Multi-component packaging system and method for manufacture

a packaging system and multi-component technology, applied in the field of multi-component packaging system and method for manufacture, can solve the problems of not being able to provide the cost nor esthetics and continuing protection required for extended shelf life or shelf image of most oxygen intolerant, shelf stable foods, and not being able to stretch more than 10% without breaking apart, and the web scrap generated in this process typically exceeds 40%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

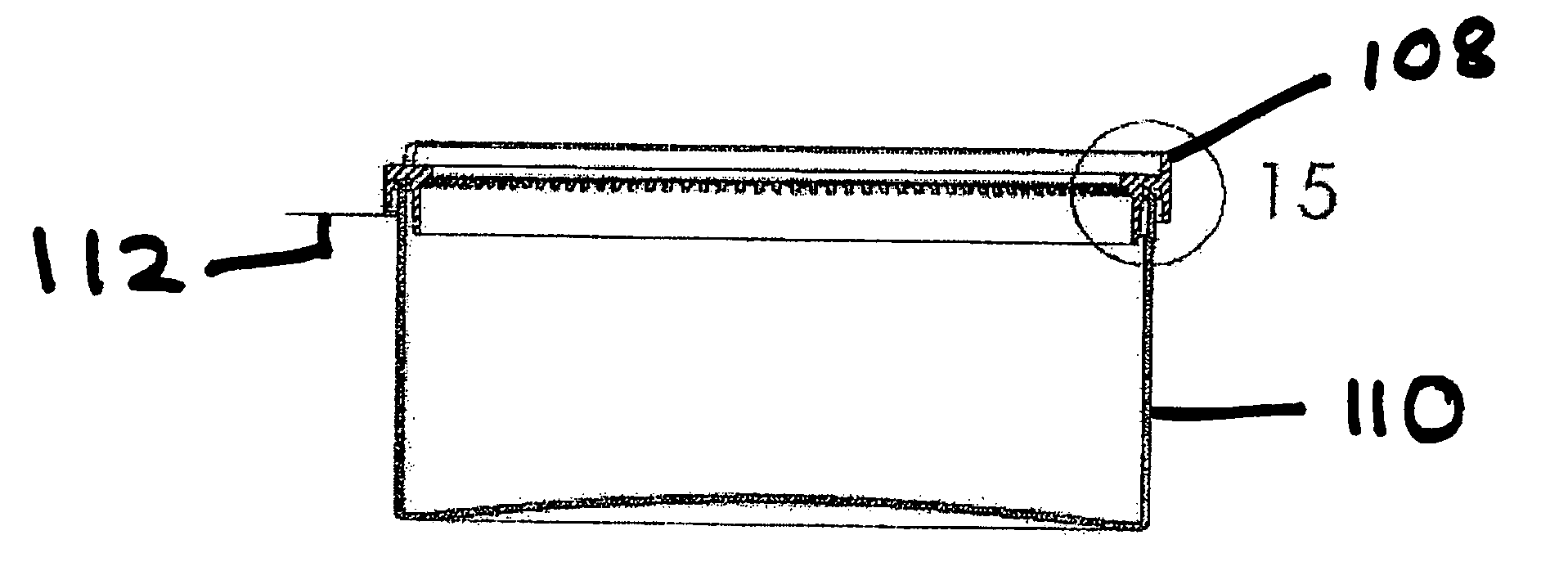

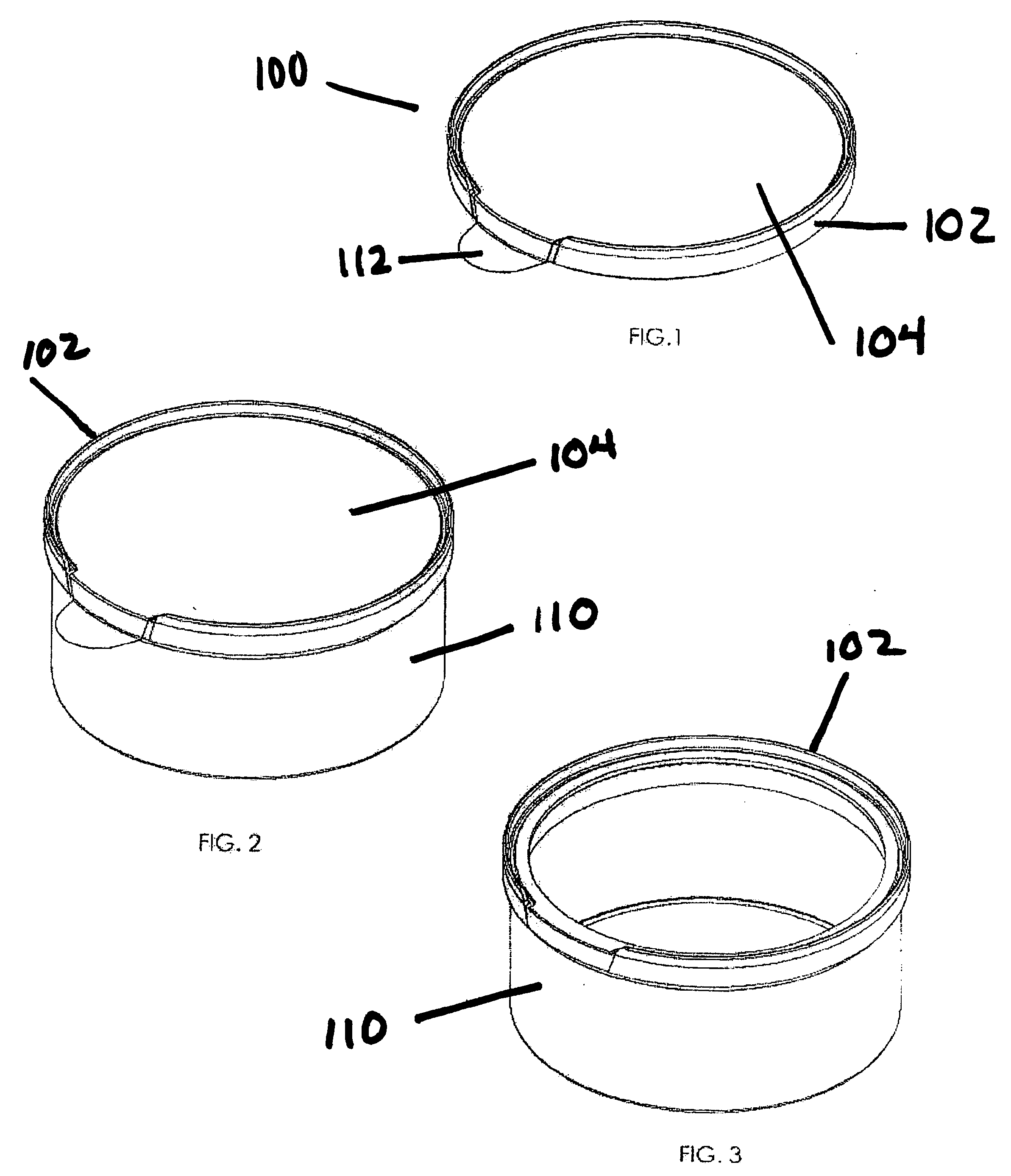

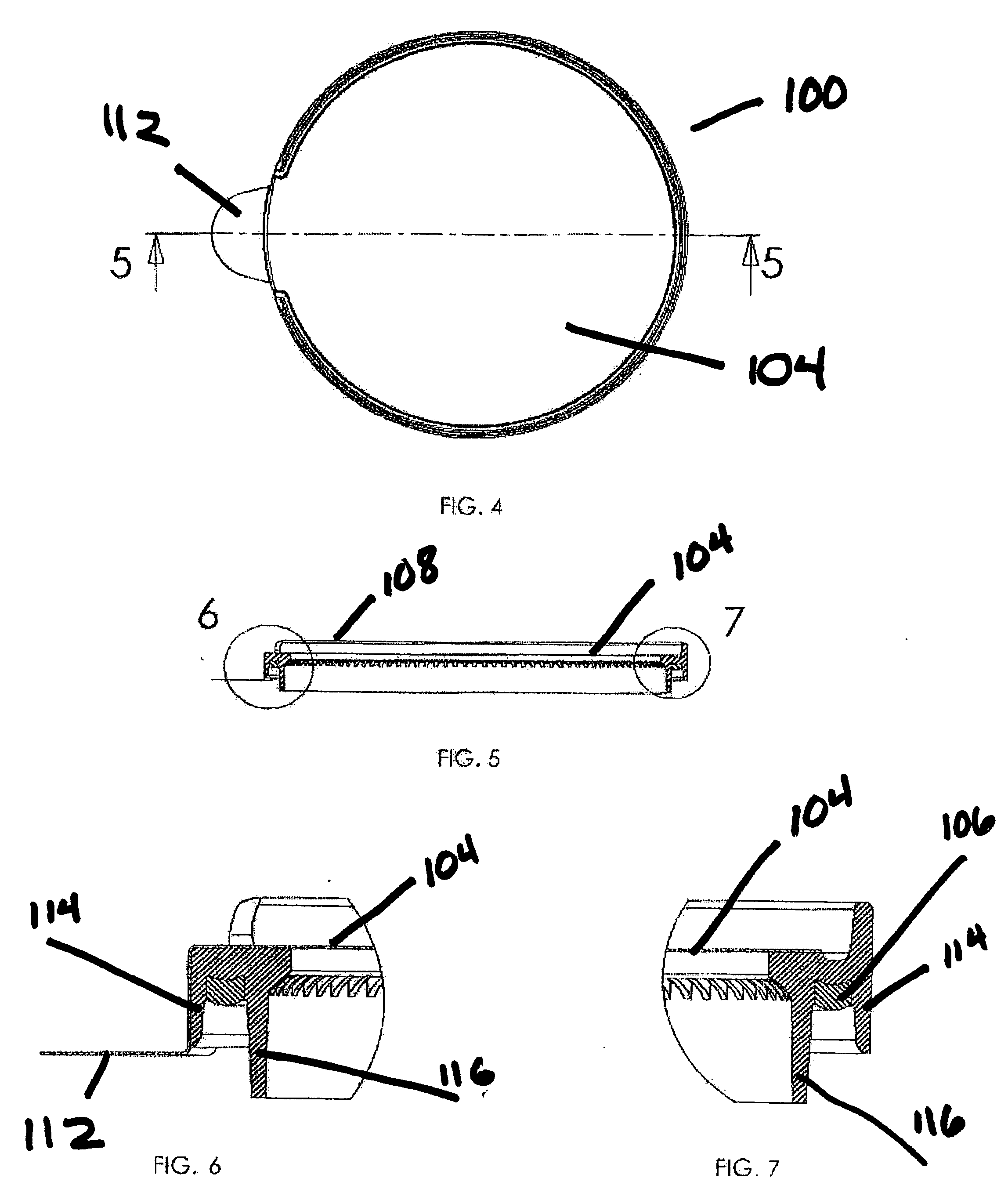

[0090] The following is a detailed description of the preferred embodiment of the invention. It is important to note that the invention is not limited to the shapes, sizes and proportions shown in the figures and discussed in the following description. Even though the embodiments shown and discussed are in the form of round or cylindrical packages and package components, it is anticipated that other shapes such as square, rectangular, oval, triangular, and polygonal, etc. could be used. Further, while the description below describes a container with a single opening, a container with openings at both ends is also contemplated. Likewise it is anticipated that other features of the design, such as the ring-pull or the pull-tab could also have a multitude of shapes, sizes and proportions. The preformed containers shown in use with these two closure embodiments are not restrictive to the specific embodiment with which they are associated in the figures. For example, the container shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| RH | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap