Patents

Literature

53results about How to "Inexpensive mean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

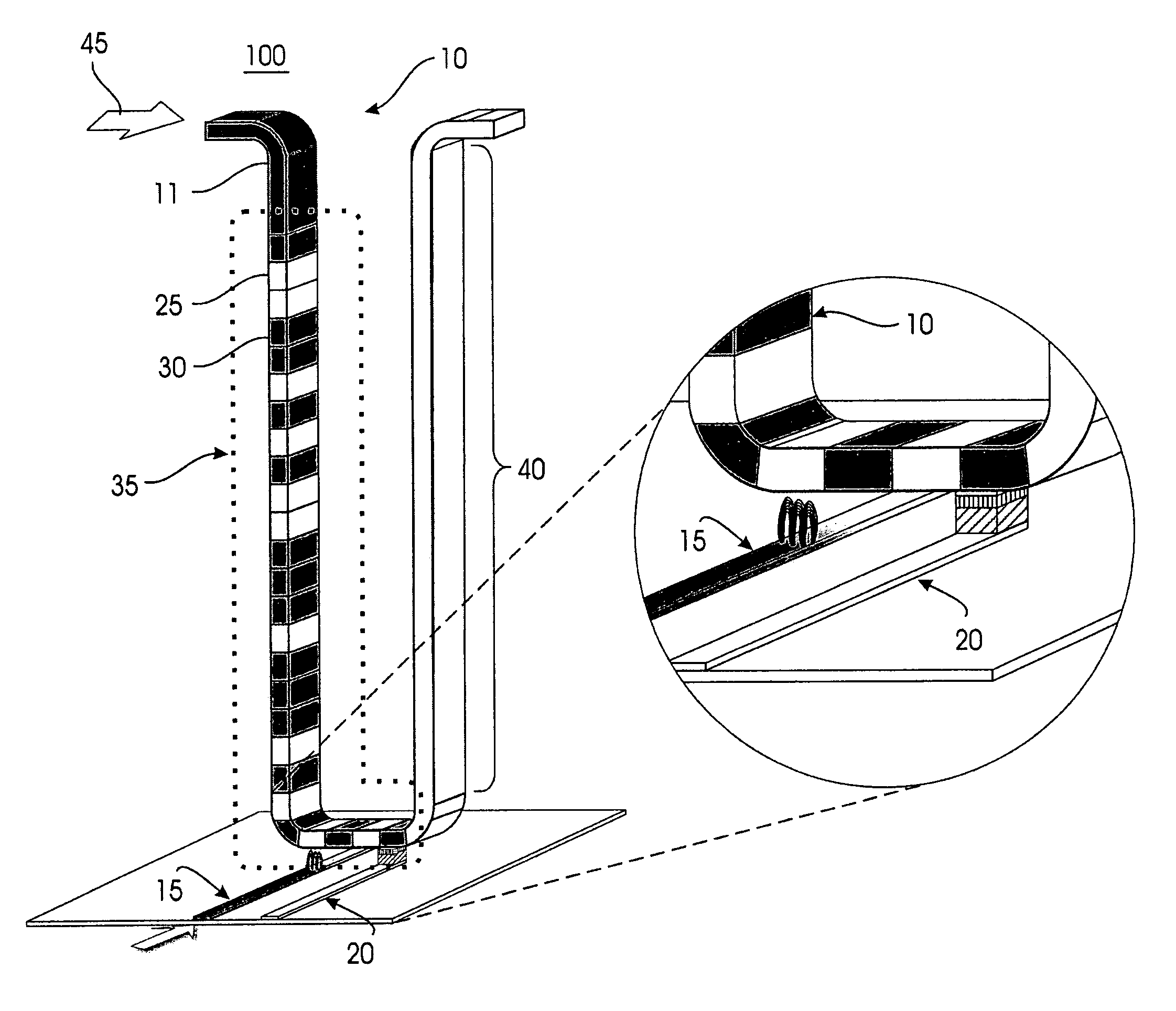

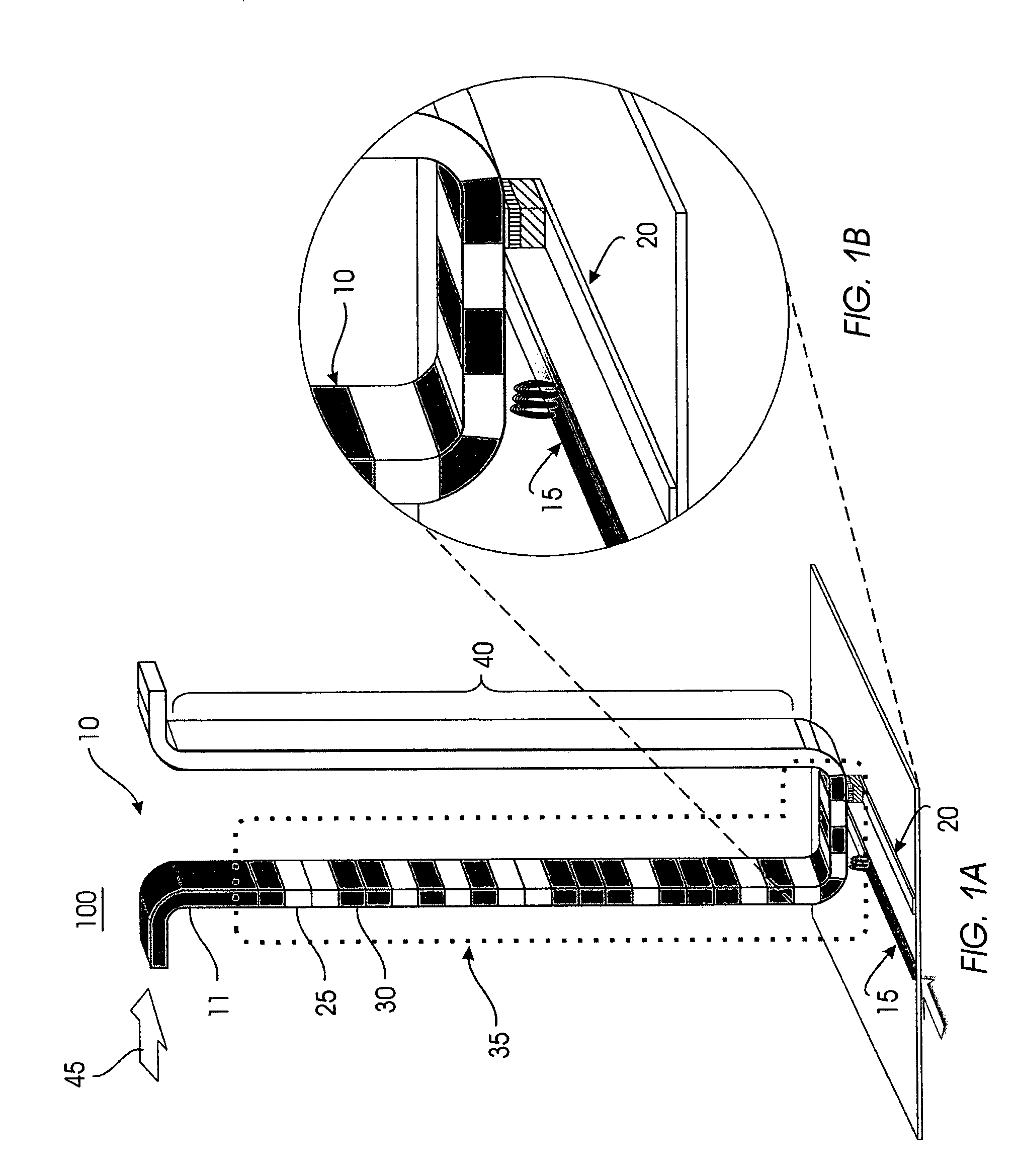

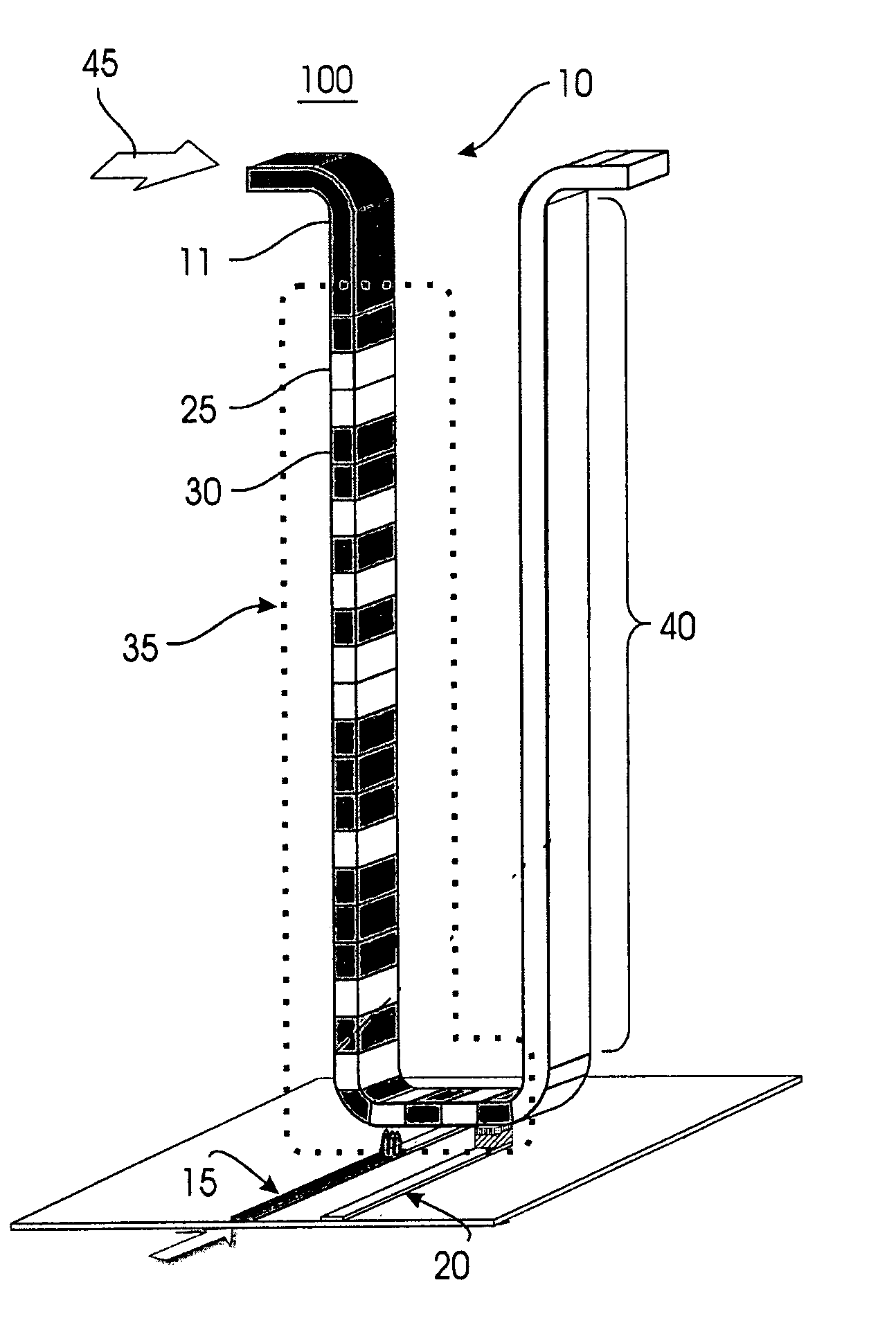

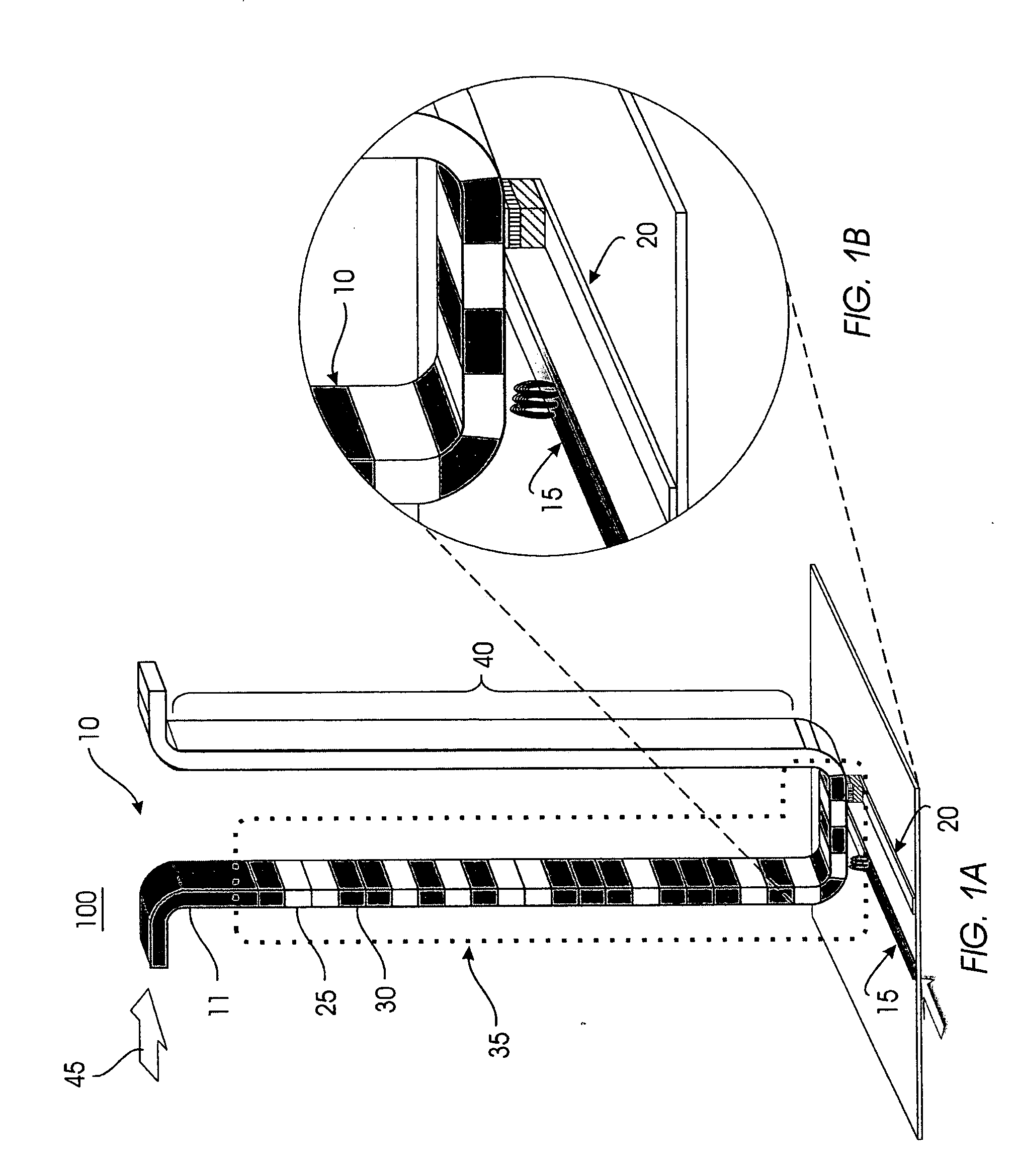

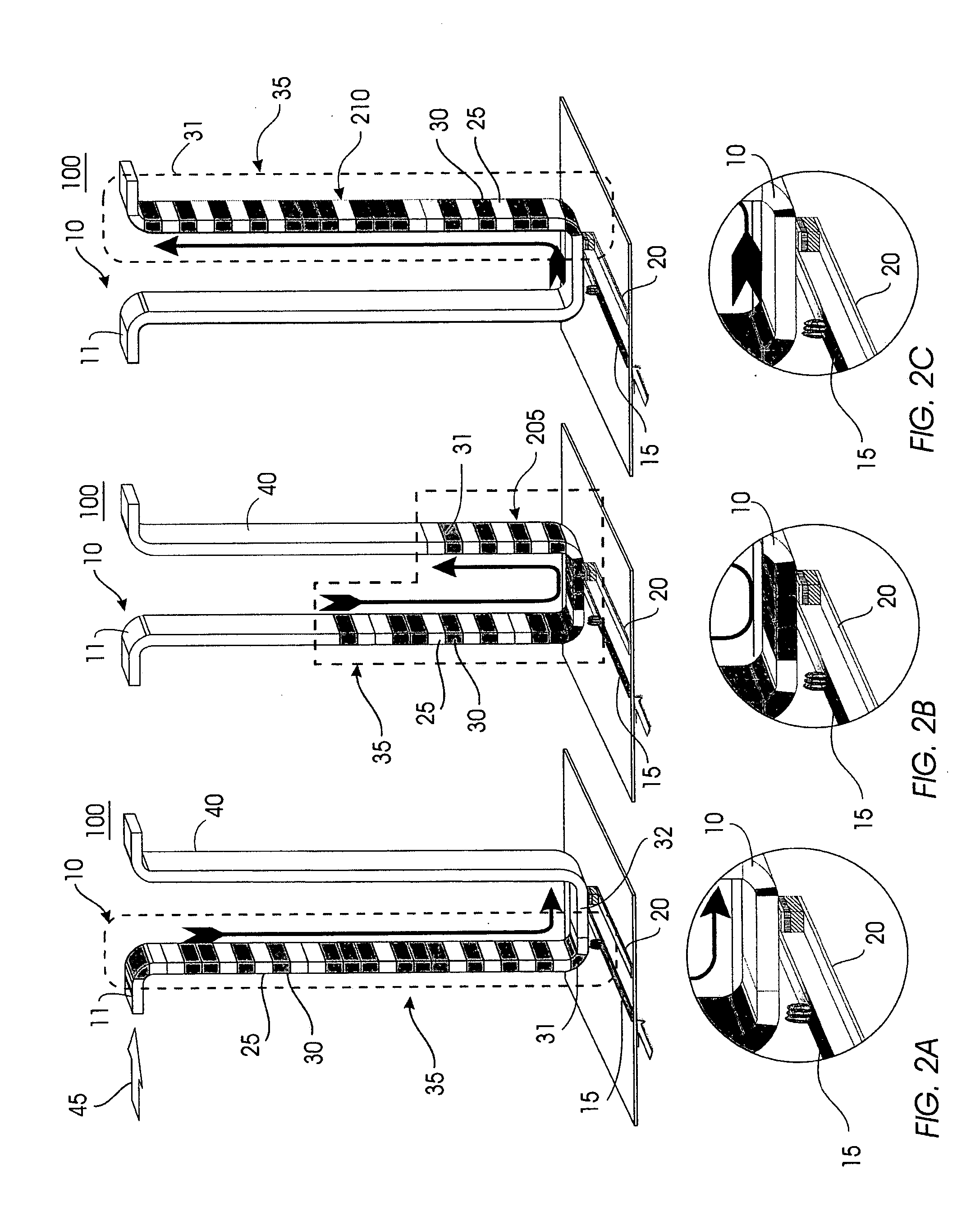

Magnetic shift register with shiftable magnetic domains between two regions, and method of using the same

InactiveUS7031178B2Highly localized and large magnetic fieldsComparable in costLiquid applicationDigital storageShift registerProcessor register

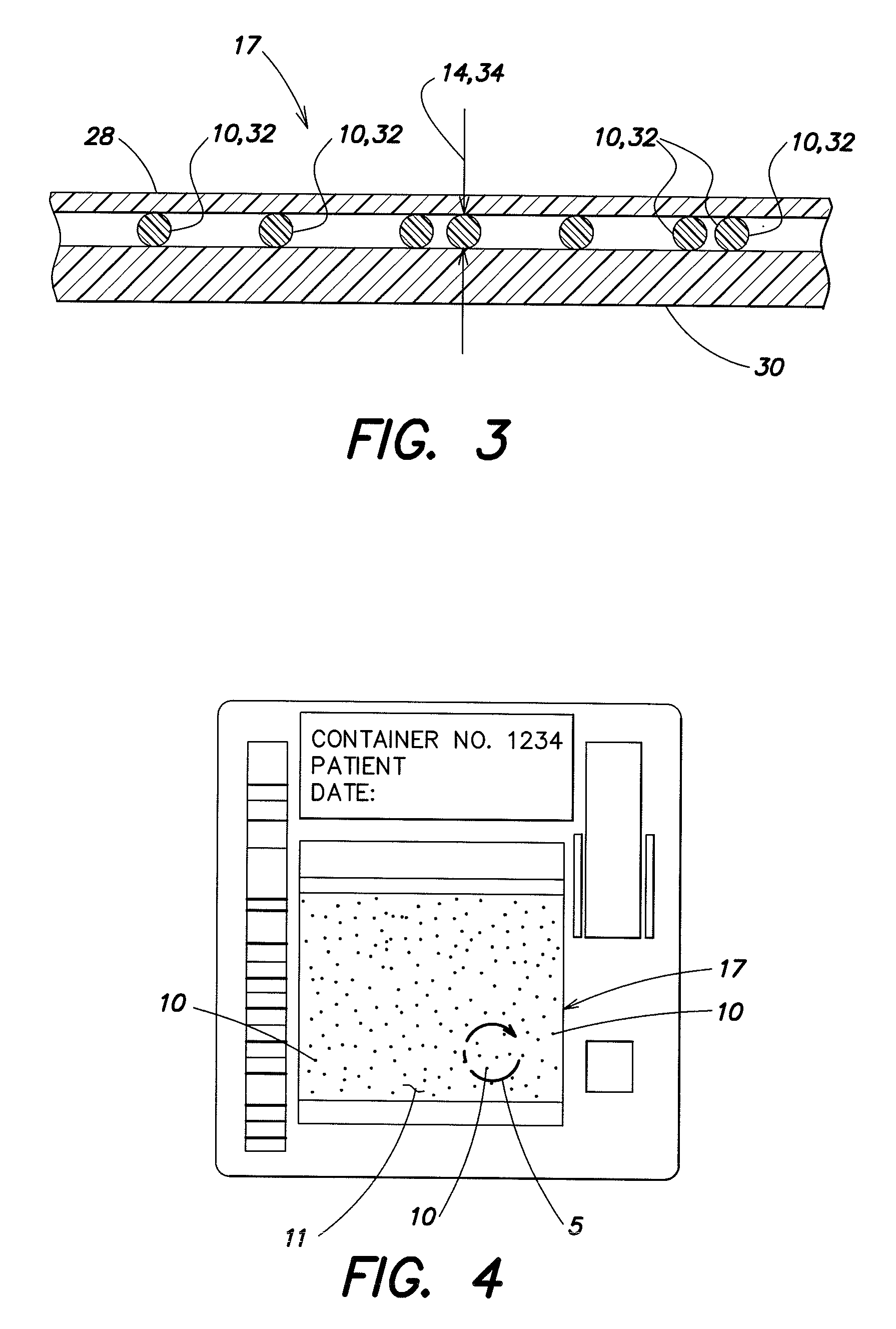

A magnetic shift register uses the inherent, natural properties of domain walls in magnetic materials to store data. The shift register uses spin electronics without changing the physical nature of its constituent materials. The shift register comprises a fine track or strip of magnetic materials. Information is stored as domain walls in the track. An electric current is applied to the track to move the magnetic moments along the track past a reading or writing device. In a magnetic material with domain walls, a current passed across the domain wall moves the domain wall in the direction of the current flow. As the current passes through a domain, it becomes “spin polarized”. When this spin polarized current passes through the next domain and across a domain wall, it develops a circle of spin torque. This spin torque moves the domain wall.

Owner:GLOBALFOUNDRIES U S INC

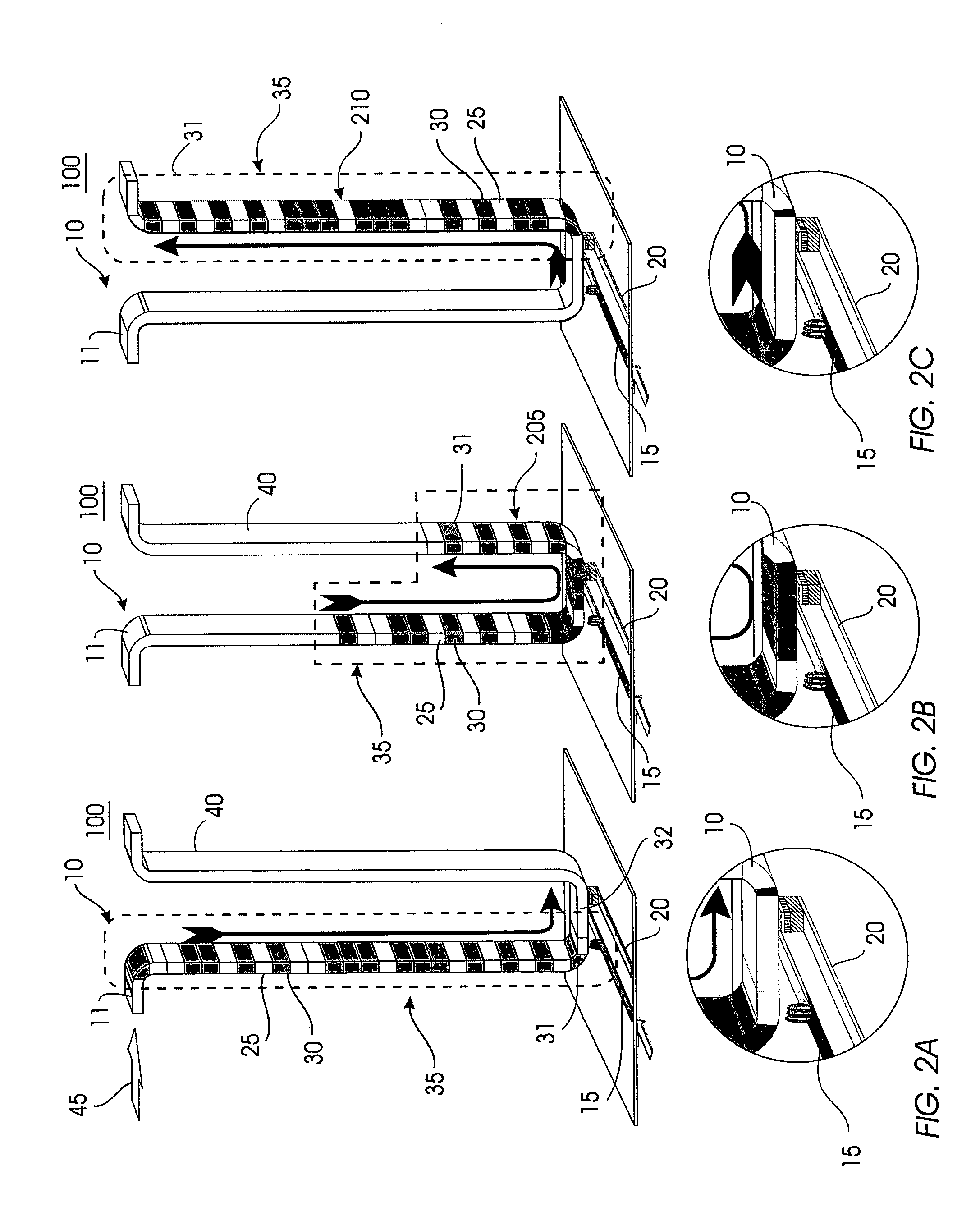

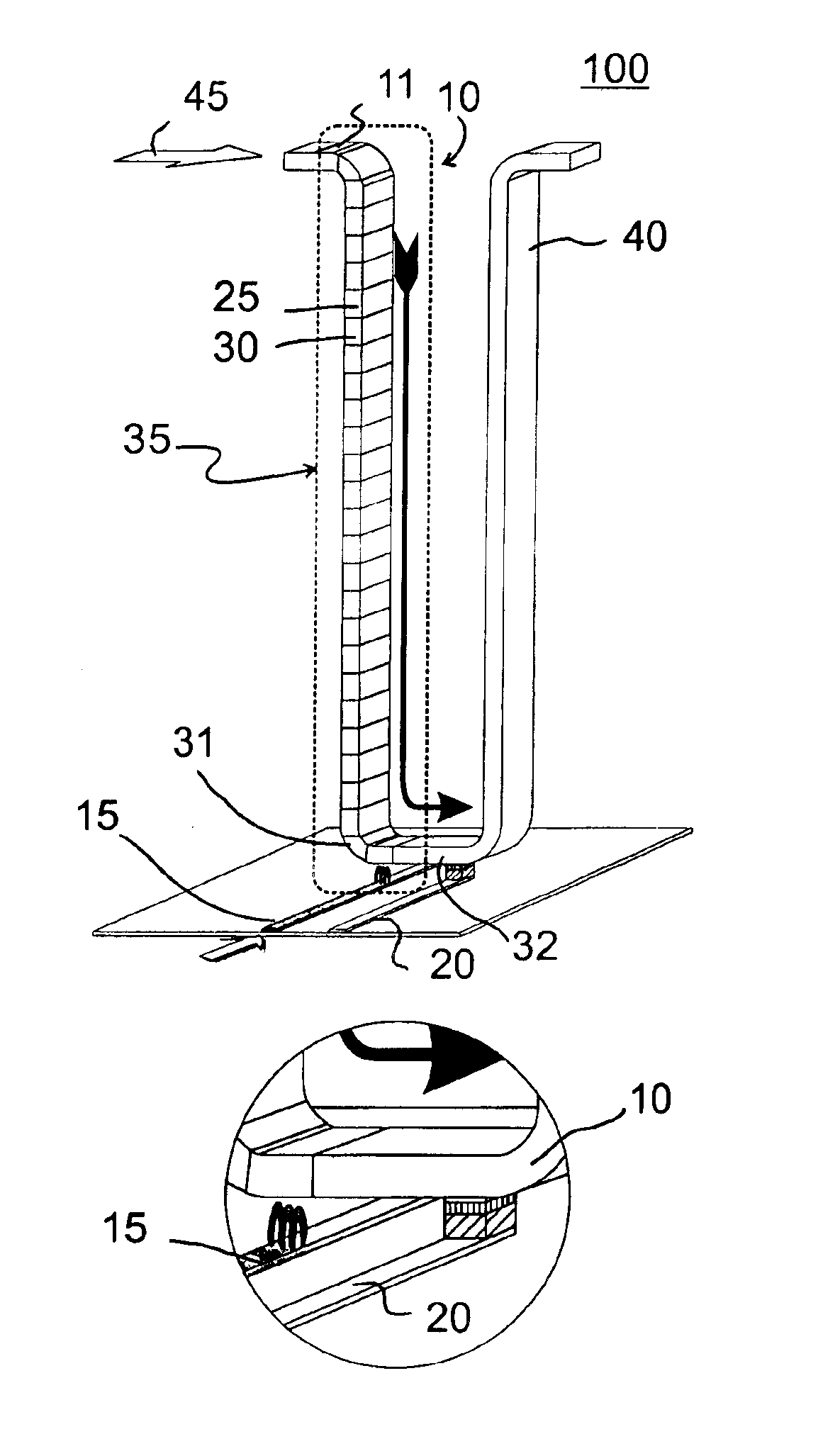

System and method for reading data stored on a magnetic shift register

InactiveUS6920062B2Highly localized and large magnetic fieldsComparable in costDigital storageShift registerData storing

A reading device reads the direction of the magnetic moment of domains in a magnetic shift register, thus reading information stored in the domains or bits in the magnetic shift register. Associated with each domain wall are large magnetic fringing fields. The domain wall concentrates the change in magnetism from one direction to another in a very small space. Depending on the nature of the domain wall, very large dipolar fringing fields can emanate from the domain wall. This characteristic of magnetic domains is used to read data stored on to the magnetic shift register. The reading device reads the direction of the magnetic moment in a magnetic shift register, thus reading information stored in the domains.

Owner:GLOBALFOUNDRIES US INC

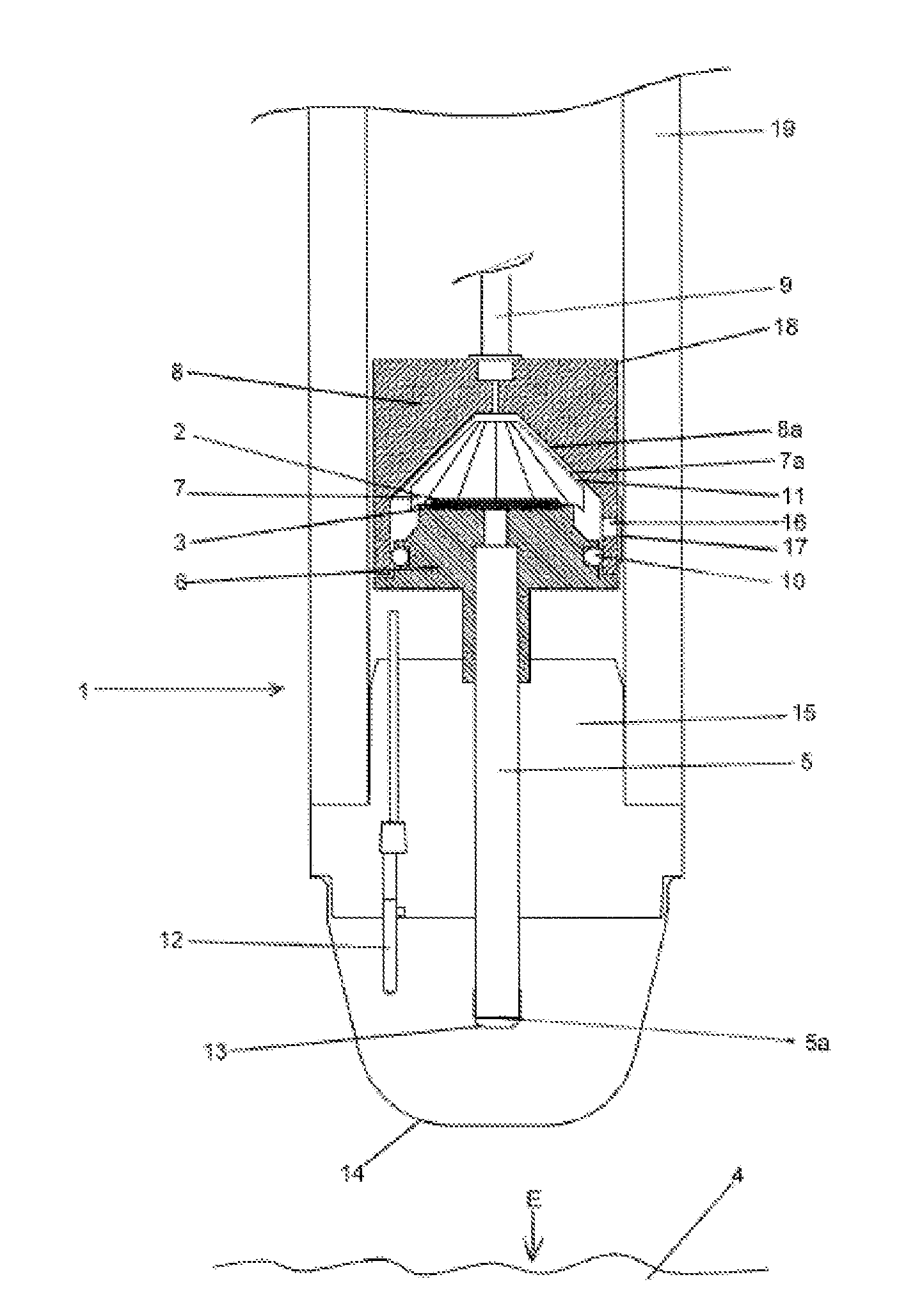

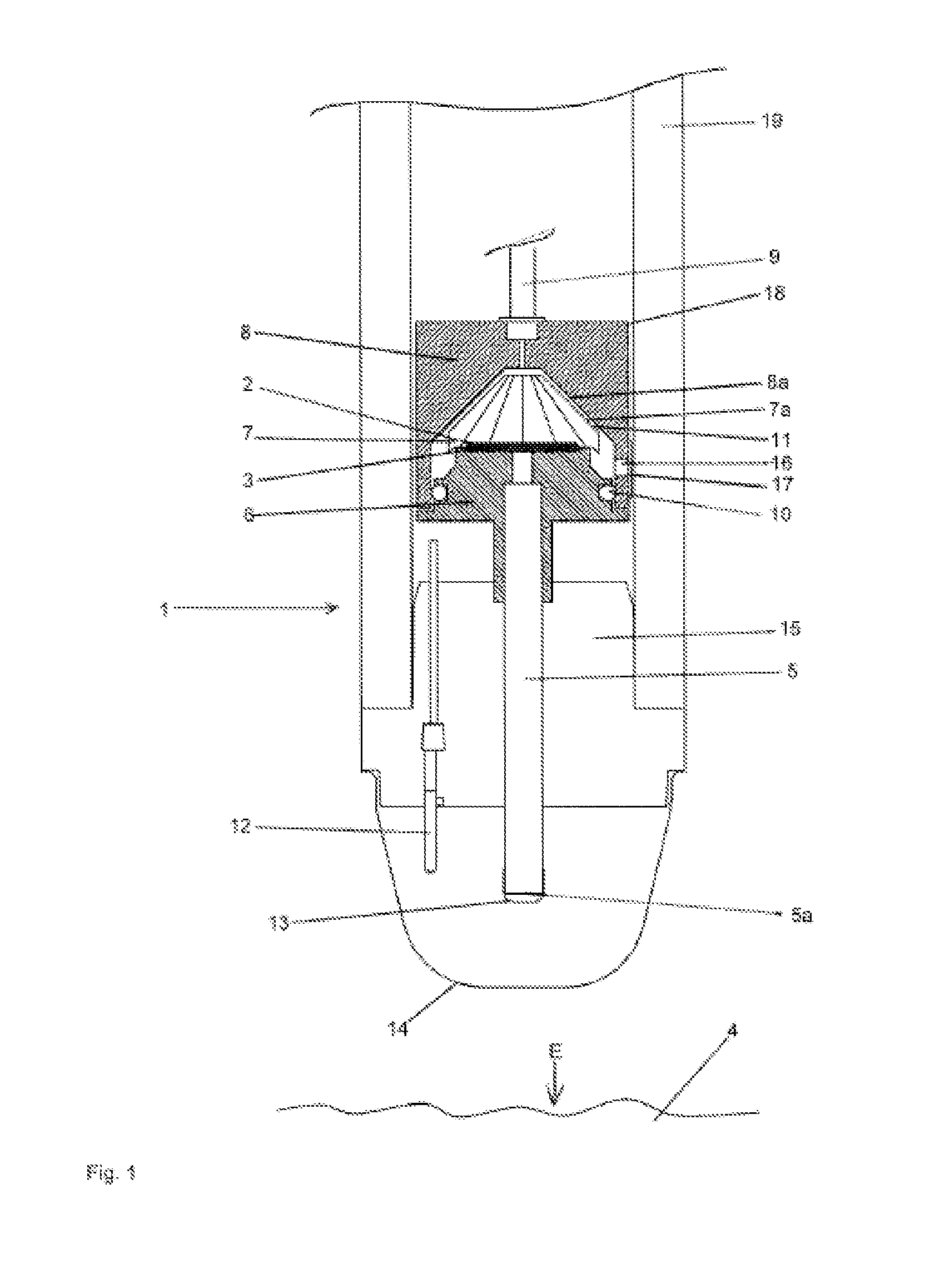

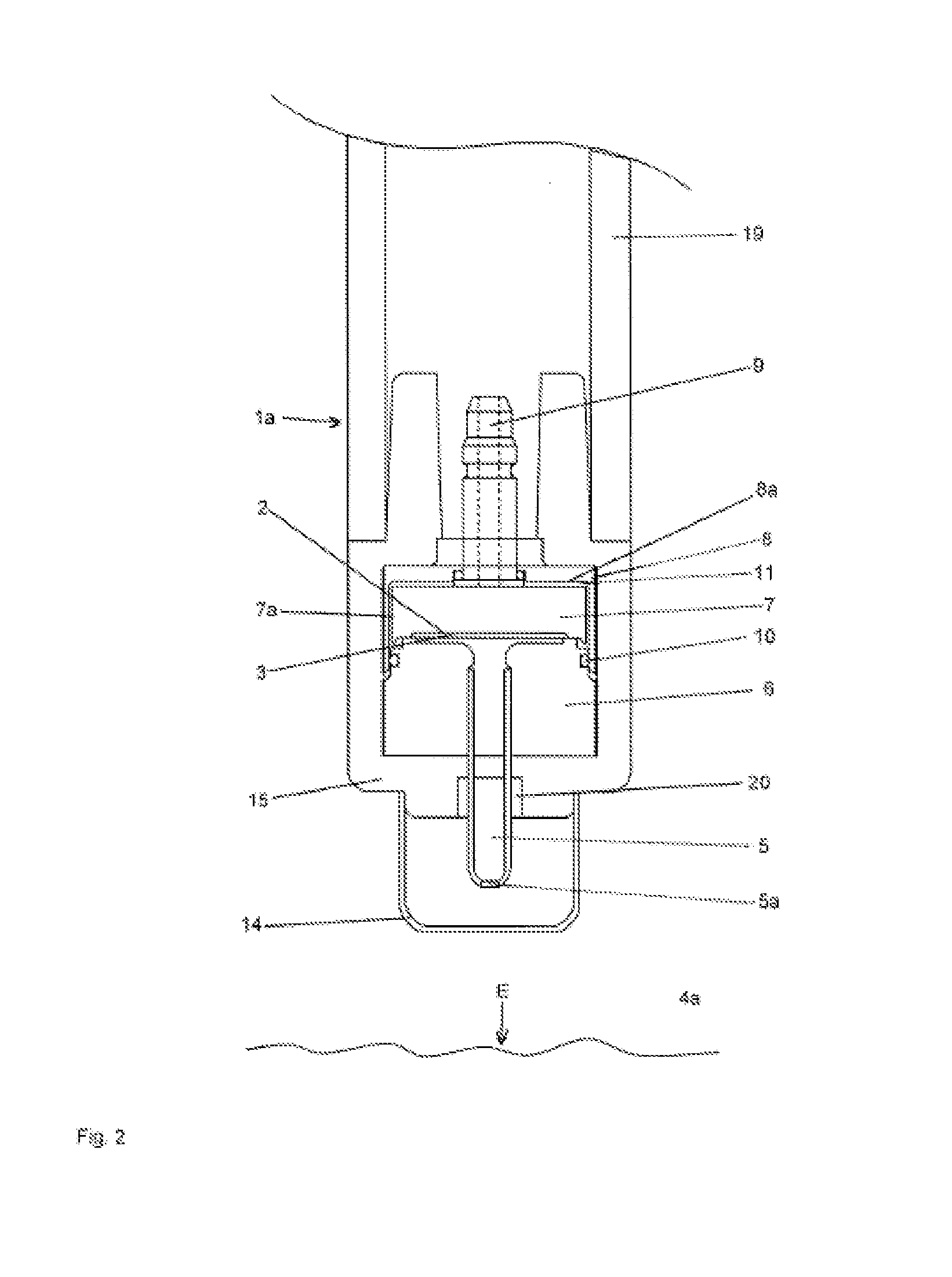

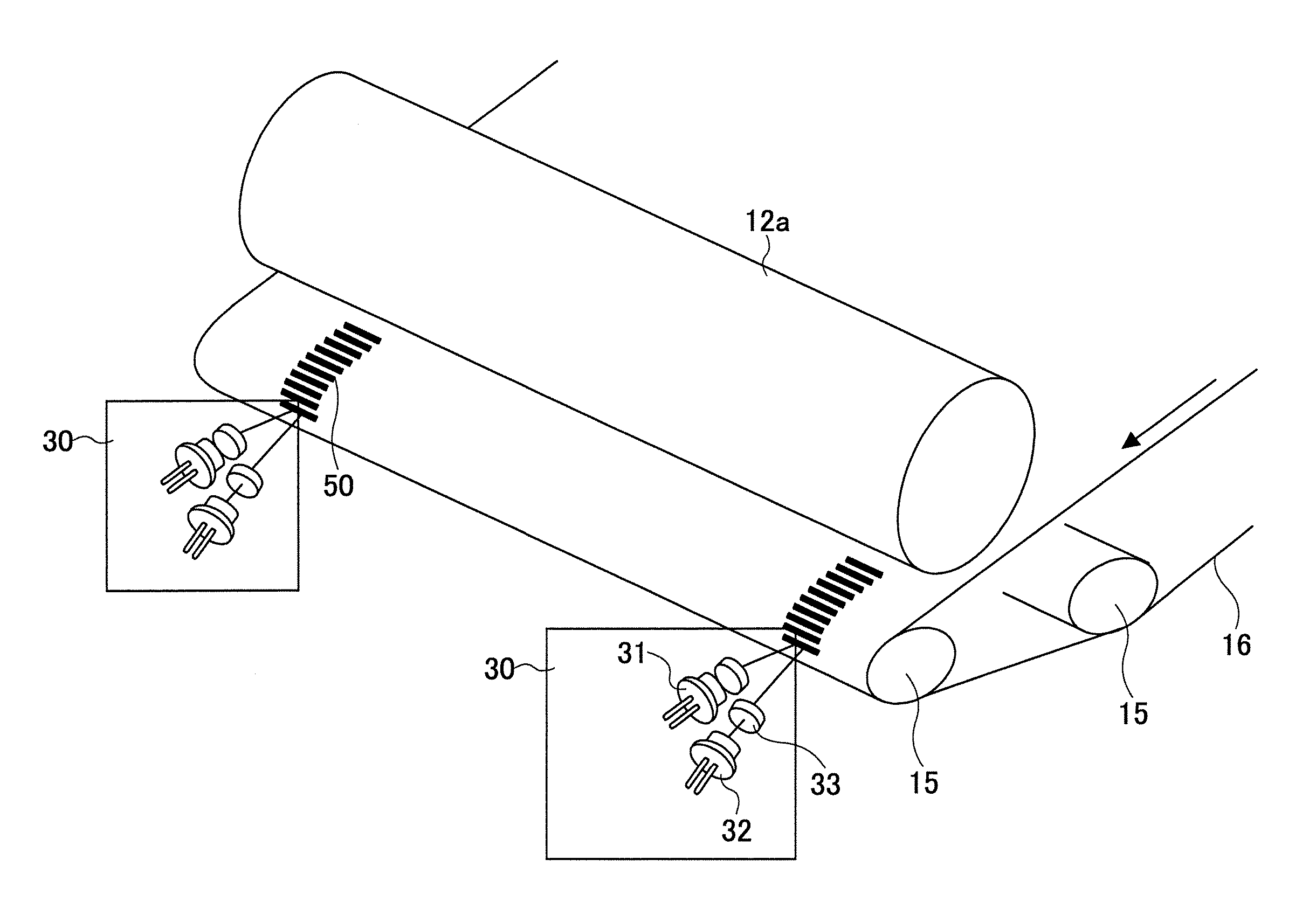

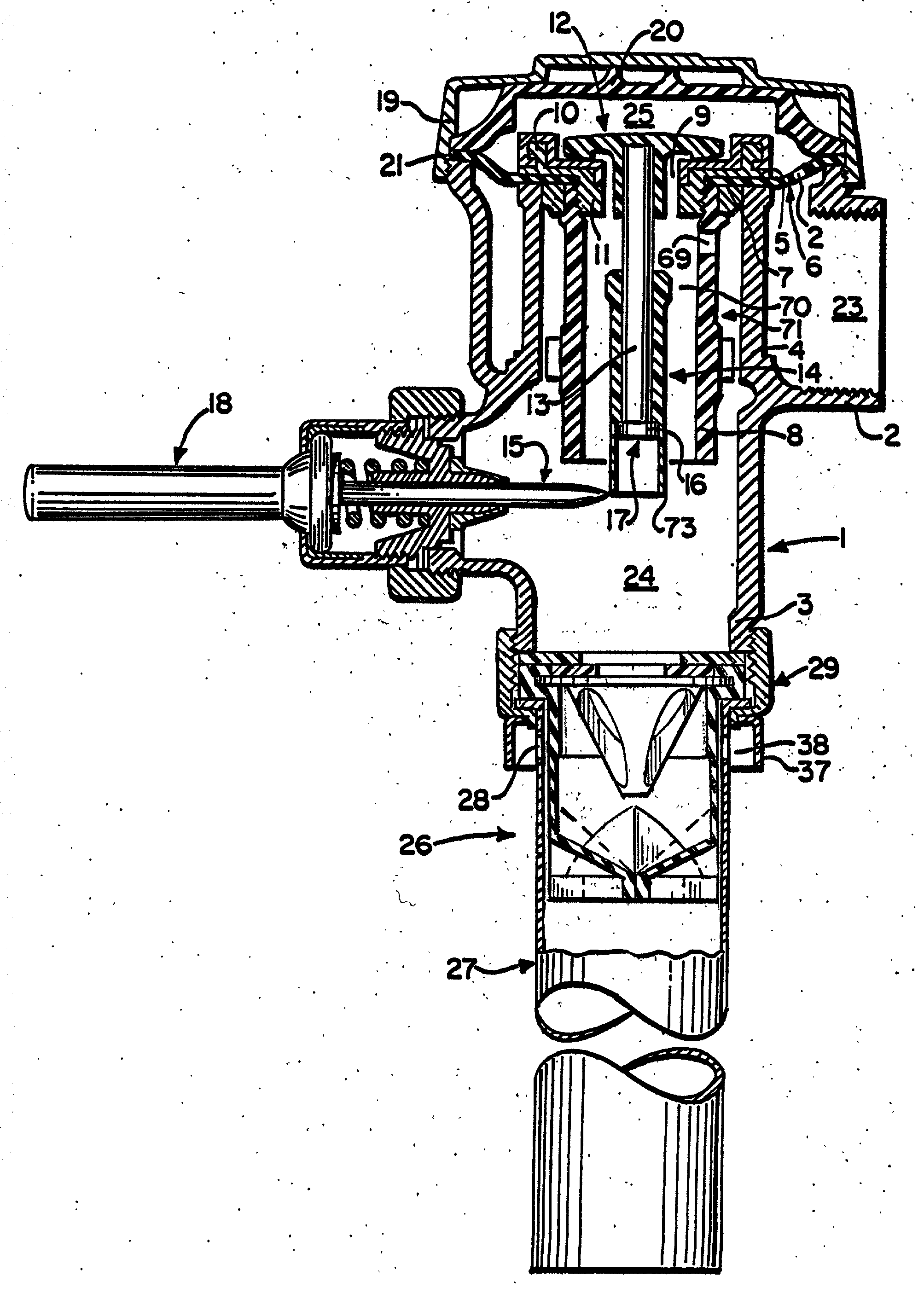

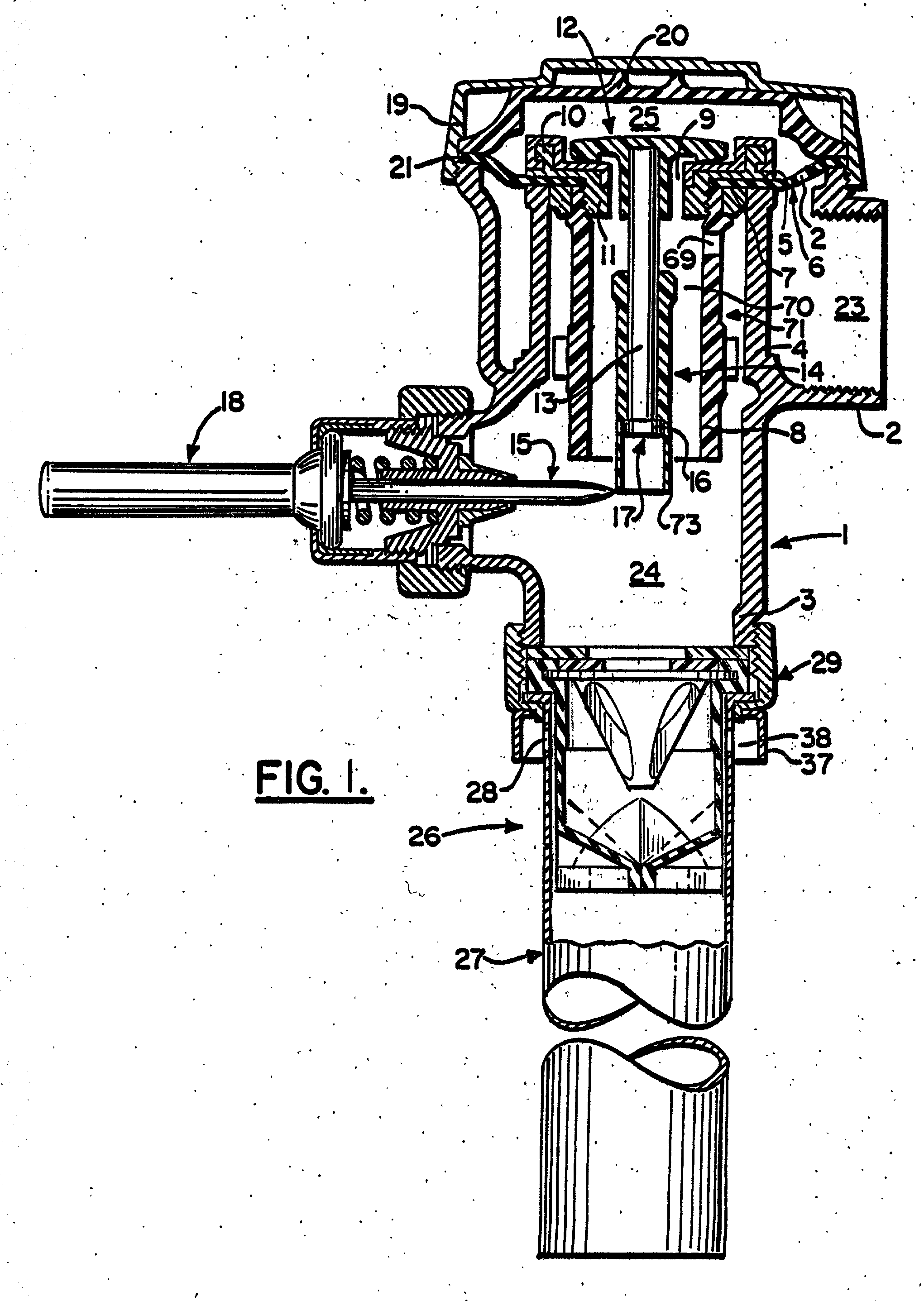

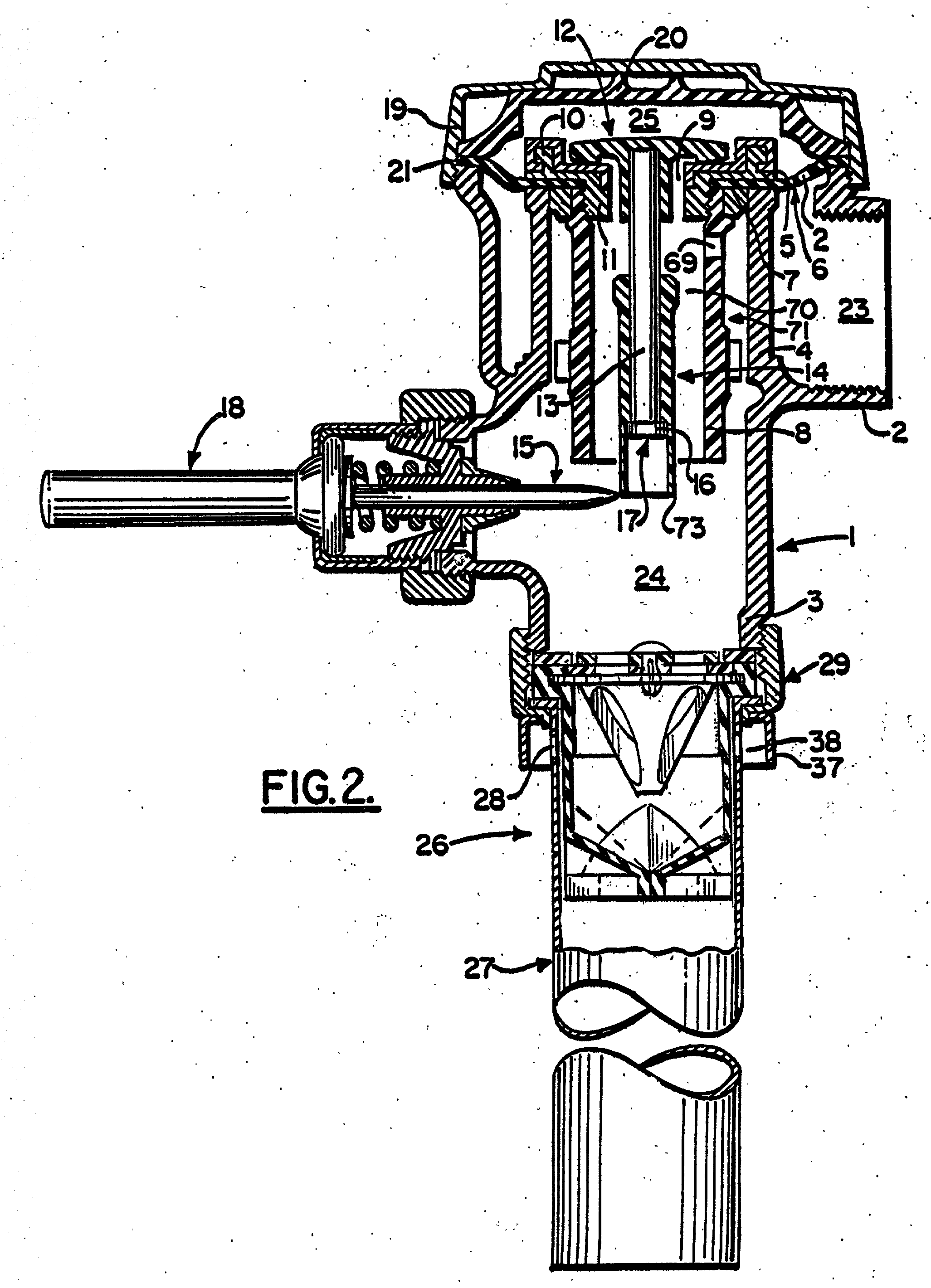

Sampler and sampling method

ActiveUS20140318276A1Rapid and easy coolingFaster cooling processWithdrawing sample devicesLaboratory glasswaresSample chamberMolten material

A sampler has a sample chamber for a sample forming from a molten material, at least one lower cooling body, at least one upper cooling body, at least one inner cooling body, and at least one filling part. The sample chamber is surrounded jointly at least by the lower cooling body and the inner cooling body, such that at least the sample chamber can be cooled by at least the lower and inner cooling bodies. The filling part merges into the sample chamber by a filling opening. Between a region of the outer surface of the inner cooling body and a region of the outer surface of the upper cooling body opposite the outer surface of the inner cooling body, the sampler has at least one gap for conducting at least one gas. The volume of the respective cooling bodies is larger than the volume of the gap.

Owner:HERAEUS ELECTRO NITE INT NV

Magnetic shift register with shiftable magnetic domains between two regions, and method of using the same

InactiveUS20050094427A1Comparable in costIncrease memory capacityLiquid applicationDigital storageShift registerSpins

A magnetic shift register uses the inherent, natural properties of domain walls in magnetic materials to store data. The shift register uses spin electronics without changing the physical nature of its constituent materials. The shift register comprises a fine track or strip of magnetic materials. Information is stored as domain walls in the track. An electric current is applied to the track to move the magnetic moments along the track past a reading or writing device. In a magnetic material with domain walls, a current passed across the domain wall moves the domain wall in the direction of the current flow. As the current passes through a domain, it becomes “spin polarized”. When this spin polarized current passes through the next domain and across a domain wall, it develops a circle of spin torque. This spin torque moves the domain wall.

Owner:GLOBALFOUNDRIES US INC

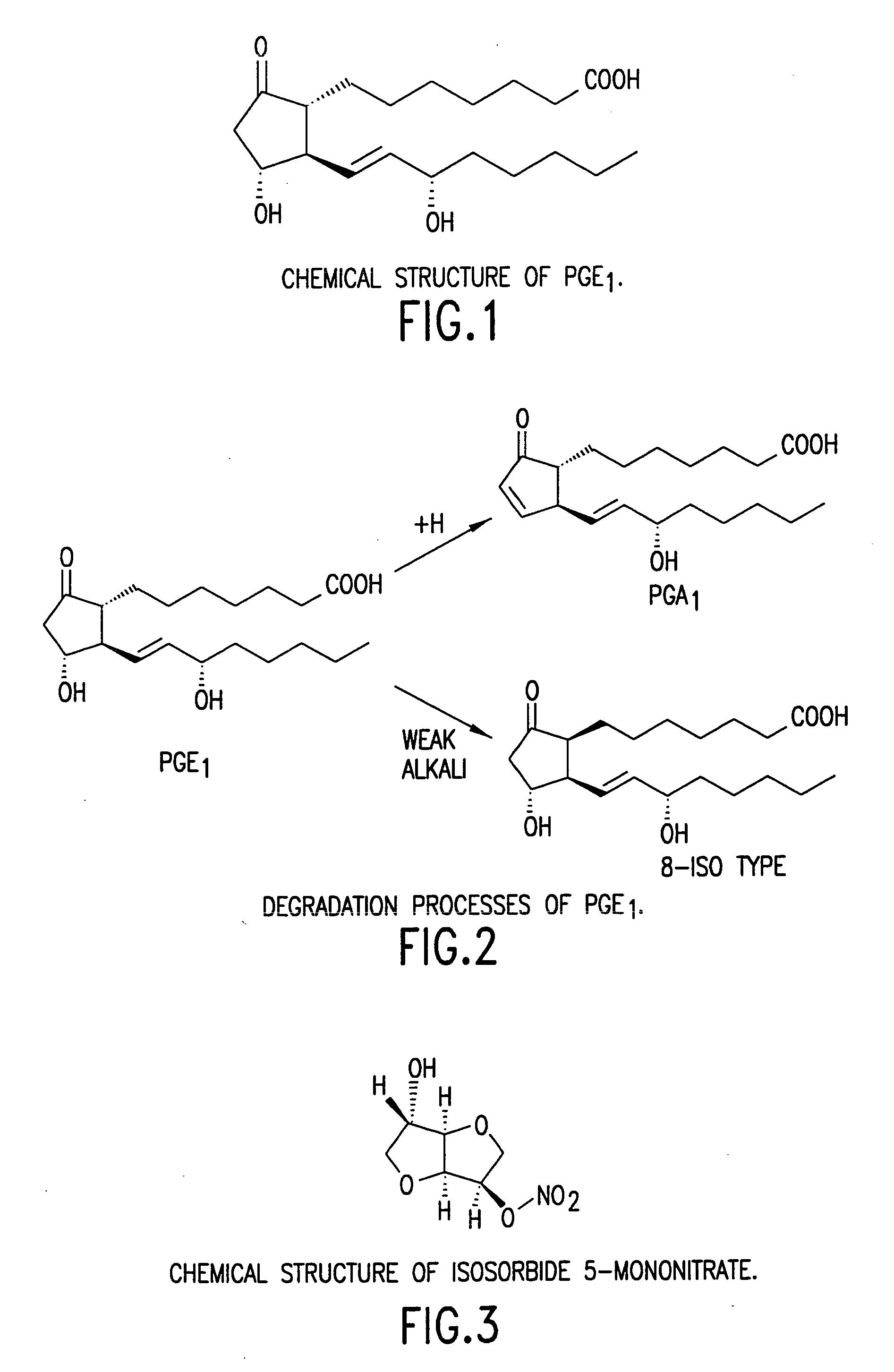

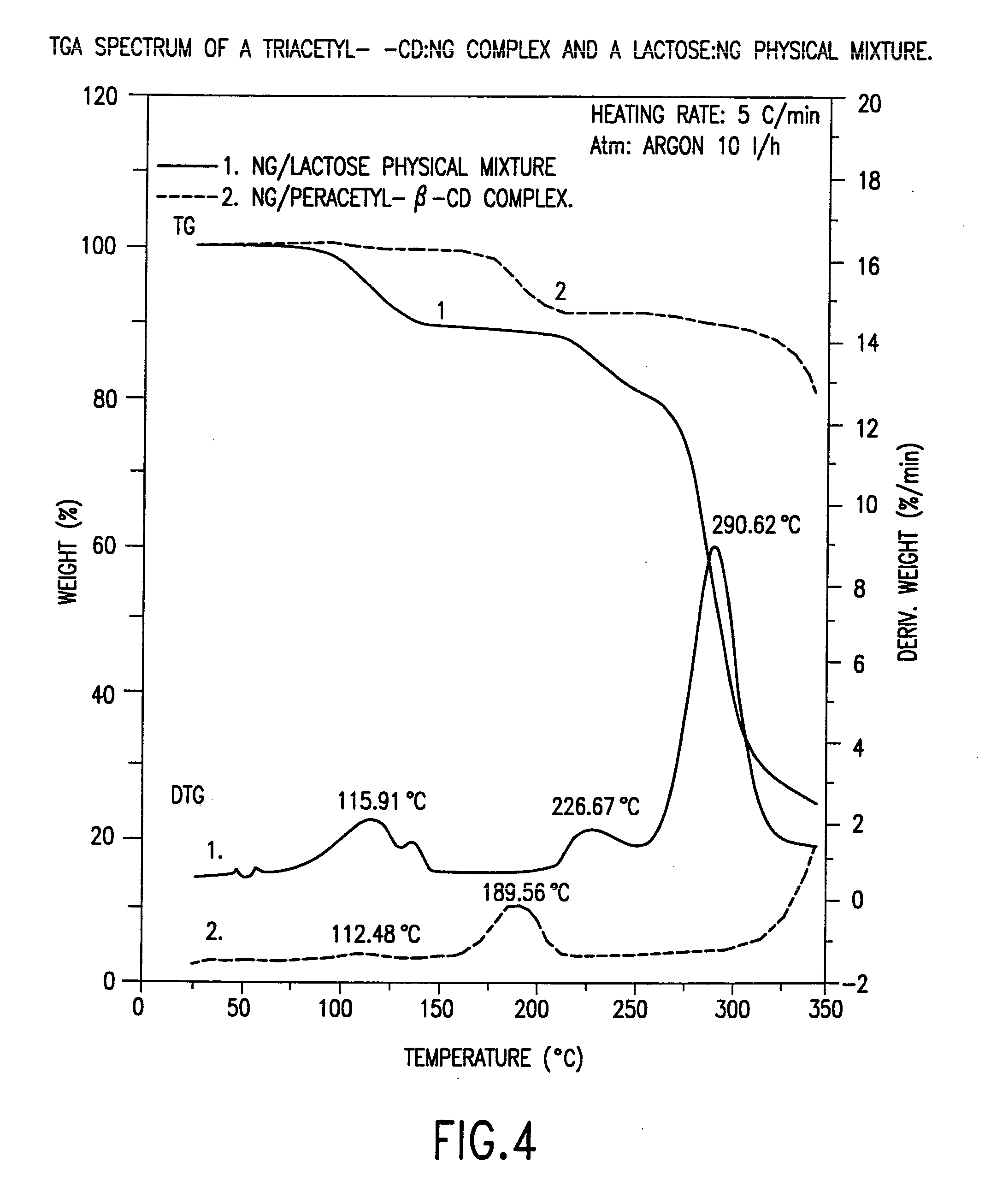

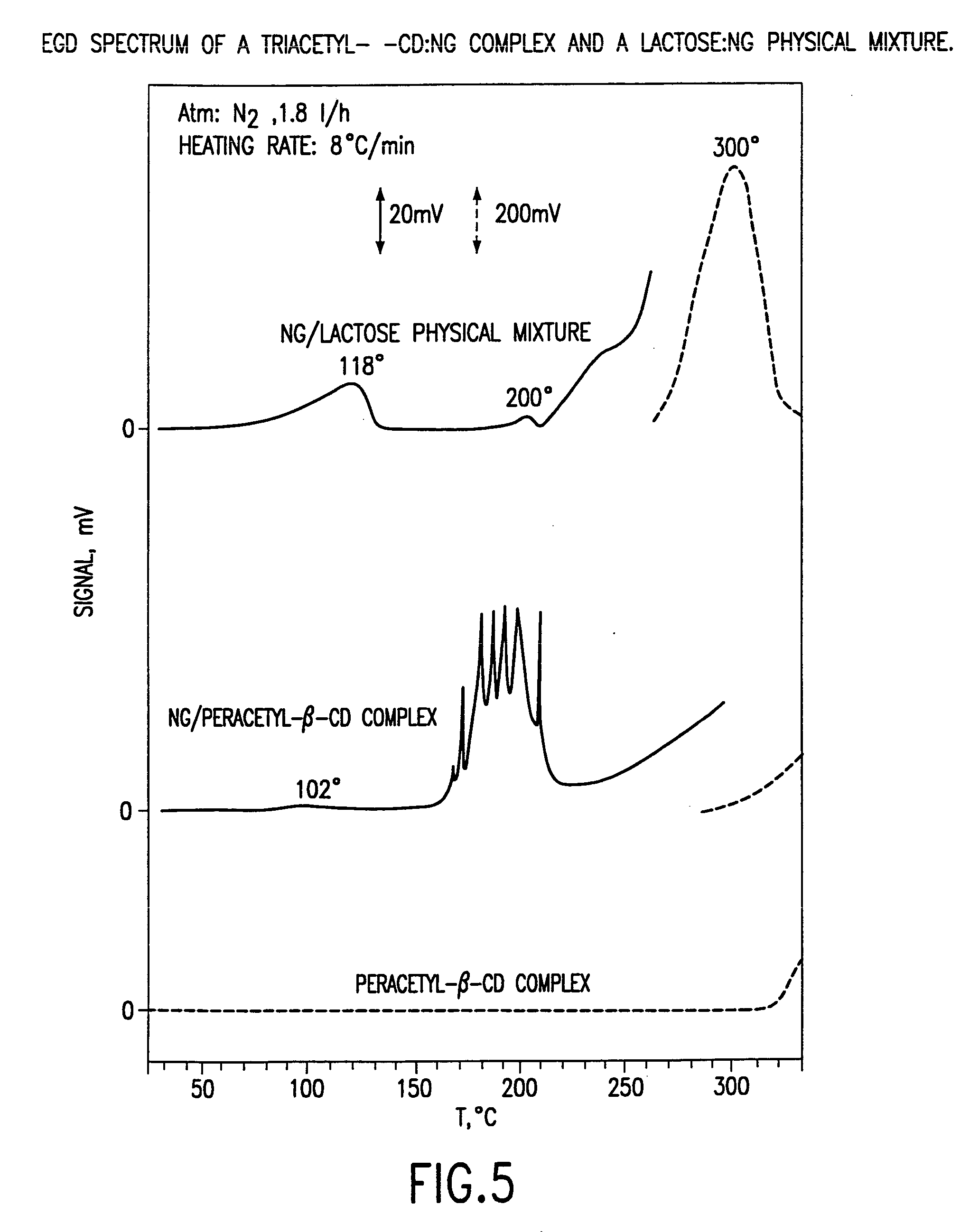

Acylated cyclodextrin: guest molecule inclusion complexes

InactiveUS20040063663A1Inhibited DiffusionLow process temperatureBiocidePowder deliveryCyclodextrinAqueous medium

Owner:BUCHANAN CHARLES M +4

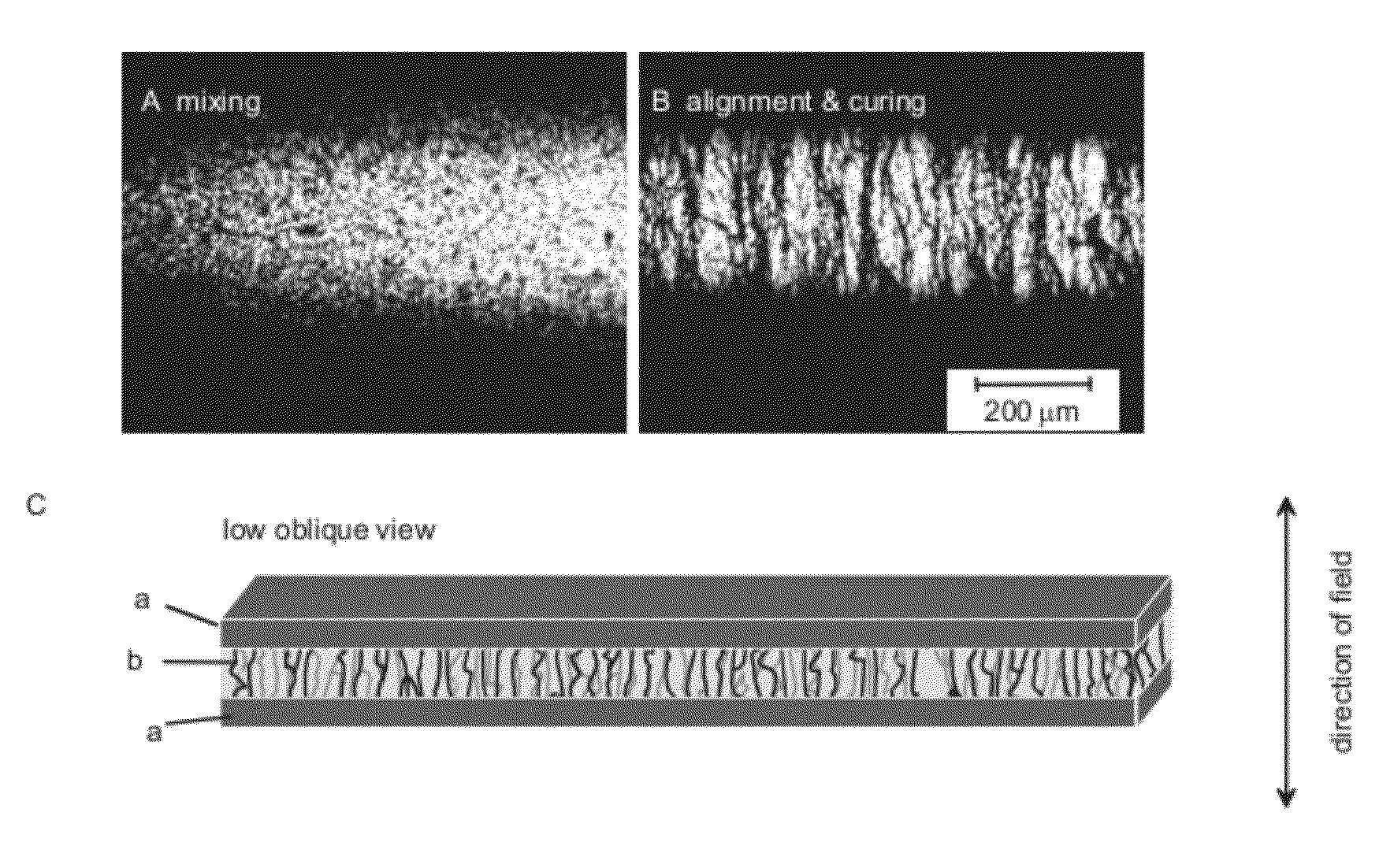

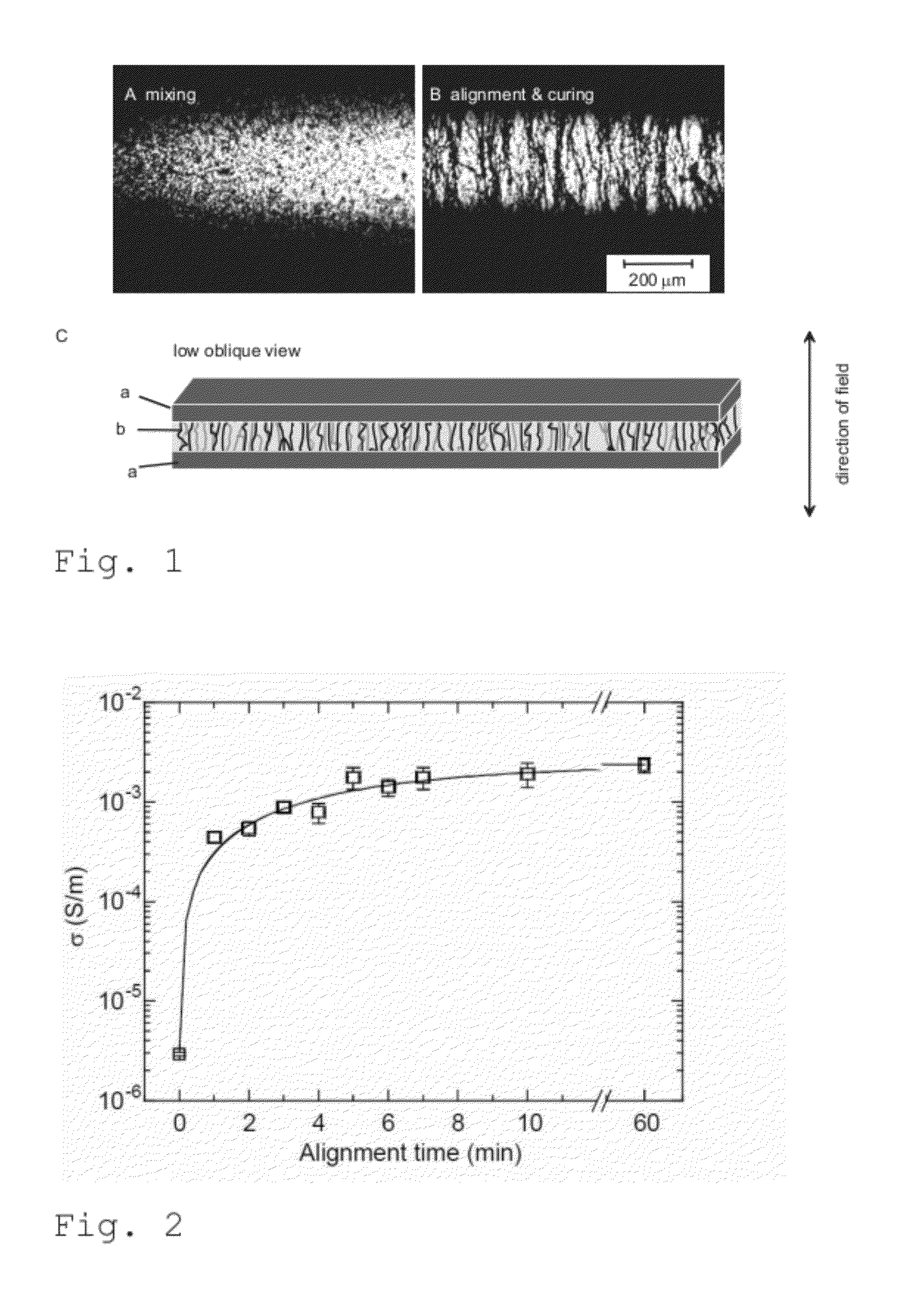

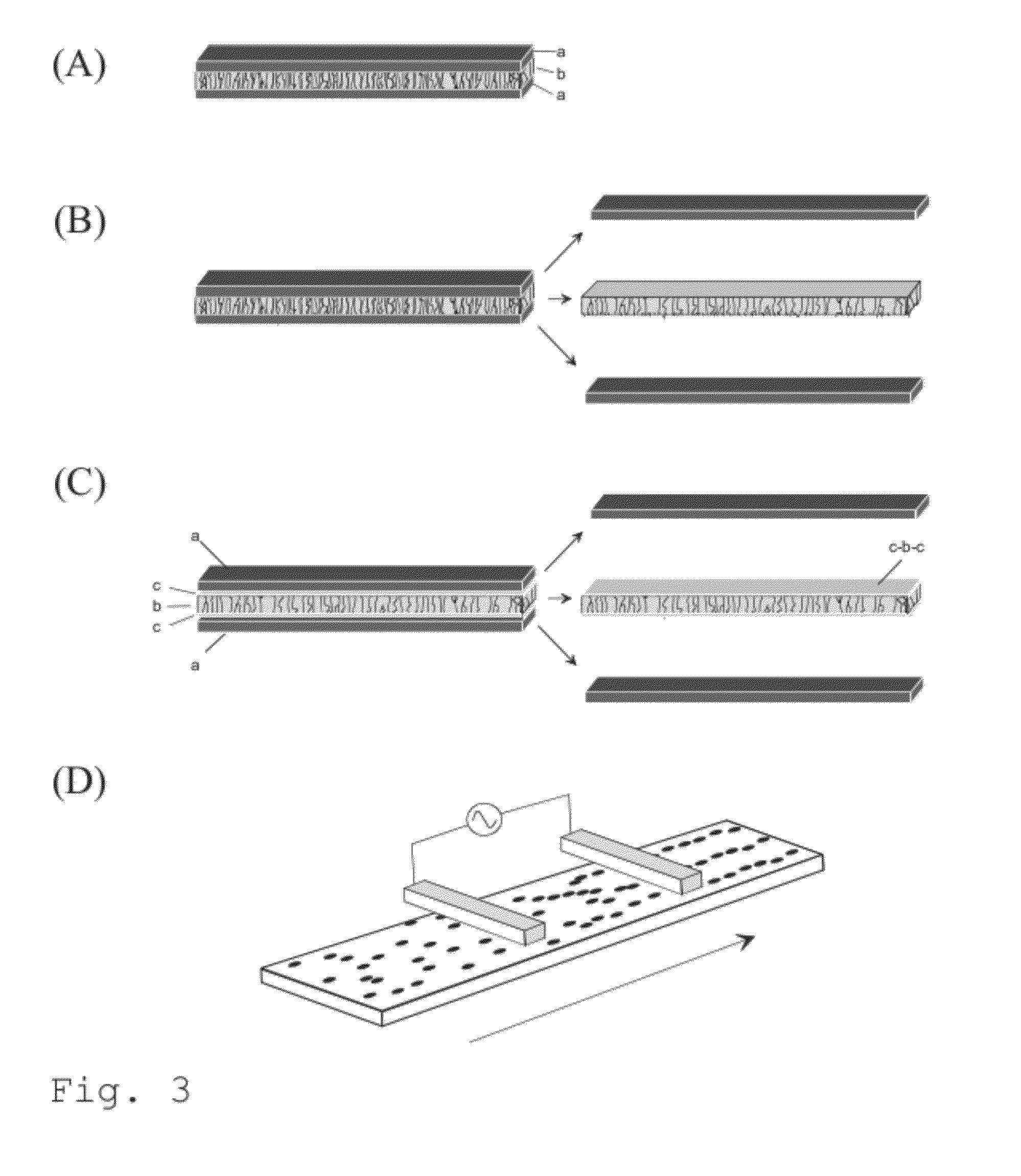

Anisotropic conductive polymer material

ActiveUS20120145315A1Fast curing timeHigh bonding strengthMaterial nanotechnologyNon-macromolecular adhesive additivesConductive polymerPercolation threshold

A method for forming a body comprising a mixture of a matrix and conductive particles, whereby the conductive particles are formed into aligned conductive pathways in an alignment step by applying an electric field between alignment electrodes and thereafter stabilizing the mixture wherein the conductive particles have a low aspect ratio; and a polymeric composition and method for producing such composition which is curable by UV light to an anisotropic electrically conductive polymer layer, comprising i) providing a non-conductive matrix of a flowable polymer composition having inherent photocurability, ii) adding to matrix conductive particles having low aspect ratio in an amount to allow the concentration of the conductive particles to be maintained at a level lower than the percolation threshold, and iii) placing the formed composition in a receptacle where exposure to UV light is prevented, and a method for establishing an anisotropic electrically conductive, optionally thermally conductive

Owner:CONDALIGN AS

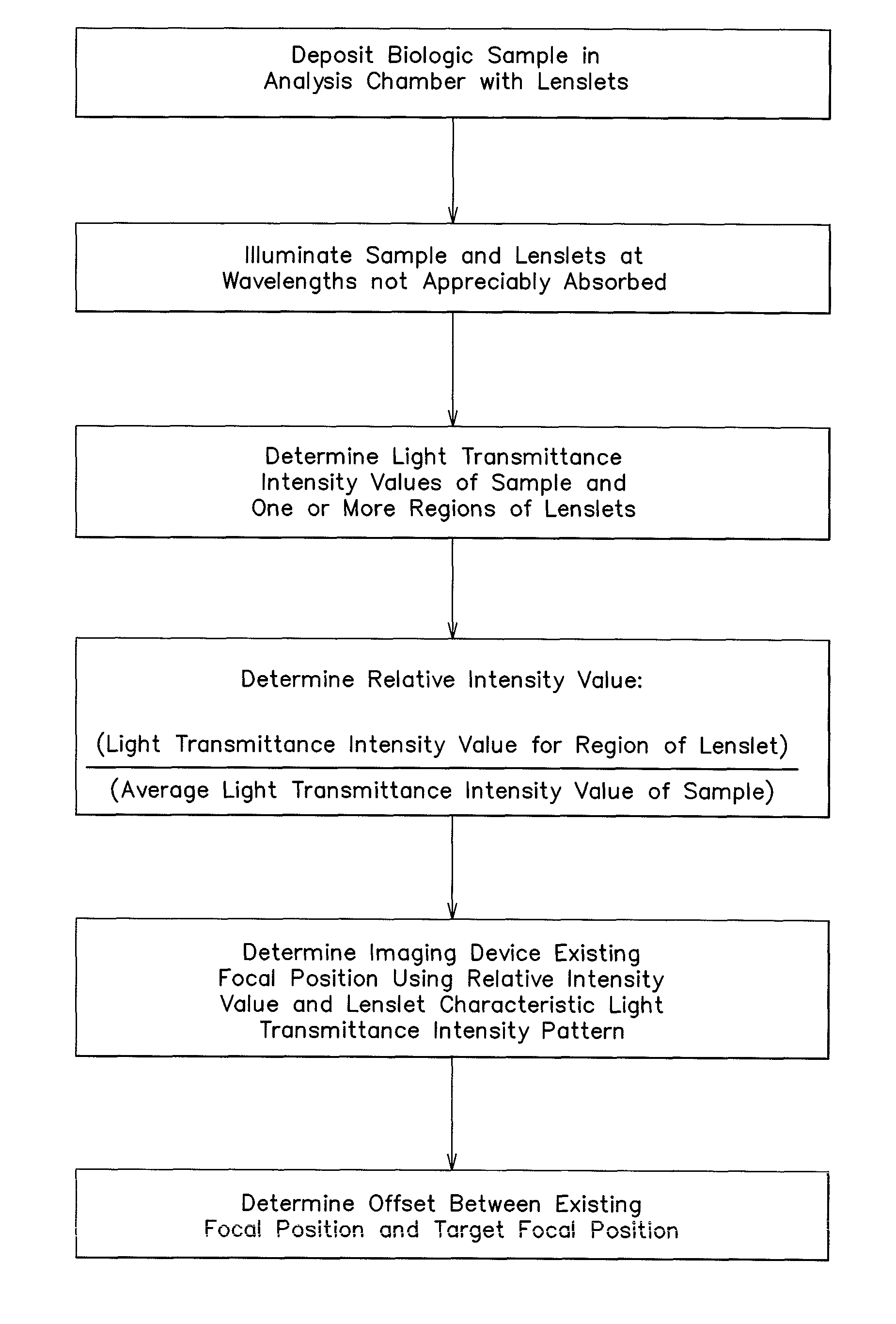

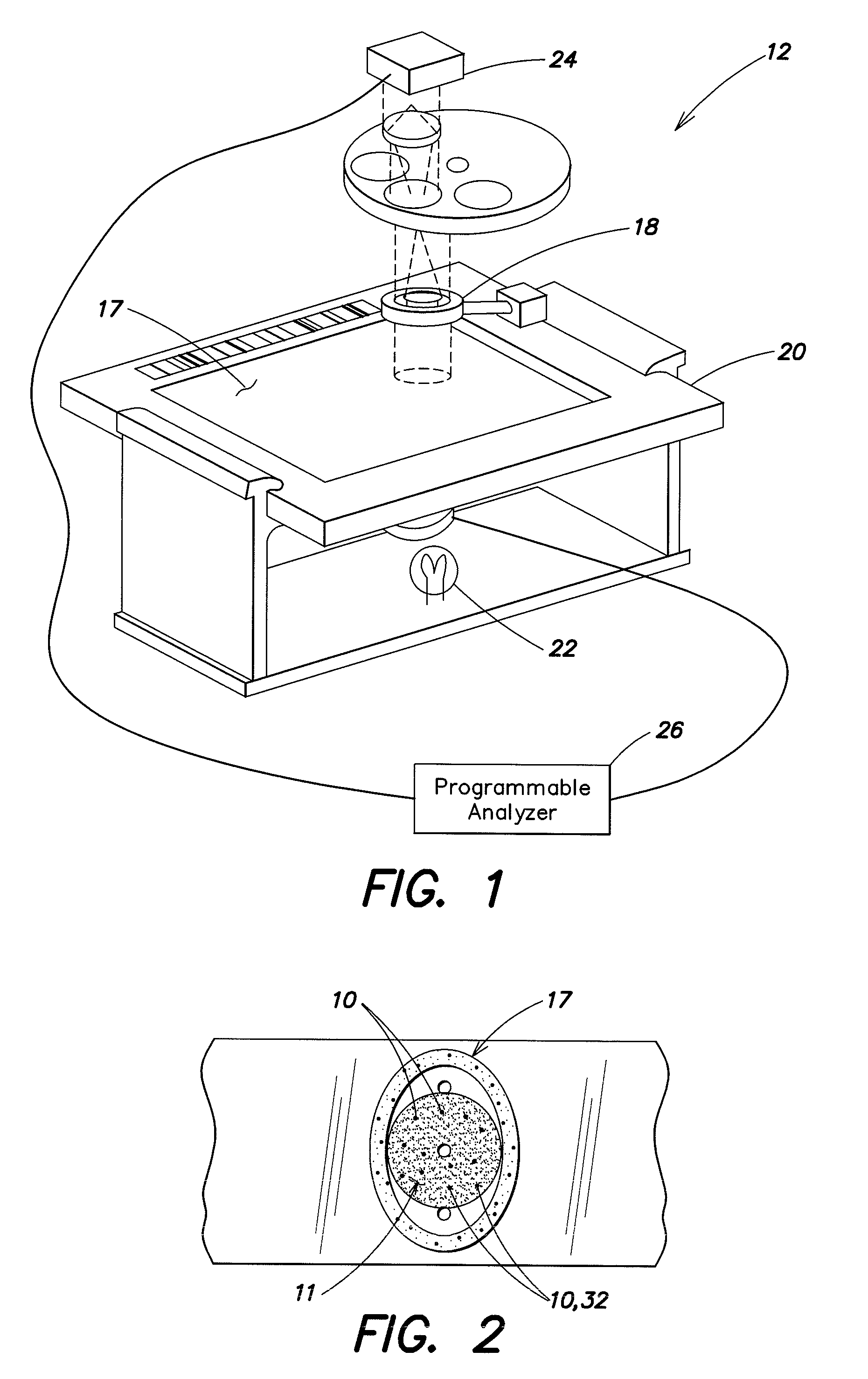

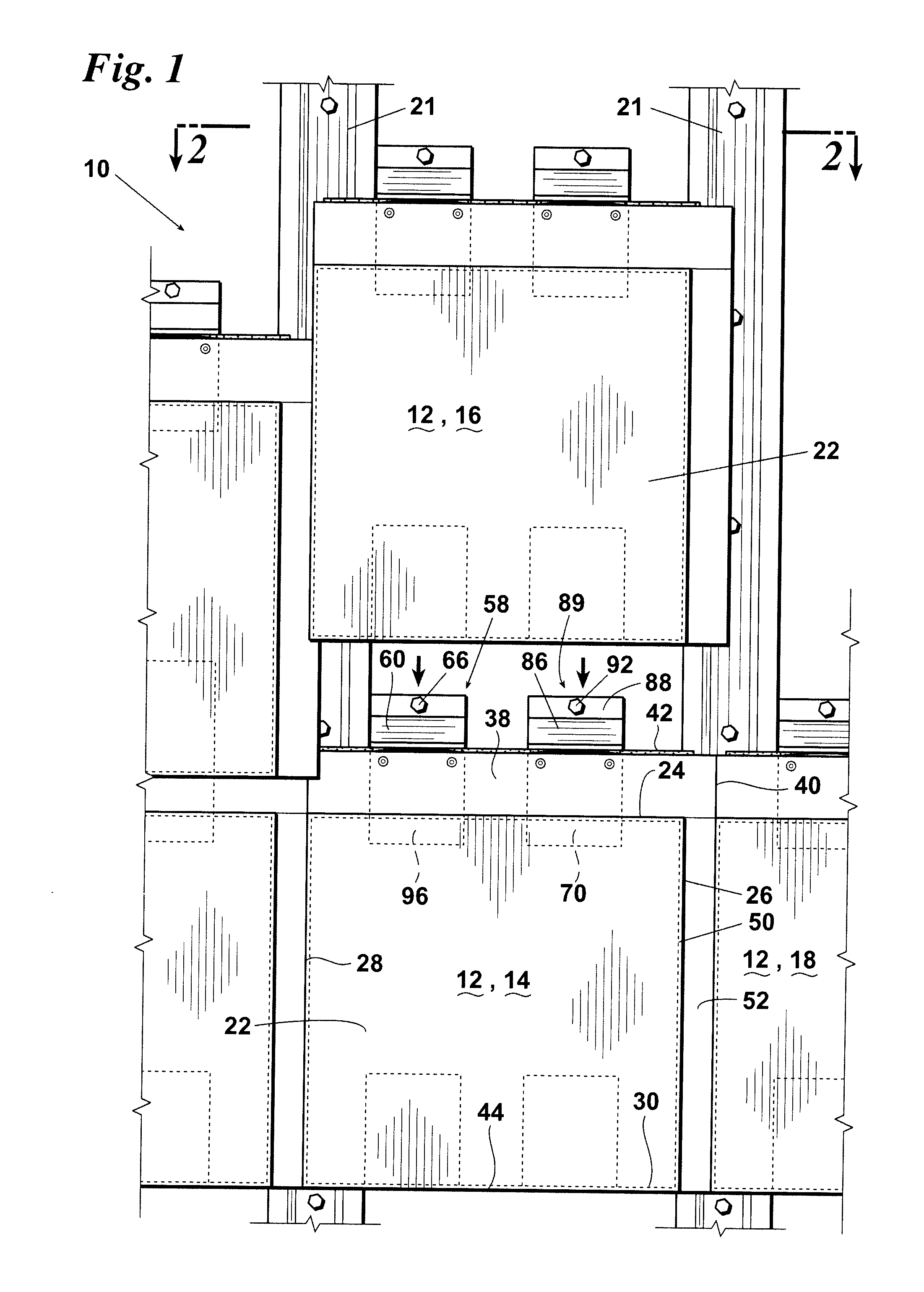

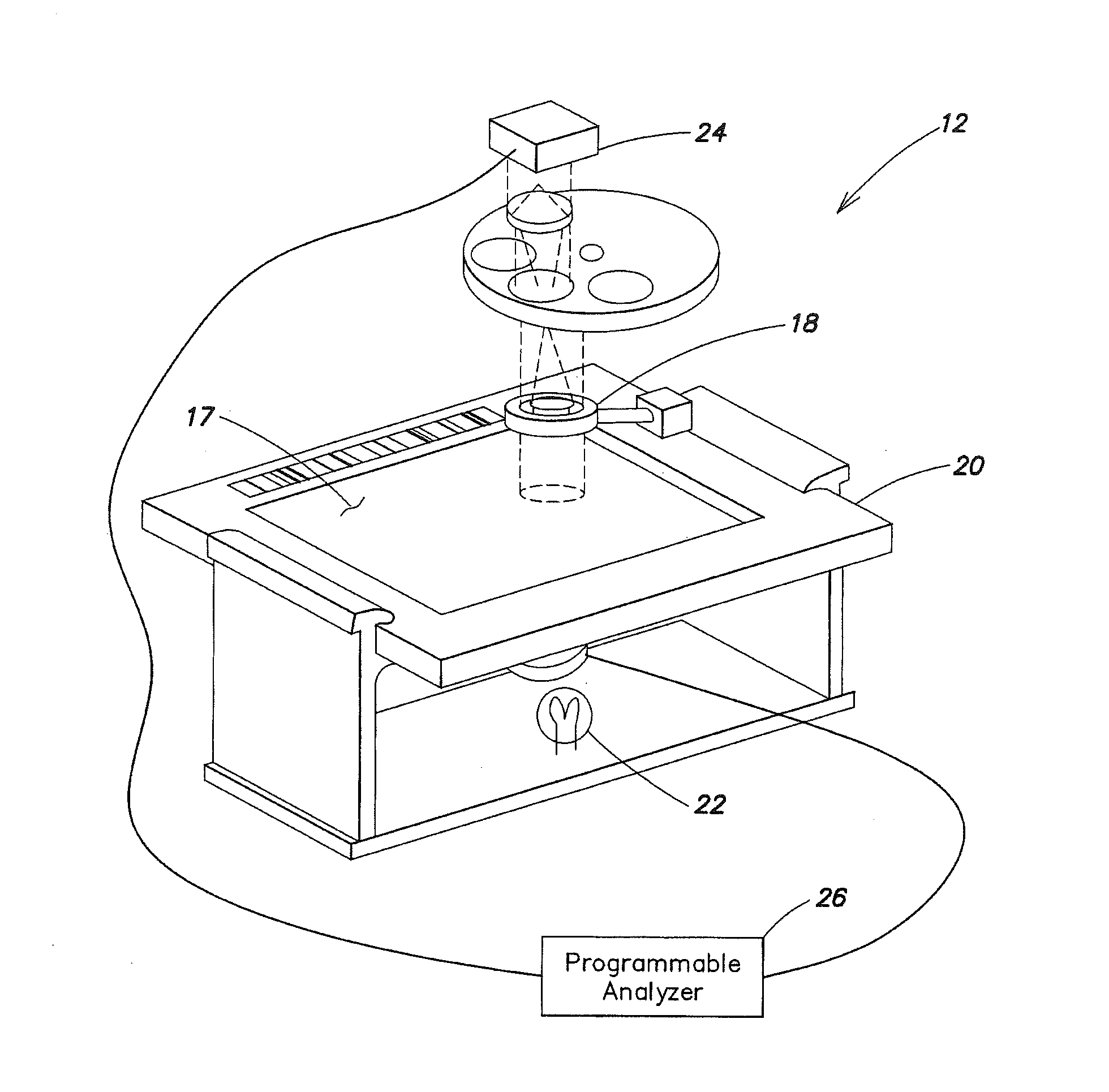

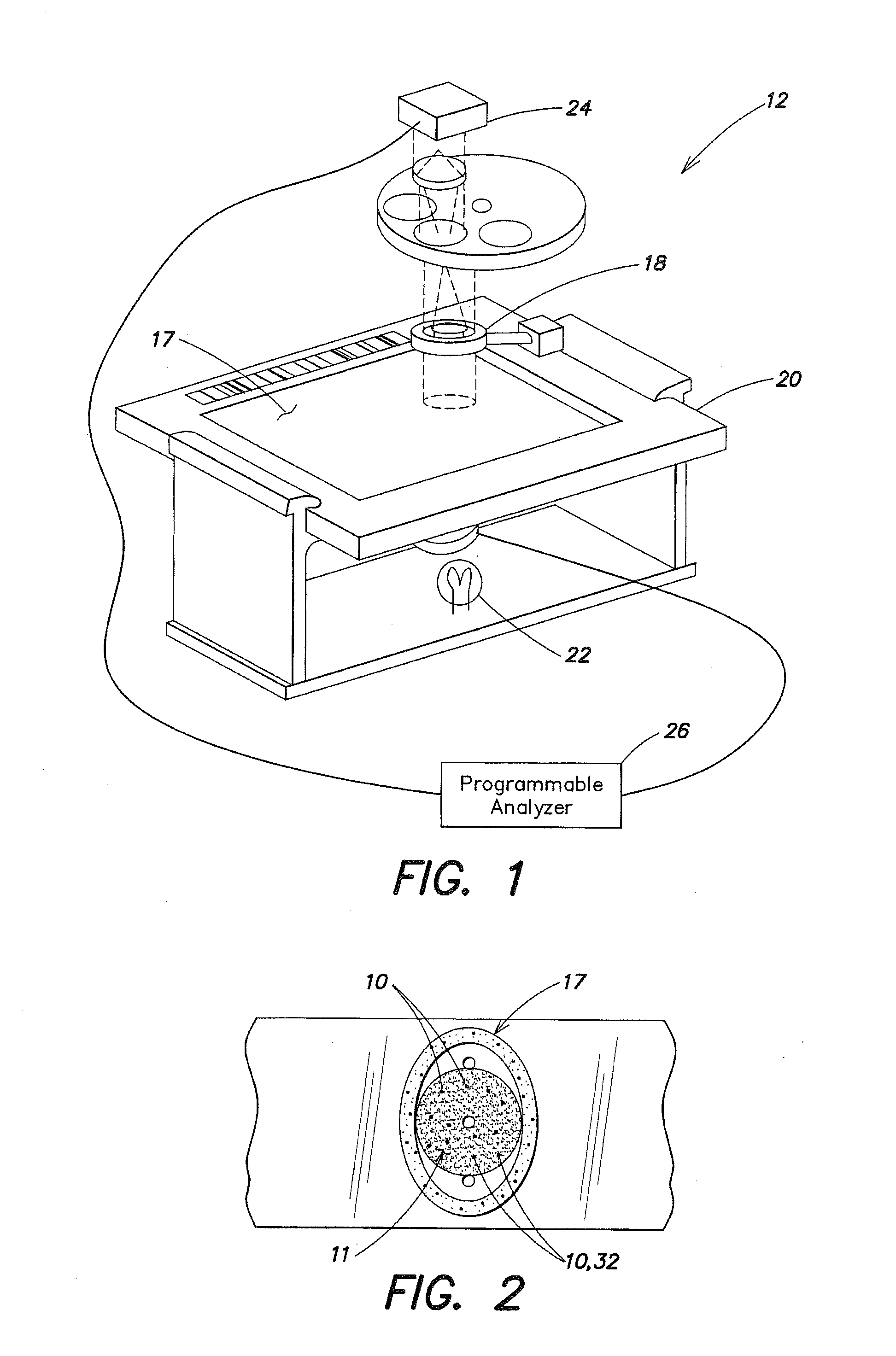

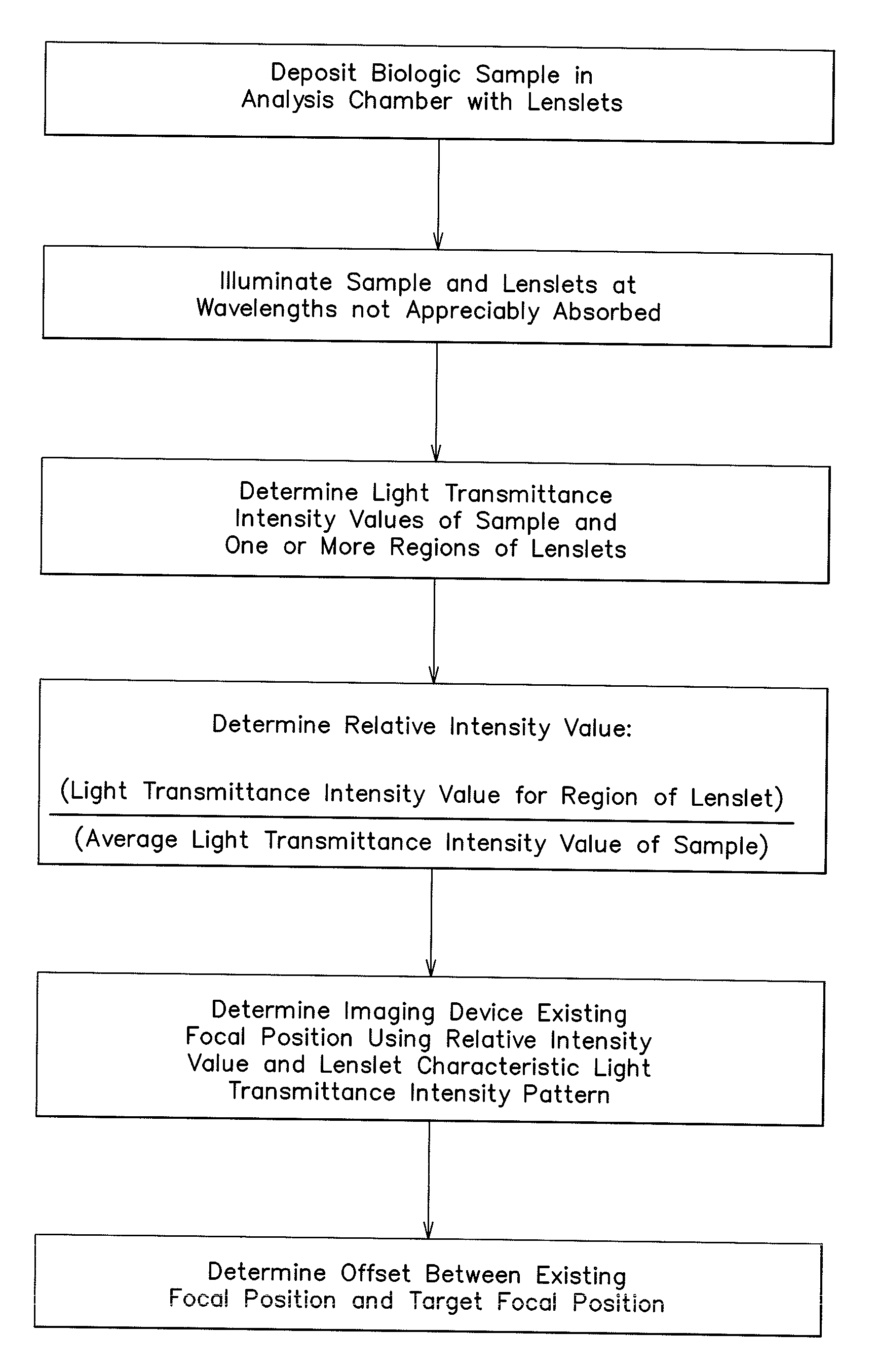

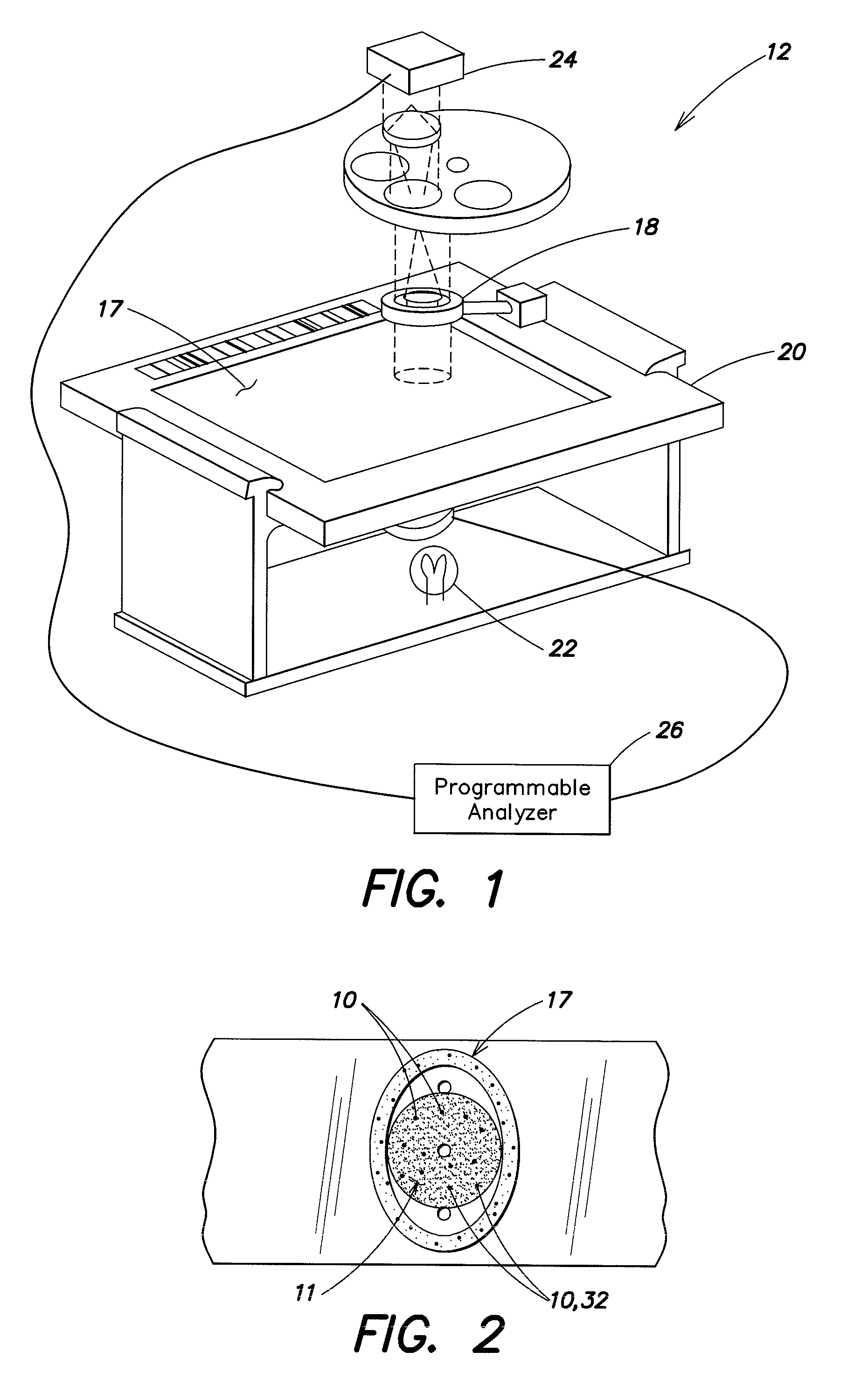

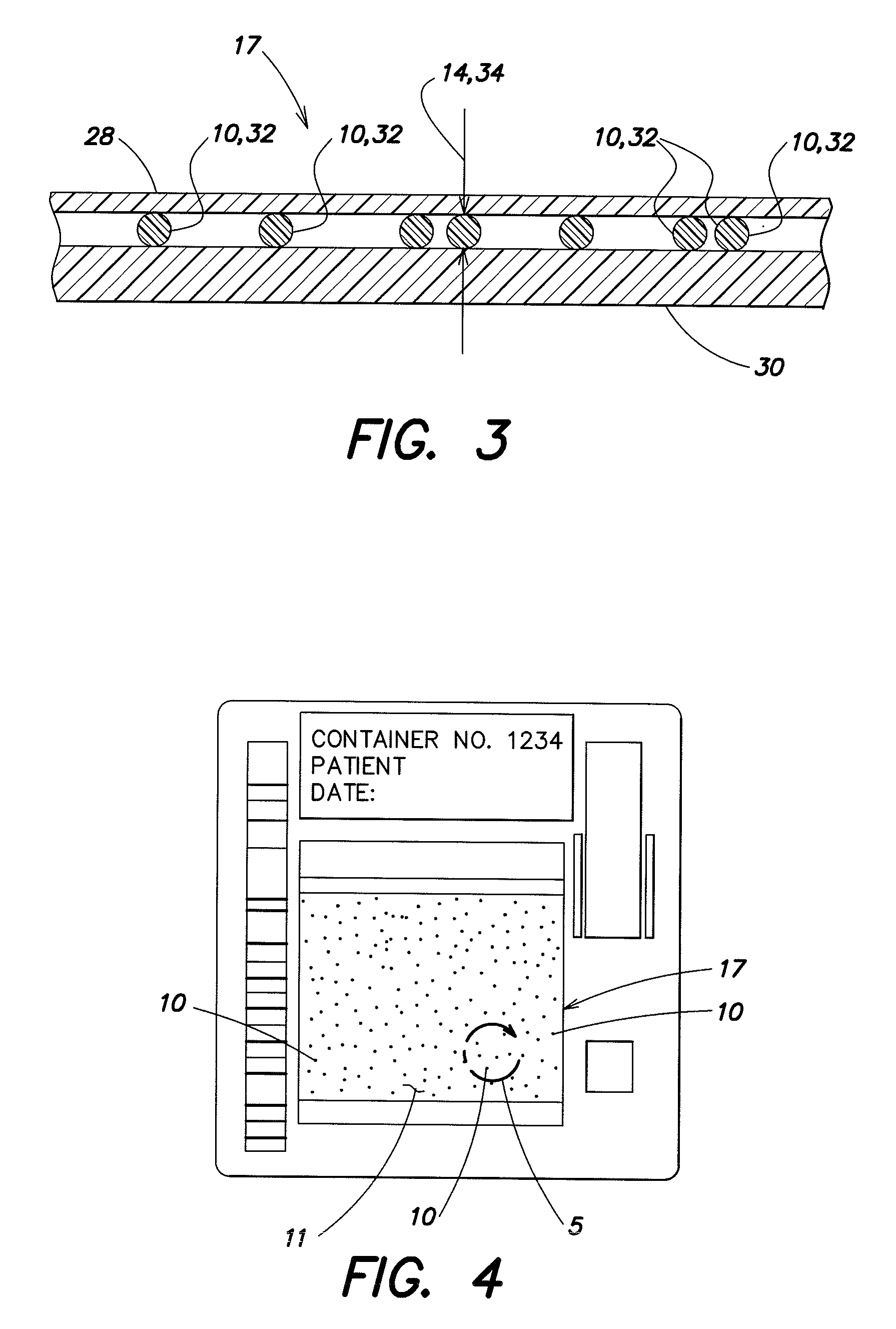

Method and apparatus for determining a focal position of an imaging device adapted to image a biologic sample

InactiveUS8045165B2Robust methodInexpensive meanMaterial analysis by optical meansMicroscopesOptical transmittanceRefractive index

A method and apparatus for focusing a device for imaging a biologic sample is provided. A method aspect of the disclosure includes the steps of: 1) disposing lenslets within a field of a biologic sample, which lenslets have a height, and have a refractive index and which refractive index is different from that of the sample, wherein one or both of the imaging device and the sample are relatively locatable so a focal position of the imaging device can be moved along the height of the lenslets; 2) imaging at least a portion of the sample including a plurality of lenslets using transmittance at one or more predetermined wavelengths; 3) determining an average light transmittance intensity of the sample at the wavelengths; 4) determining an average light transmittance intensity of a region of each lenslet at the wavelengths; and 5) determining the focal position of the imaging device using the average light transmittance intensity of the sample and the average light transmittance intensity of the region of the lenslets.

Owner:ABBOTT POINT CARE

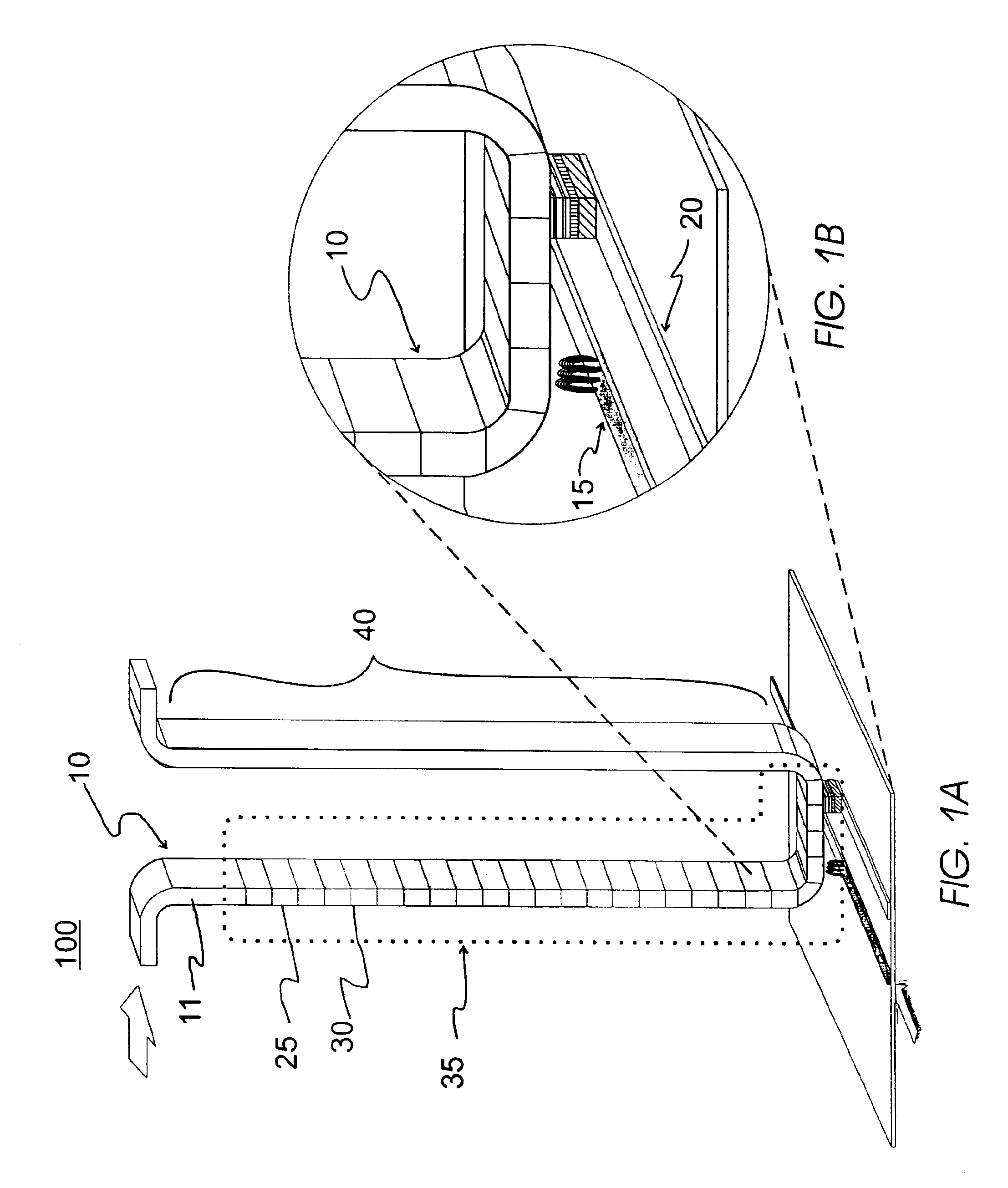

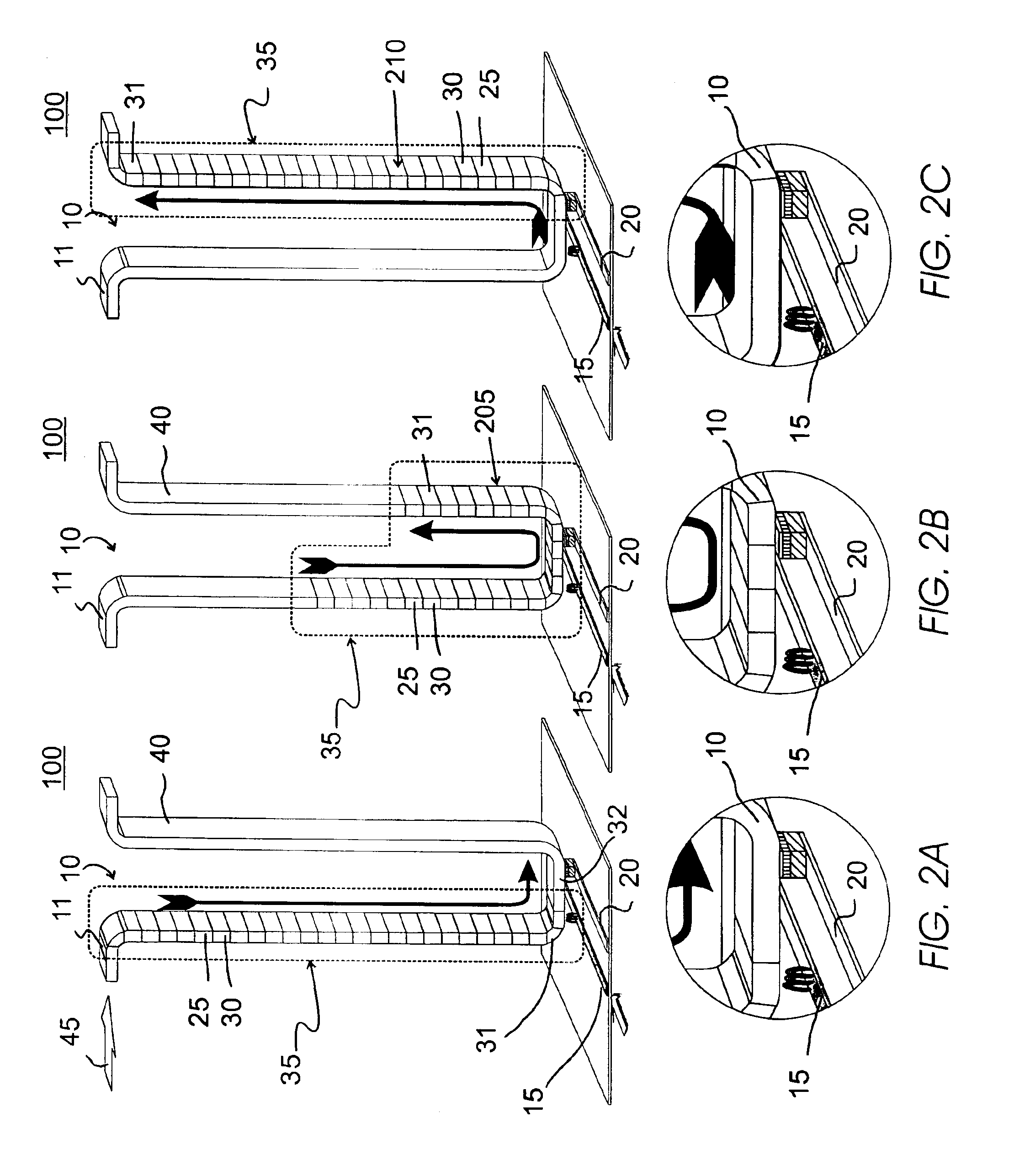

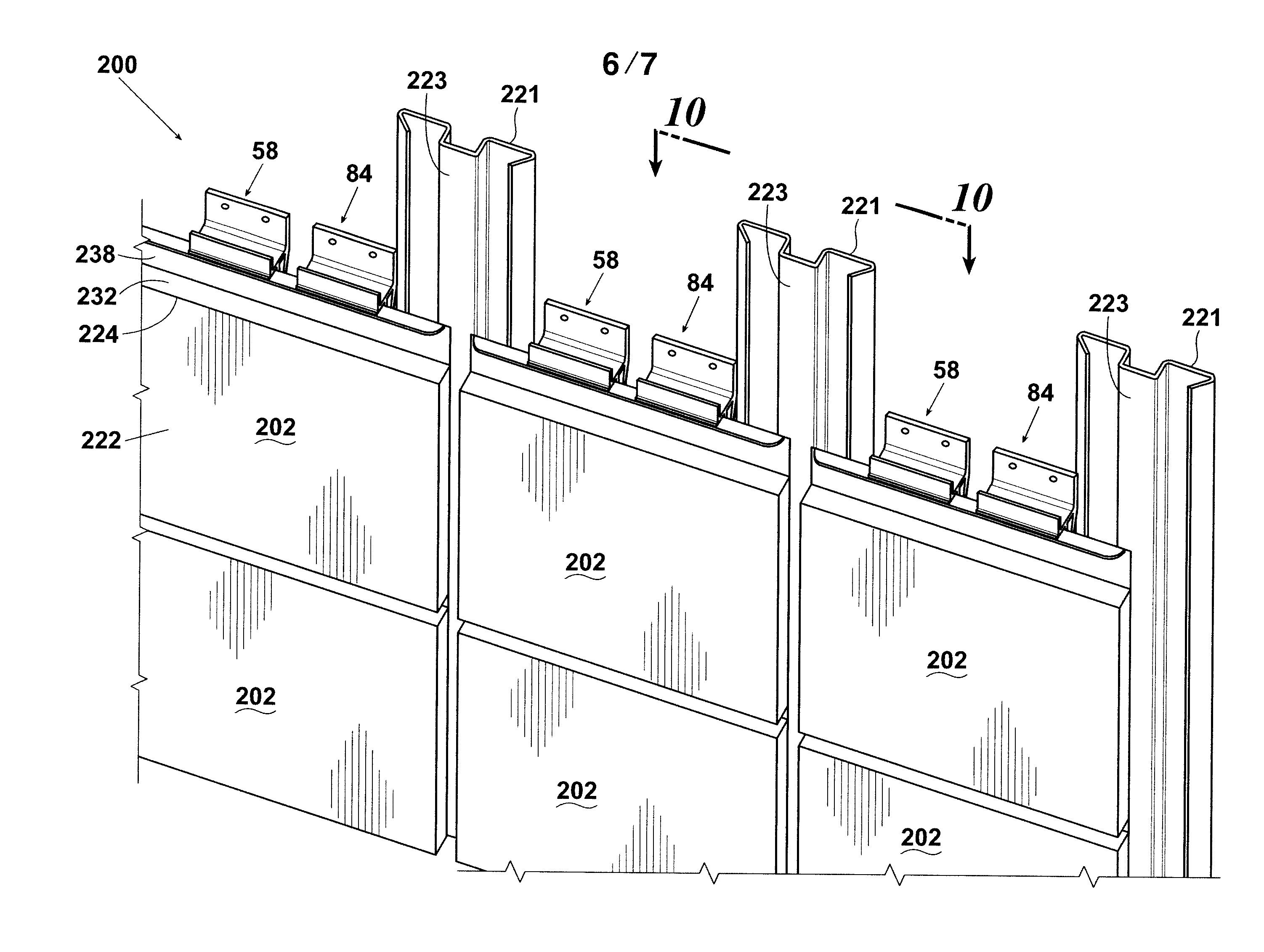

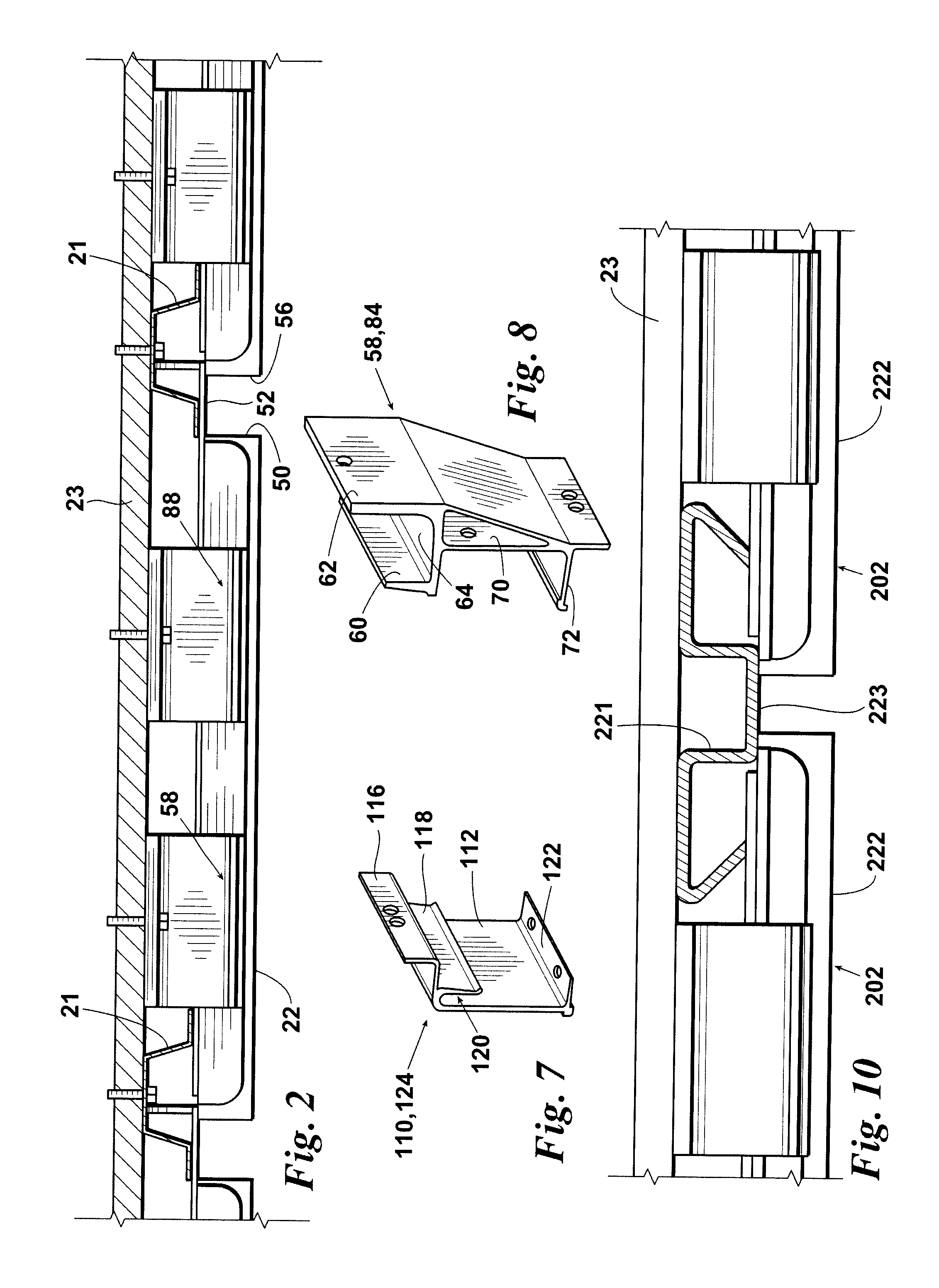

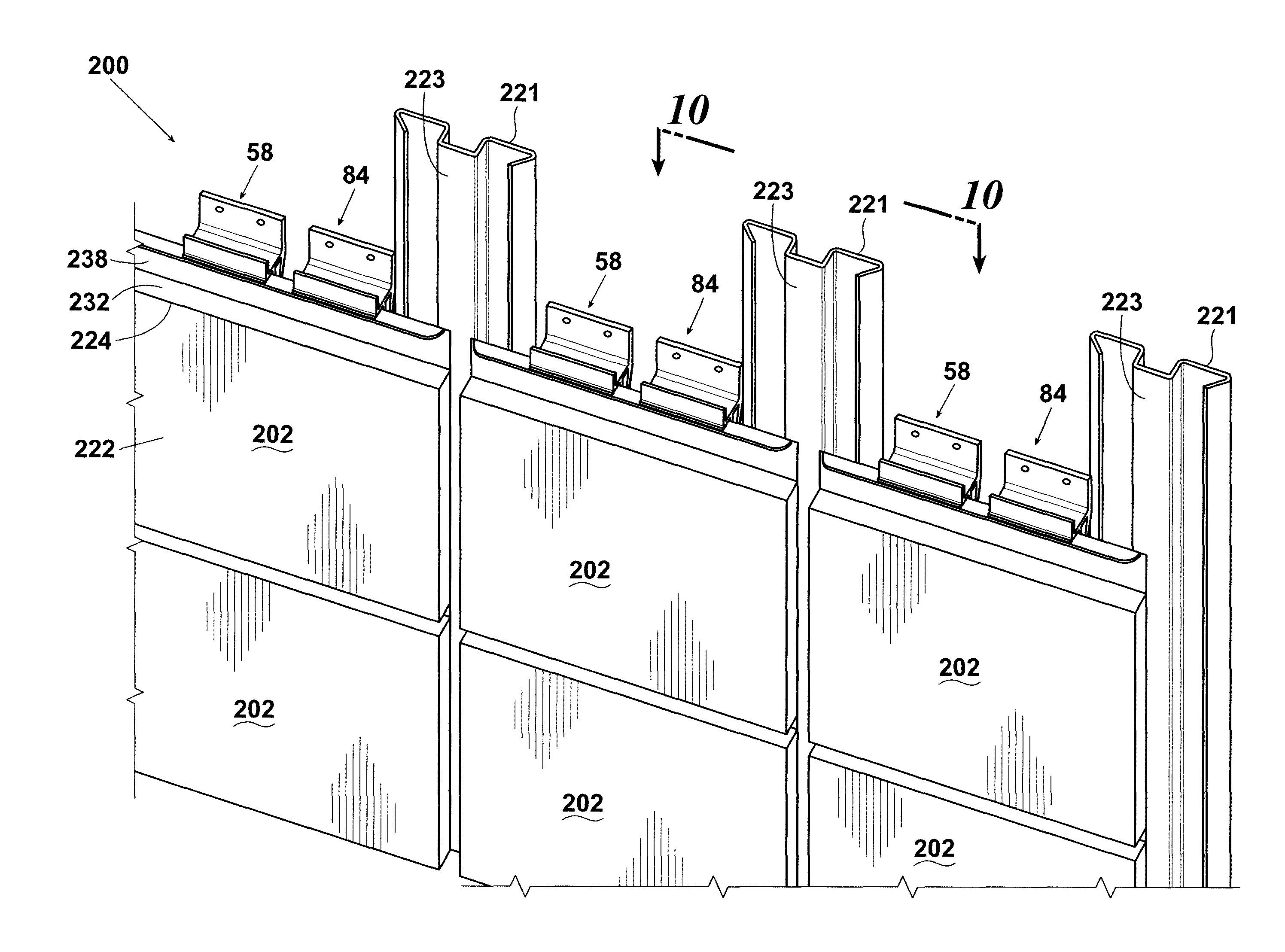

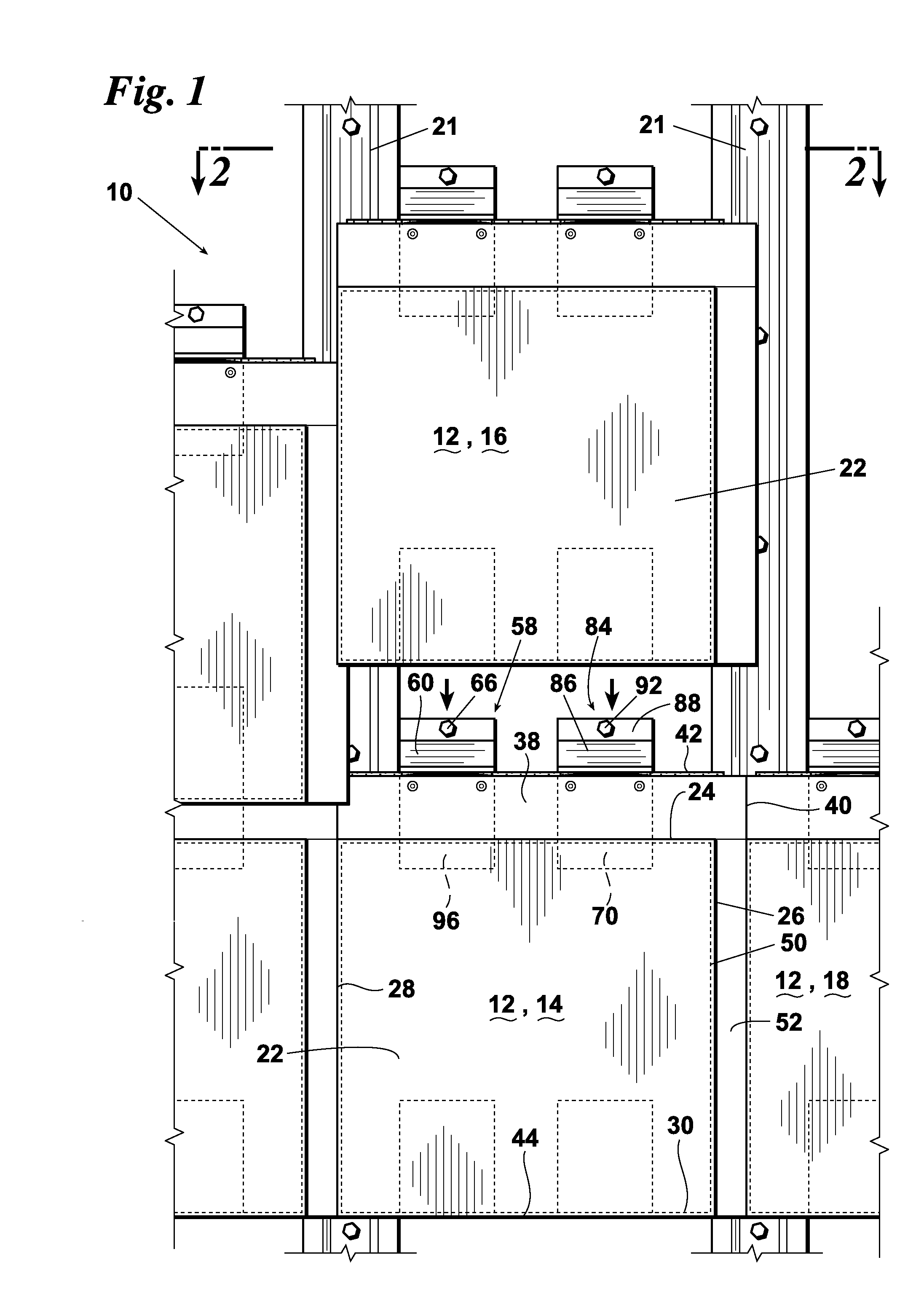

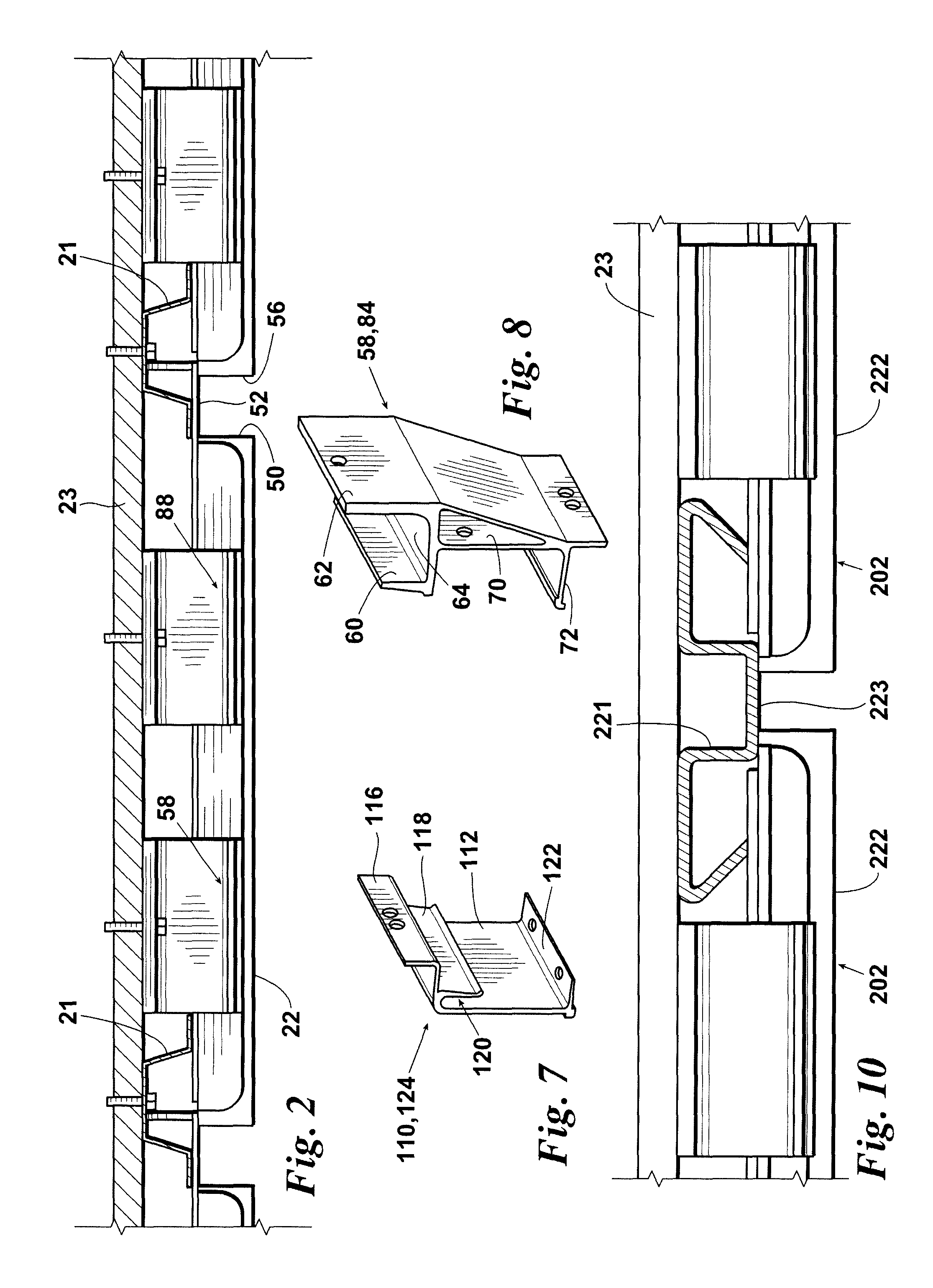

Rainscreen attachment system

A wall mounted panel system wherein panels are permitted three directions of expansion and contraction since each of panel is affixed to the wall at a single point. For example, the system includes a first and second panel adjacent to one another. An upper bracket and a lower bracket are affixed to the back of each panel, wherein the upper brackets are affixed to the wall and wherein the lower bracket of the first panel is movably engaged with the upper bracket of the second panel. The panels do not communicate with any sealing members, thereby allowing for air to flow freely behind the panels for providing a means of removing moisture from behind the panels. A brace member in communication with the interior surface of each panel has an upper end affixed to the upper bracket and a lower end affixed to the lower bracket.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY

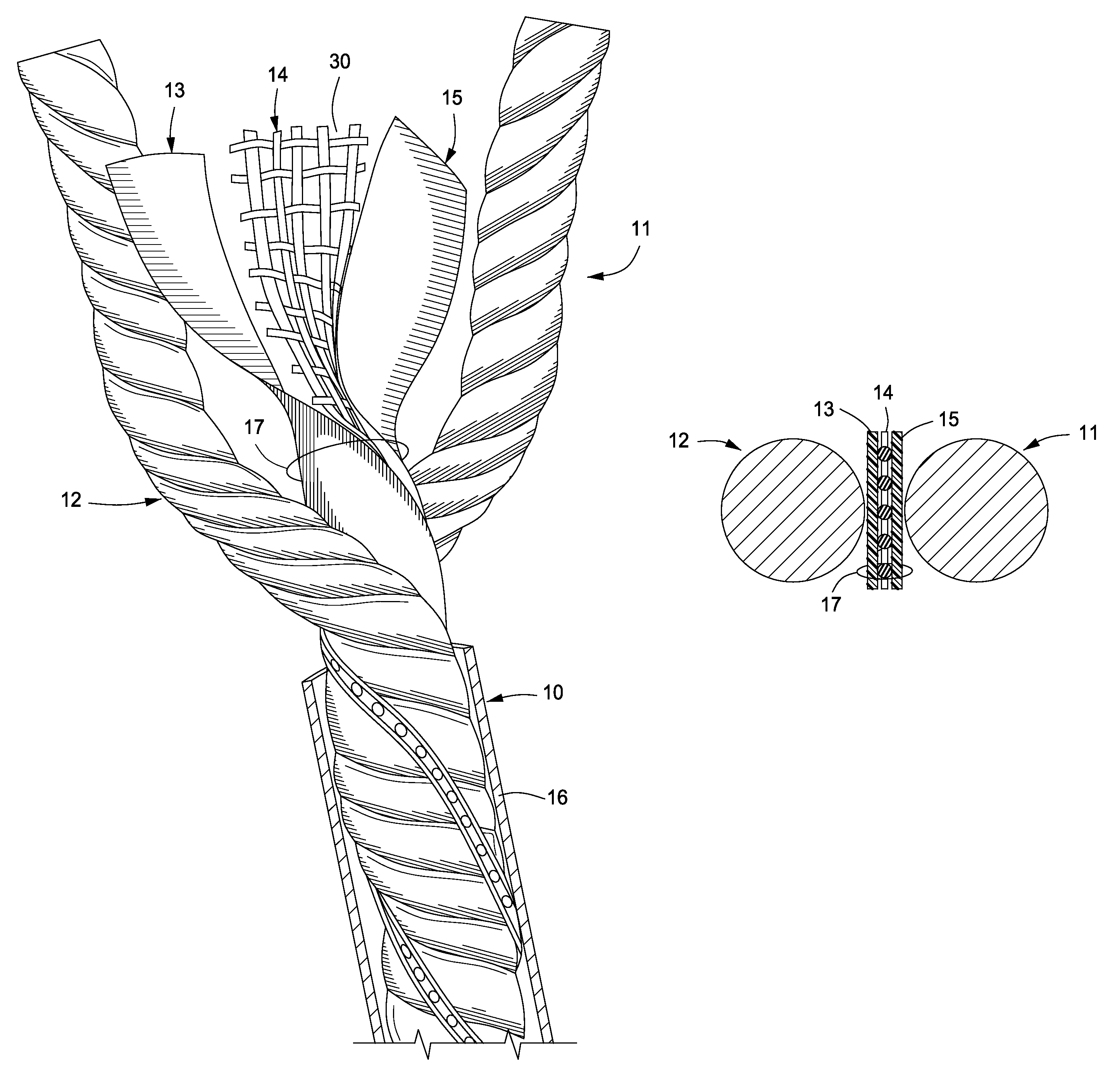

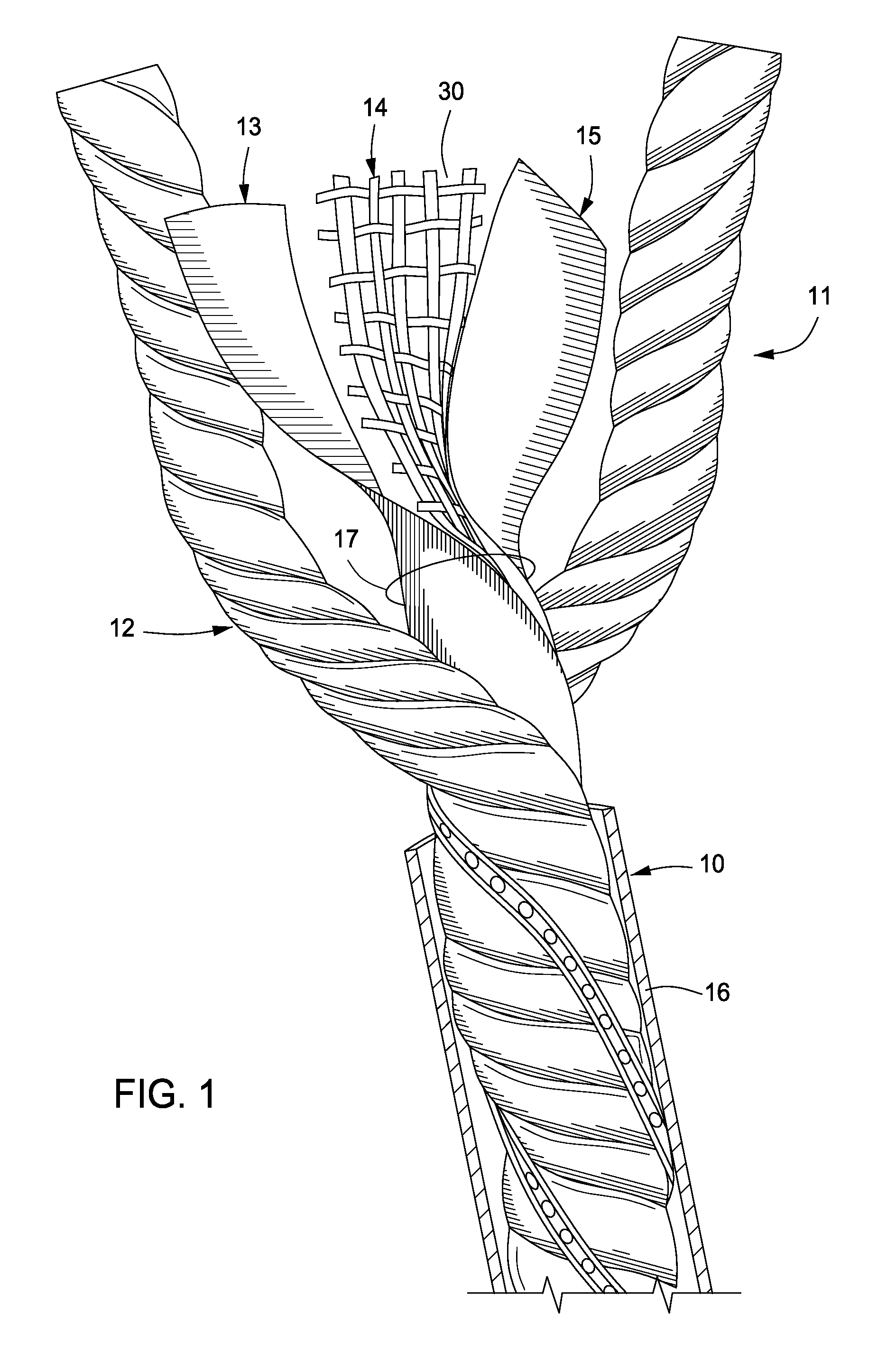

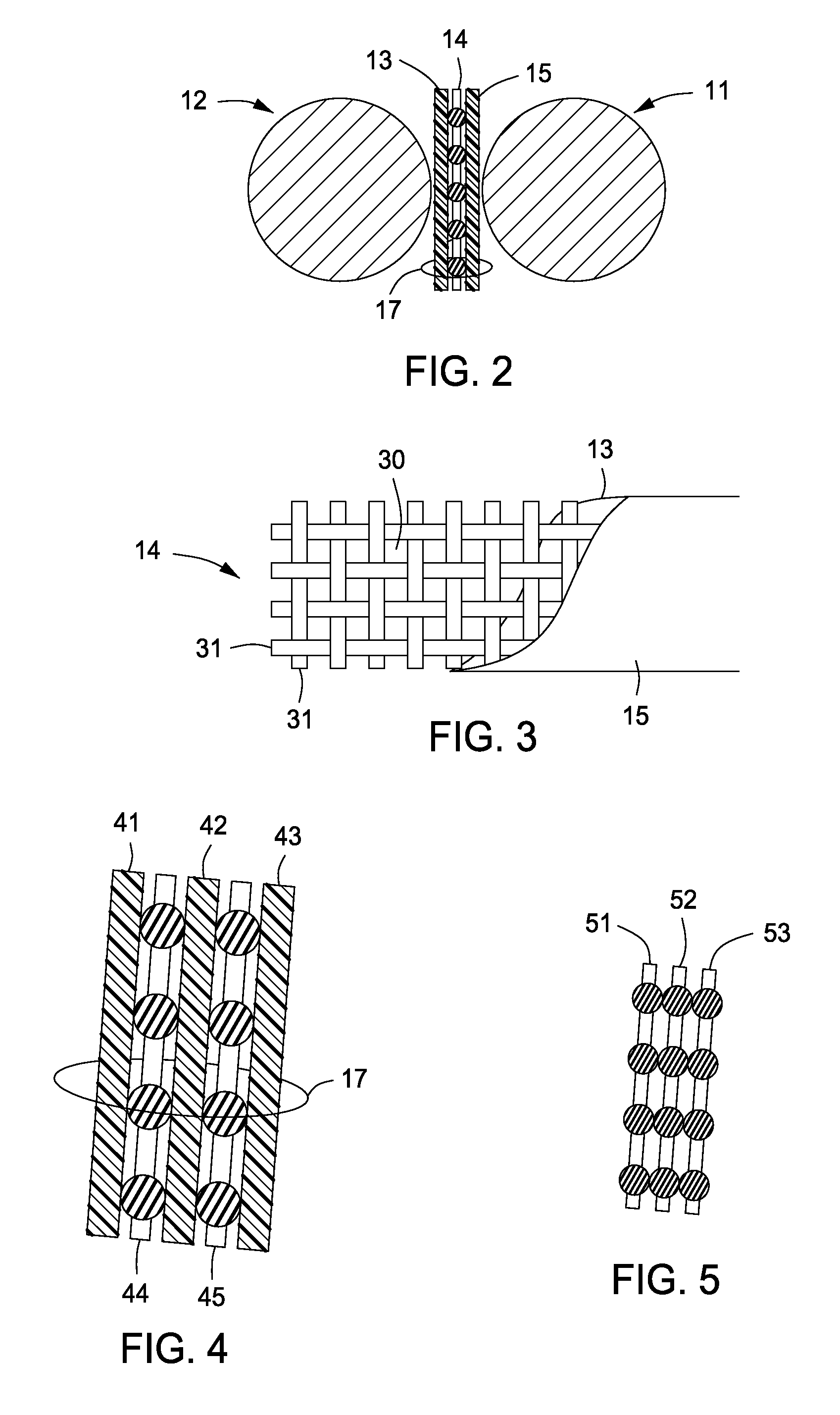

Electrical signal cable

InactiveUS7214883B2Minimal susceptibility to skin effectMinimal signal degradationPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorEngineering

The present invention provides an electrical cable having two or more conductors, one or more multistrip insulators separating the two or more conductors from one another, and a protective cover formed around the two or more conductors and one or more multistrip insulators. The multistrip insulator may include one or more dielectric strips, one or more protective strips or a combination thereof. The present invention also provides a method for manufacturing an electrical cable by providing two or more conductors, separating the two or more conductors from one another using one or more multistrip insulators, and forming a protective cover around the two or more conductors and one or more multistrip insulators.

Owner:LEYENDECKER ROBERT R

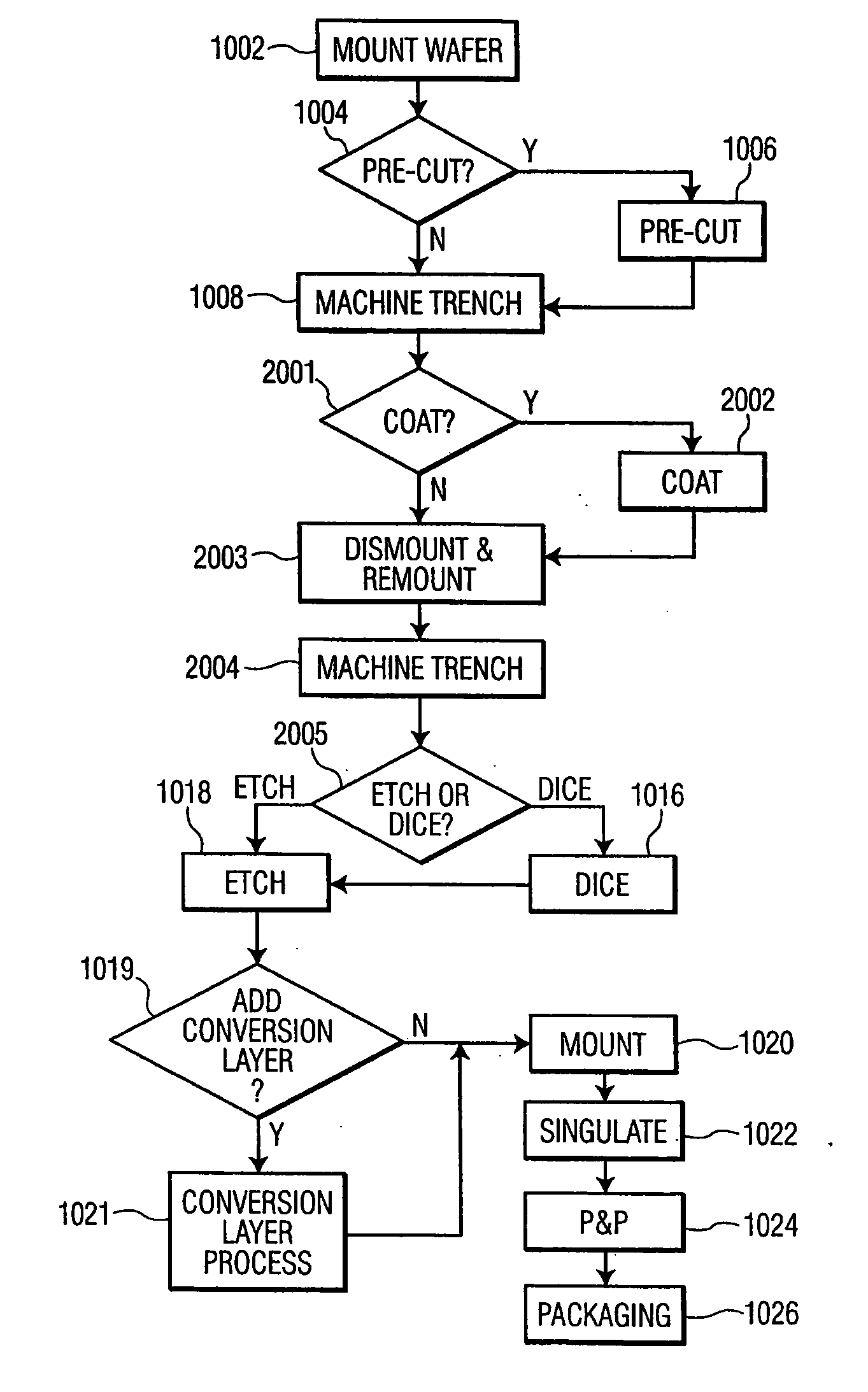

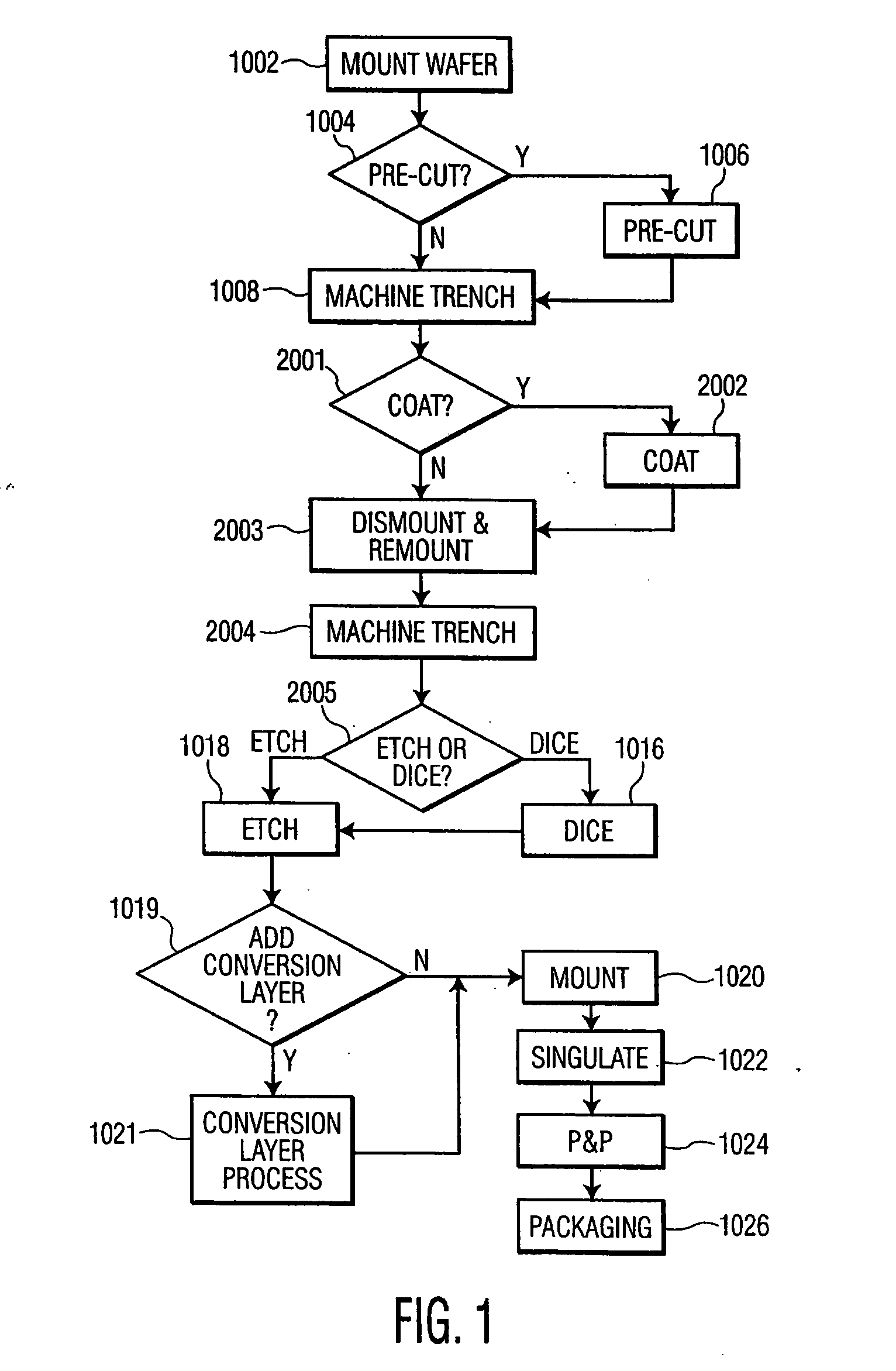

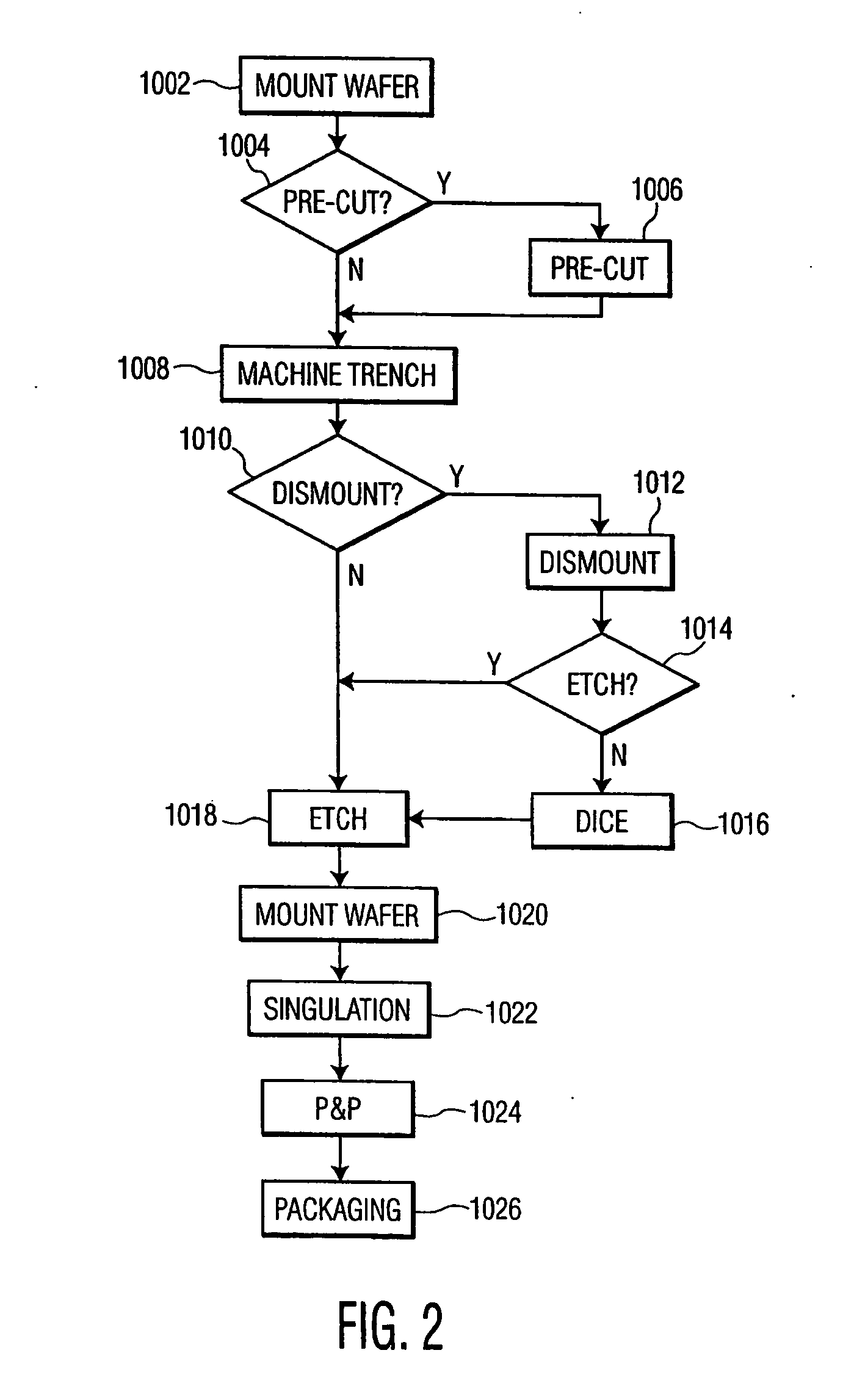

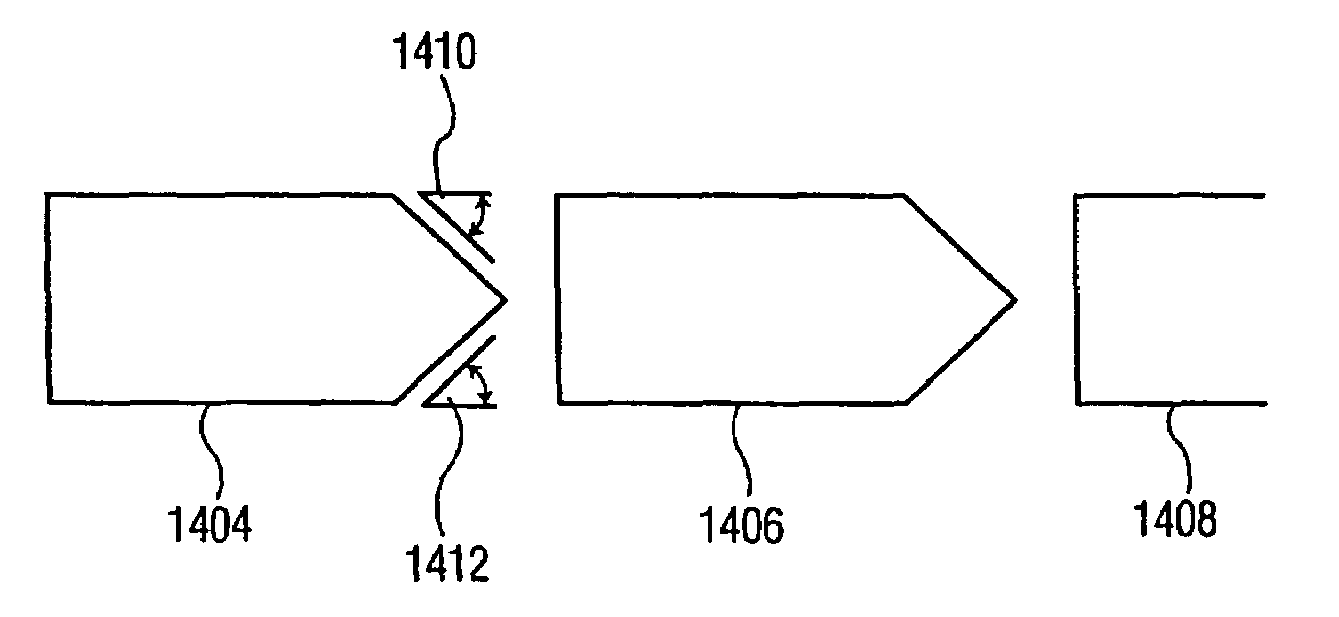

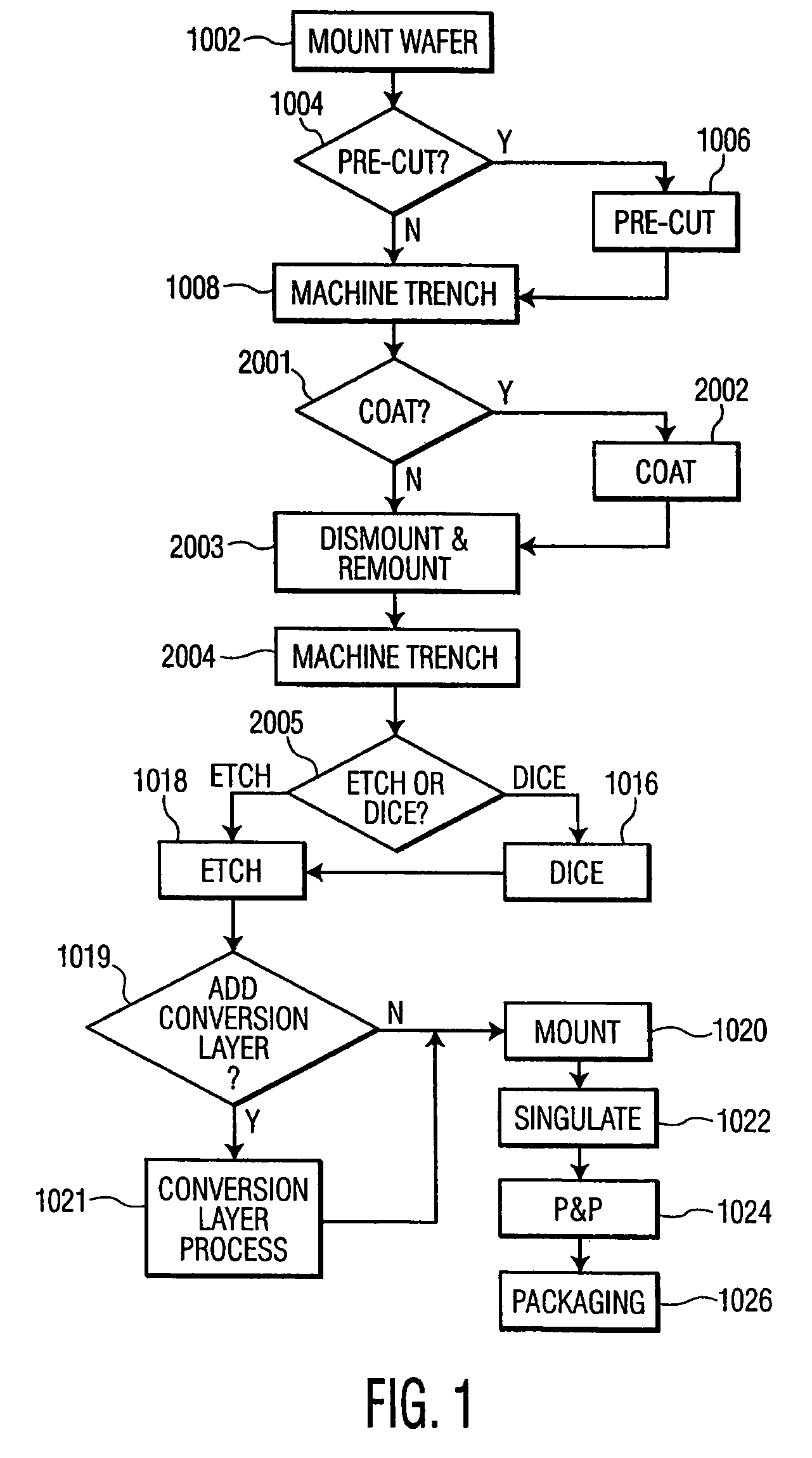

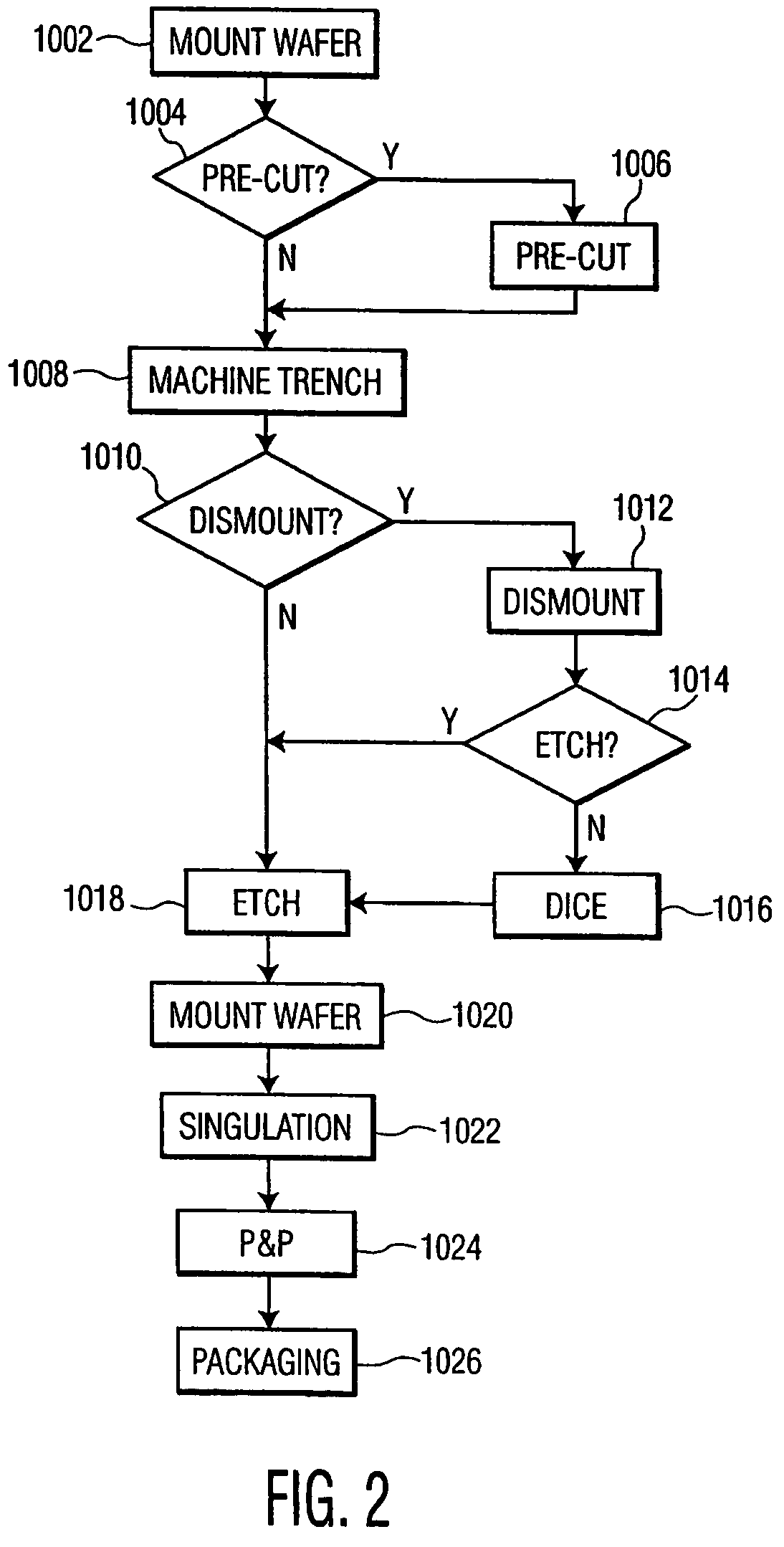

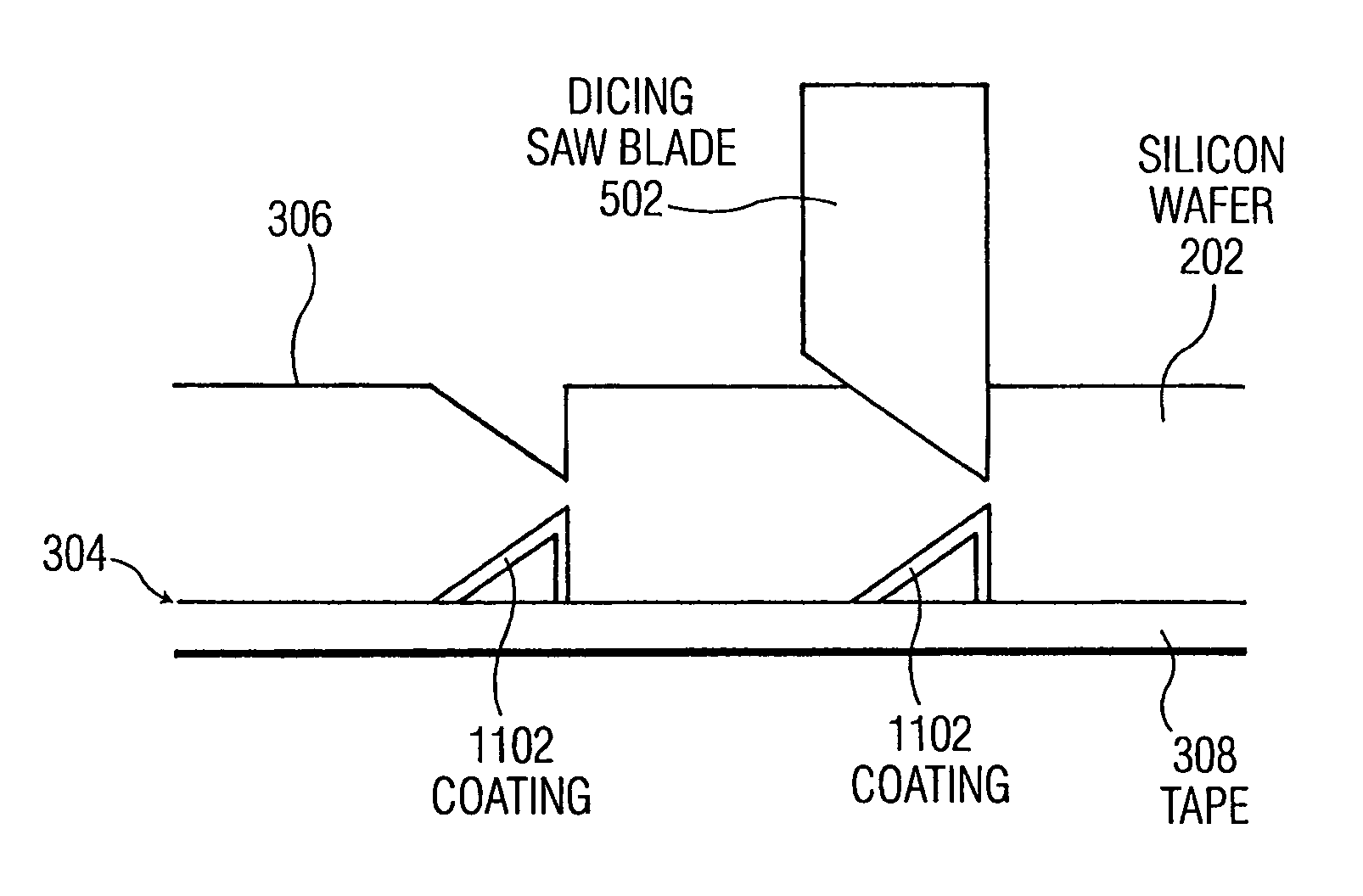

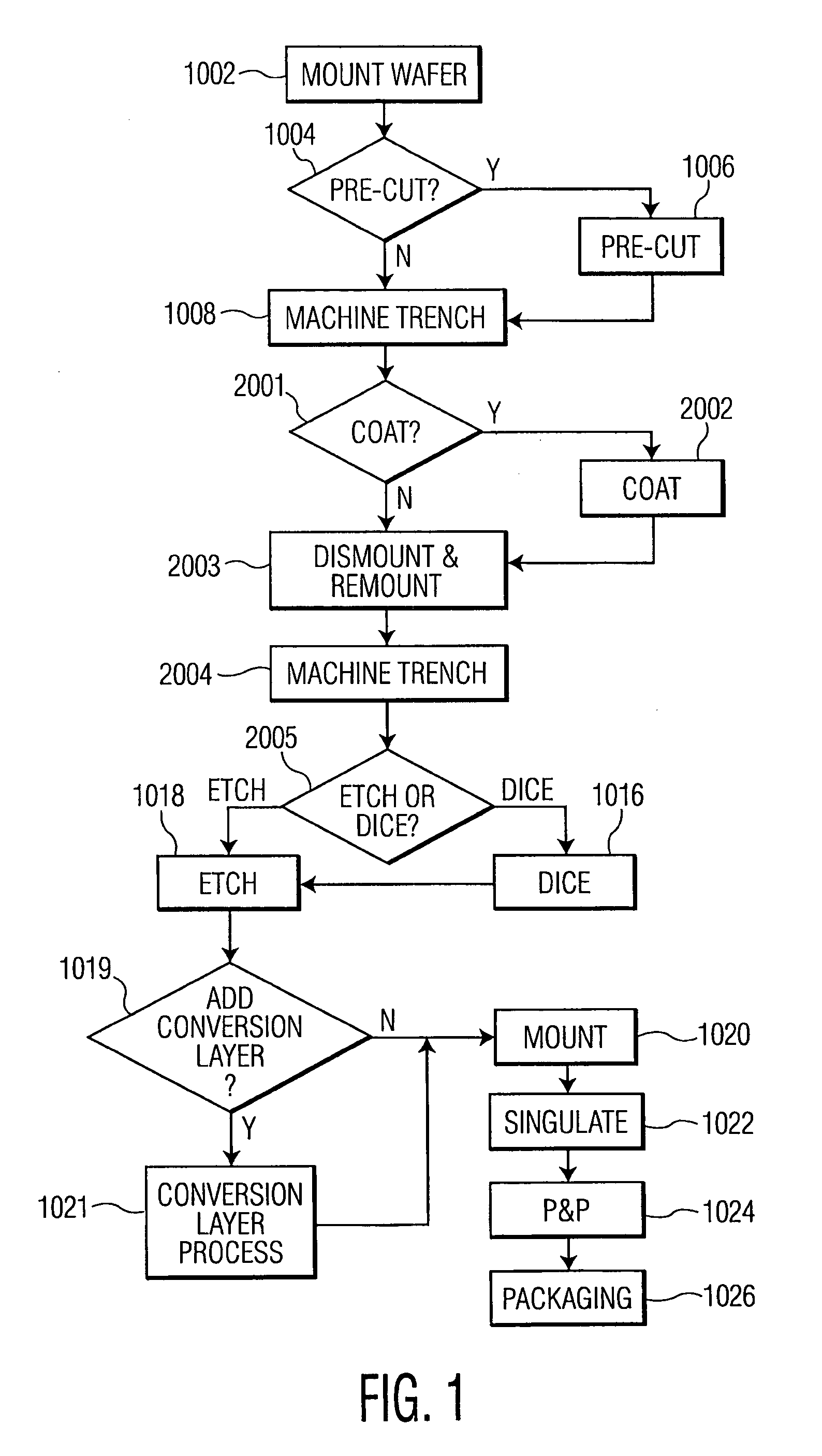

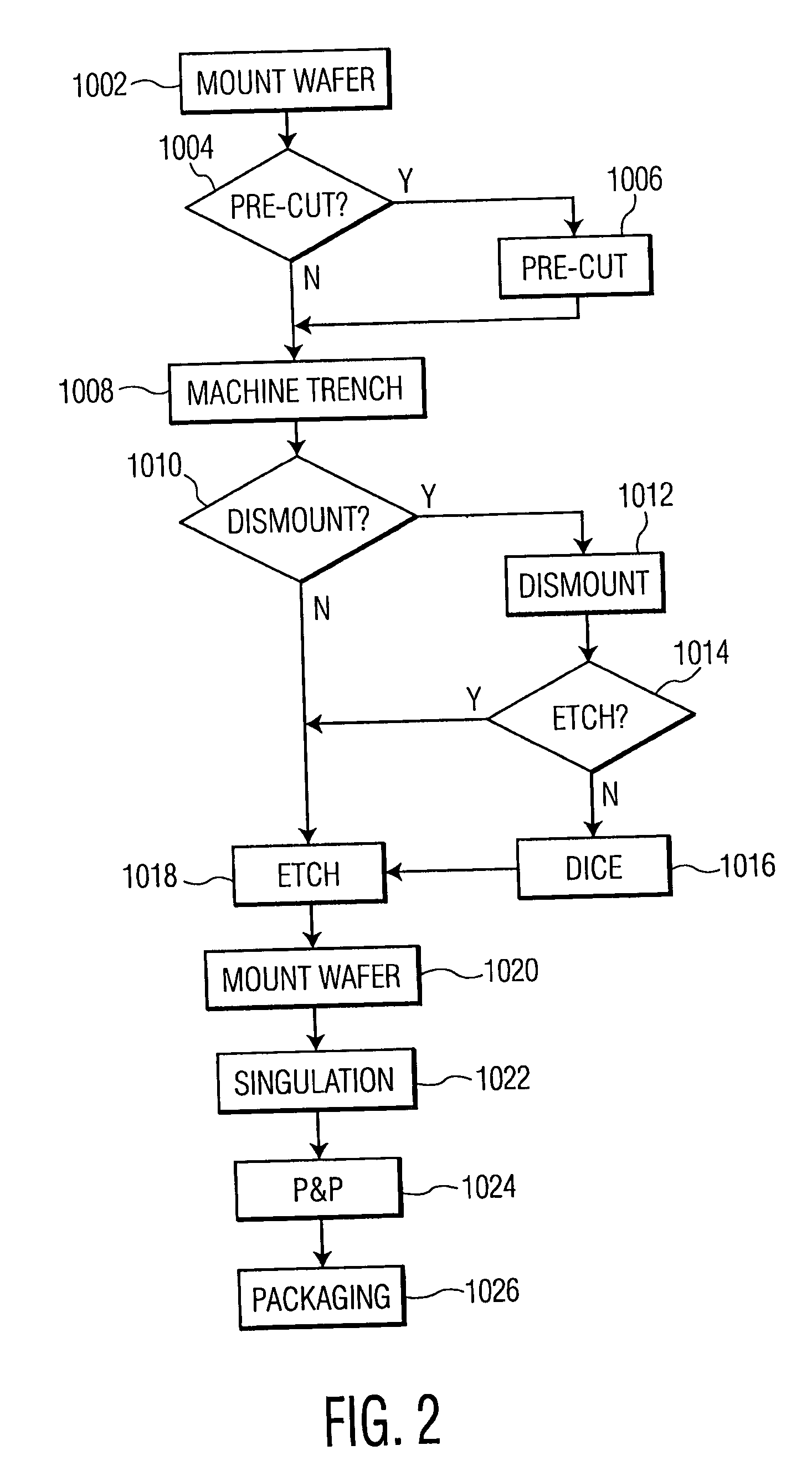

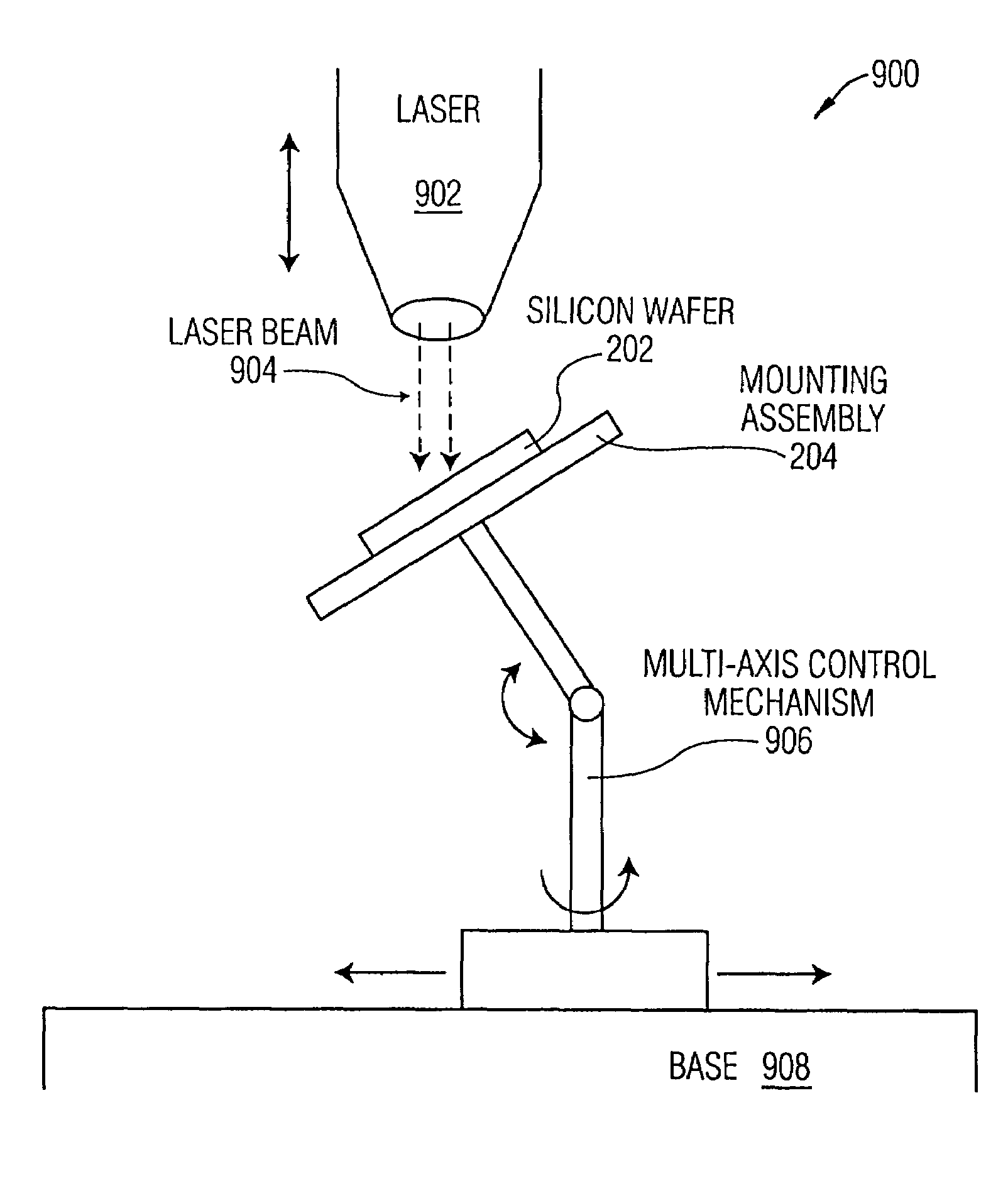

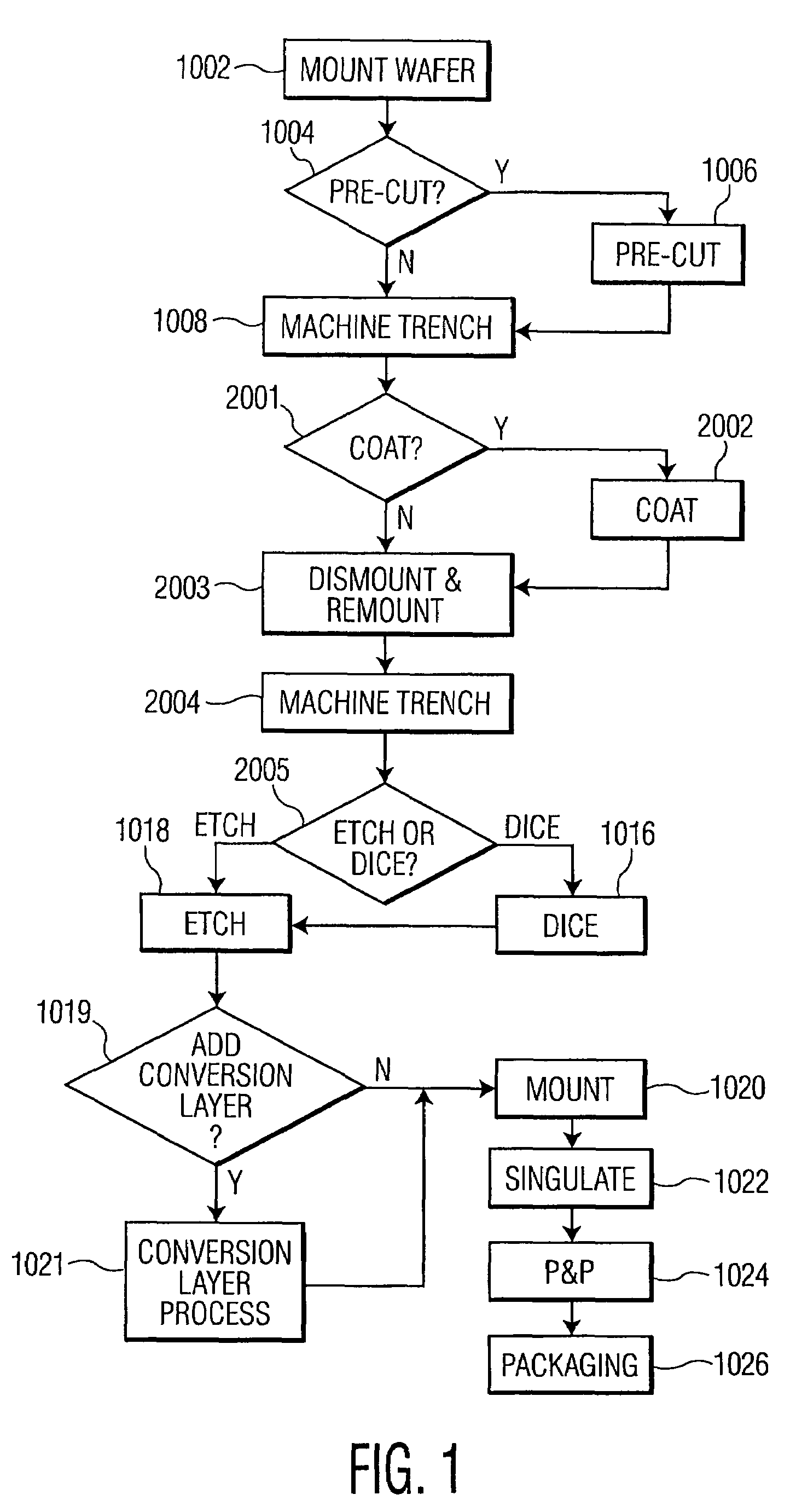

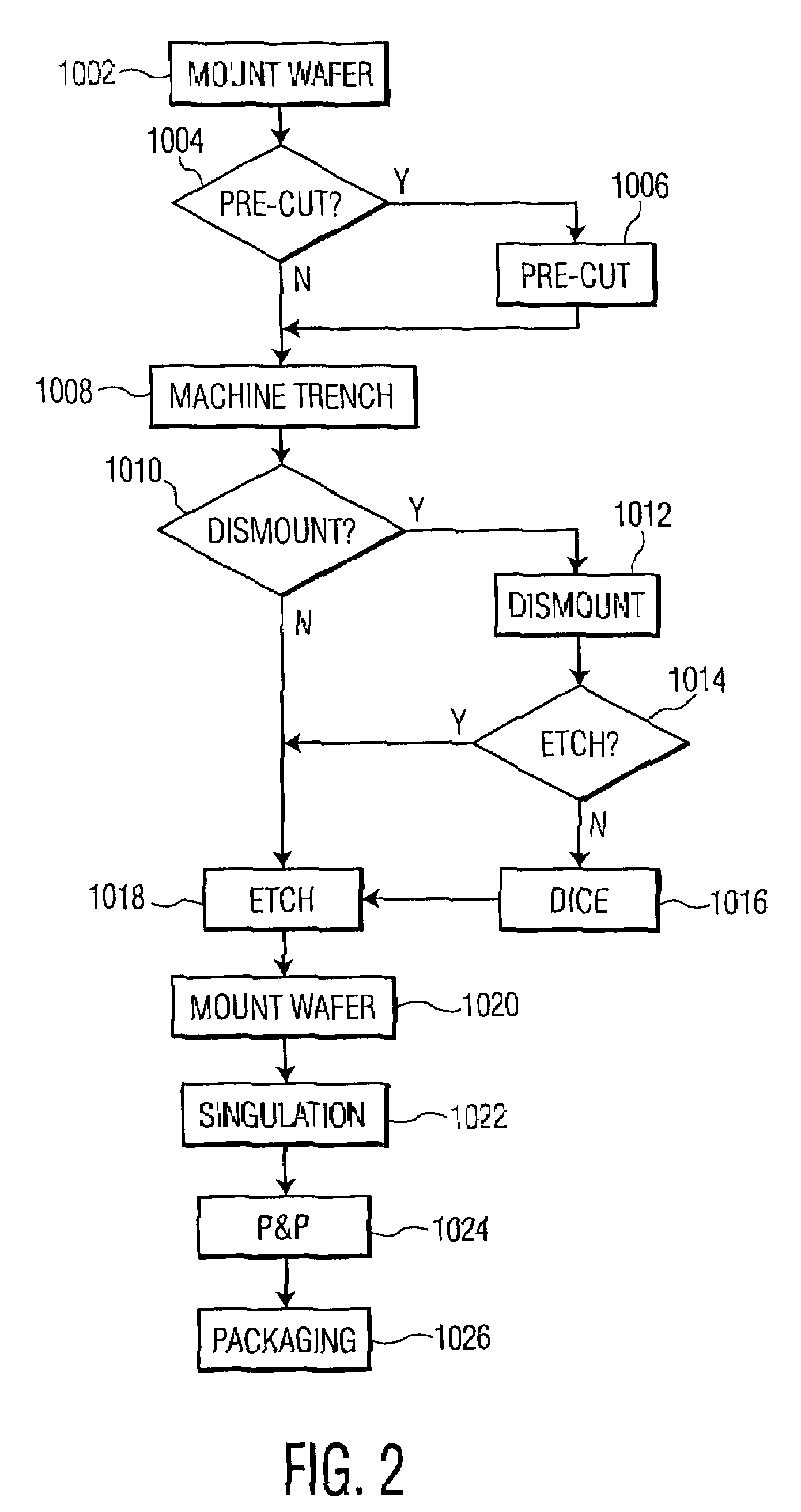

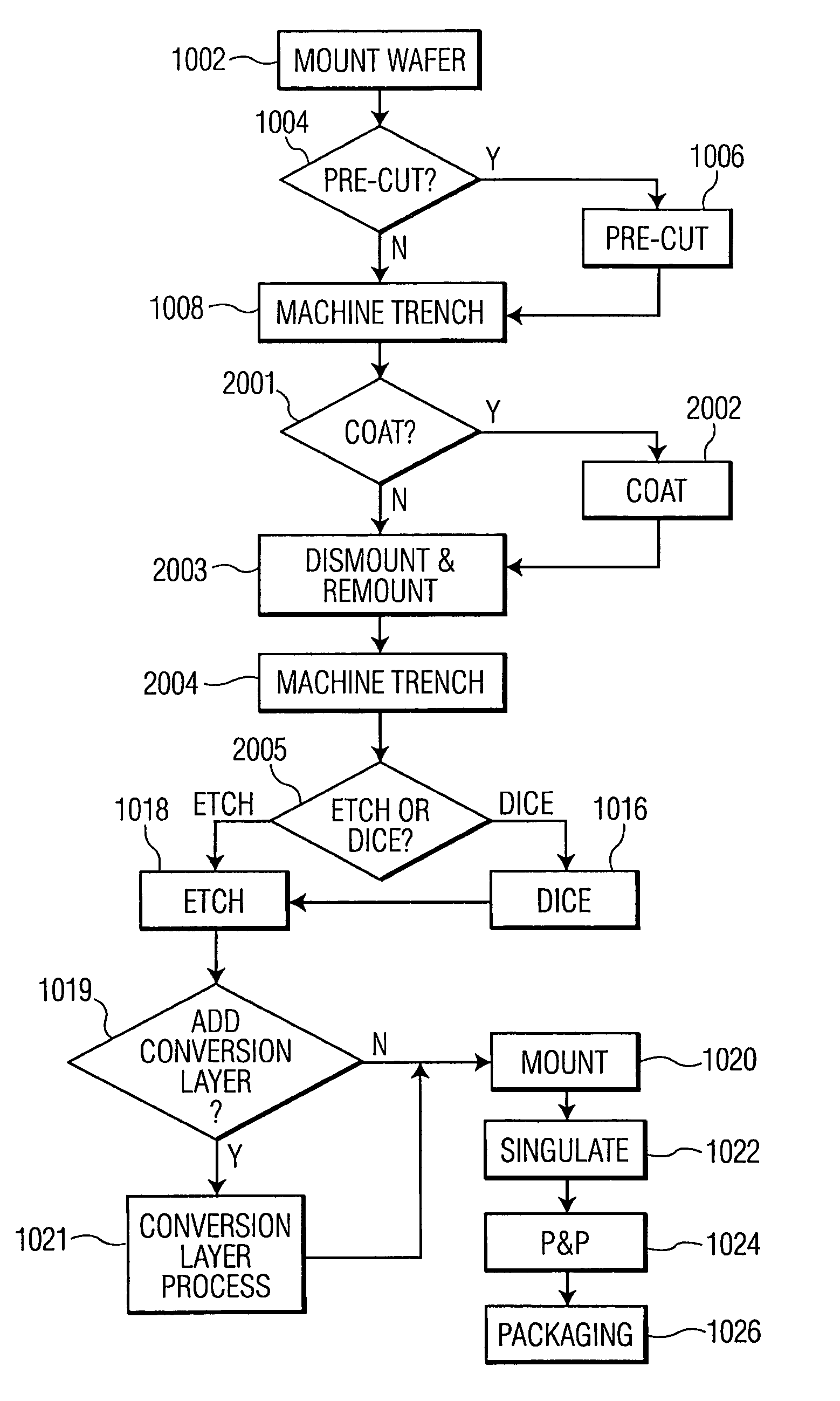

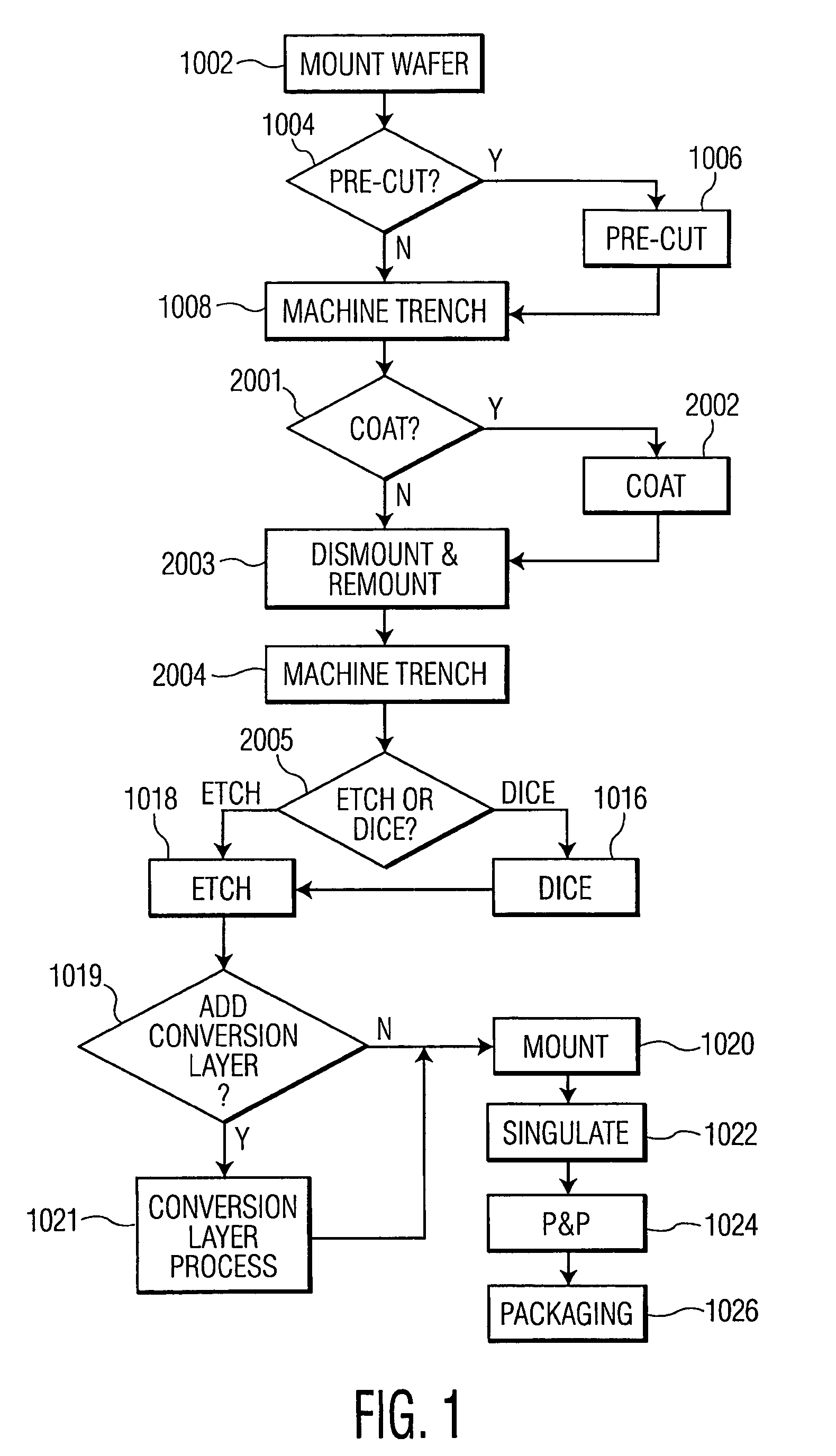

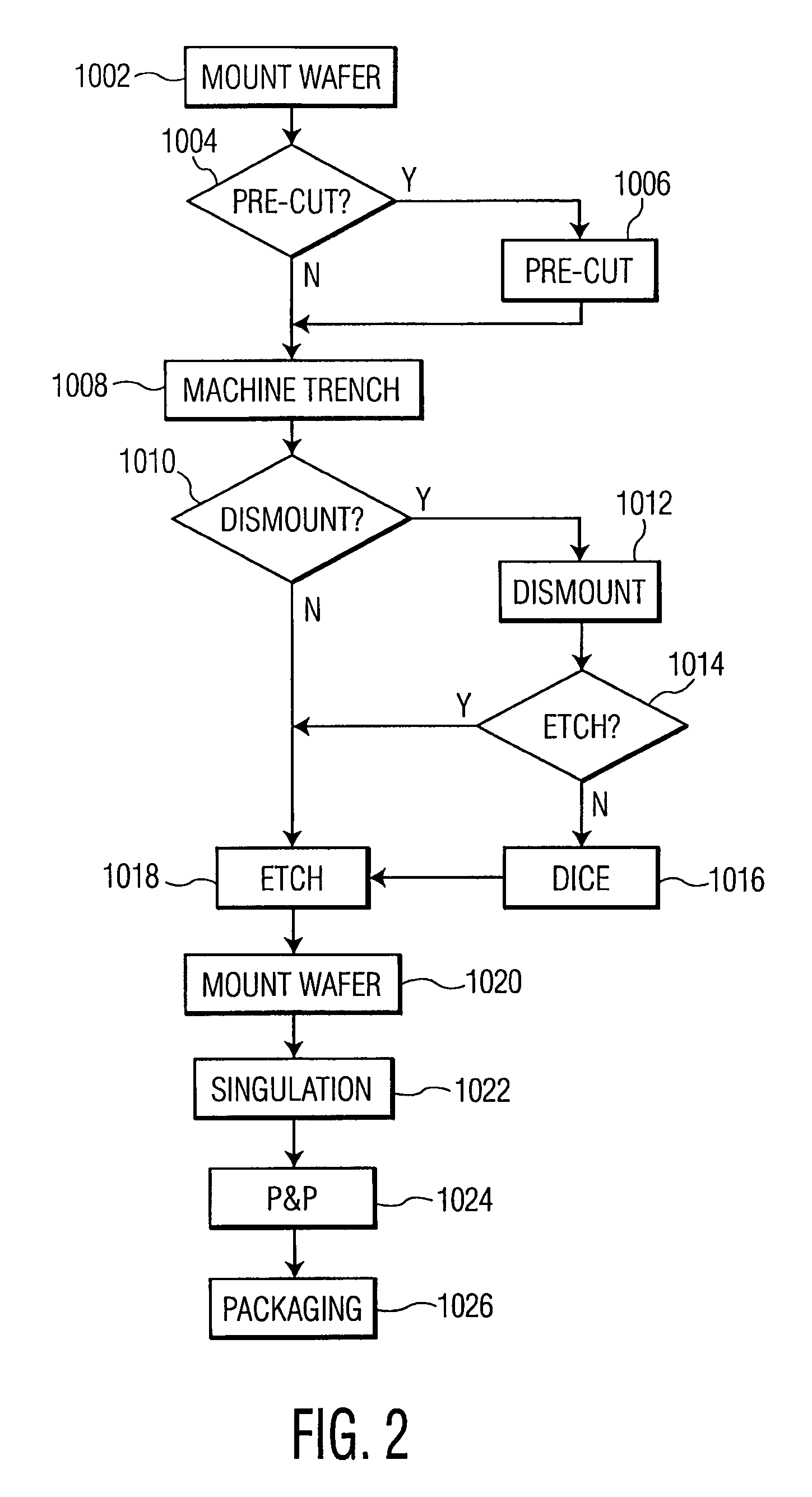

Methods of fabricating complex blade geometries from silicon wafers and strengthening blade geometries

ActiveUS20050266680A1High strengthEasy to controlIncision instrumentsDecorative surface effectsSurgical bladeEngineering

Ophthalmic surgical blades are manufactured from either a single crystal or poly-crystalline material, preferably in the form of a wafer. The method comprises preparing the single crystal or poly-crystalline wafers by mounting them and etching trenches into the wafers using one of several processes. Methods for machining the trenches, which form the bevel blade surfaces, include a diamond blade saw, laser system, ultrasonic machine, a hot forge press and a router. Other processes include wet etching (isotropic and anisotropic) and dry etching (isotropic and anisotropic, including reactive ion etching), and combinations of these etching steps. The wafers are then placed in an etchant solution which isotropically etches the wafers in a uniform manner, such that layers of crystalline or poly-crystalline material are removed uniformly, producing single, double or multiple bevel blades. Nearly any angle can be machined into the wafer, and the machined angle remains after etching. The resulting radii of the blade edges is 5-500 nm, which is the same caliber as a diamond edged blade, but manufactured at a fraction of the cost. A range of radii may be 30 to 60 nm, with a specific implementation being about 40 nm. The blade profile may have an angle of, for example, about 60°. The ophthalmic surgical blades can be used for cataract and refractive surgical procedures, as well as microsurgical, biological and non-medical, non-biological purposes. Surgical and non-surgical blades and mechanical devices manufactured as described herein can also exhibit substantially smoother surfaces than metal blades.

Owner:BEAVER VISITEC INT US

Rainscreen attachment system

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY

Method and apparatus for determining a focal position of an imaging device adapted to image a biologic sample

InactiveUS20140368631A1RobustInexpensive meanColor television detailsClosed circuit television systemsRefractive indexOptical transmittance

A method and apparatus for focusing a device for imaging a biologic sample is provided. A method aspect includes the steps of: disposing lenslets within a biologic sample, which lenslets have a height and a refractive index, which refractive index is different from that of the sample, wherein one or both of the imaging device and the sample are relatively locatable so a focal position of the imaging device can be moved along the height of the lenslets; imaging a portion of the sample including lenslets using transmittance at one or more wavelengths; determining an average light transmittance intensity of the sample at the wavelengths; determining an average light transmittance intensity of a region of each lenslet at the wavelengths; and determining the focal position of the imaging device using the average light transmittance intensity of the sample and the average light transmittance intensity of the region of the lenslets.

Owner:ABBOTT POINT CARE

Oil spill recovery method using surface-treated iron powder

ActiveUS7303679B2Great potentialDecrease in flowabilityFerroso-ferric oxidesSedimentation separationRecovery methodIron powder

A method of recovering spilled hydrocarbon fluids from a body of water utilizing the increased oleophilic properties of reacted iron particles suspended in a magnetorheological (MR) fluid. The iron particles normally used to create MR fluids, are reacted with an organic compound containing an oleophilic chain end which attaches to the surface of the iron, prior to suspension in a liquid vehicle such as an organic oil. The reacted iron particles in the MR fluid are then applied to and mixed with a hydrocarbon spill on a body of water such as an oil spill, whereby subsequent exposure to a significant magnetic field provides for subsequent recovery of both the reacted magnetic particles and the hydrocarbon spill.

Owner:GM GLOBAL TECH OPERATIONS LLC

Oil spill recovery method using surface-treated iron powder

ActiveUS20050139550A1Great potentialDecrease in flowabilityFerroso-ferric oxidesSedimentation separationRecovery methodSimple Organic Compounds

A method of recovering spilled hydrocarbon fluids from a body of water utilizing the increased oleophilic properties of reacted iron particles suspended in a magnetorheological (MR) fluid. The iron particles normally used to create MR fluids, are reacted with an organic compound containing an oleophilic chain end which attaches to the surface of the iron, prior to suspension in a liquid vehicle such as an organic oil. The reacted iron particles in the MR fluid are then applied to and mixed with a hydrocarbon spill on a body of water such as an oil spill, whereby subsequent exposure to a significant magnetic field provides for subsequent recovery of both the reacted magnetic particles and the hydrocarbon spill.

Owner:GM GLOBAL TECH OPERATIONS LLC

Methods of fabricating complex blade geometries from silicon wafers and strengthening blade geometries

ActiveUS7396484B2Quality improvementUniform radiusIncision instrumentsDecorative surface effectsSurgical bladeSingle crystal

Ophthalmic surgical blades are manufactured from either a single crystal or poly-crystalline material, preferably in the form of a wafer. The method comprises preparing the single crystal or poly-crystalline wafers by mounting them and etching trenches into the wafers using one of several processes. Methods for machining the trenches, which form the bevel blade surfaces, include a diamond blade saw, laser system, ultrasonic machine, a hot forge press and a router. Other processes include wet etching (isotropic and anisotropic) and dry etching (isotropic and anisotropic, including reactive ion etching), and combinations of these etching steps. The wafers are then placed in an etchant solution which isotropically etches the wafers in a uniform manner, such that layers of crystalline or poly-crystalline material are removed uniformly, producing single, double or multiple bevel blades. Nearly any angle can be machined into the wafer, and the machined angle remains after etching. The resulting radii of the blade edges is 5-500 nm, which is the same caliber as a diamond edged blade, but manufactured at a fraction of the cost. A range of radii may be 30 to 60 nm, with a specific implementation being about 40 nm. The blade profile may have an angle of, for example, about 60°. The ophthalmic surgical blades can be used for cataract and refractive surgical procedures, as well as microsurgical, biological and non-medical, non-biological purposes. Surgical and non-surgical blades and mechanical devices manufactured as described herein can also exhibit substantially smoother surfaces than metal blades.

Owner:BEAVER VISITEC INT US

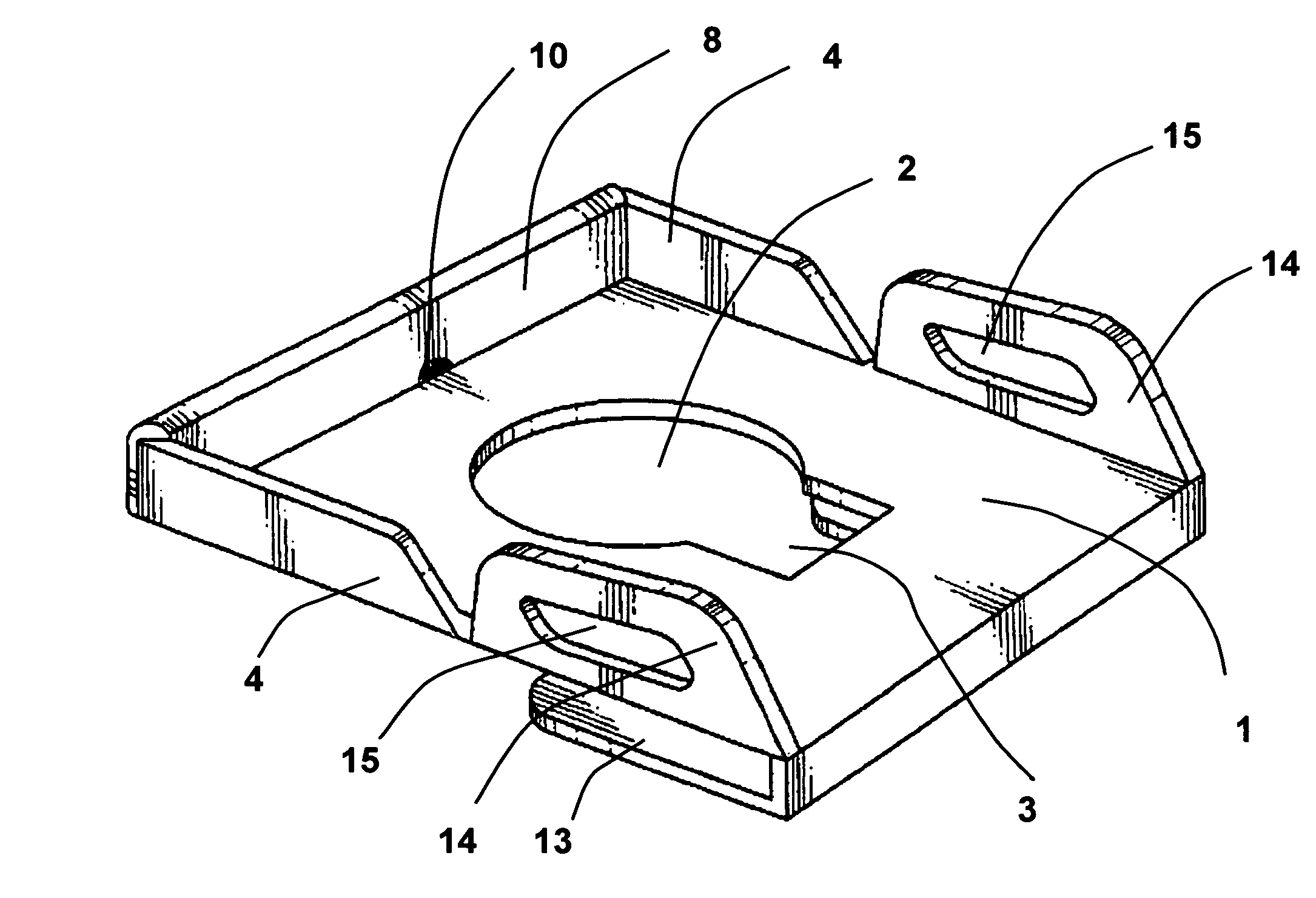

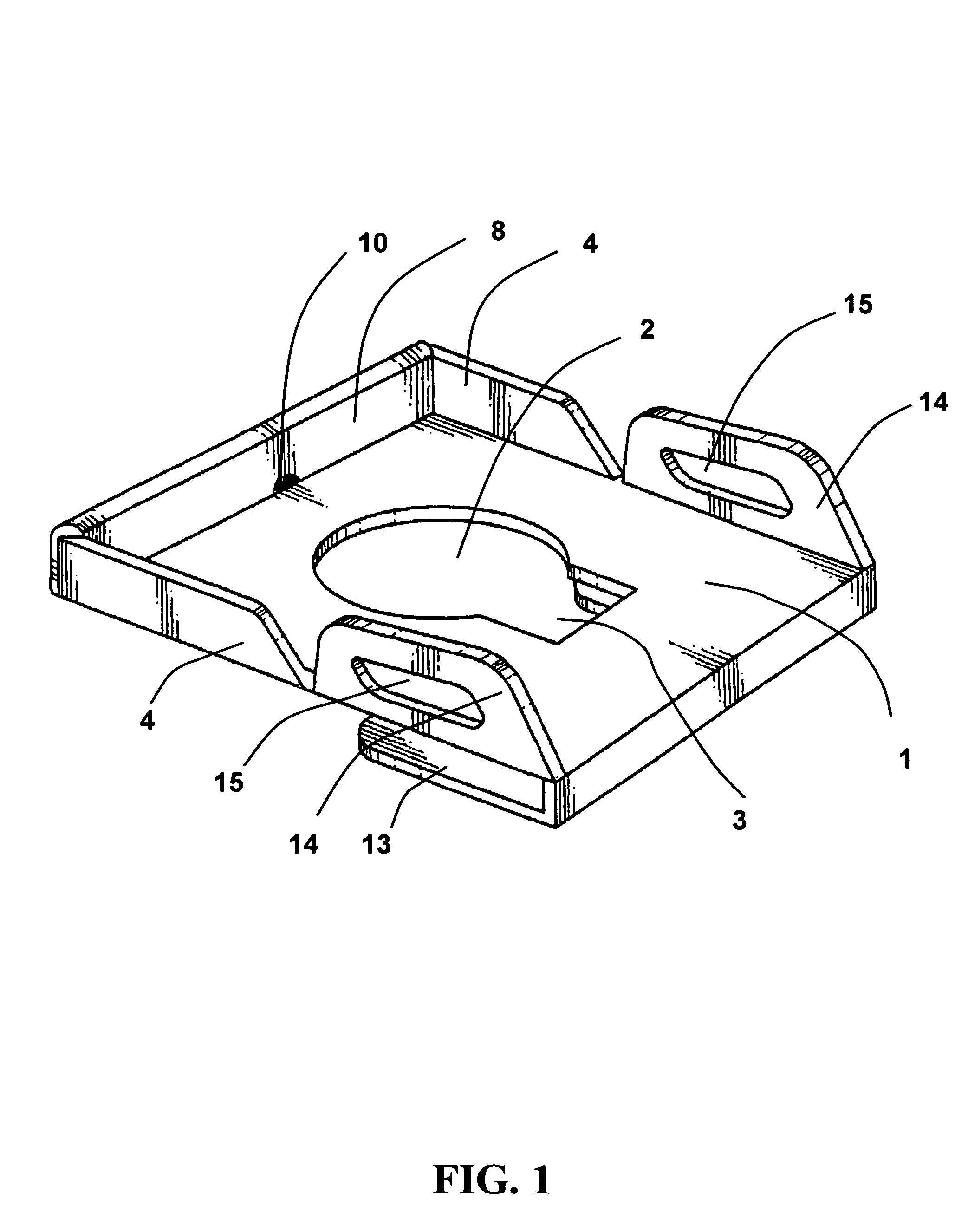

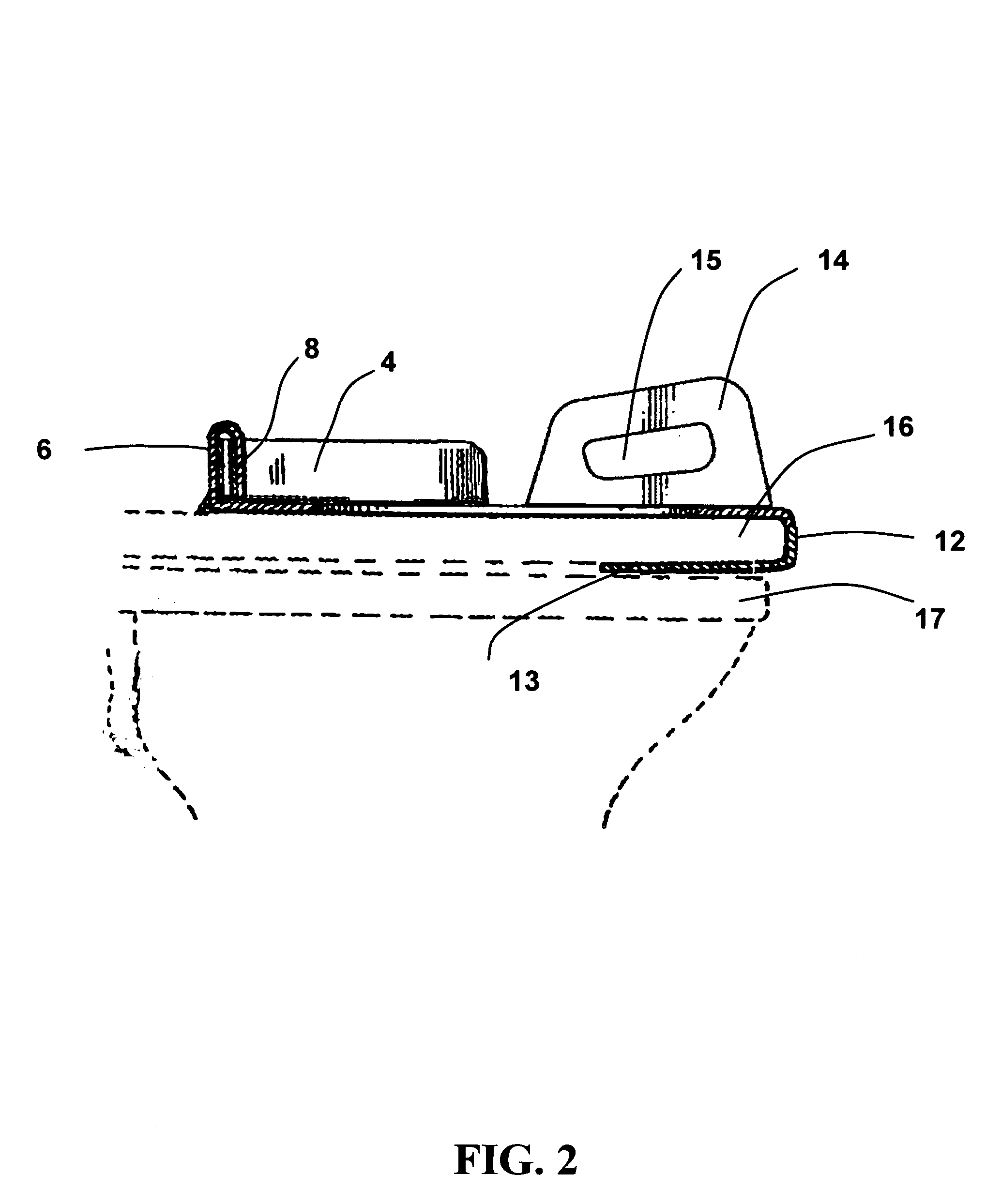

Child's disposable toilet seat adaptor with side handles and fold-under flap

A barrier comprised of a single sheet of inexpensive, disposable and foldable material, sufficient in width to rest upon the full-size toilet seat, with a central cutout sized and positioned so as to provide a smaller toilet seating surface to accommodate the buttocks of a toddler, and which is capable of supporting a child's weight as a result of such material's natural firmness and folds along the distal edge, comprises a disposable toilet seat cover / adapter. Key innovative features include side handles and a fold-under flap to secure the toilet seat in place.

Owner:BERNSLEY MARK

Silicon blades for surgical and non-surgical use

ActiveUS20050188548A1Quality improvementUniform radiusIncision instrumentsEye surgerySurgical bladeRefractive surgery

Ophthalmic surgical blades are manufactured from either a crystalline or polycrystalline material, preferably in the form of a wafer. The method comprises preparing the crystalline or polycrystalline wafers by mounting them and machining trenches into the wafers. Methods for machining the trenches, which form the bevel blade surfaces, include a diamond blade saw, laser system, ultrasonic machine, a hot forge press and a router. The wafers are then placed in an etchant solution which isotropically etches the wafers in a uniform manner, such that layers of crystalline or polycrystalline material are removed uniformly, producing single, double or multiple bevel blades. Nearly any bevel angle can be machined into the wafer which remains after etching. The resulting radii of the blade edges is 5-500 nm, which is the same caliber as a diamond edged blade, but manufactured at a fraction of the cost. The ophthalmic surgical blades can be used for cataract and refractive surgical procedures, as well as microsurgical, biological and non-medical, non-biological purposes.

Owner:BEAVER VISITEC INT US

Method and apparatus for determining a focal position of an imaging device adapted to image a biologic sample

InactiveUS20090237665A1RobustInexpensive meanTransmissivity measurementsMicroscopesRefractive indexOptical transmittance

A method and apparatus for focusing a device for imaging a biologic sample is provided. A method aspect of the disclosure includes the steps of: 1) disposing lenslets within a field of a biologic sample, which lenslets have a height, and have a refractive index and which refractive index is different from that of the sample, wherein one or both of the imaging device and the sample are relatively locatable so a focal position of the imaging device can be moved along the height of the lenslets; 2) imaging at least a portion of the sample including a plurality of lenslets using transmittance at one or more predetermined wavelengths; 3) determining an average light transmittance intensity of the sample at the wavelengths; 4) determining an average light transmittance intensity of a region of each lenslet at the wavelengths; and 5) determining the focal position of the imaging device using the average light transmittance intensity of the sample and the average light transmittance intensity of the region of the lenslets.

Owner:ABBOTT POINT CARE

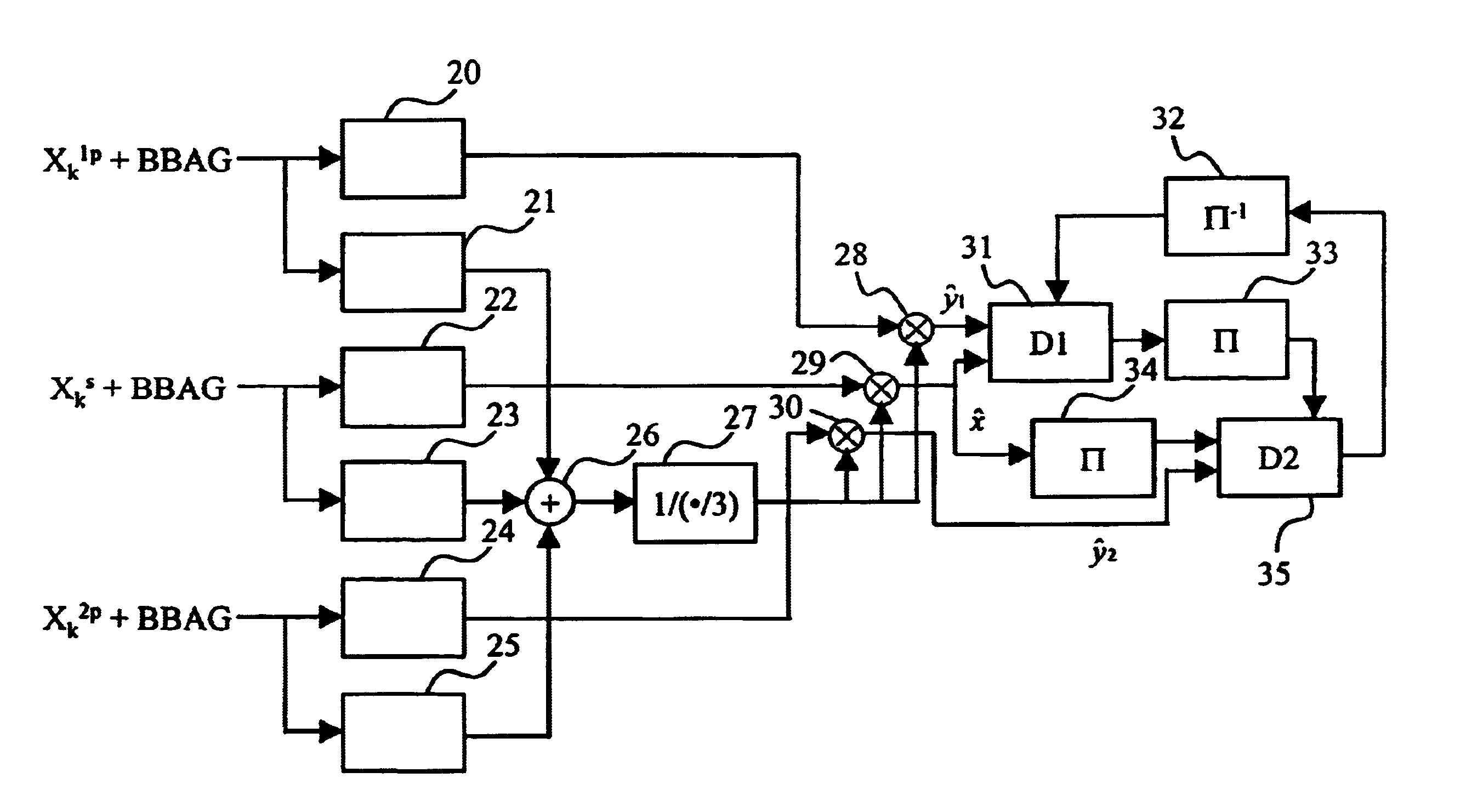

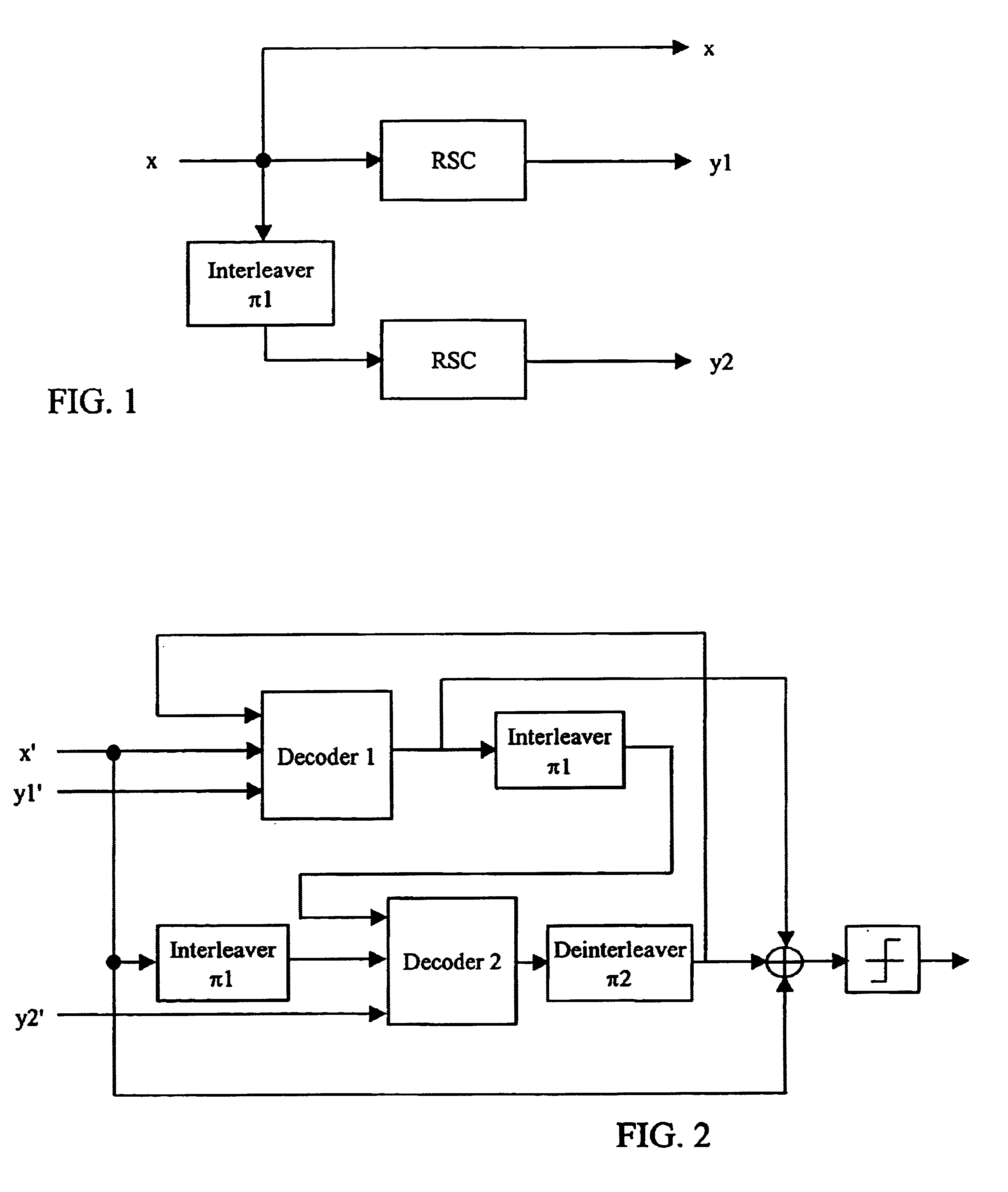

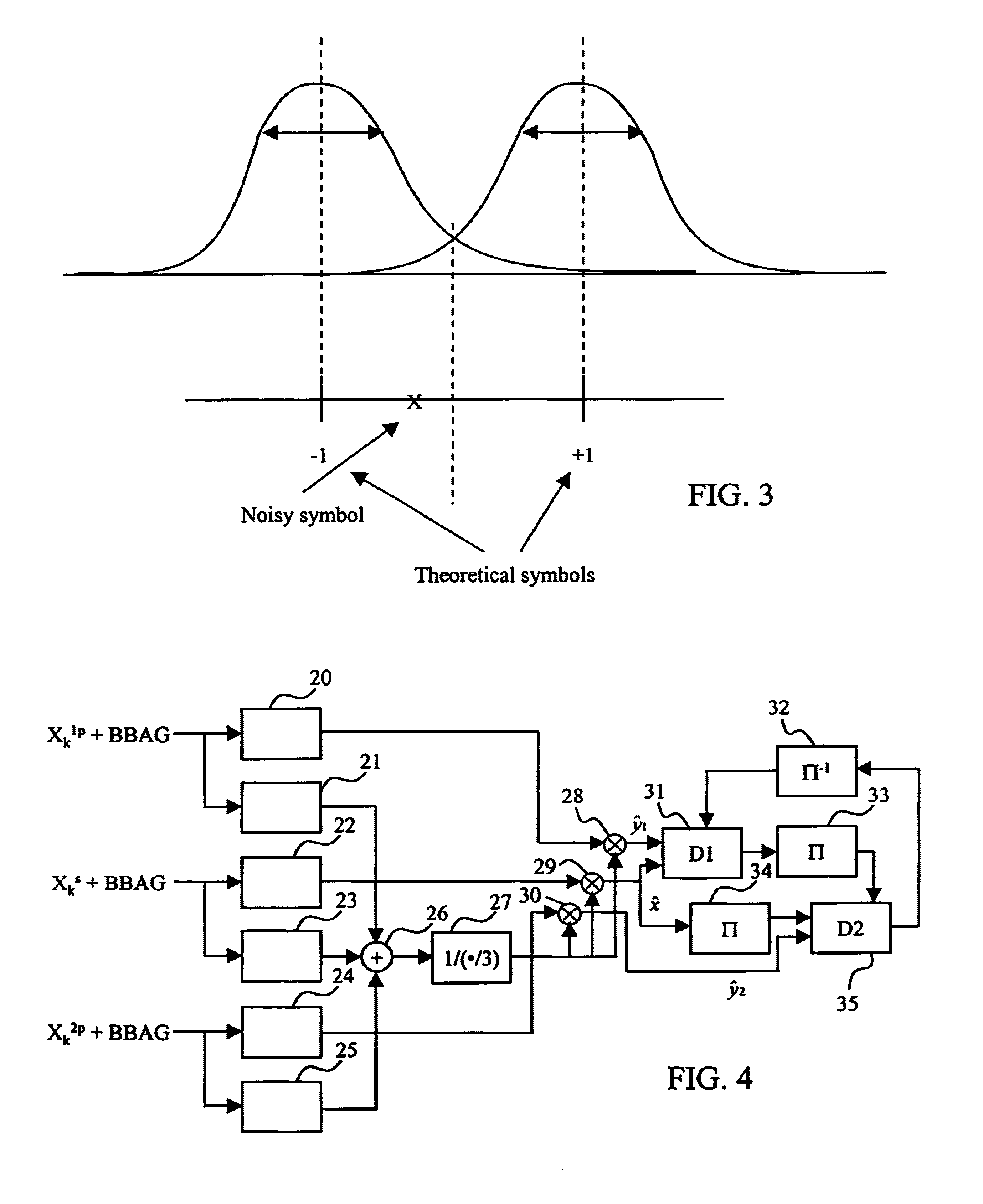

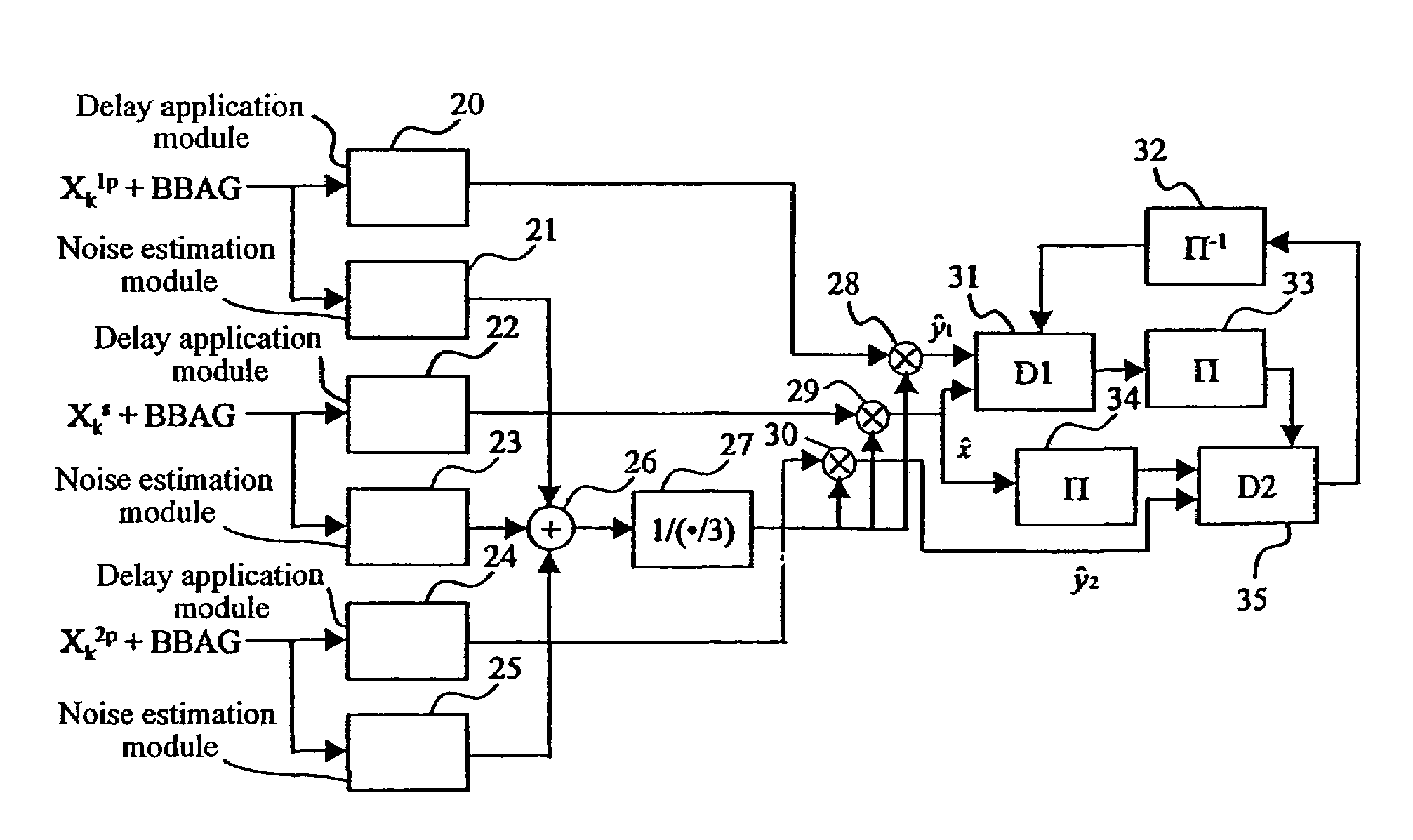

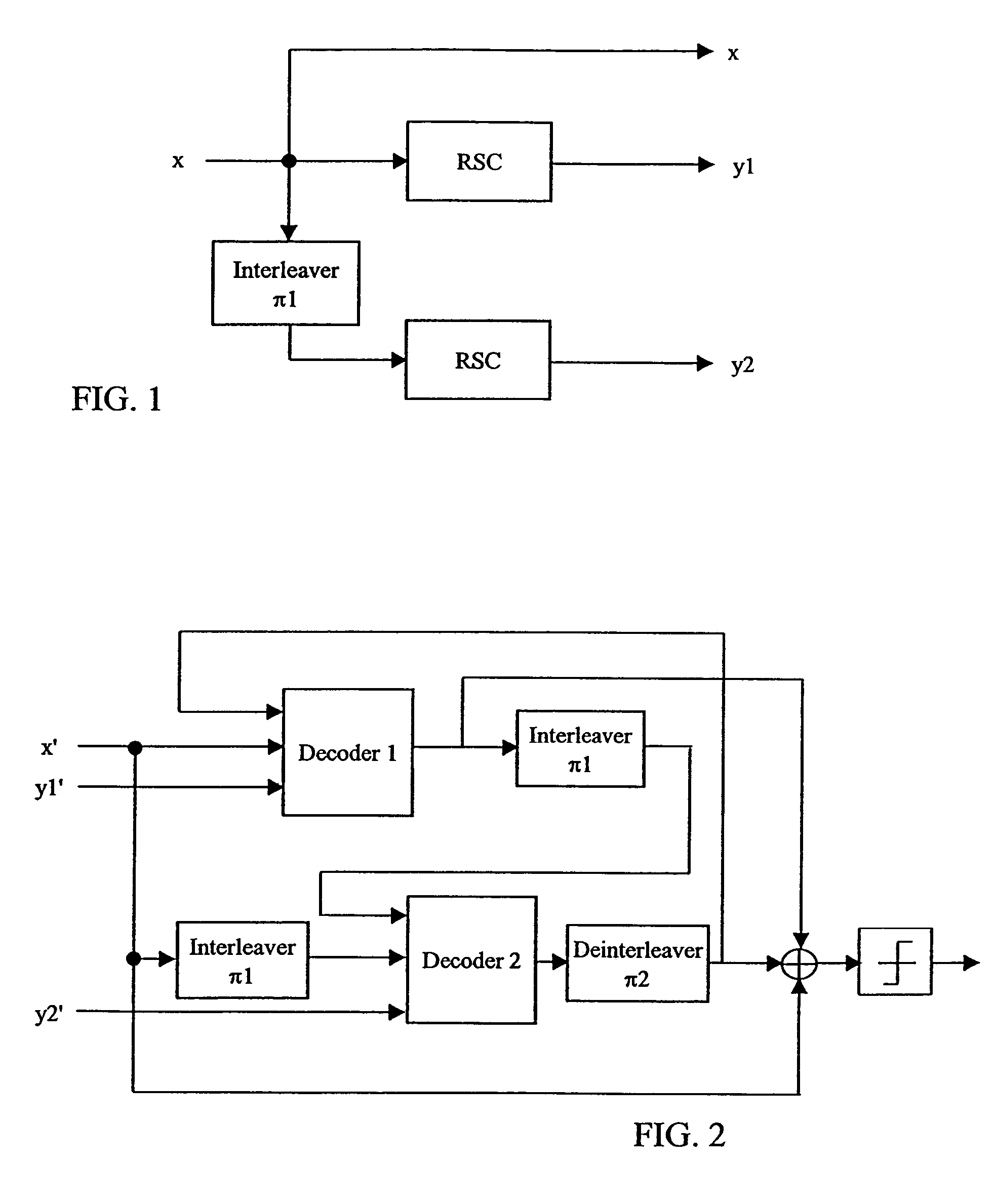

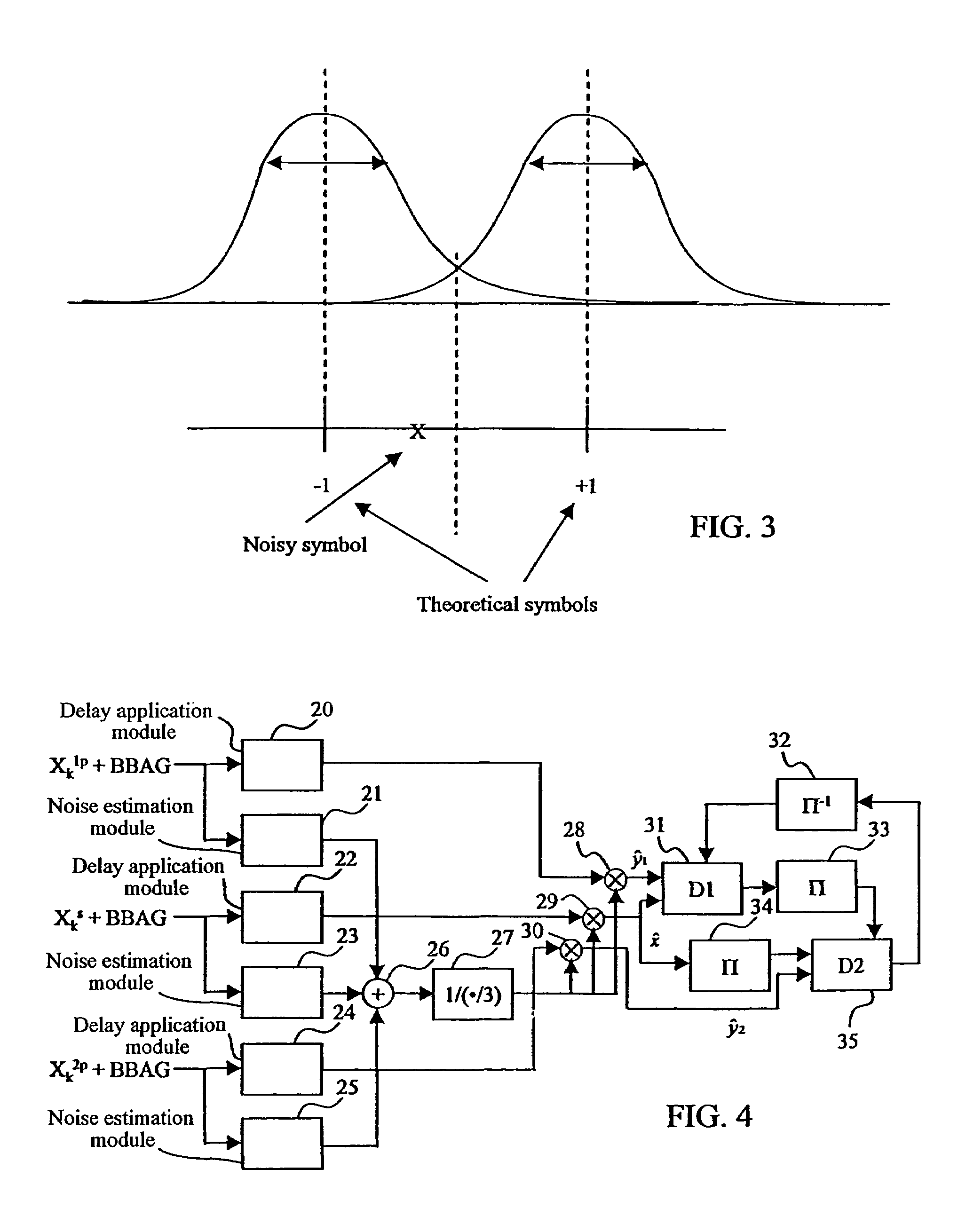

Method and device for evaluating the noise associated with turbocodes, and systems using them

InactiveUS6898251B2Improve decoding performanceEasy to implementData representation error detection/correctionPicture reproducers using cathode ray tubesTurbo encoderNoise estimation

In order to evaluate the noise related to data issuing from a turbo-encoder, estimates of the noise related to its systematic output, to the data issuing from its first elementary encoder, and to the data issuing from its second elementary encoder are determined. At least two of the estimates of the noise related to the systematic output, to the data issuing from the first encoder, and to the data issuing from the second encoder, are added. The results of these additions are divided by the number of augends added, and then inverted, so as to obtain a noise factor, and the noise factor is multiplied with the data issuing from at least one of the first encoder, second encoder, and systematic output.

Owner:CANON KK

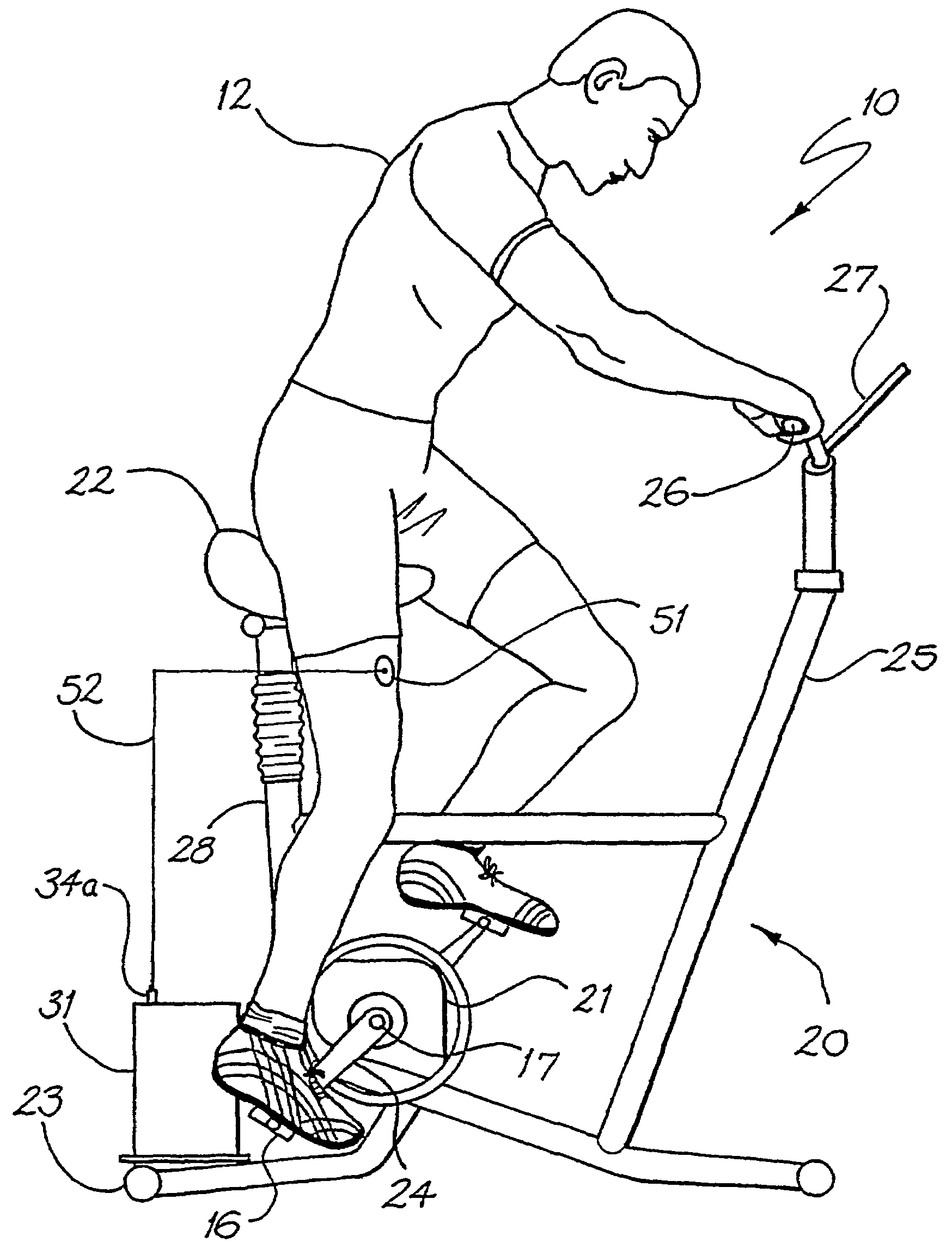

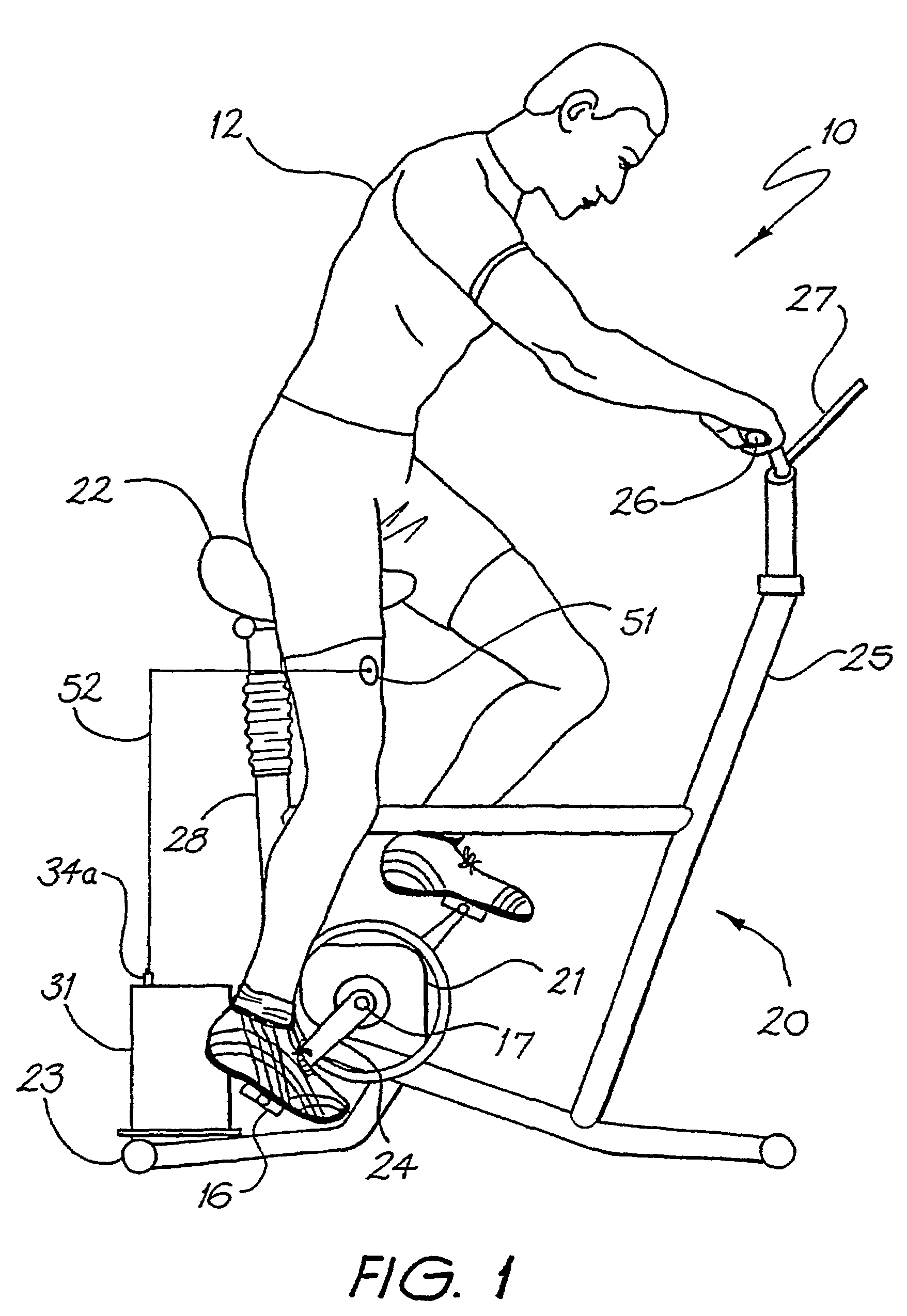

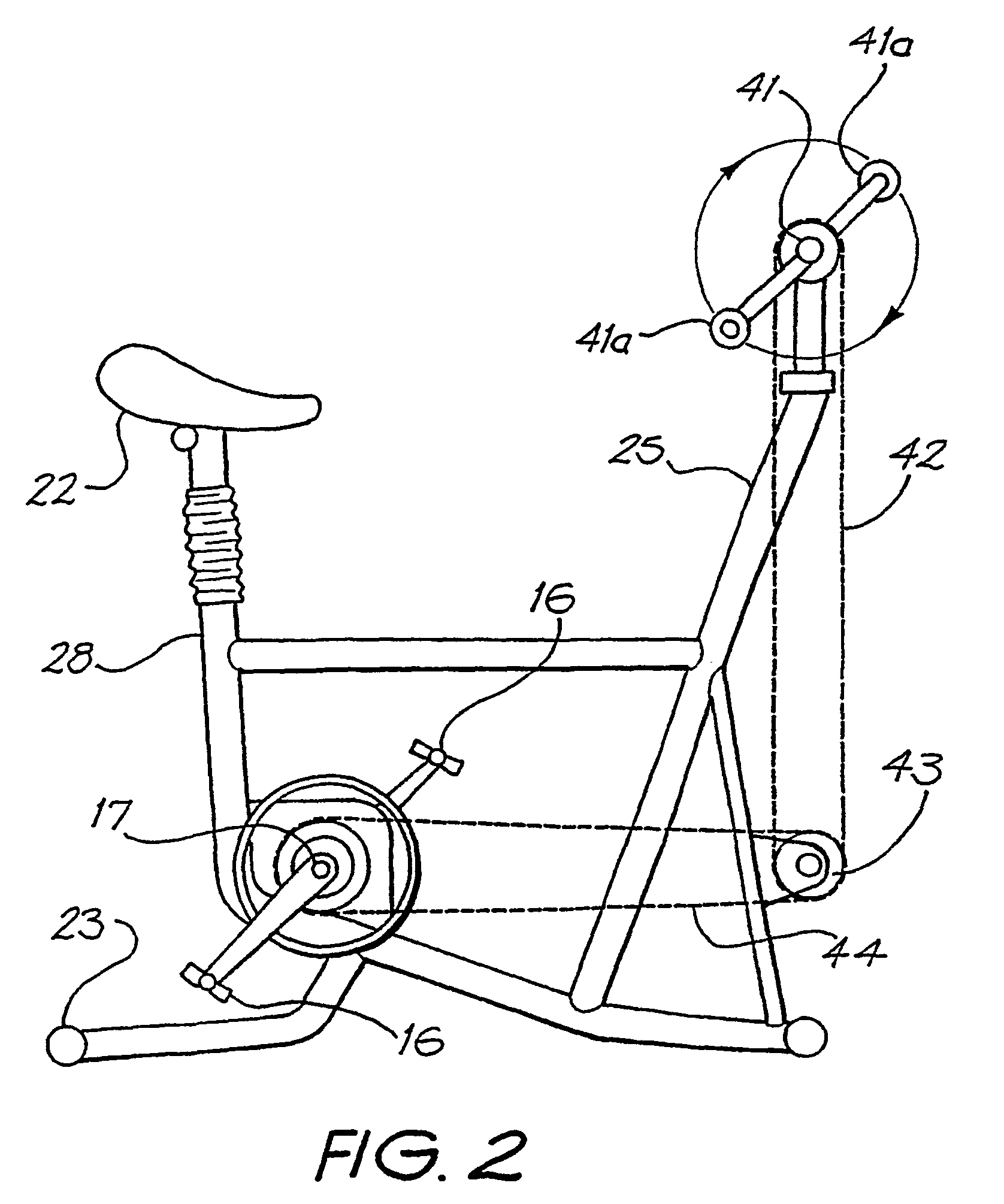

Exercise apparatus for a person with muscular deficiency

InactiveUS7497806B2High strengthSuitable for operationClubsElectrotherapyPhysical medicine and rehabilitationControl signal

Owner:NEOPRAXIS

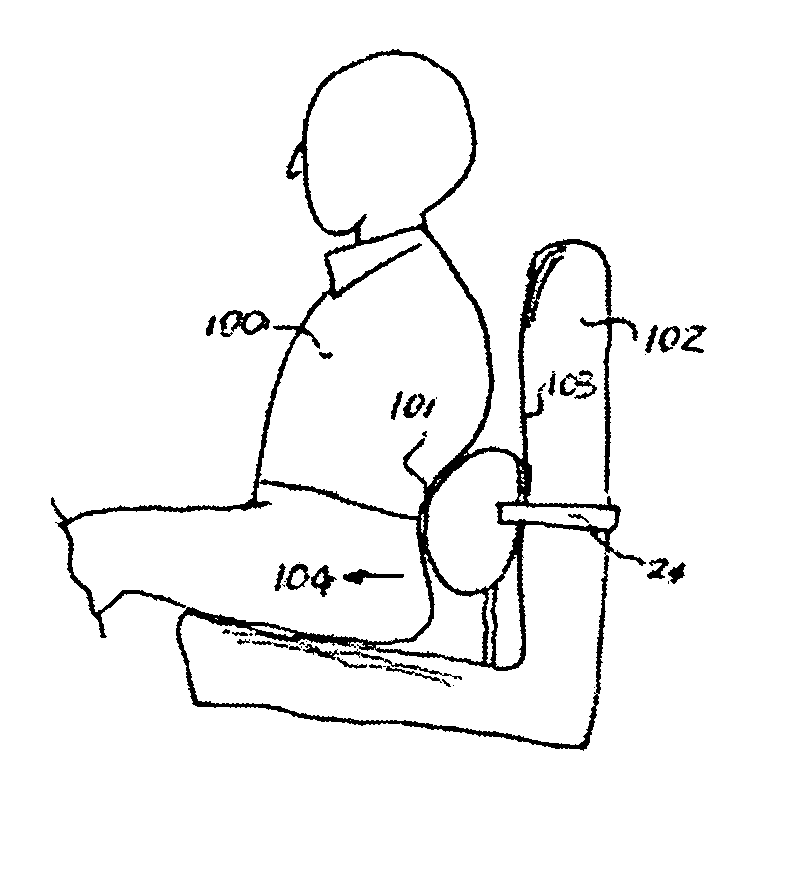

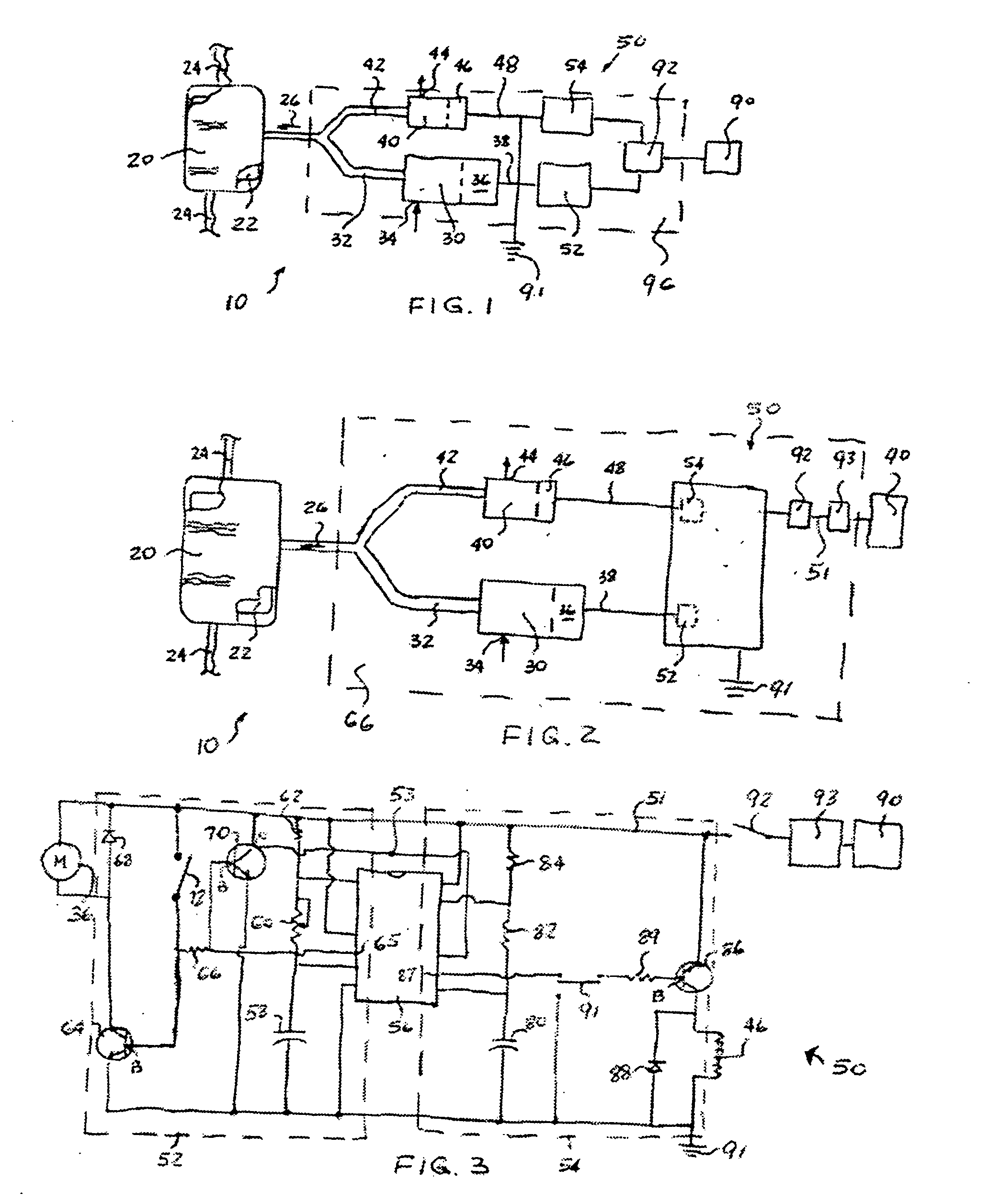

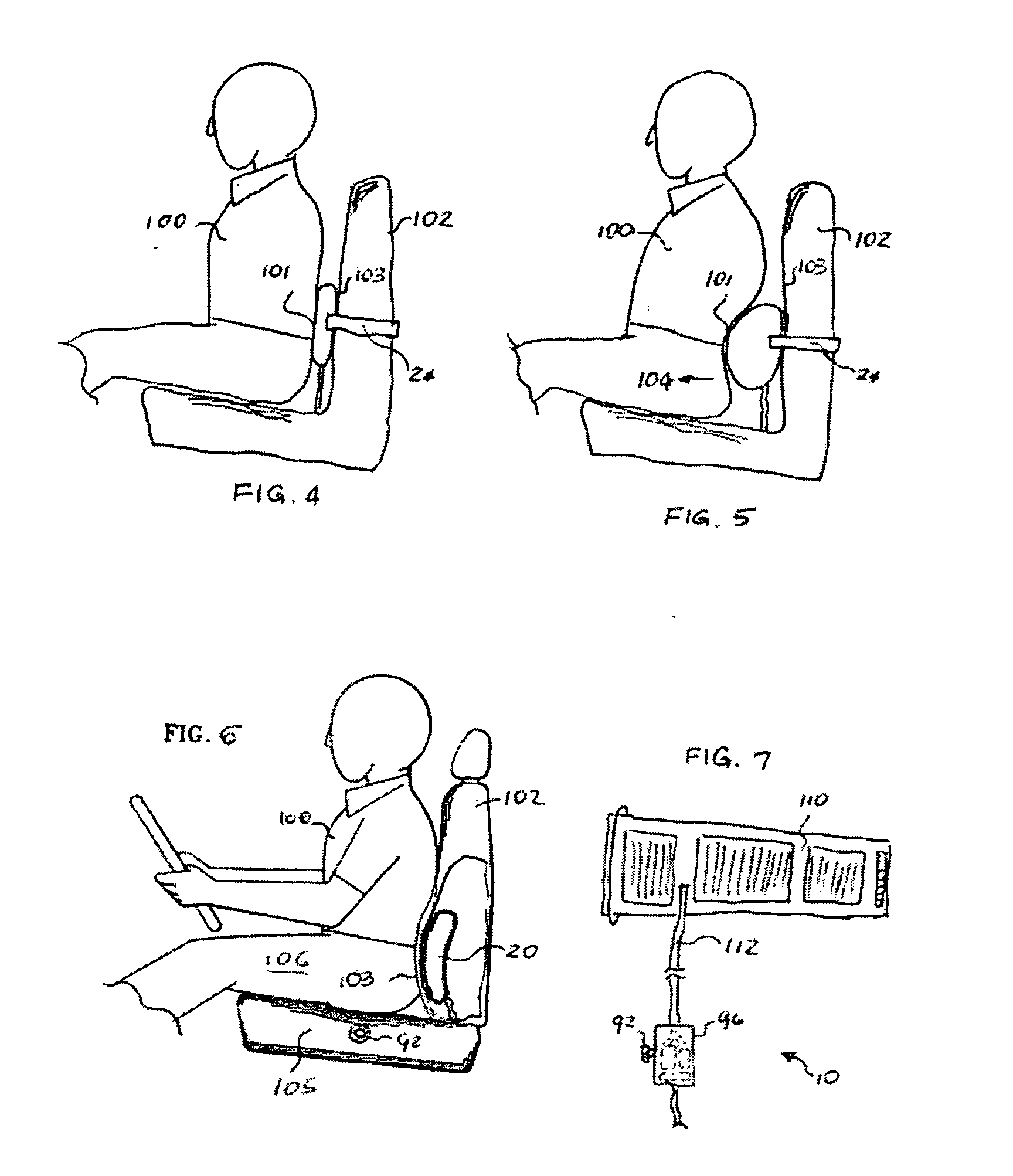

Passive exercise apparatus

InactiveUS20050137506A1Promote sportsPromote blood circulationClubsBack restsCapacitanceSolenoid valve

Apparatus for passively exercising at least a portion of a human body includes an inflatable bag which exerts a force during inflation, an electrical air pump disposed in fluid communication with the bag for supplying an atmospheric air medium to inflate the bag, a solenoid valve disposed in fluid communication with the inflatable bag for discharging the atmospheric air medium to deflate the bag and a timing control circuit coupled to the pump and to the solenoid valve for cyclically inflating and deflating the bag. The control circuit includes a dual integrated circuit timer operable with an external resistor-capacitor timer control to provide such cyclical inflation and deflation of the bag. The duration of the cycle is adjusted with a variable resistor coupled to the dual timer. The apparatus can be integrated into a seat or an article of furniture.

Owner:CHOW LOYAL

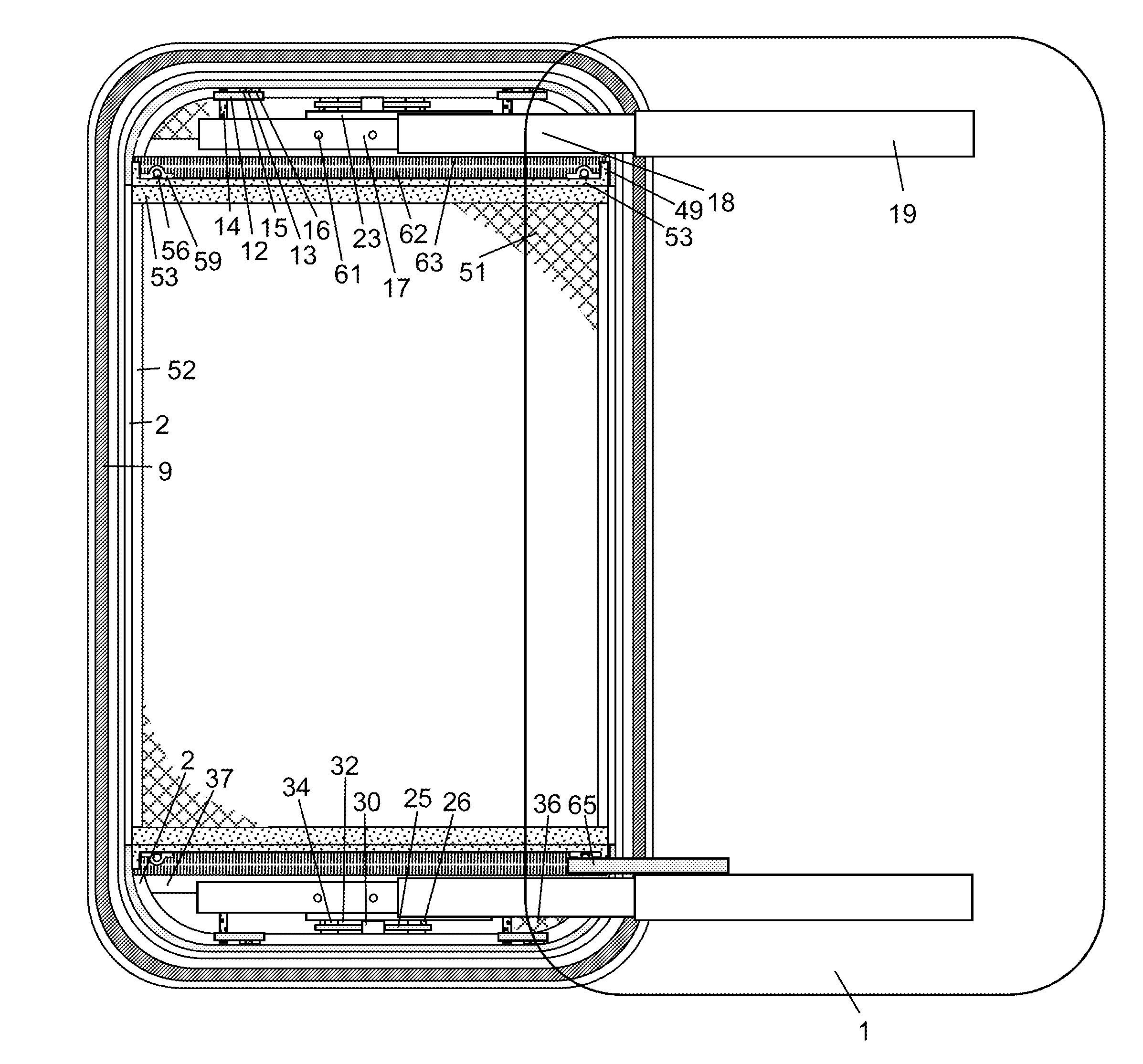

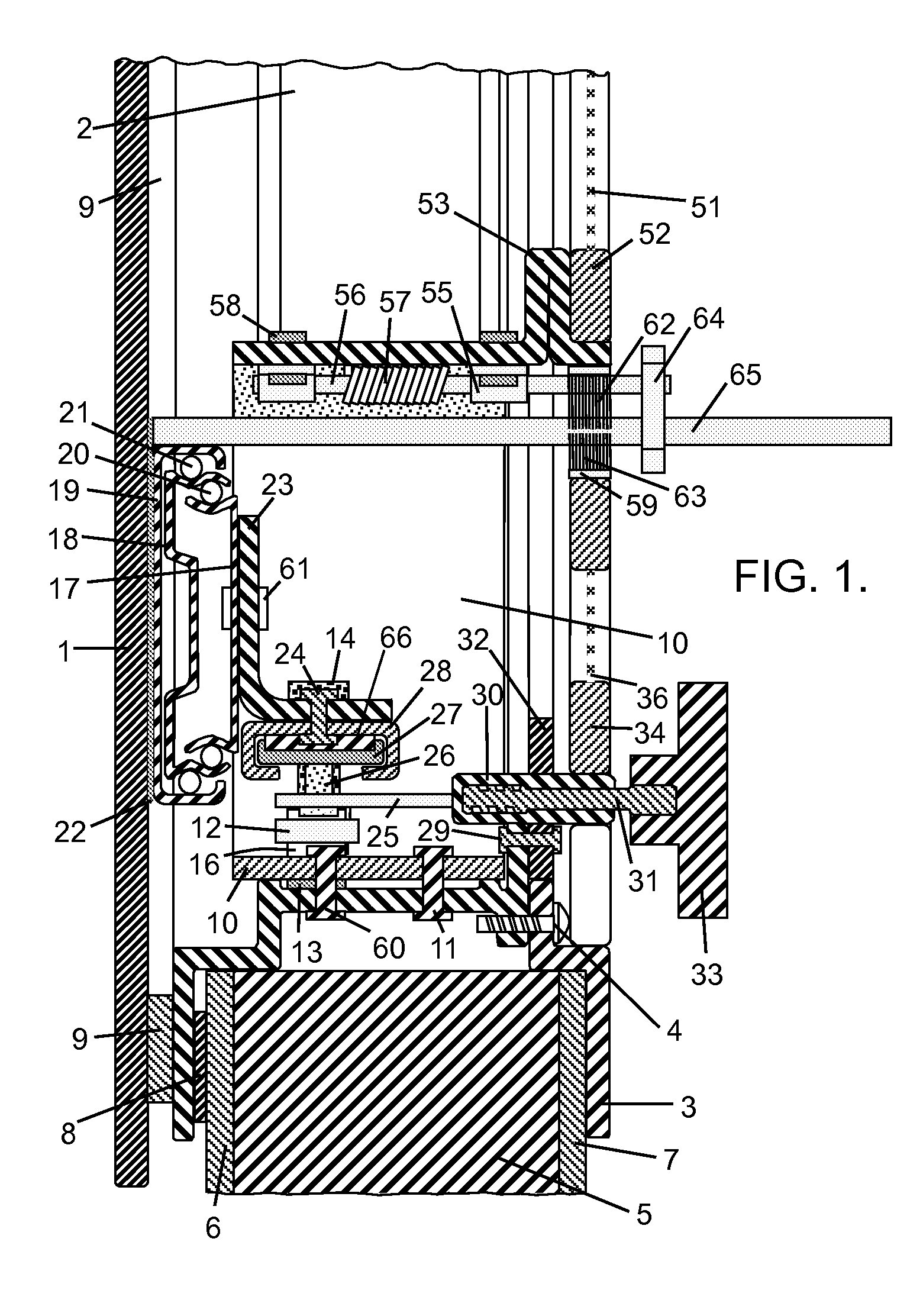

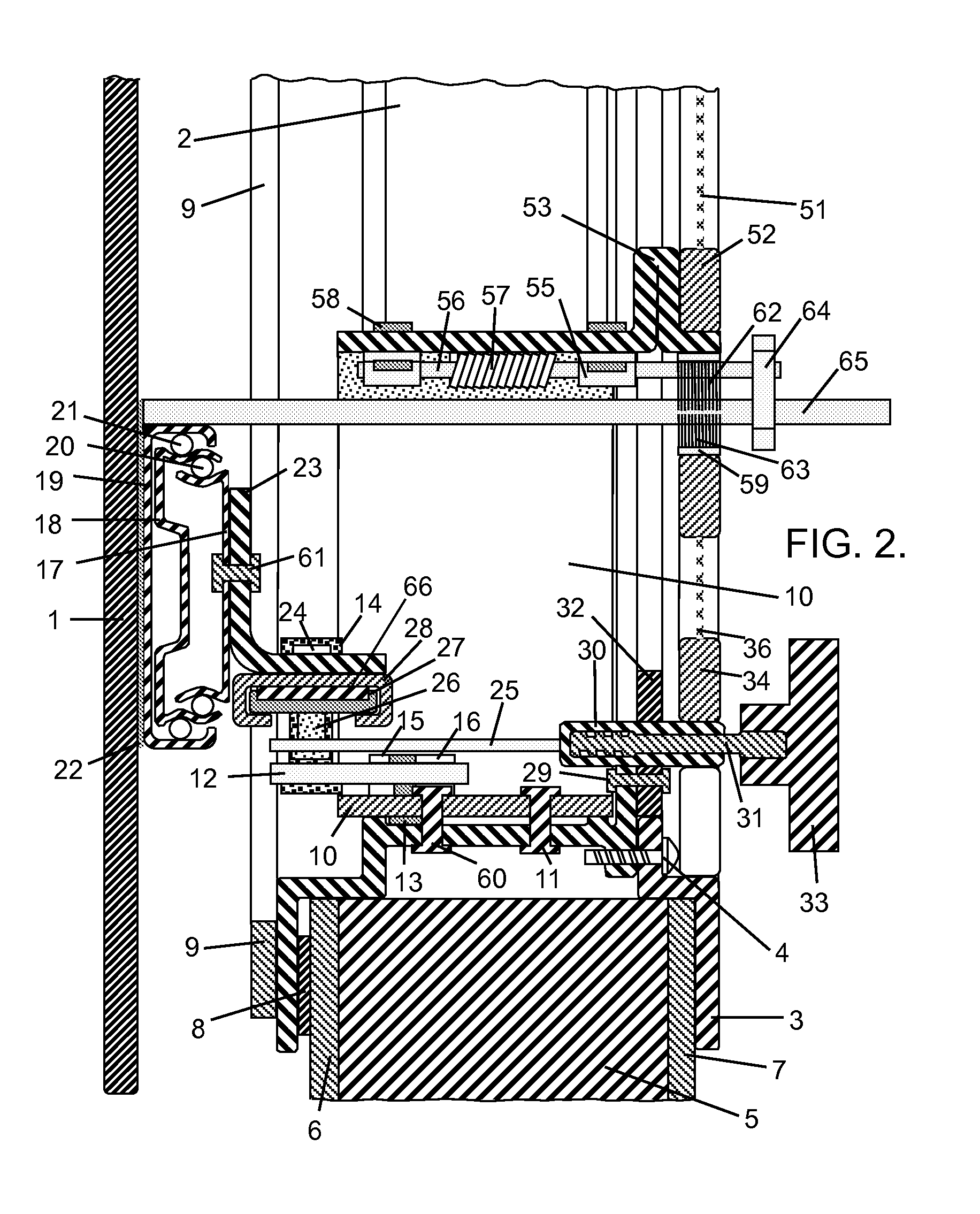

Hardware for opening a frameless window into laterally displaced parallel positions

InactiveUS20150089875A1Simple and inexpensive methodGreat distanceBuilding braking devicesMan-operated mechanismEmbedded systemControl arm

A window pane is mounted in a closed position outside a window frame, commonly referred to as a frameless window, and is movable into open positions parallel to the closed position. The window pane can be slid into a fully open position. Sliding mechanisms are attached to the window pane. Swing arms connect the sliding mechanisms to the window frame. Control arms also connect the sliding mechanisms to the window frame. They determine the distance of and control the translation of the window pan from the closed position to the initial open position. A handle is attached to at least one of the sliding mechanisms or window pane. Latching mechanisms secure the handle in the open positions. The invention is designed so that a plurality of screens allows air flow through the window frame, preventing passage of insects or debris through the window frame.

Owner:MALMROSE ROGER

Silicon blades for surgical and non-surgical use

InactiveUS7387742B2Quality improvementUniform radiusIncision instrumentsEye surgerySurgical bladeEngineering

Ophthalmic surgical blades are manufactured from either a crystalline or polycrystalline material, preferably in the form of a wafer. The method comprises preparing the crystalline or polycrystalline wafers by mounting them and machining trenches into the wafers. Methods for machining the trenches, which form the bevel blade surfaces, include a diamond blade saw, laser system, ultrasonic machine, a hot forge press and a router. The wafers are then placed in an etchant solution which isotropically etches the wafers in a uniform manner, such that layers of crystalline or polycrystalline material are removed uniformly, producing single, double or multiple bevel blades. Nearly any bevel angle can be machined into the wafer which remains after etching. The resulting radii of the blade edges is 5-500 nm, which is the same caliber as a diamond edged blade, but manufactured at a fraction of the cost. The ophthalmic surgical blades can be used for cataract and refractive surgical procedures, as well as microsurgical, biological and non-medical, non-biological purposes.

Owner:BEAVER VISITEC INT US

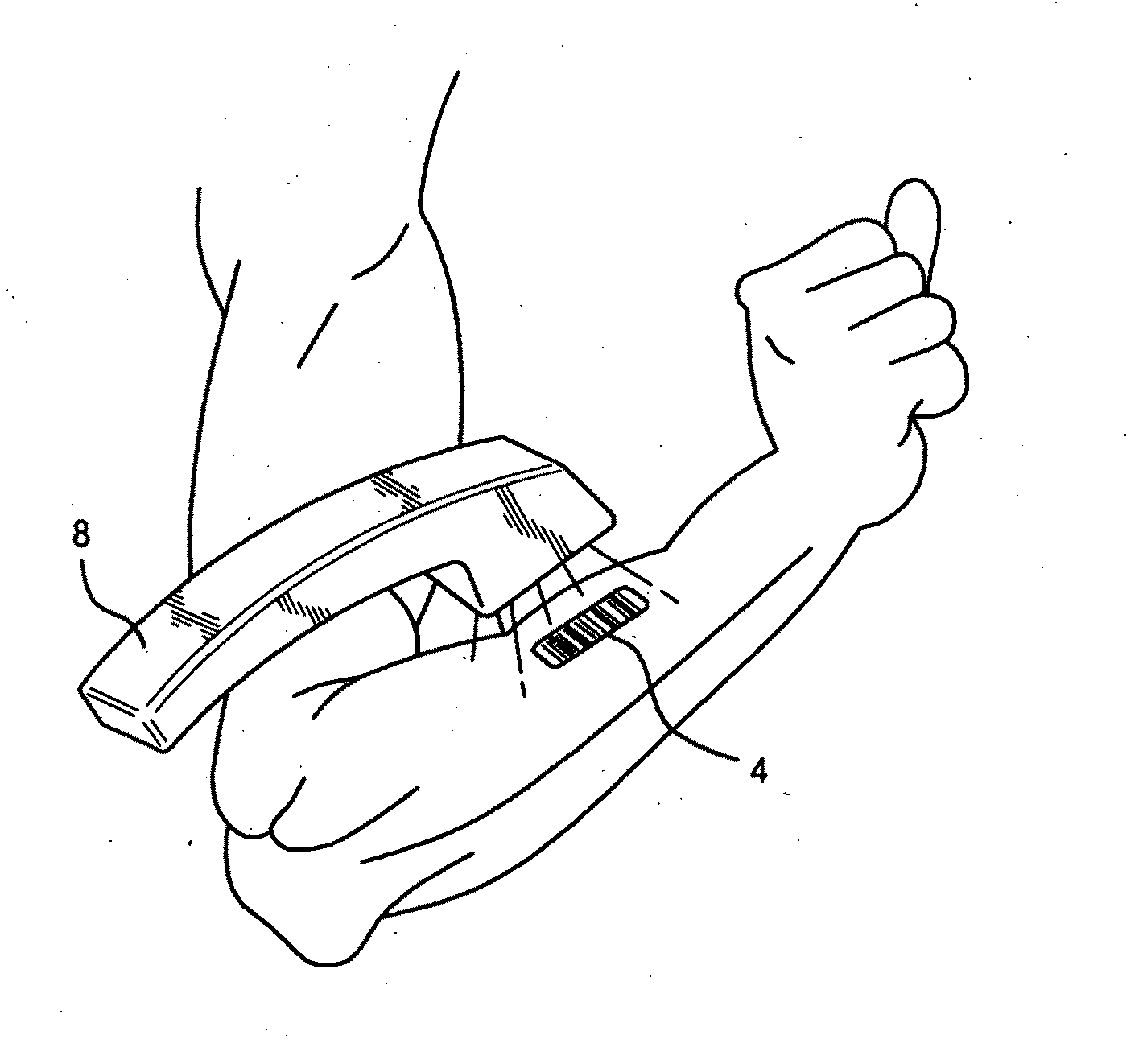

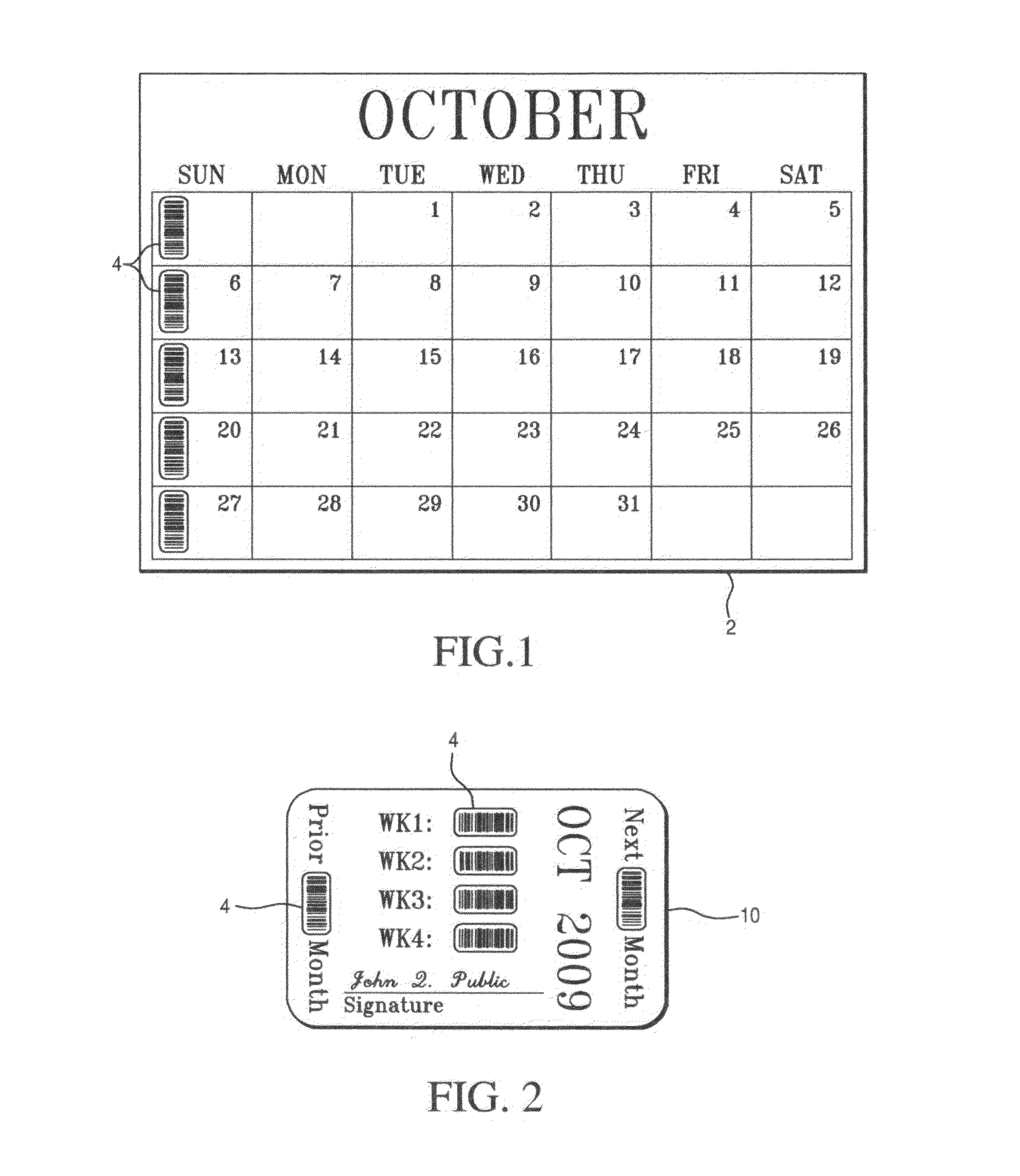

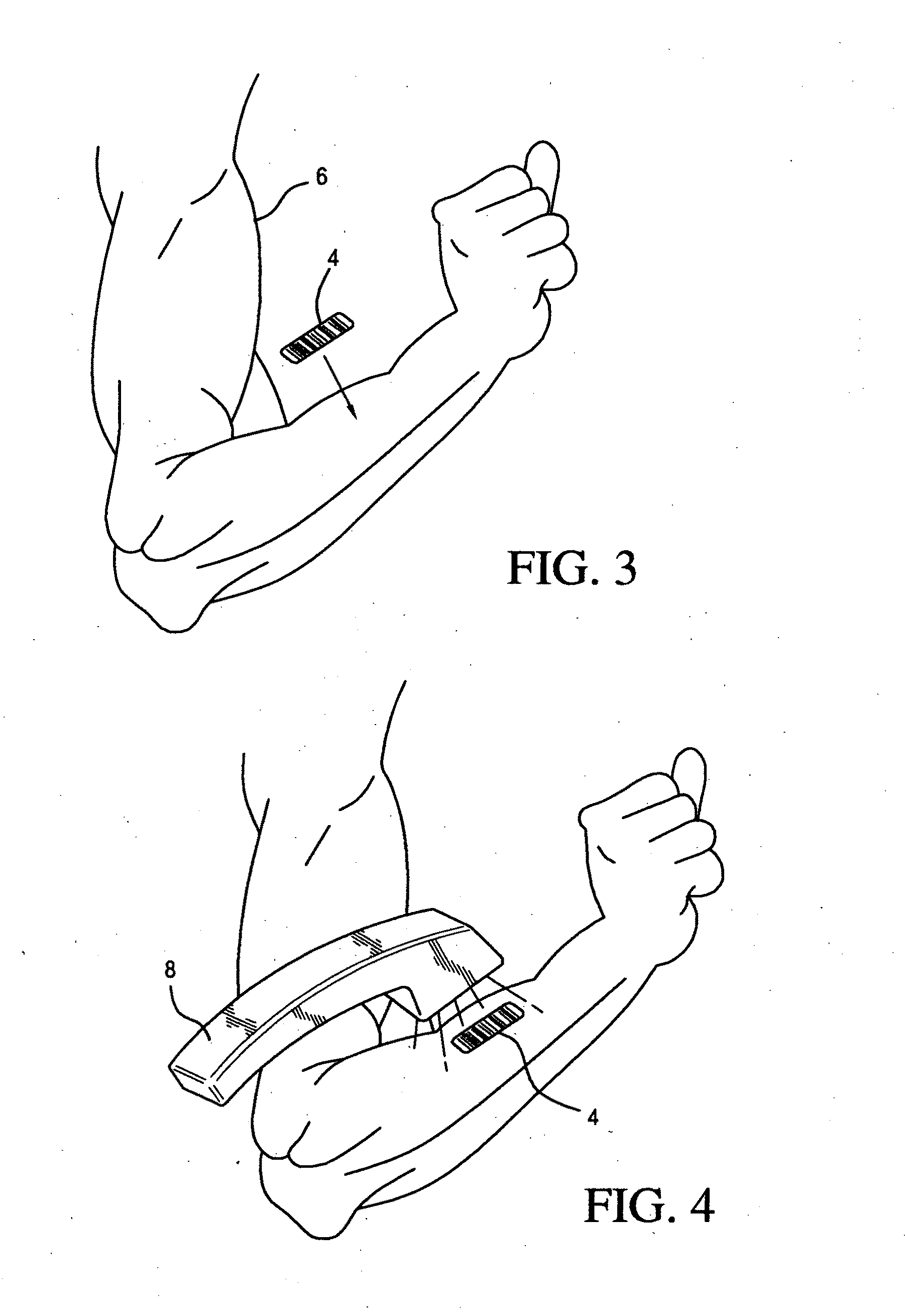

Electronic sales method

InactiveUS20110119187A1Easy to changeKeep appearanceComplete banking machinesFinanceBank accountBarcode

A method is presented for facilitating sales transactions by electronic media. A temporary barcode or other design is tattooed onto a tattoo sheet, previously organized by verifiable chronological date. The tattoo sheet is made with an adhesive sufficient to allow the tattoo, once printed, to be transferred onto the skin of a person or to a personal object and remain affixed to said person or personal object during the period of time for which a financial transaction might occur. The transferable temporary tattoo is then removed from the sheet and applied to the skin of the individual or to a personal object in their possession. Before the sales transaction can be consummated, the tattoo information along with the corresponding valid date information is scanned with a scanner. Characteristics about the scanned tattoo are compared to characteristics about other tattoos stored on a computer database for the specific time period in question in order to verify the identity of the buyer for a given time period. Additionally, the chronological information is verified to ensure that the transaction is occurring only during a previously prescribed valid time period for which a given tattoo is valid. Once both pieces of information are verified, the seller may be authorized to debit the buyer's bank electronic bank account in order to consummate the transaction or transactions during the given period of time. The seller's electronic bank account may be similarly updated.

Owner:HEETER THOMAS W MR

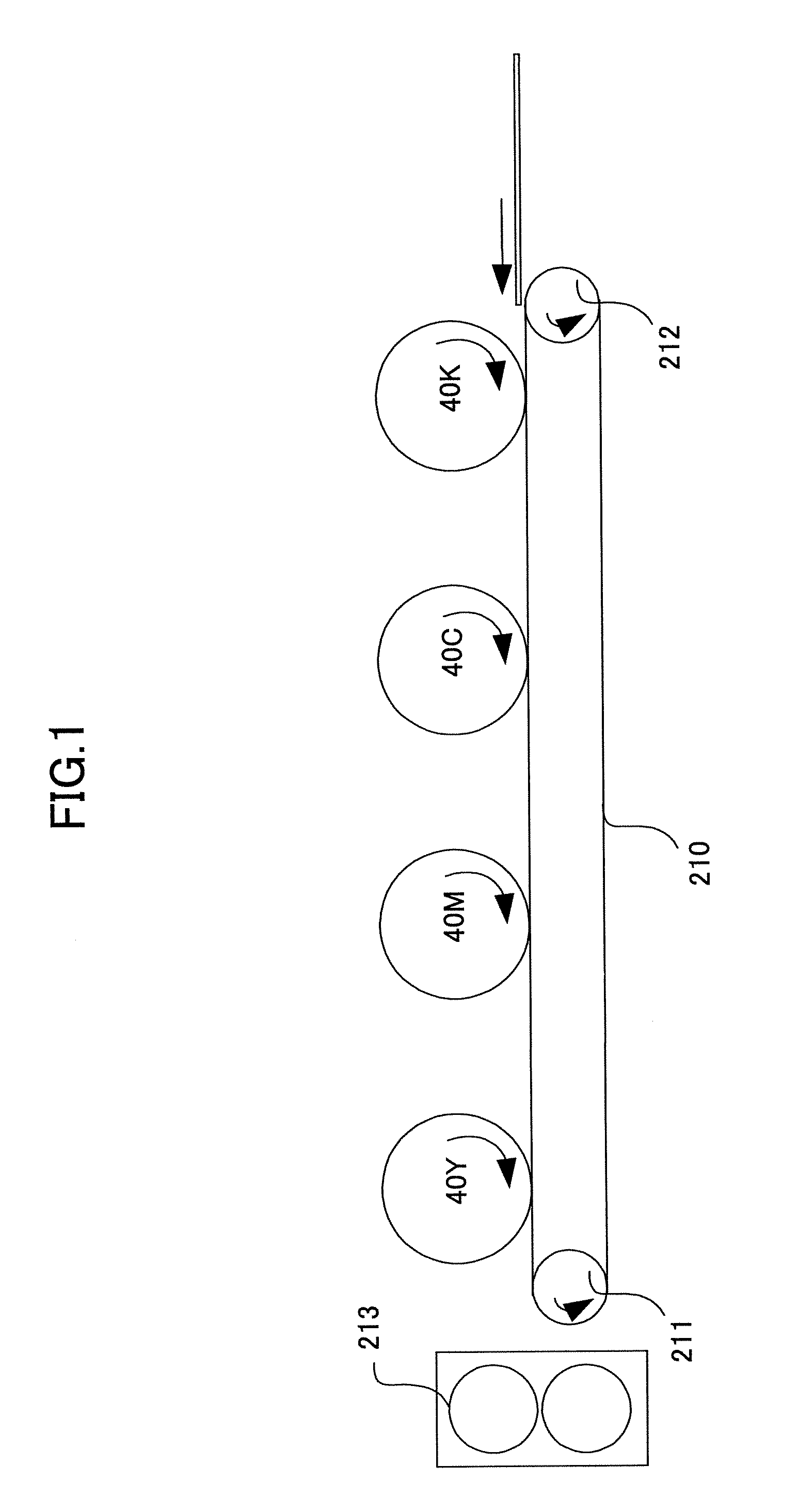

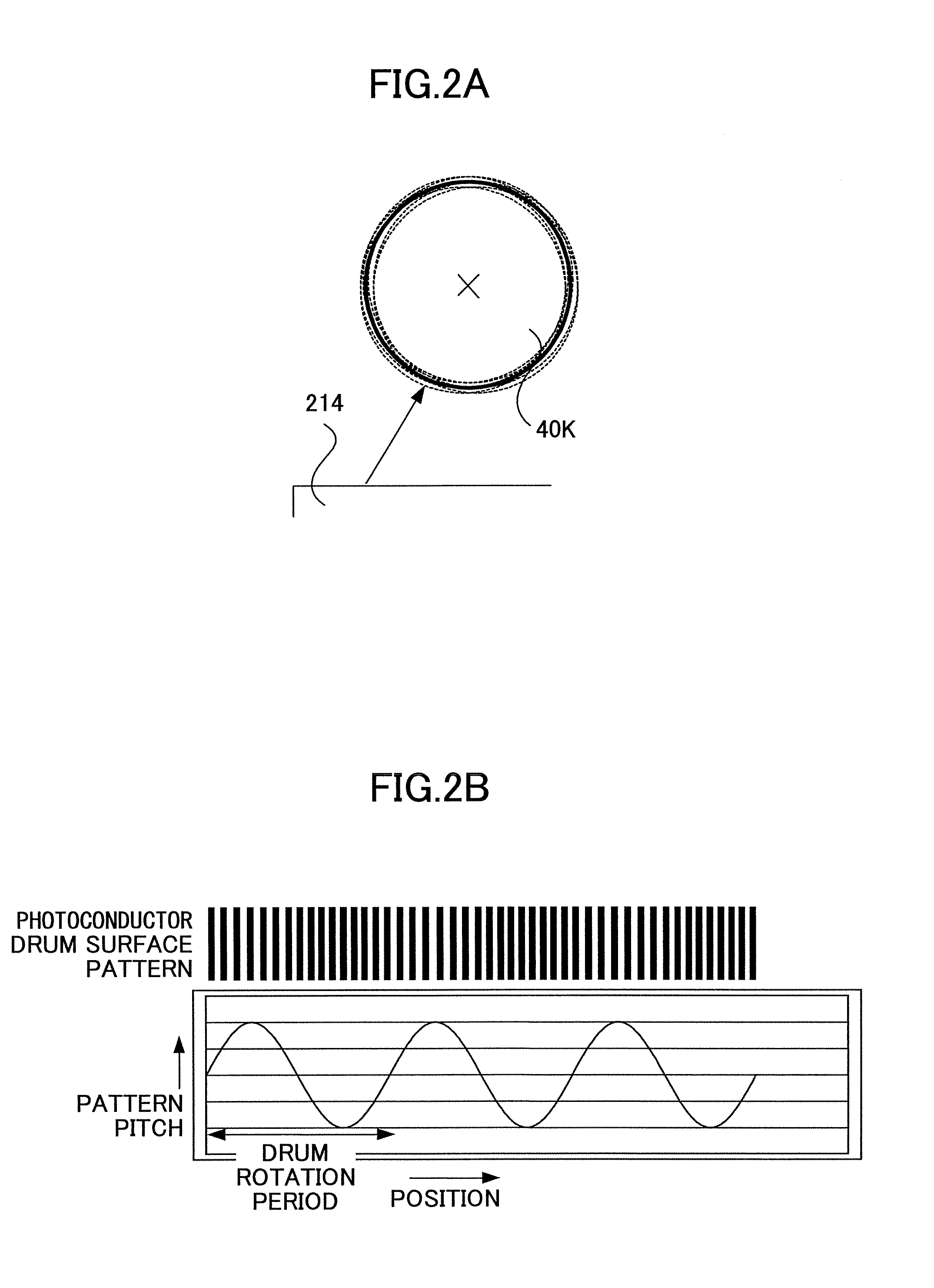

Imaging apparatus

InactiveUS20070217830A1Accurately reducingInexpensive meanElectrographic process apparatusEngineeringImaging equipment

An imaging apparatus is disclosed that includes plural image carriers on which different-colored toner images are formed, the image carriers being driven and rotated to transfer the different-colored toner images onto one of an endless transfer member that is driven to rotate in contact with the image carriers or a transfer material that is carried by the endless transfer member. The imaging apparatus includes a phase calculating unit that extracts a periodic rotational variation component of each of the image carriers from a combination of periodic rotational variation components generated within said imaging apparatus and calculates a rotational phase of each of the image carriers based on the extracted periodic rotational variation component, and a rotational phase adjusting unit that adjusts a rotation stop phase of each of the image carriers based on the calculated rotational phase.

Owner:RICOH KK

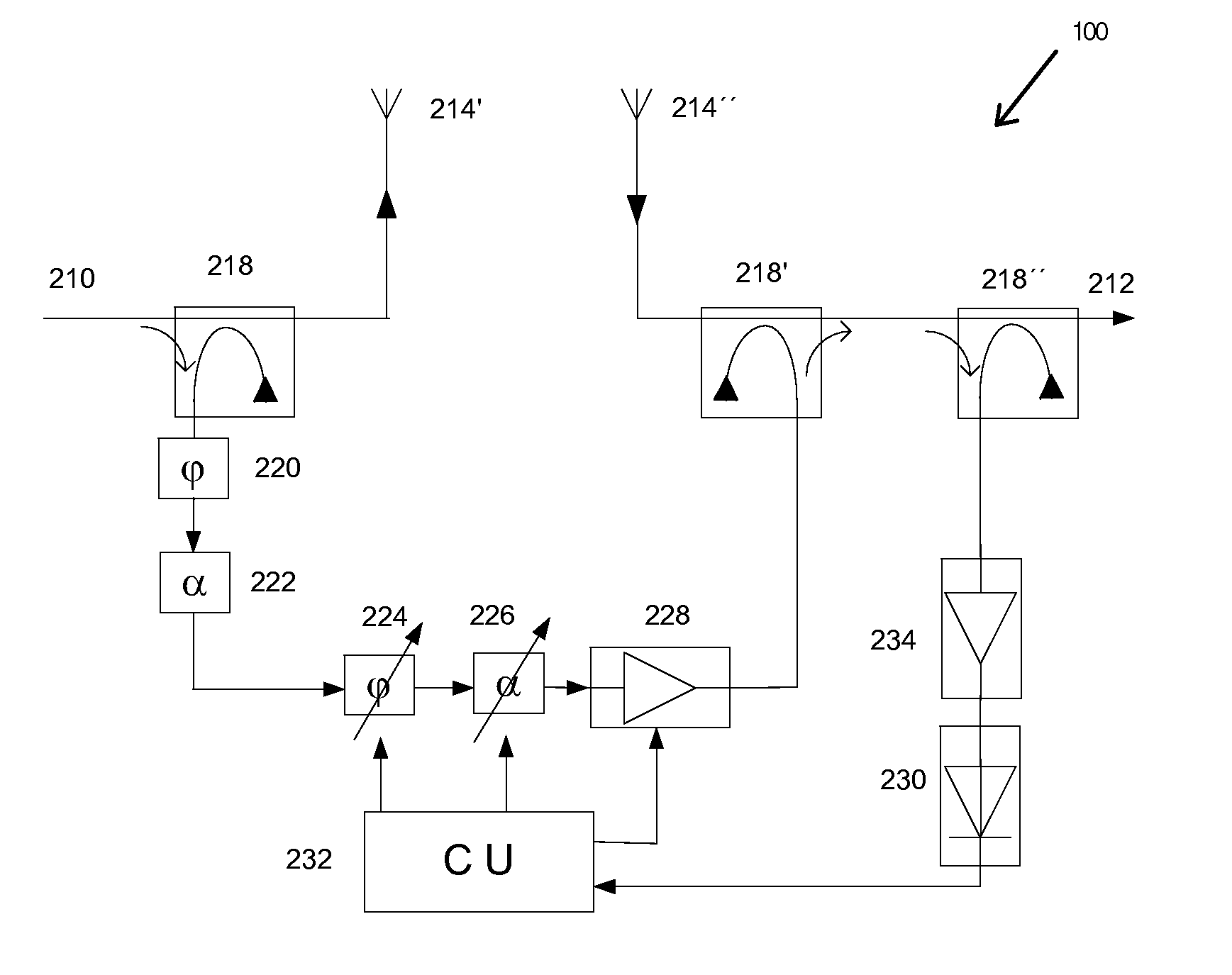

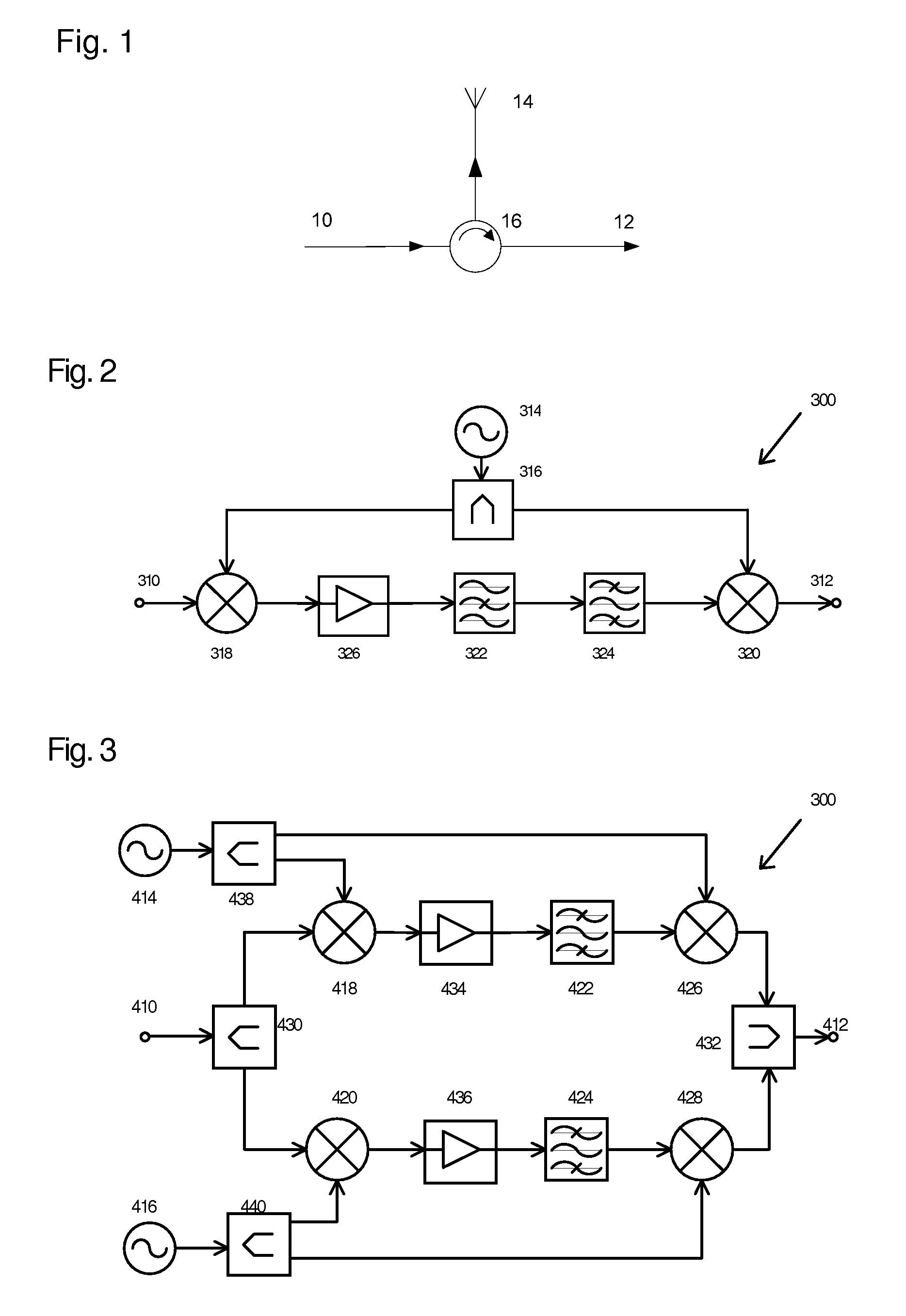

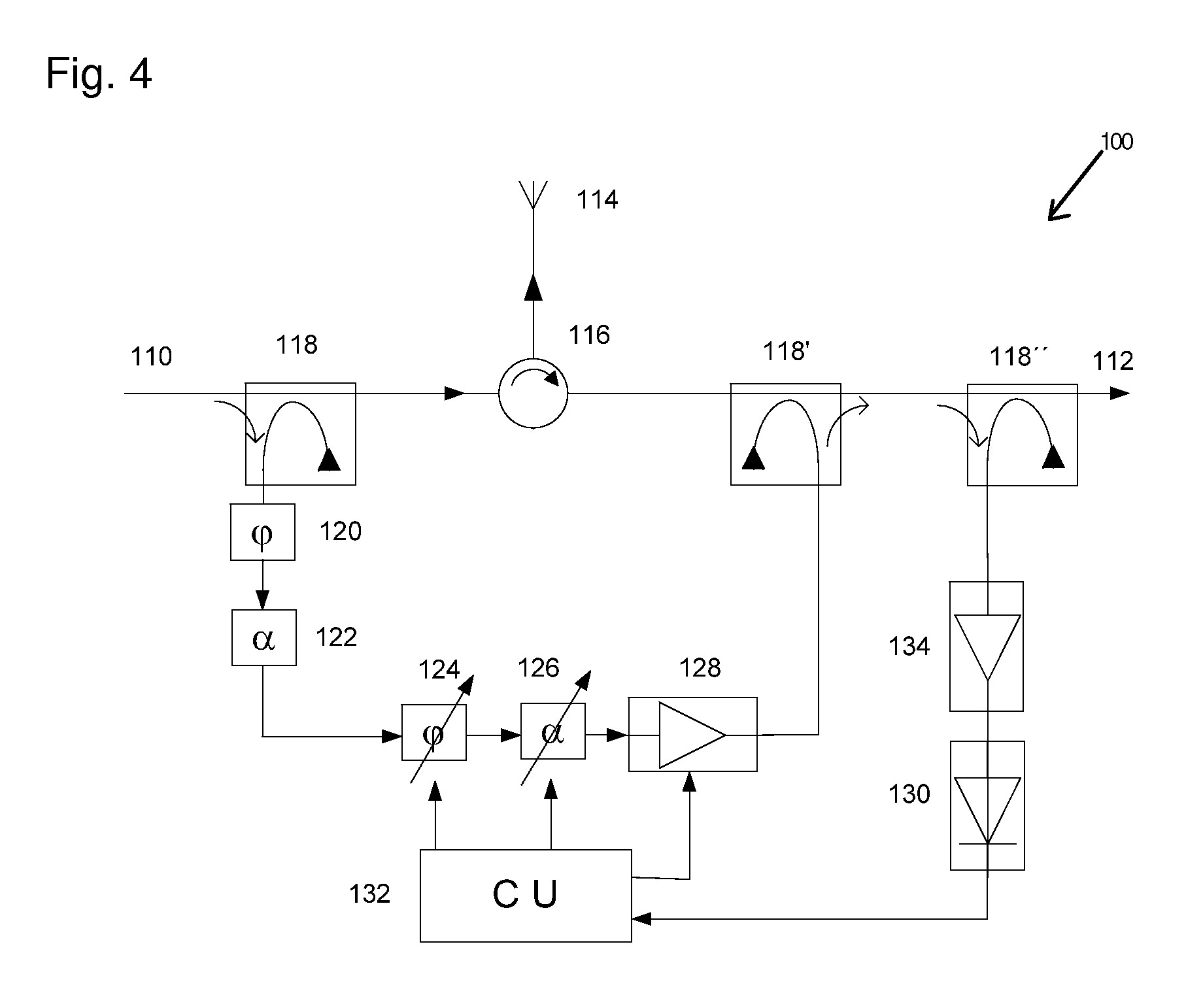

Adjustable circuit and RFID reader device

InactiveUS8285214B2Inhibition is effectiveInexpensive meanError preventionLine-faulsts/interference reductionIntermediate frequencyTransmission channel

The present invention relates to an adjustable circuit for filtering a transmission channel of an RFID signal and for suppressing a carrier signal in the reception path between an input gate and an output gate, including at least one adjustable oscillator for generating an oscillator signal, at least one input mixing stage cooperating with the oscillator for mixing an input signal by means of the oscillator signal to an intermediate frequency and a blocking device arranged downstream of the input mixing stage or the input mixing stages for suppressing the carrier signal at the intermediate frequency.

Owner:PEPPERL FUCHS GMBH

Water closet flushing system

InactiveUS20030074725A1Easy to adjustInexpensive meanOperating means/releasing devices for valvesFlushing devicesEnvironmental engineeringFlush toilet

Owner:PINO WILTON J

Method and device for evaluating the noise associated with turbocodes, and systems using them

InactiveUS7424070B2Improve performanceImprove decoding performanceData representation error detection/correctionCode conversionTurbo encoderComputer science

In order to evaluate the noise related to data issuing from a turbo-encoder, estimates of the noise related to its systematic output, to the data issuing from its first elementary encoder, and to the data issuing from its second elementary encoder are determined. At least two of the estimates of the noise related to the systematic output, to the data issuing from the first encoder, and to the data issuing from the second encoder, are added. The results of these additions are divided by the number of augends added, and then inverted, so as to obtain a noise factor, and the noise factor is multiplied with the data issuing from at least one of the first encoder, second encoder, and systematic output.

Owner:CANON KK

System and method for creating linear and non-linear trenches in silicon and other crystalline materials with a router

InactiveUS7785485B2Quality improvementUniform radiusIncision instrumentsDecorative surface effectsWaferingCrystalline materials

A method for manufacturing blades for surgical and other uses from either a crystalline or polycrystalline material, preferably in the form of a wafer, comprises preparing the crystalline or polycrystalline wafers by mounting them and machining trenches into the wafers. The methods for machining the trenches, which form the bevel blade surfaces, include a diamond blade saw, laser system, ultrasonic machine, a hot forge press and a router. When a router is used, through-holes are drilled in the wafer to define the starting locations of the trenches. After the trenches are formed, the wafers are placed in an etchant solution which isotropically etches the wafers in a uniform manner, such that layers of crystalline or polycrystalline material are removed uniformly, producing single or double bevel blades, with each bevel having one or more facets. Nearly any bevel angle can be machined into the wafer which remains after etching. The resulting radii of the blade edges is 5-500 nm, which is the same caliber as a diamond edged blade, but manufactured at a fraction of the cost.

Owner:BEAVER VISITEC INT US

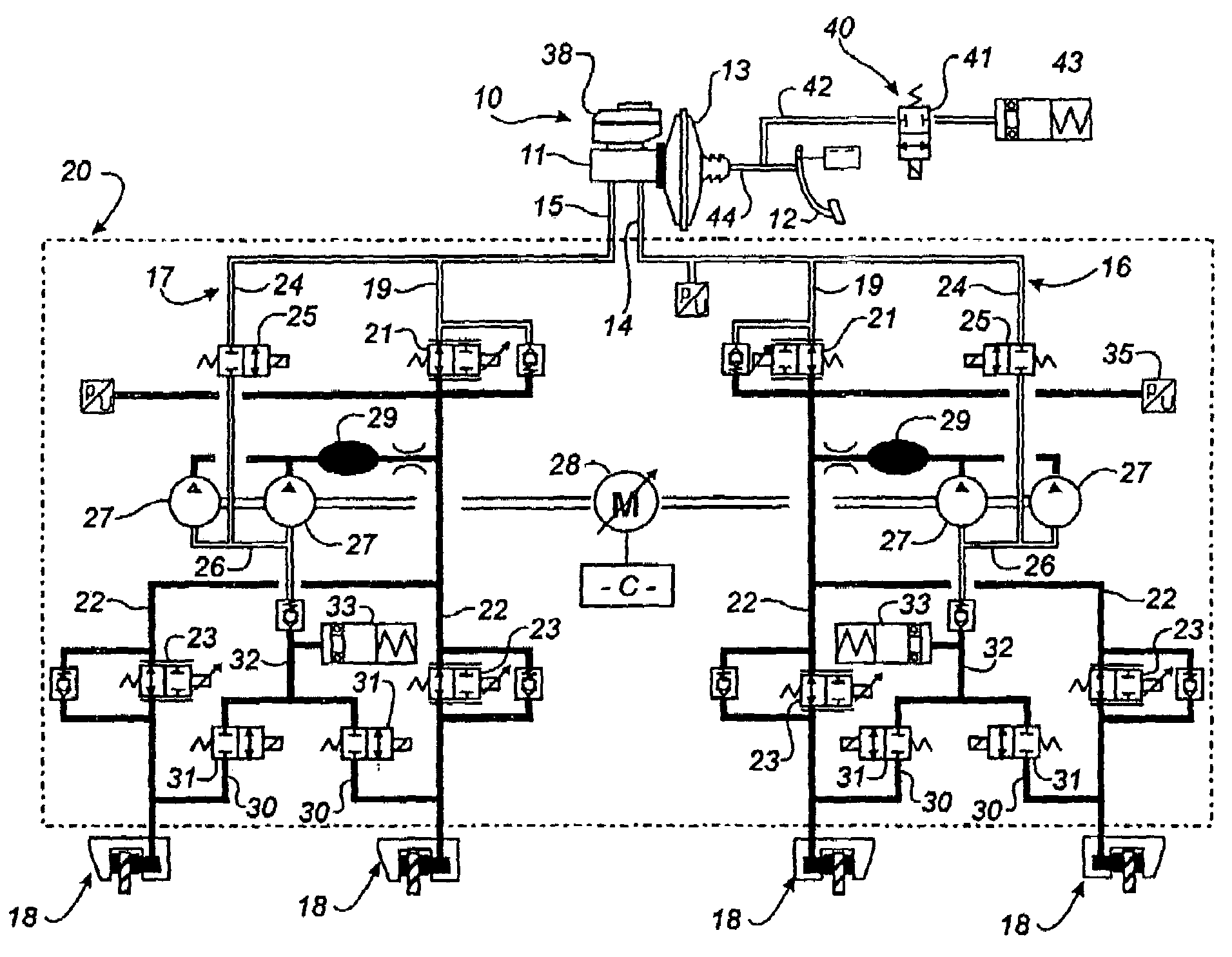

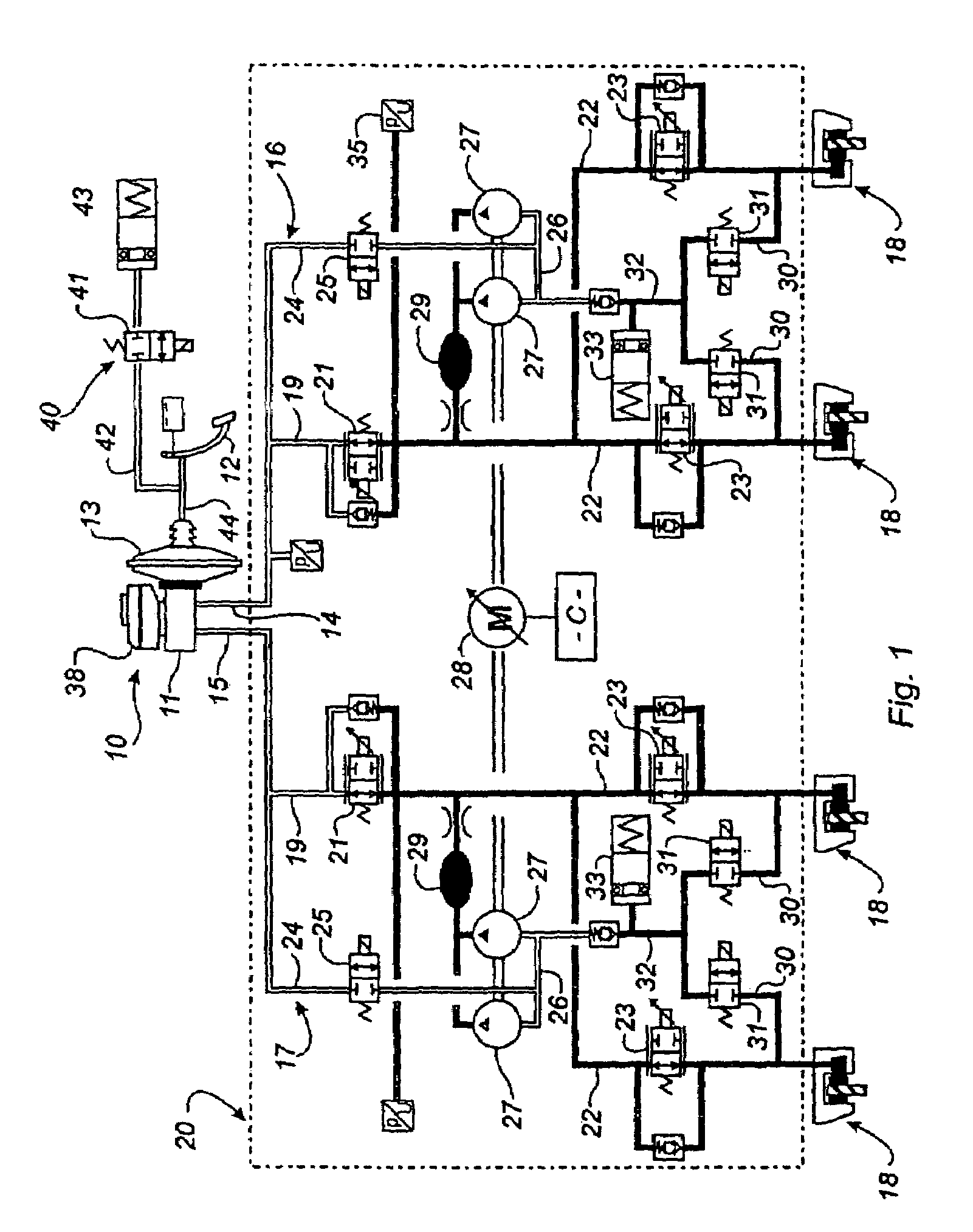

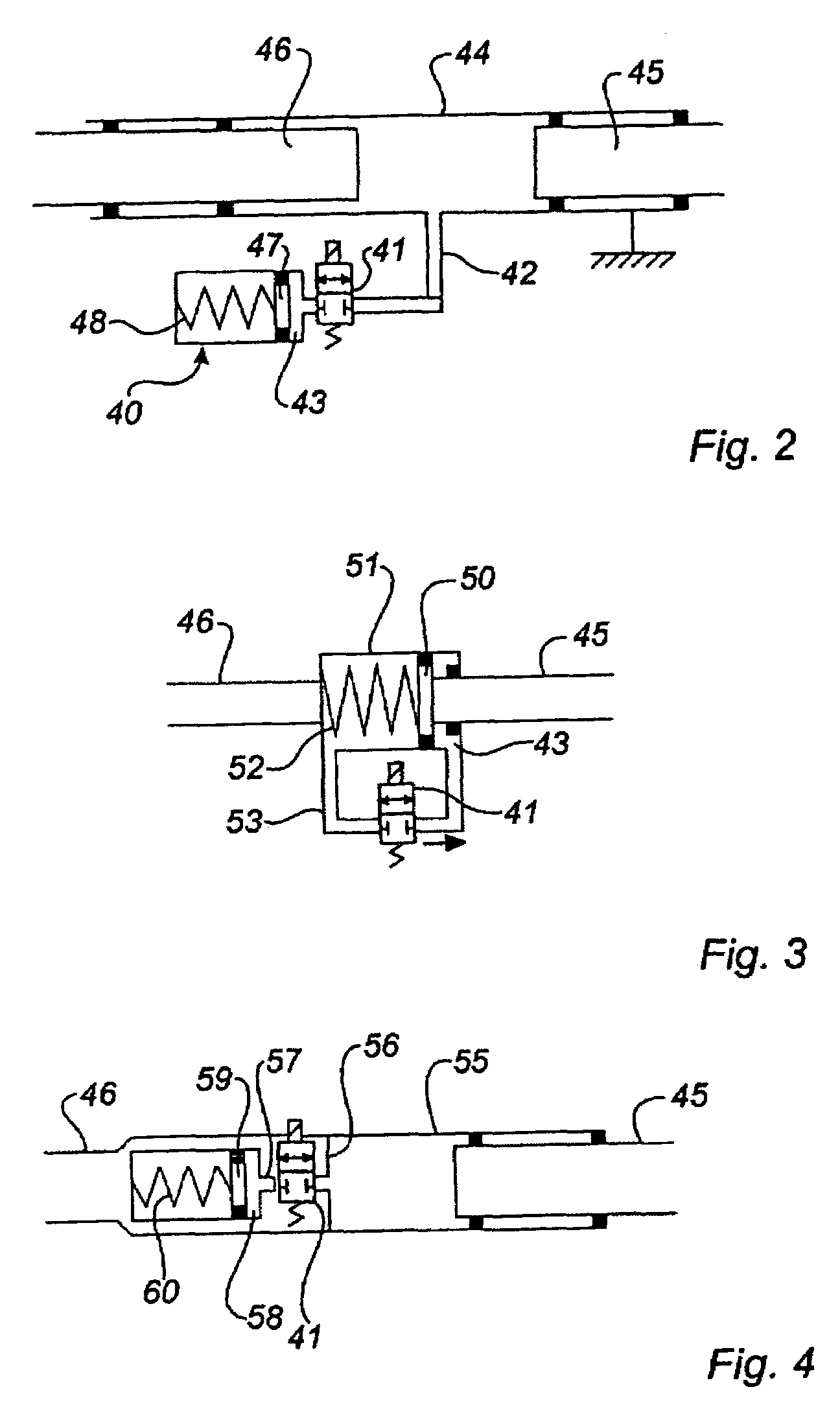

Braking device for a motor vehicle

InactiveUS7419227B2Simple and effective and inexpensive solutionInexpensive meanBraking action transmissionApplication and release valvesMobile vehicleMotor vehicle part

A braking device for a motor vehicle having a first brake circuit (10) with a master cylinder (11) controlled by a brake pedal (12), a second brake circuit (20) with at least one pump (27) that is controlled by a computer (C), and a pedal travel simulation mechanism (40). The simulation mechanism (40) includes a solenoid valve (41) that is mounted in a pipe (42) connected to a hydraulic fluid storage chamber (43) and controlled by the computer (C) so as to allow the brake fluid to flow toward the chamber (43) when the second brake circuit (20) is active and when the driver presses on the brake pedal. The pipe (42) is also connected to another pipe (44) in which hydraulic fluid is displaced by a first part (45) of a control rod connected to the brake pedal (12) and second part (46) associated with the master cylinder (11).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com