Liquid crystal display device and manufacturing method of liquid crystal display device

a technology of liquid crystal display device and manufacturing method, which is applied in the direction of liquid crystal compositions, instruments, chemistry apparatus and processes, etc., can solve the problems of insufficient purity of displayed colors, difficult to achieve high-resolution display, and increase in power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment 2

[0050] [Embodiment 2]

[0051] An empty panel with an electrode pattern different from that of Embodiment 1 was produced by the same method as in Embodiment 1. The basic specifications of the electrode pattern were 640.times.480 pixels and the electrode area of 6.times.10.sup.-5 cm.sup.2, and the size of the panel was 3.2 inches in diagonal. A TFT as a switching element was also formed for each pixel, and the pretilt angle was set only at 1.degree..

[0052] An evaluation panel (liquid crystal display device) was produced by introducing into the empty panel a liquid crystal showing the phase sequence: isotropic liquid (Iso) phase-cholesteric (Ch) phase-chiral smectic C (Sc*) phase from a high temperature side to a low temperature side. The transition temperature between the Iso phase and the Ch phase was 108.degree. C., the transition temperature between the Ch phase and the Sc* phase was 68.degree. C., and the magnitude of spontaneous polarization was 3.7 nC / cm.sup.2.

[0053] In the coolin...

embodiment 3

[0055] [Embodiment 3]

[0056] The following description will explain the present invention applied to a liquid crystal display device utilizing an active matrix driving scheme (active matrix liquid crystal display device, hereinafter referred to as TFT-LCD). Since the basic structures of the TFT-LCD as a liquid crystal display device are the same as those in Embodiment 1 and Embodiment 2, the major features are mainly explained. Note that, as a liquid crystal (monostable ferroelectric liquid crystal having spontaneous polarization), it is possible to use a liquid crystal showing the phase sequence: isotropic liquid (Iso) phase-cholesteric (Ch) phase (chiral nematic (N*) phase)-chiral smectic C (Sc*) phase, or a liquid crystal showing the phase sequence: isotropic liquid (Iso) phase-cholesteric (Ch) phase-smectic A (SA) phase-chiral smectic C (Sc*) phase, from a high temperature side to a low temperature side.

[0057] FIG. 6 is a structural view of a TFT-LCD, depicting the pixels arrange...

example 1 of embodiment 3

[0062] In Embodiment 3, in a temperature range in which the liquid crystal has a temperature between 73.degree. and 63.degree. (about 10 minutes at a cooling rate of 1.degree. / minute, the vicinity of the transition temperature from a higher temperature phase than chiral smectic C phase to the chiral smectic C phase) in the cooling process, a DC voltage of 5 V was applied to all the scanning lines (supply of a control voltage), a DC voltage of 4 V was applied to all the data lines (supply of a pixel voltage), and a voltage of 0 V was applied to the common electrode (common electrode line). Note that a pixel substrate potential equalizing line (Lds) for connecting the scanning lines and the data lines and a potential equalizing line between substrates (Ldsc) for connecting the pixel substrate potential equalizing line (Lds) and a common electrode line (Lc) are disconnected beforehand. Since the application of voltage as an alignment treatment is performed before installing (connecting...

PUM

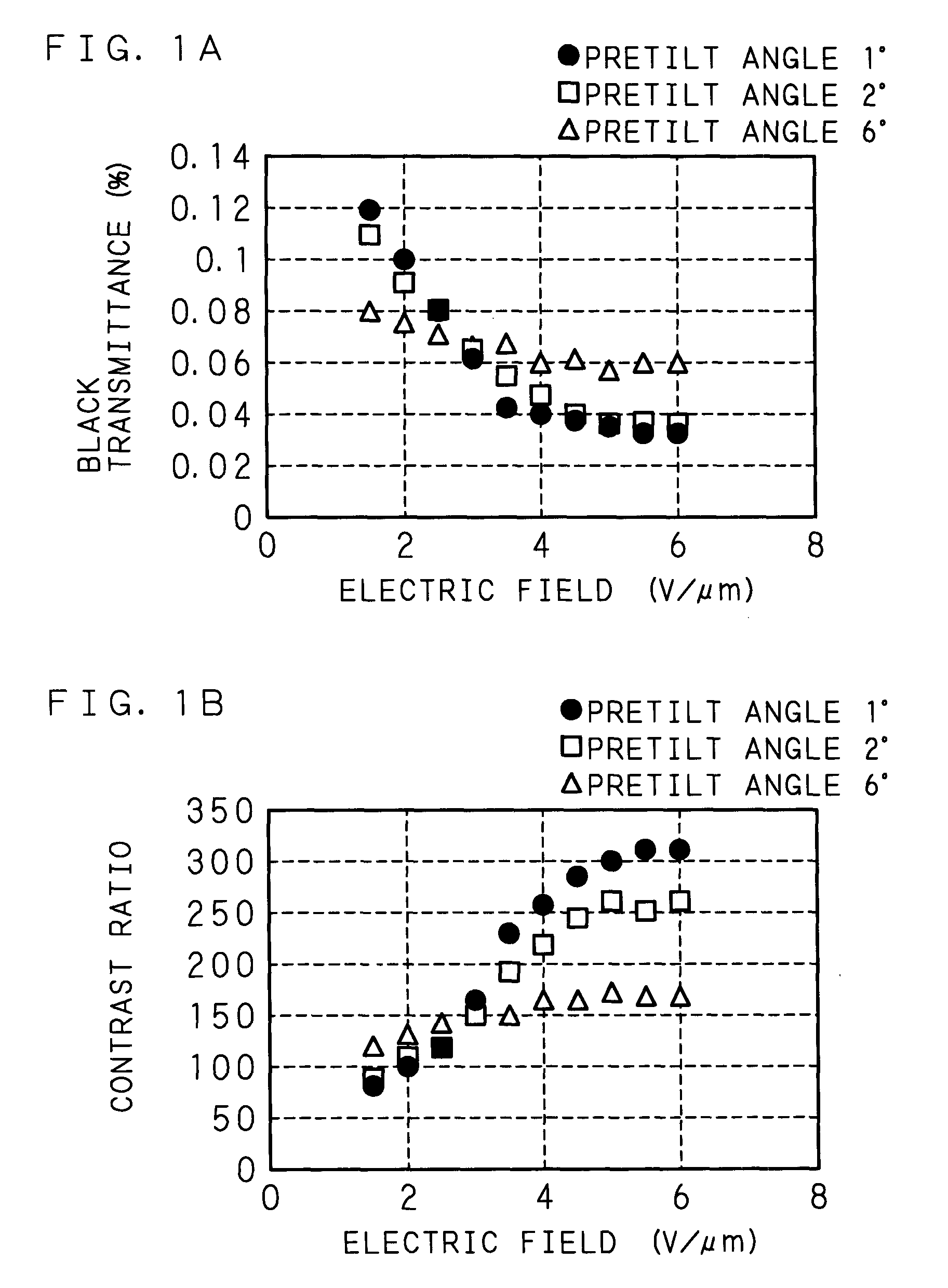

| Property | Measurement | Unit |

|---|---|---|

| electric field strength | aaaaa | aaaaa |

| electric field | aaaaa | aaaaa |

| pretilt angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap