Golf club head of iron or wood type

a golf club and iron or wood technology, applied in golf clubs, racket sports, golf, etc., can solve the problems of affecting the quality of golf clubs, so as to achieve the effect of convenient manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

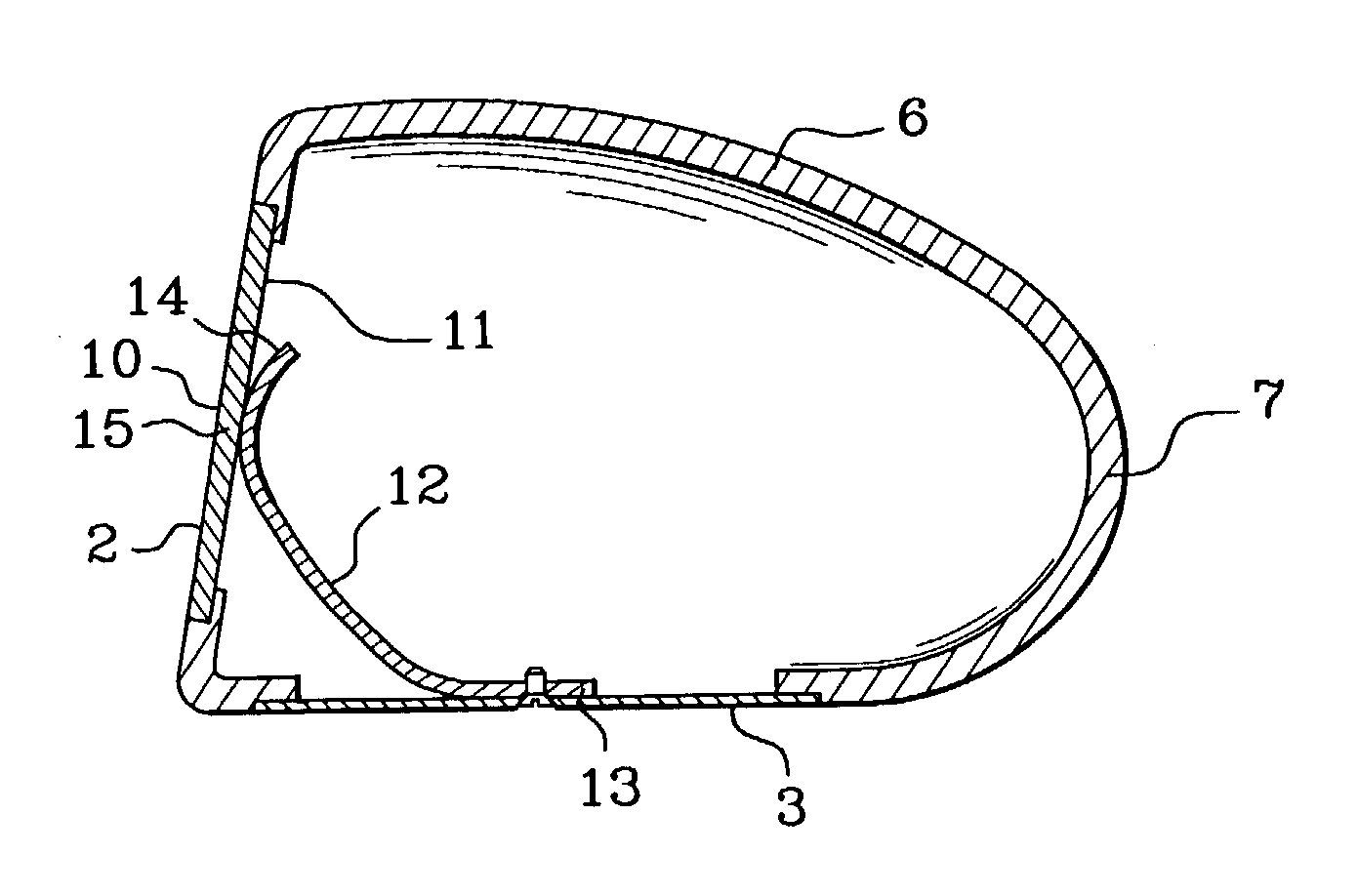

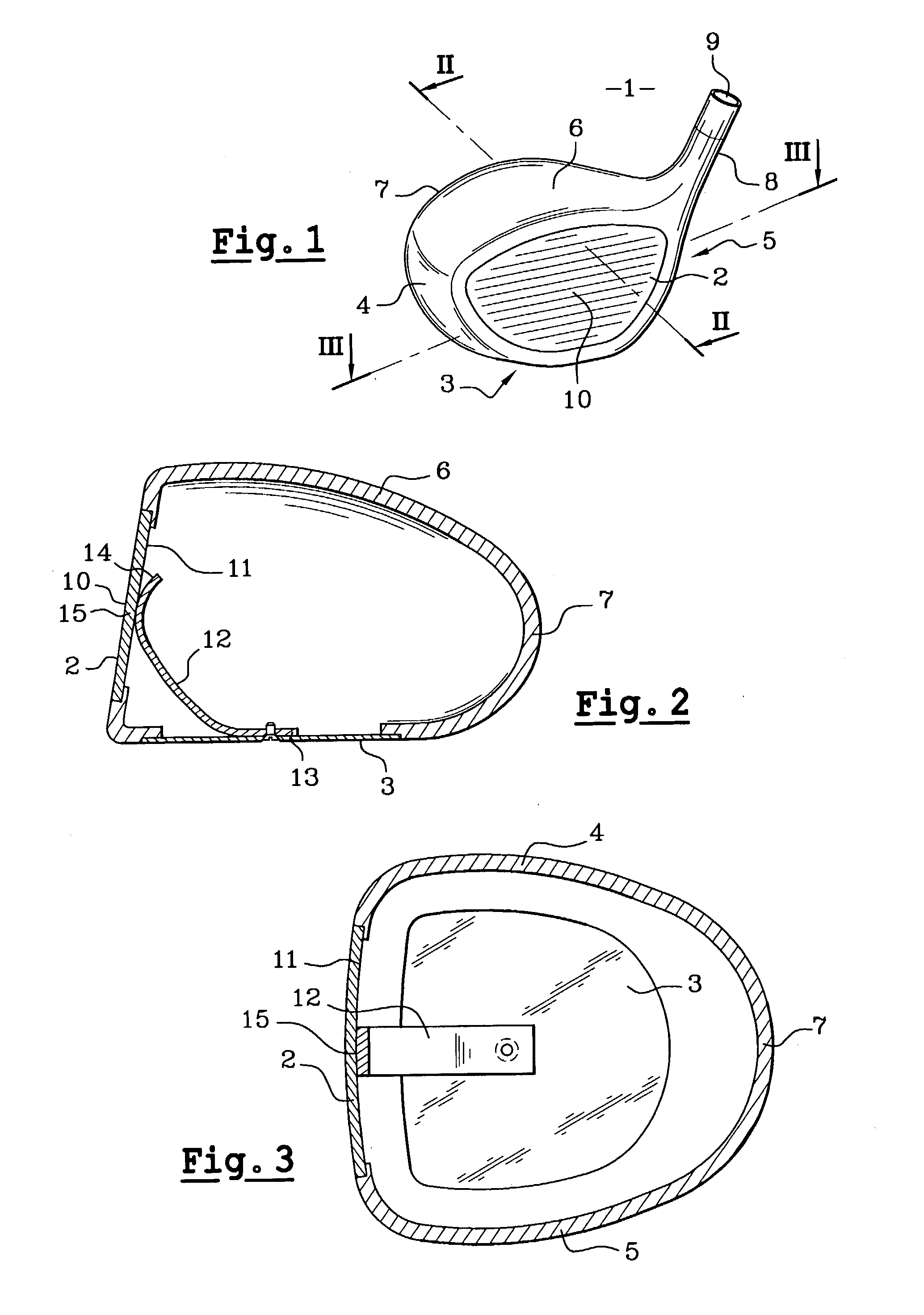

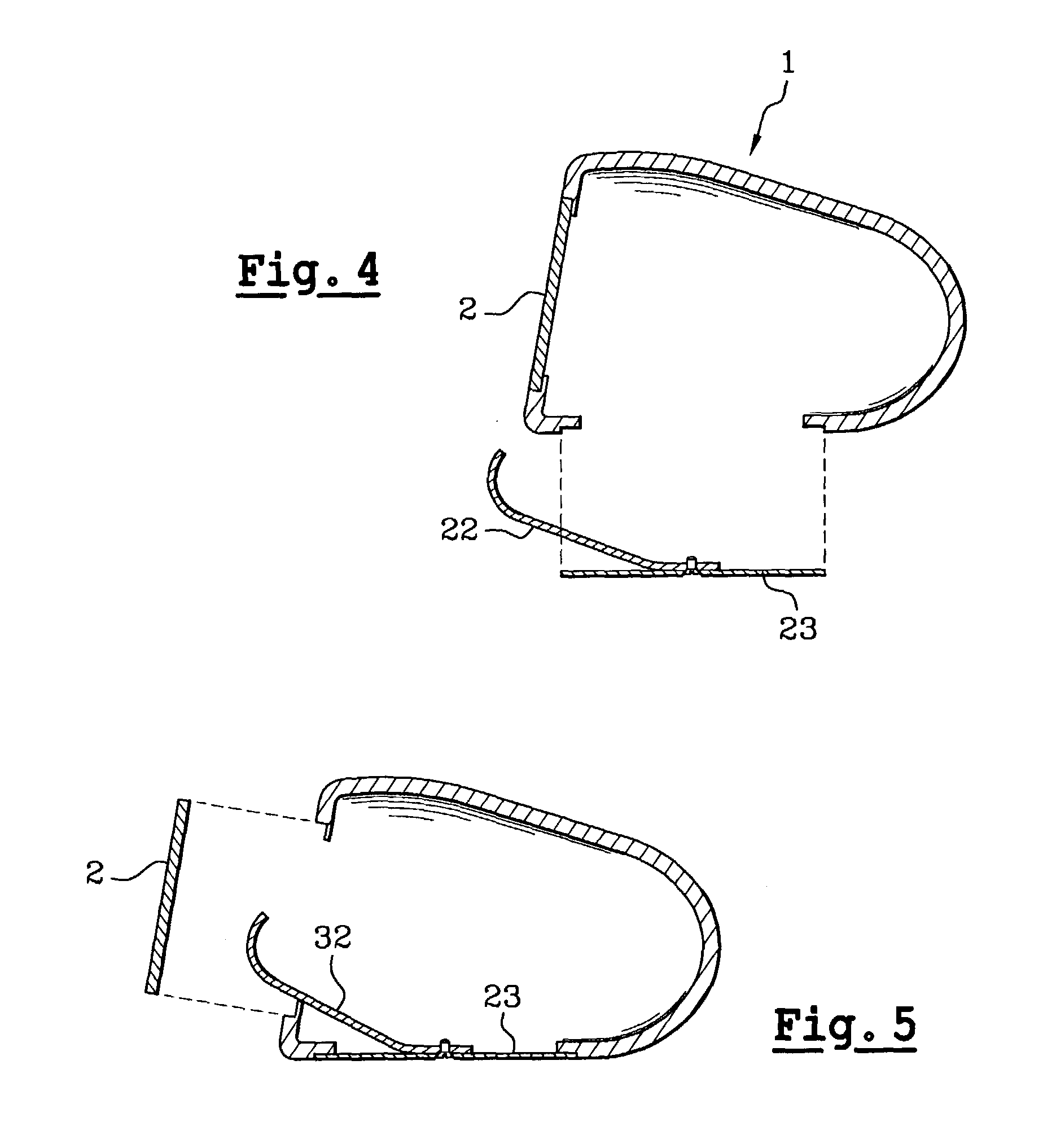

[0037] As already mentioned, the invention relates to a golf club head (1). FIG. 1 depicts a head of the "wood" type. Such a head comprises a striking face (2), a sole (3), lateral faces (4, 5), a crown face (6) and a back wall (7) defined in the continuity of the lateral faces (4, 5), of the crown face (6) and of the sole (3). The striking face is fixed rigidly to the rest of the head, for example by welding around its periphery. This head (1) also comprises a hosel (8) intended to accommodate, inside a housing (9), the shaft of the club.

[0038] Traditionally, the striking face (2) has a horizontally scored surface. The point (10) situated on the striking face and corresponding to the optimum point of impact is generally known as the sweet spot.

[0039] In the form illustrated in FIG. 2, it can be seen that the sole (3) has a metal leaf (12) fixed by one of its ends (13), for example by screwing. This screwing may be done as in the embodiment illustrated through the sole by at least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com