Water closet flushing system

a technology for flushing systems and water closets, applied in the direction of valve operating means/releasing devices, functional valve types, transportation and packaging, etc., can solve the problems of ineffective attempts to adjust, the pressure of the water supply is often too high for the water closet system to function properly, and the inability to accept the high pressure of the water supply used to operate the flush valv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

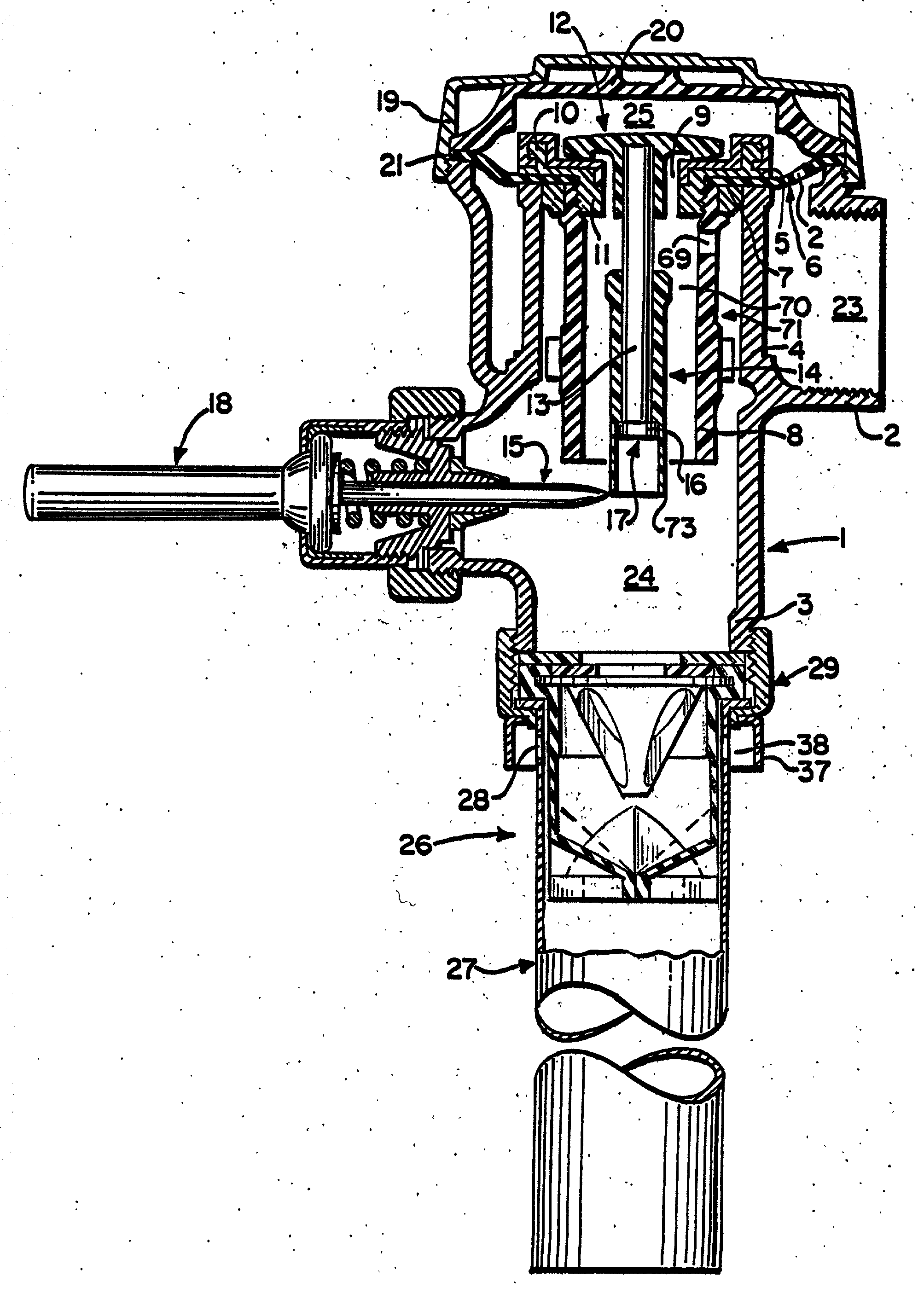

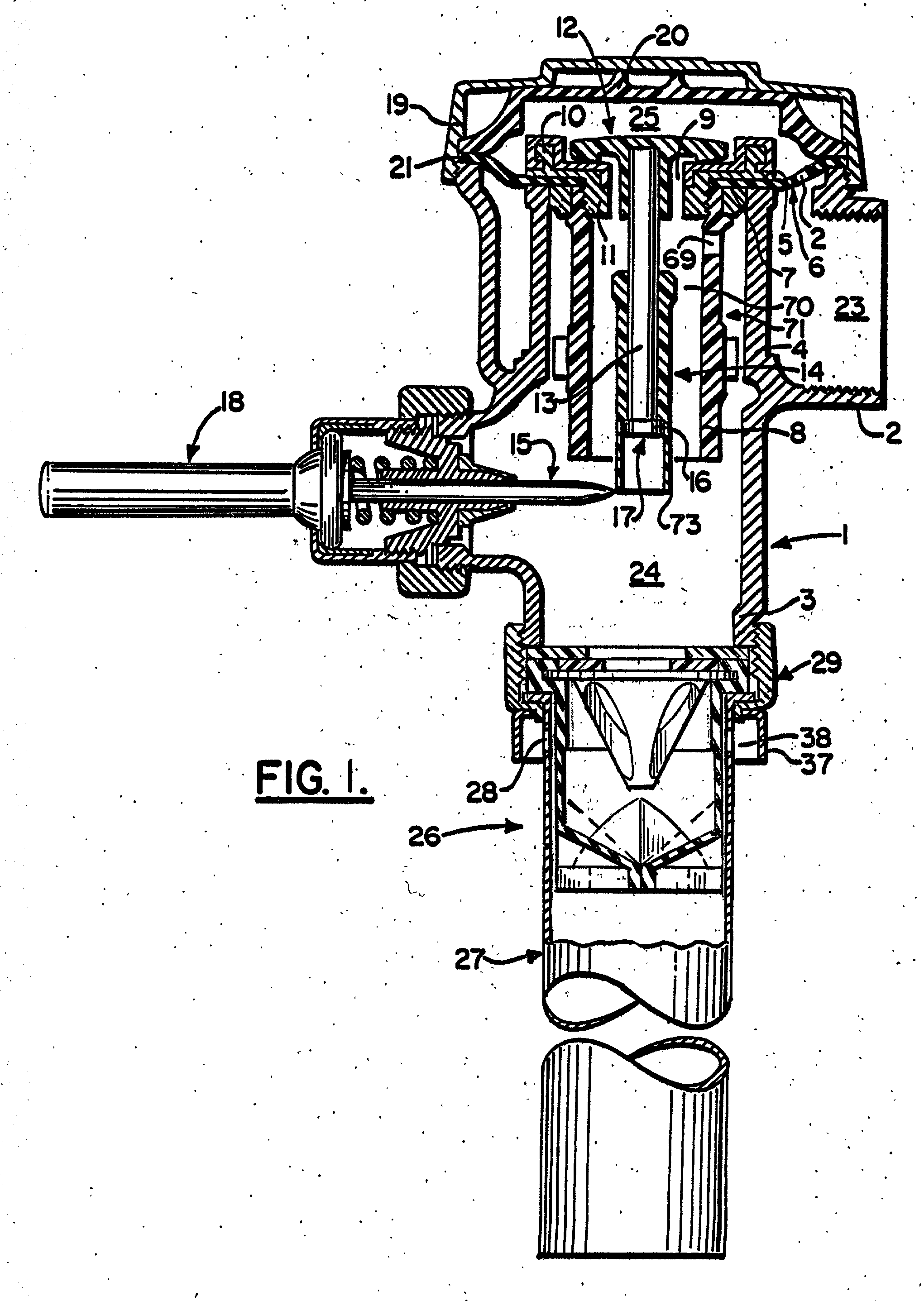

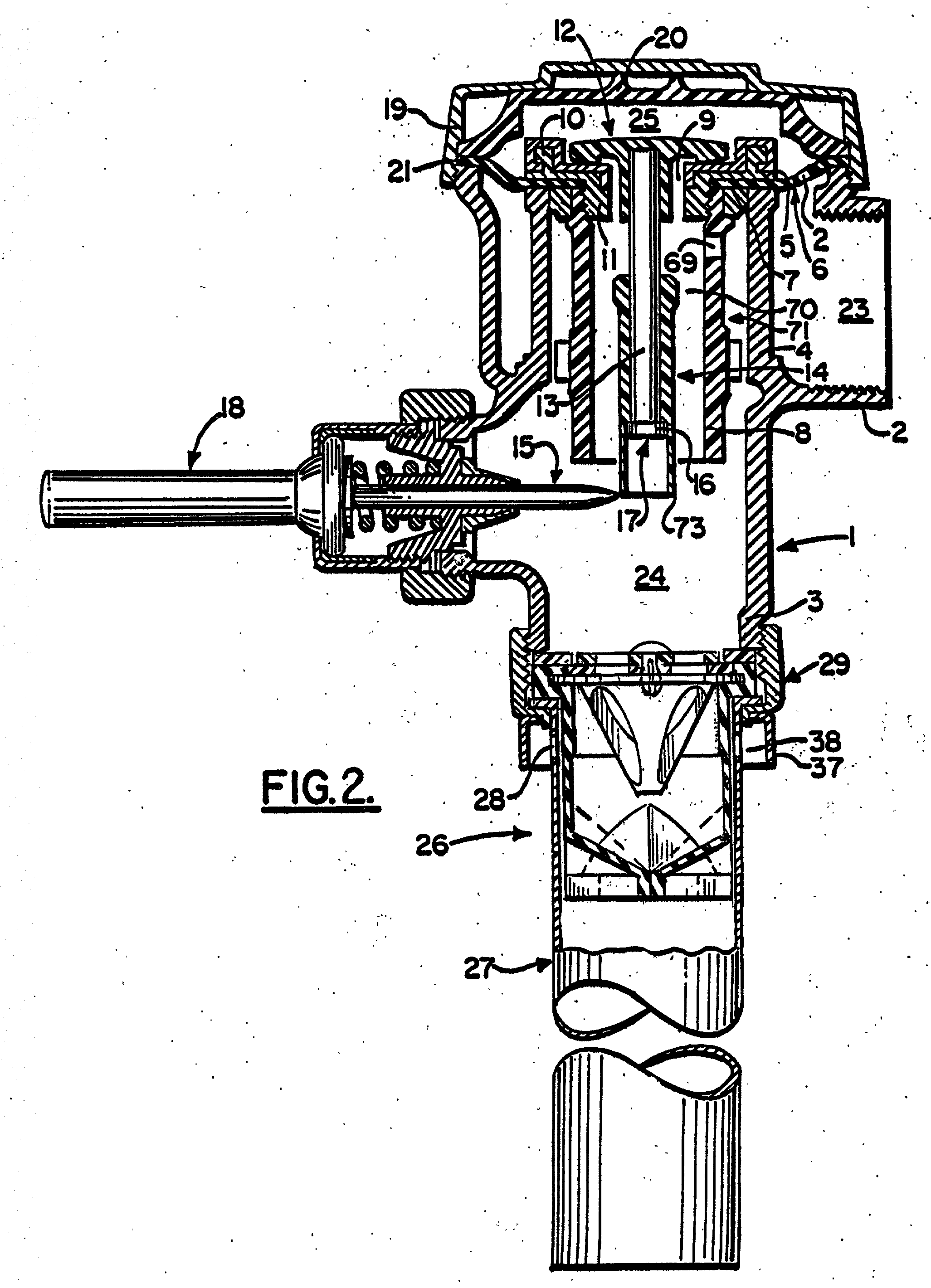

[0025] As used in this patent, the term "diaphragm flush valve" refers to a flush valve having a fluid inlet chamber, an upper chamber and an outlet chamber, wherein the chambers are separated from one another by a flexible diaphragm provided with a by-pass opening connecting the fluid inlet chamber to the upper chamber and with a central opening connecting the upper and outlet chambers, which central opening is sealable by a relief valve assembly comprising a relief valve having a vertically disposed stem about which a sleeve member can freely slide a predetermined distance, and a plunger assembly having a flush initiating means which when engaged causes a plunger pin to operatively contact the sleeve member unseating the sealing member and permitting flow of fluid from the upper chamber to the lower chamber. Without any intent to restrict the definition of diaphragm flush valves, examples of such are described in U.S. Pat. Nos. 1,714,573, 2,776,812, 3,399,860, 3,556,137, 3,656,499...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com