Magnetic head assembly having a rotational arm for electrically connecting the magnetic head to an external circuit and methods of manufacturing the same

a magnetic head and head assembly technology, applied in the direction of maintaining the head carrier alignment, recording information storage, instruments, etc., can solve the problems of complex connection operation, defects in connection, and inability to work with the connection condition observed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

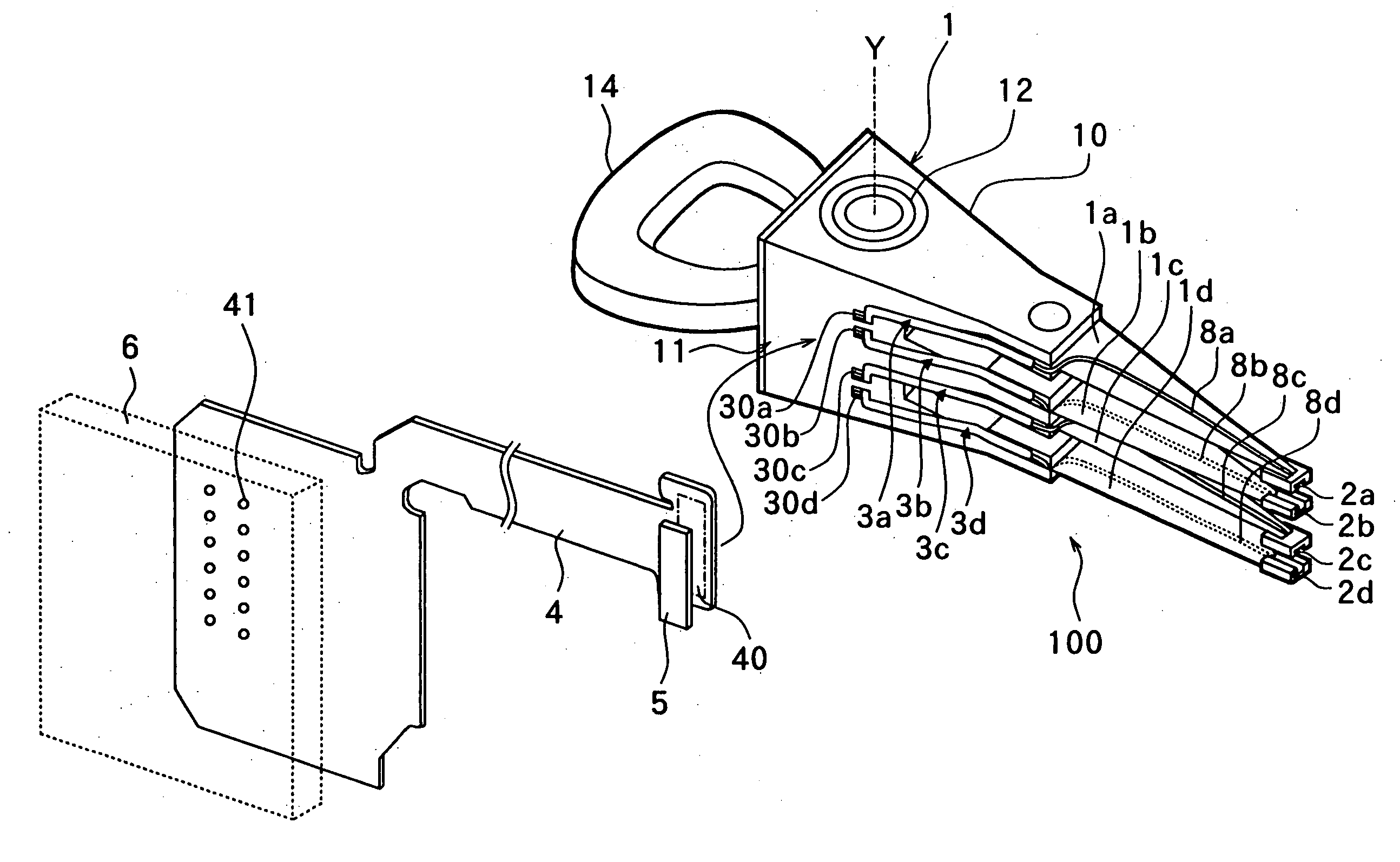

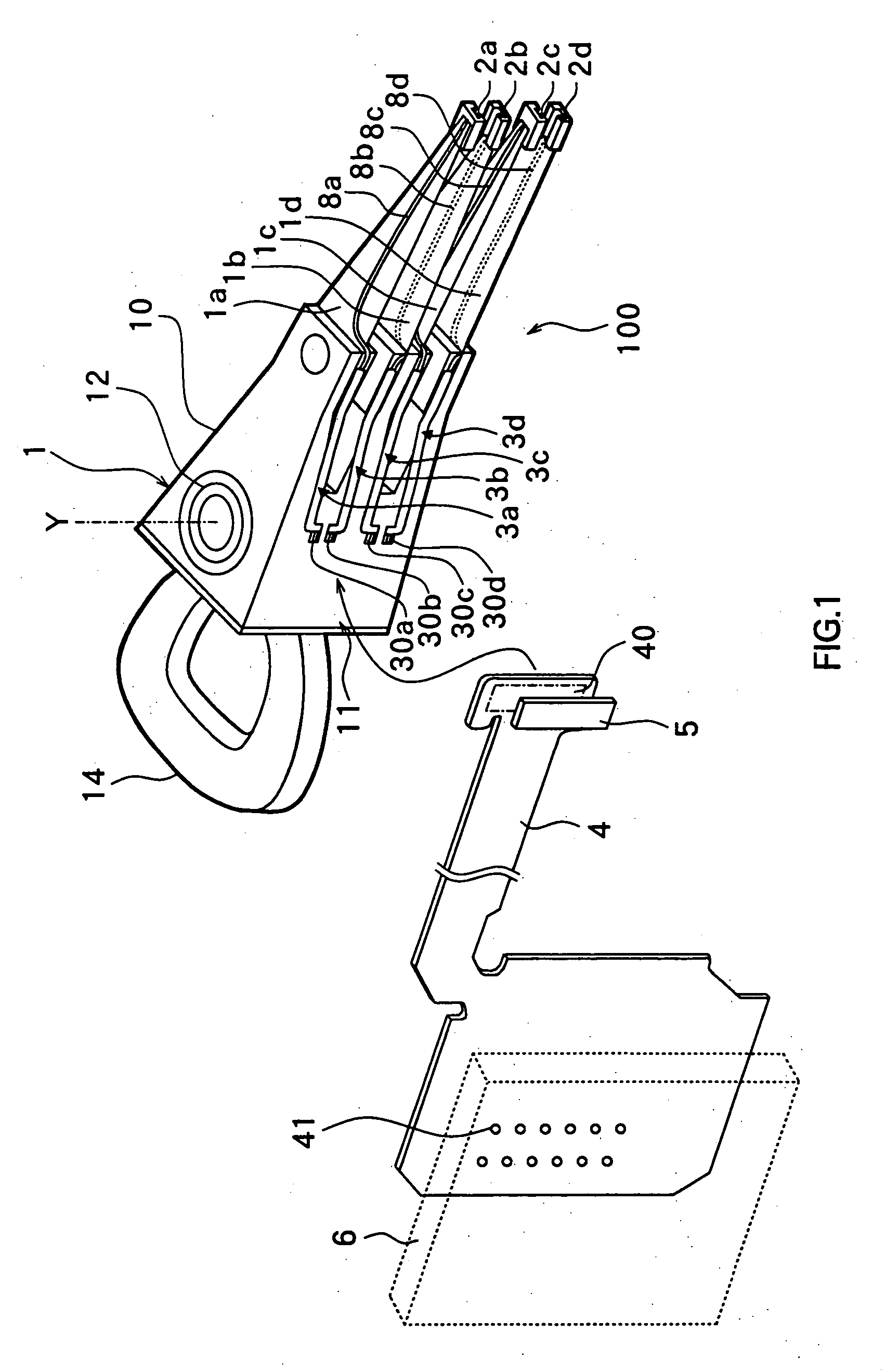

[0060] As described above, according to the method of wiring a magnetic head assembly of this embodiment, the connecting portion 40 of the external side FPC board 4 and the connecting terminals 30a to 30d of the relay FPC boards 3a to 3d are overlapped and fixed by the anisotropic conductive tape 5. This enables to connect a plurality of wirings of both connecting portions in a single step. As a result, defects in connection are reduced and connecting process is simplified as compared to the individual connection by each wiring. This also prevents peeling of gold plate formed on, for example, the external side FPC board 4 without using ultrasonic welding. The connecting portion 40 of the external side FPC board 4 is connected to the connecting terminals 30a to 30d of the relay FPC board 3a to 3d on the side 11 of the arm body 10. This enables to operate with observing the connecting condition and therefore the workability is improved.

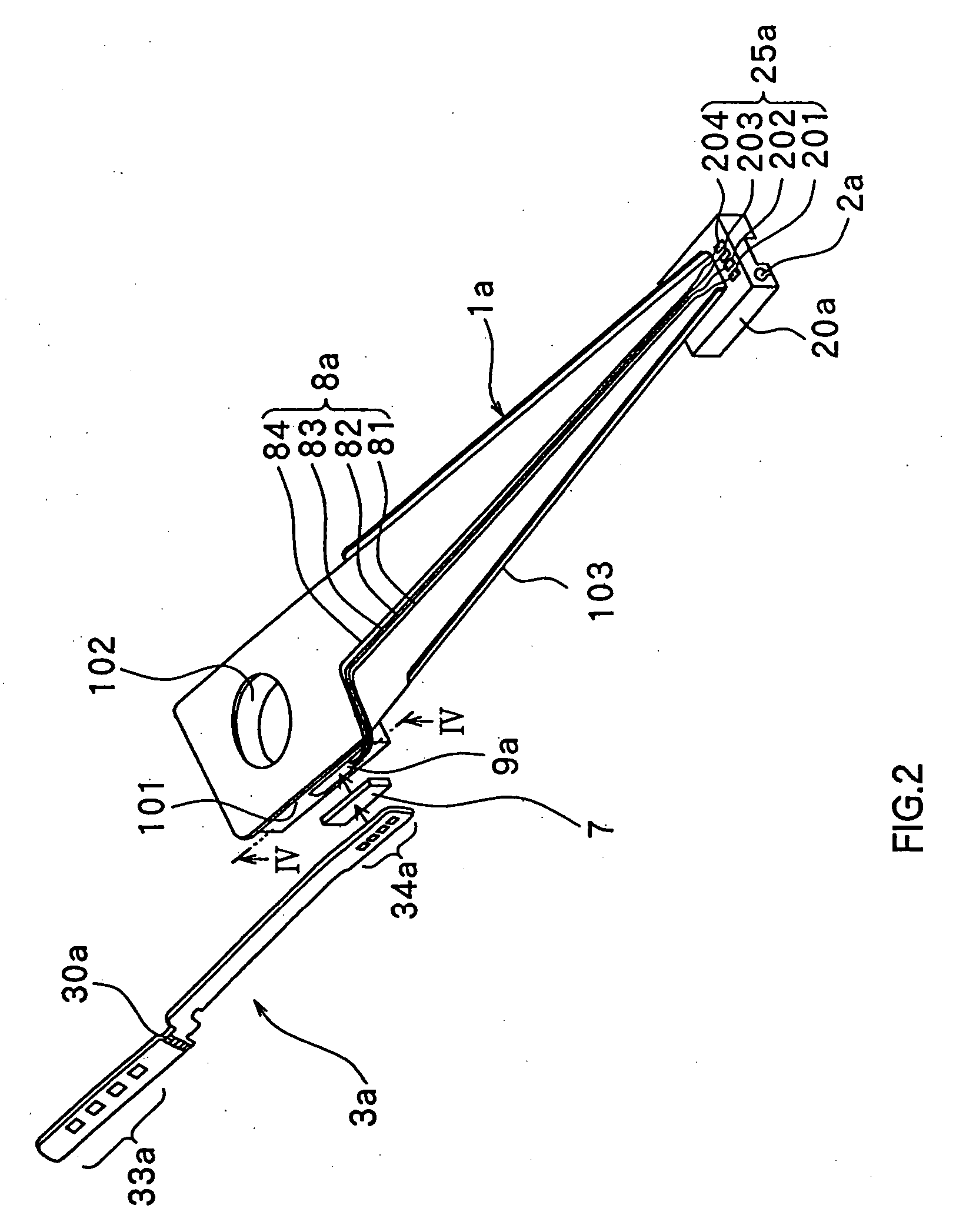

[0061] The relay terminals 34a to 34d of the rela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap