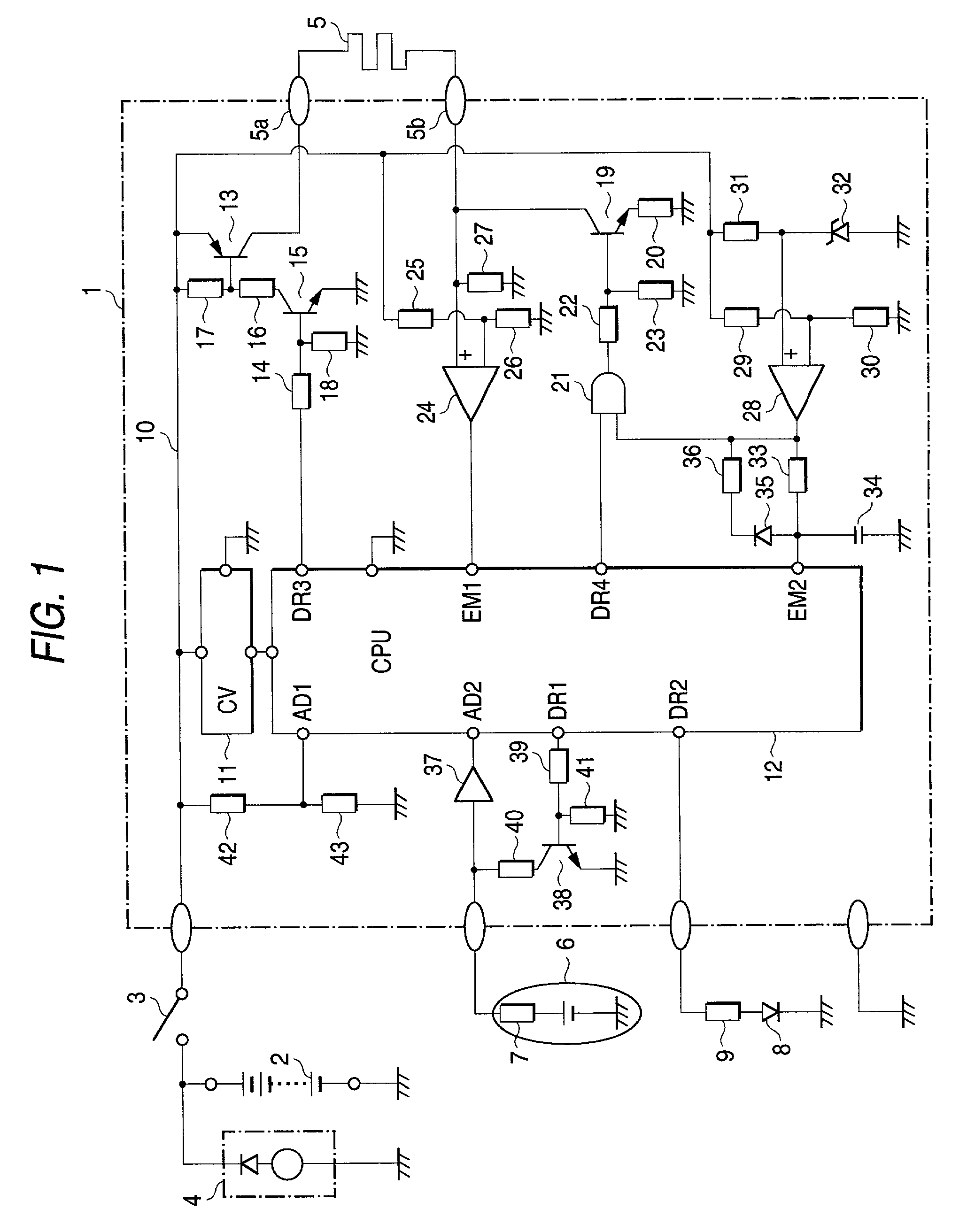

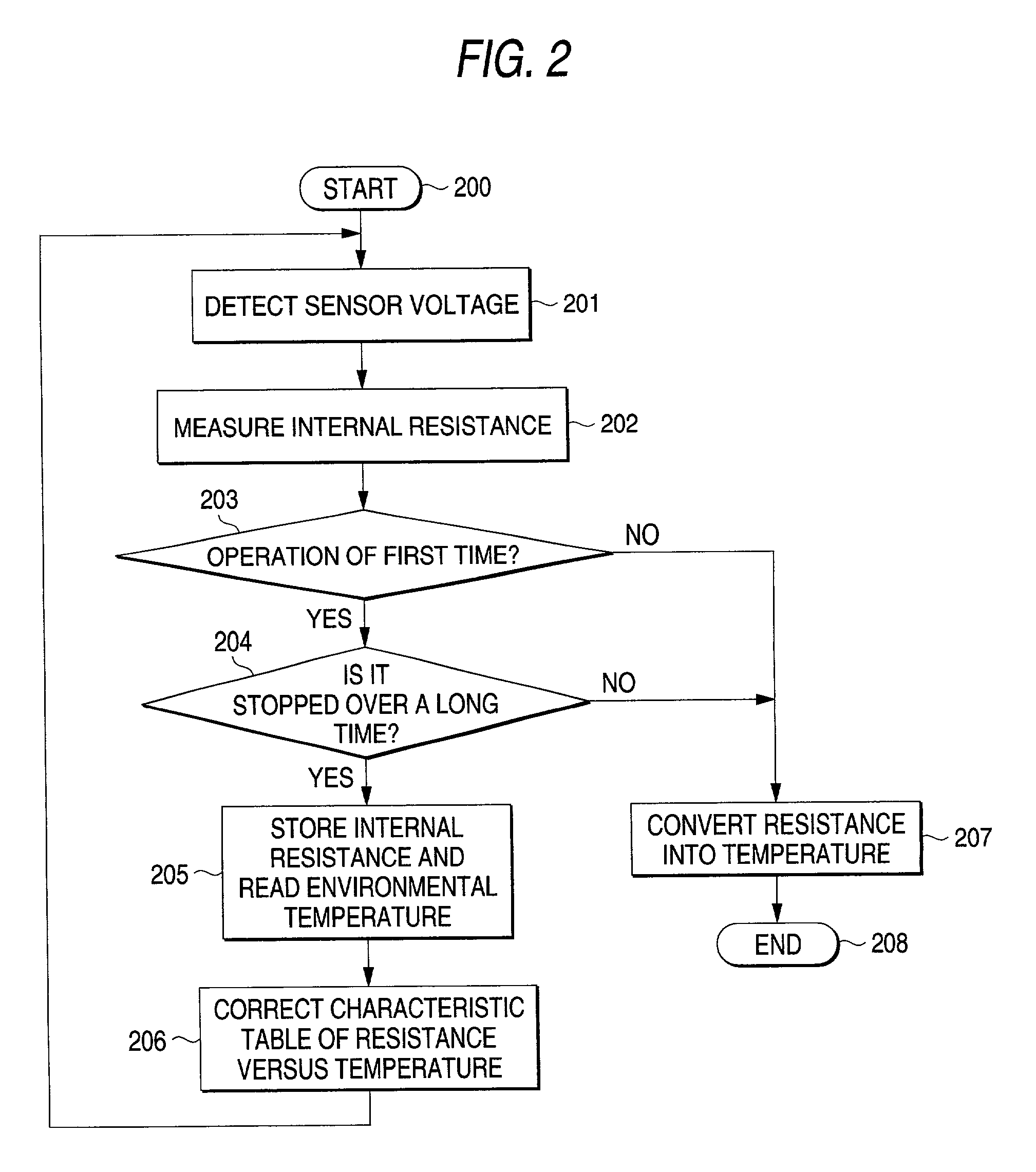

[0022] FIG. 1 is a circuit diagram of a heater control apparatus for exhaust gas sensor according to a first embodiment of the invention, and FIGS. 2 and 3 are flowcharts illustrating the operations. In FIG. 1, numeral 1 is a heater control apparatus, and numeral 2 is a battery for supplying electric power to the heater control apparatus 1 through a key switch 3, and numeral 4 is a charging generator for vehicle mounting for charging the battery 2, and numeral 5 is a heater controlled by the heater control apparatus 1, and numeral 6 is an exhaust gas sensor having an internal resistor 7 while being constructed so as to be integrated or closely placed with the heater 5 to be heated, and numeral 8 is a light emitting diode acting as display means driven by the heater control apparatus 1 through a resistor 9.

[0023] Numeral 10 is a power line within the heater control apparatus 1, and numeral 11 is a constant-voltage power source for supplying a constant voltage (...

second embodiment

[0038] Second Embodiment

[0039] FIG. 4 is a circuit diagram of a heater control apparatus for exhaust gas sensor according to a second embodiment of the invention, and FIG. 5 is a flowchart illustrating the operations, and like reference characters are given to the same parts as the first embodiment. In FIG. 4, numeral 50 is a heater control apparatus, and numeral 2 is a battery for supplying electric power to the heater control apparatus 50 through a key switch 3, and numeral 4 is a charging generator for vehicle mounting for charging the battery 2, and numeral 5 is a heater controlled by the heater control apparatus 50 and the heater 5 is integrated or closely placed with an exhaust gas sensor (not shown in FIG. 4). Numeral 8 is a light emitting diode acting as display means driven by the heater control apparatus 50 through a resistor 9.

[0040] Numeral 10 is a power line within the heater control apparatus 50, and numeral 11 is a constant-voltage power source for supplying a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| constant voltage | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com