Patents

Literature

244results about "Electrical connection between arm and support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

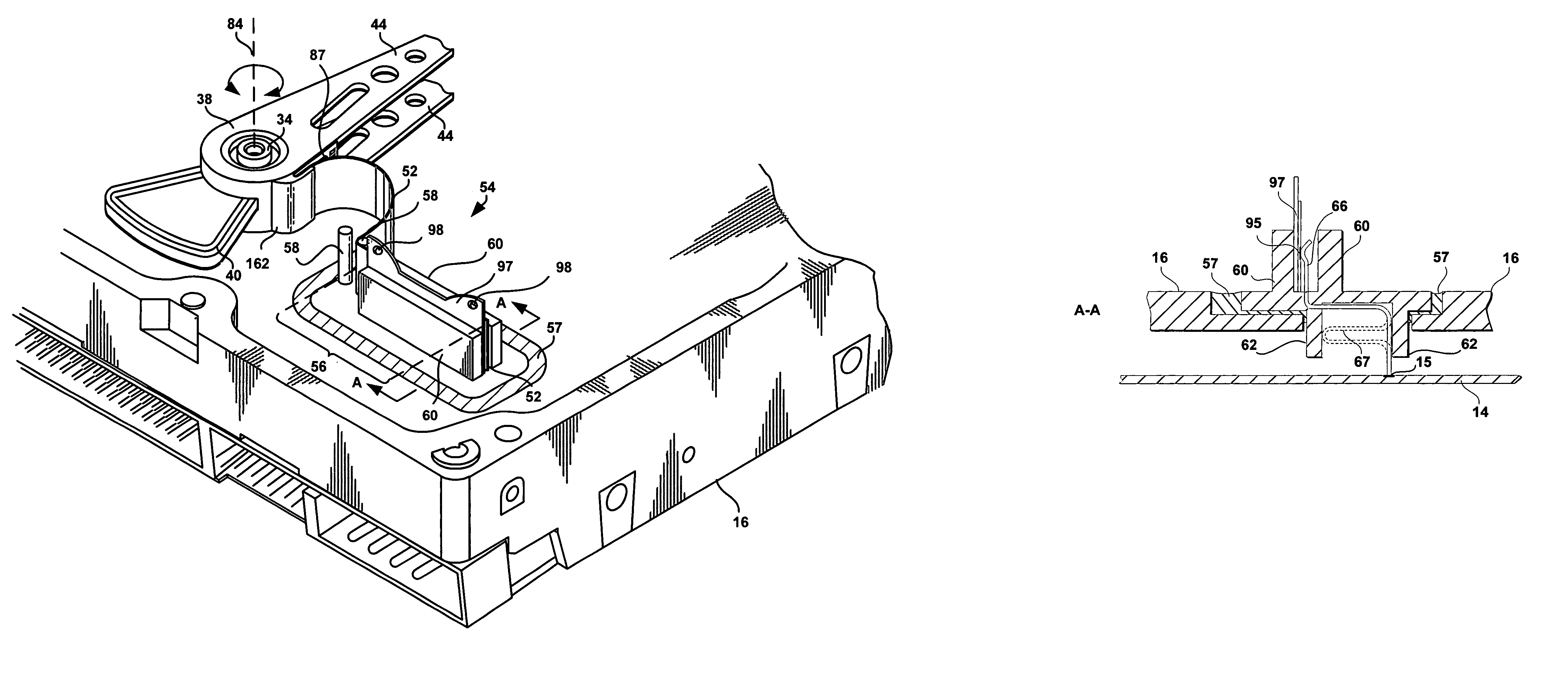

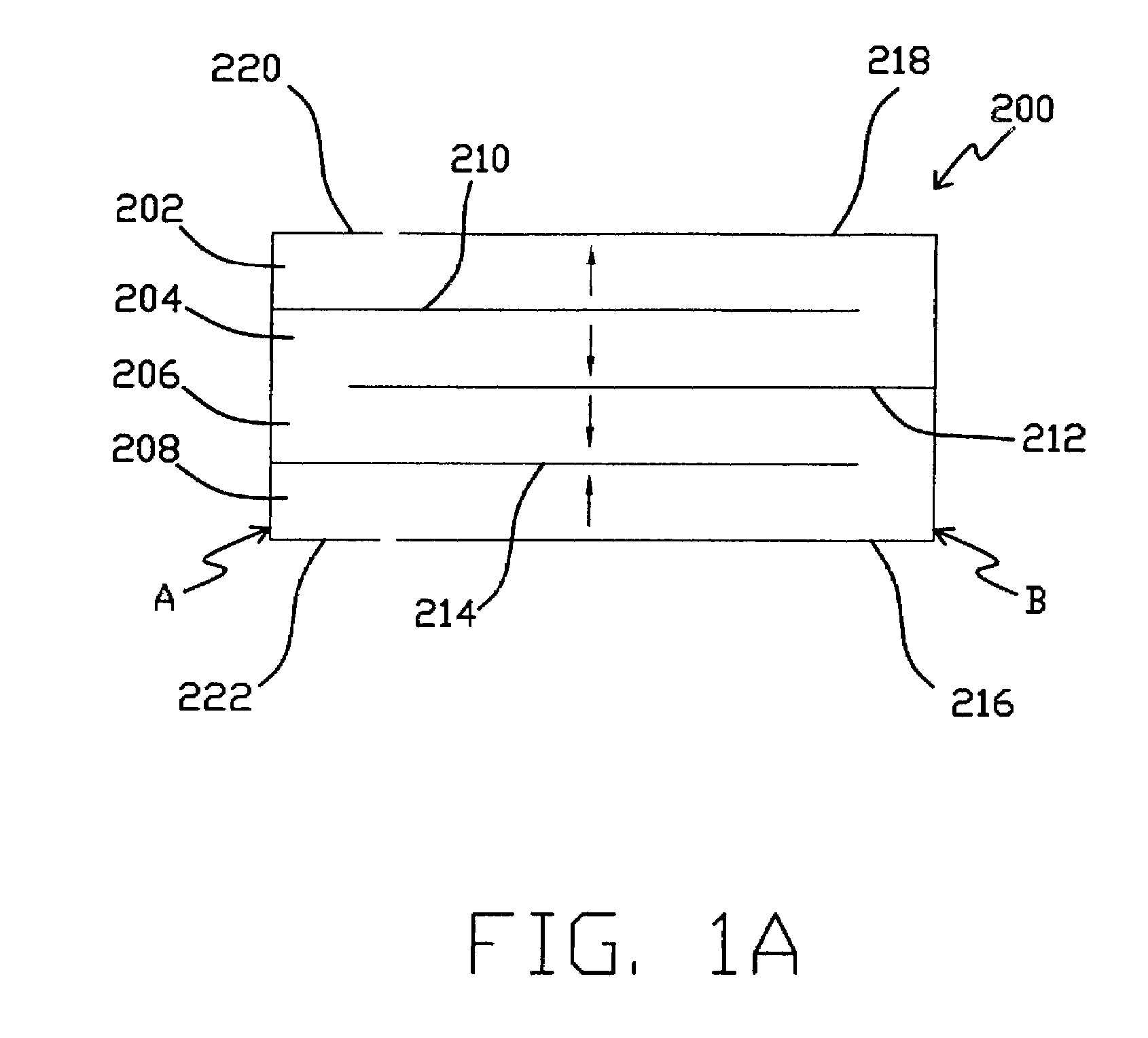

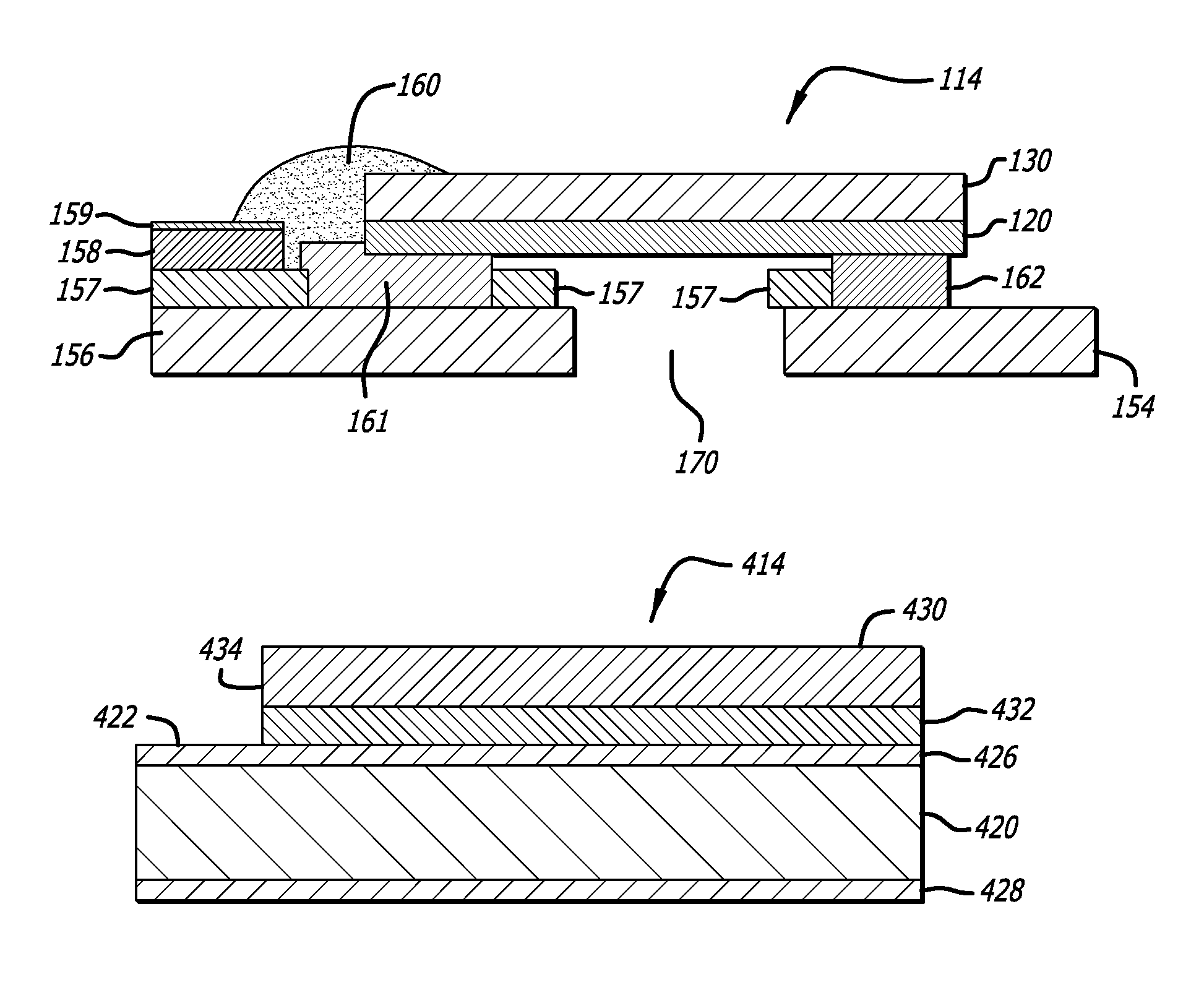

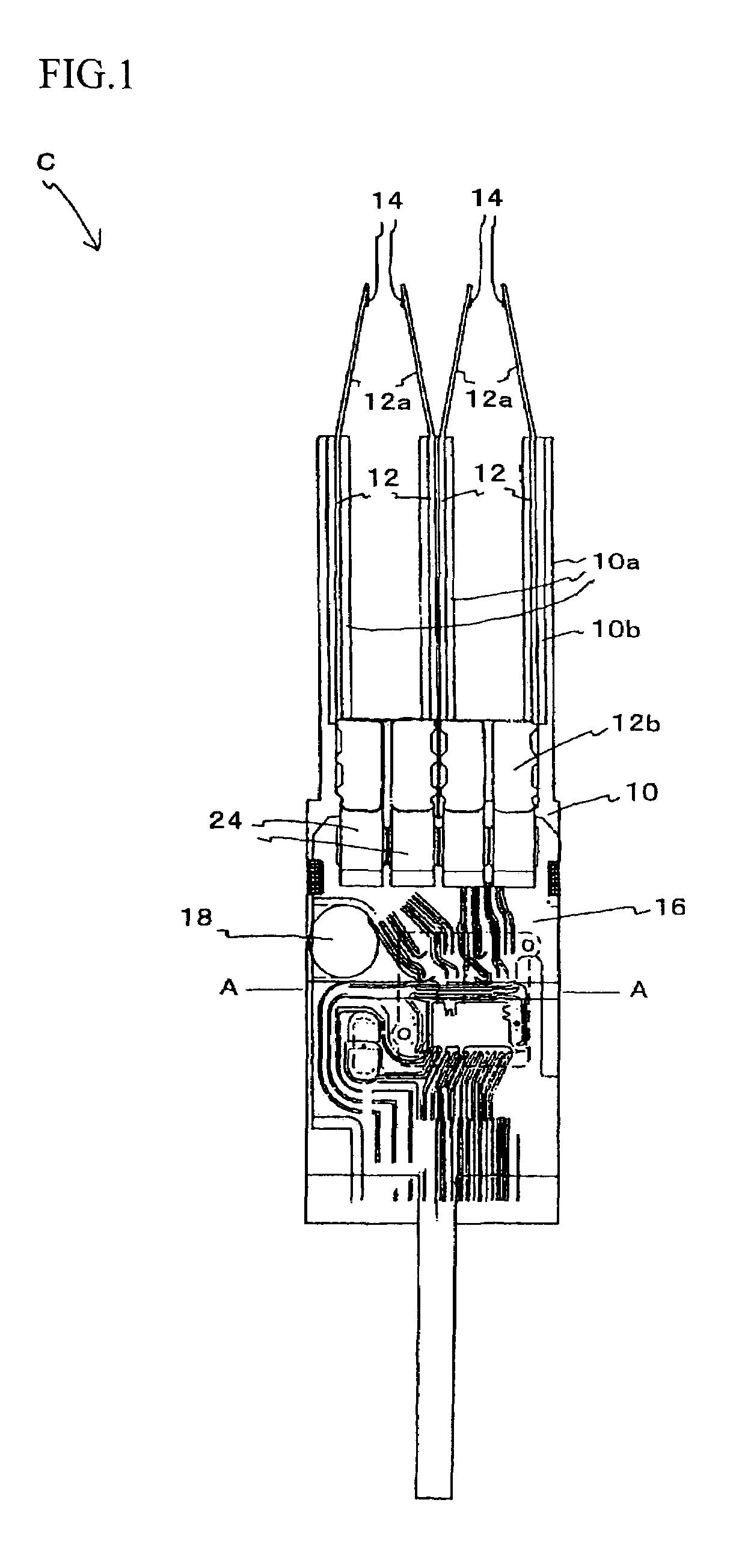

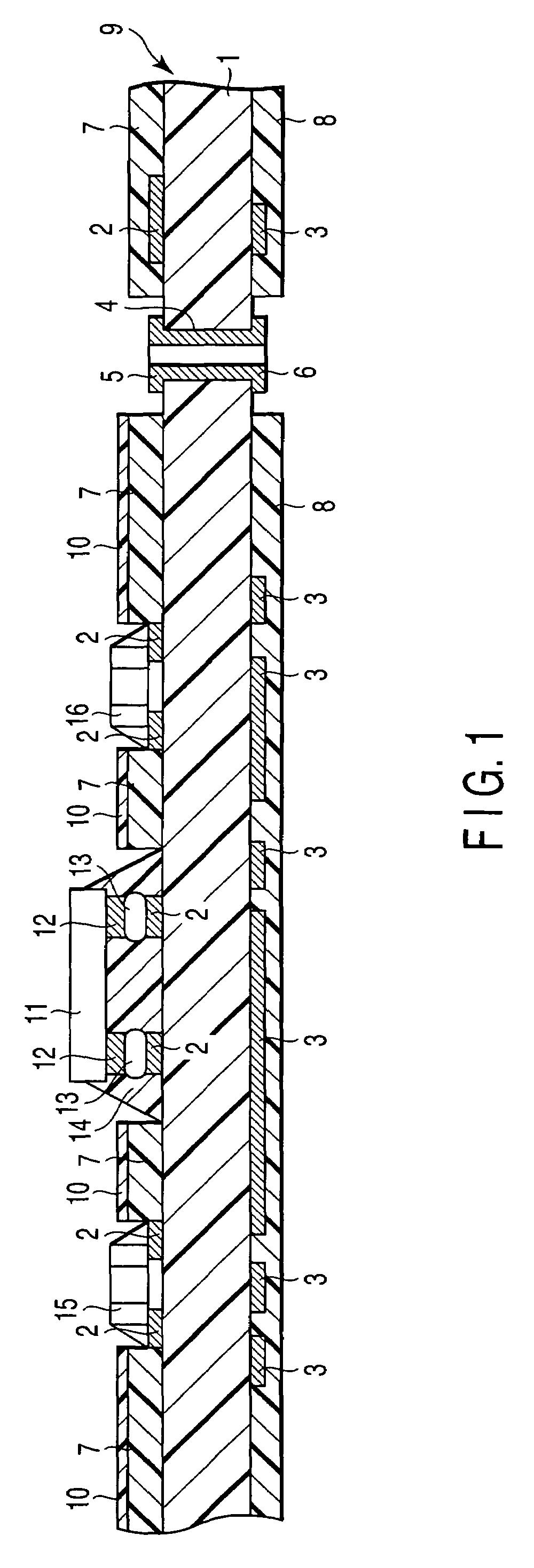

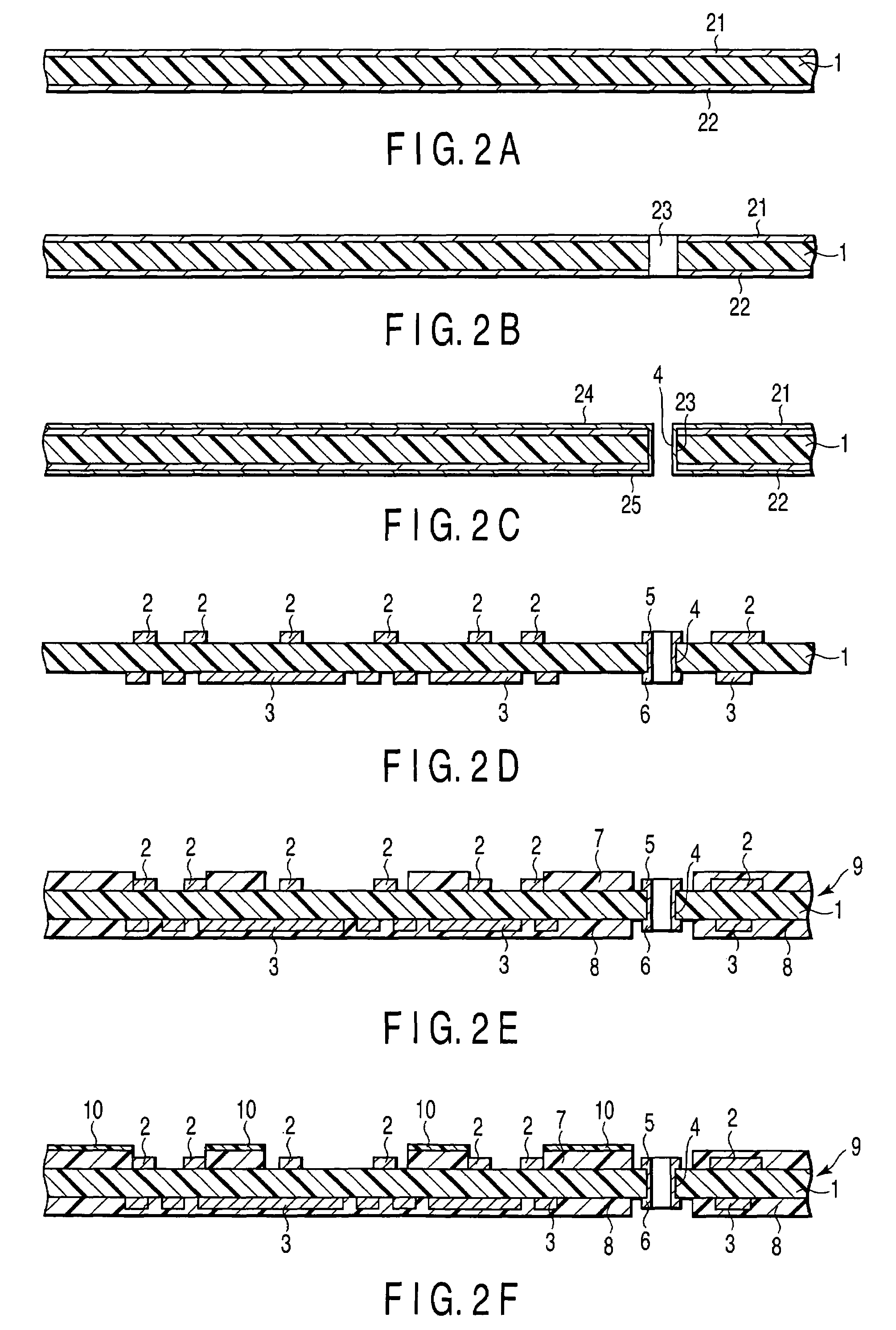

Electrical connecting structure for piezoelectric element, piezoelectric actuator, head suspension, and electrical connecting structure for conductive part

ActiveUS20100067151A1Accurate wiringReliability is deterioratedArm with actuatorsPiezoelectric/electrostriction/magnetostriction machinesAdhesivePiezoelectric actuators

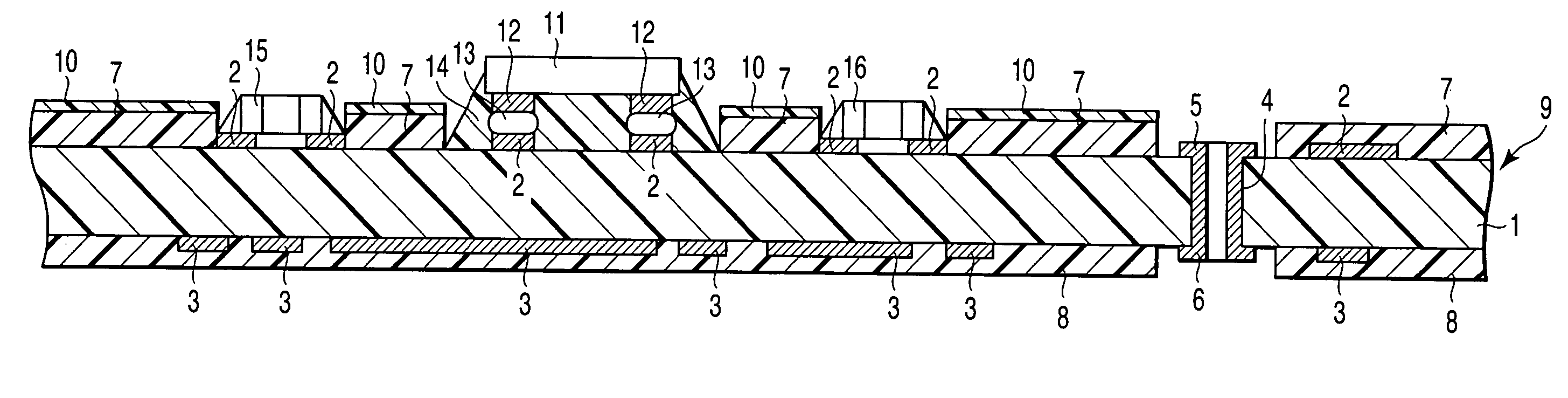

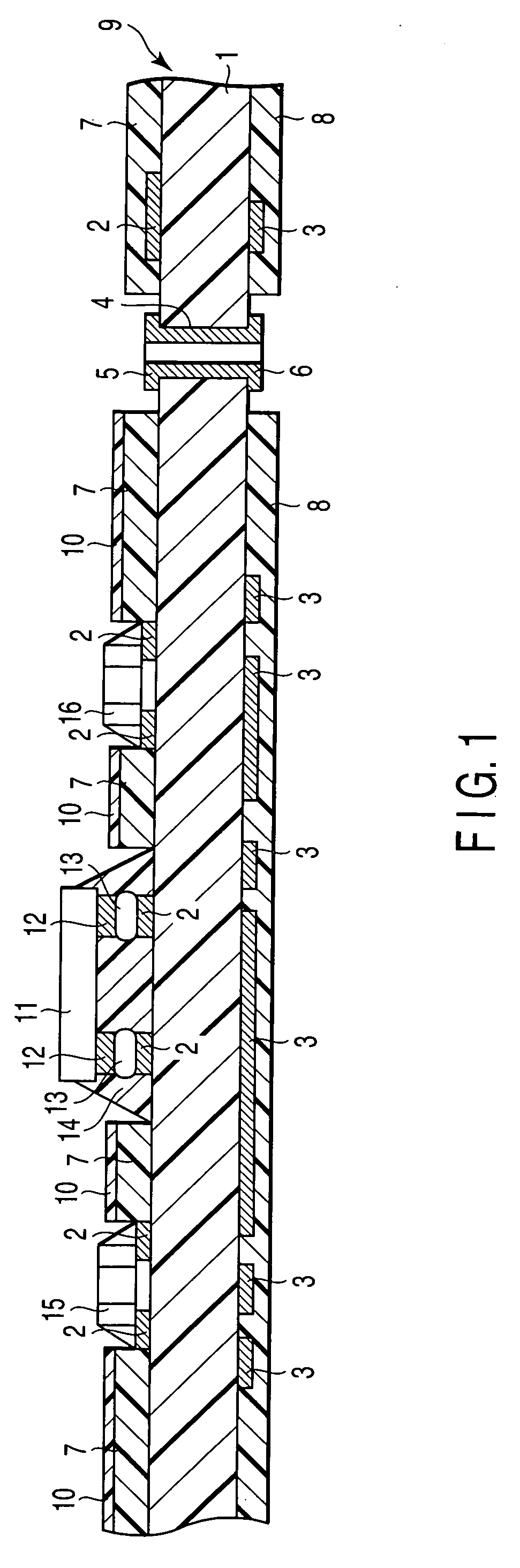

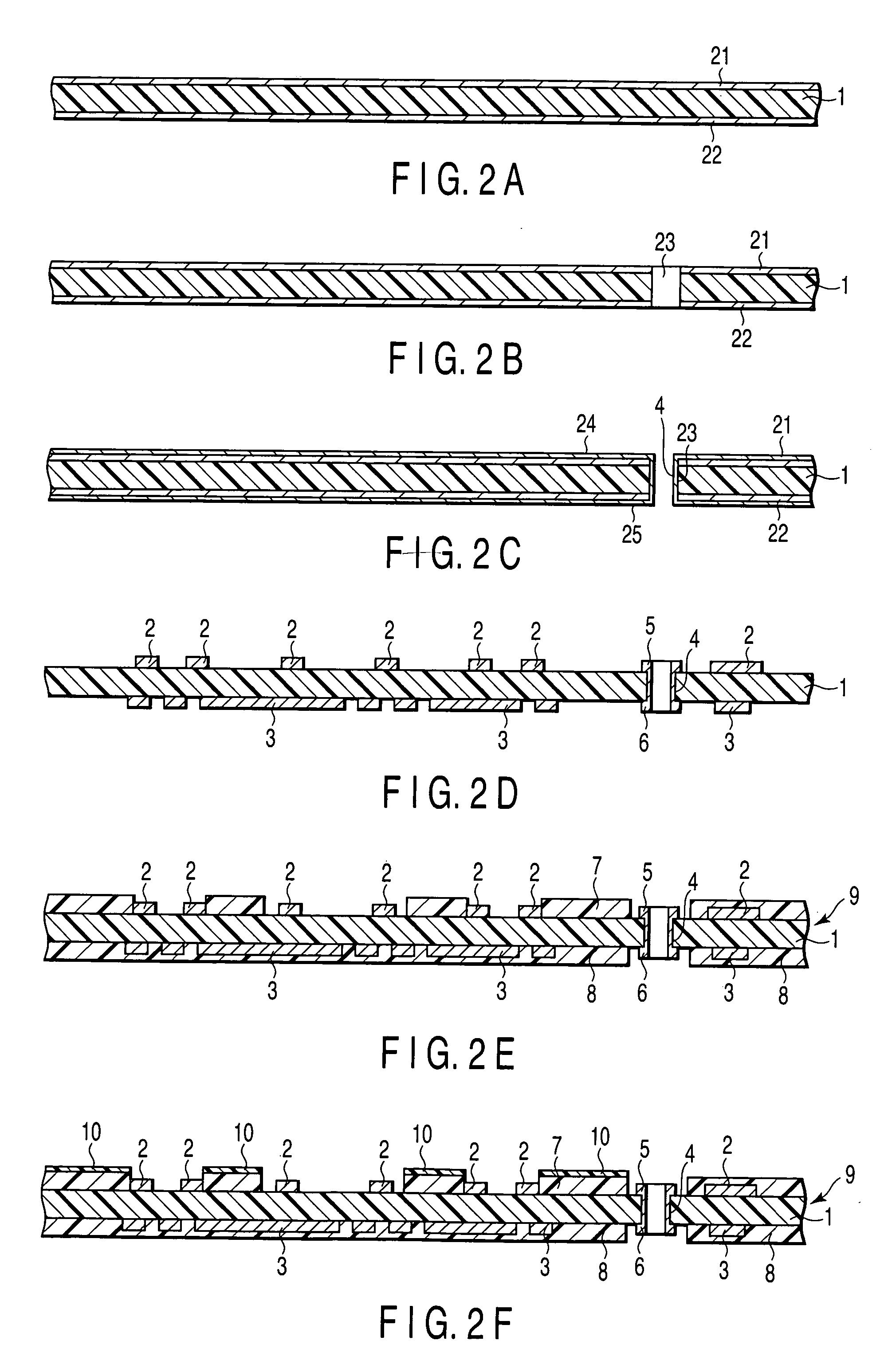

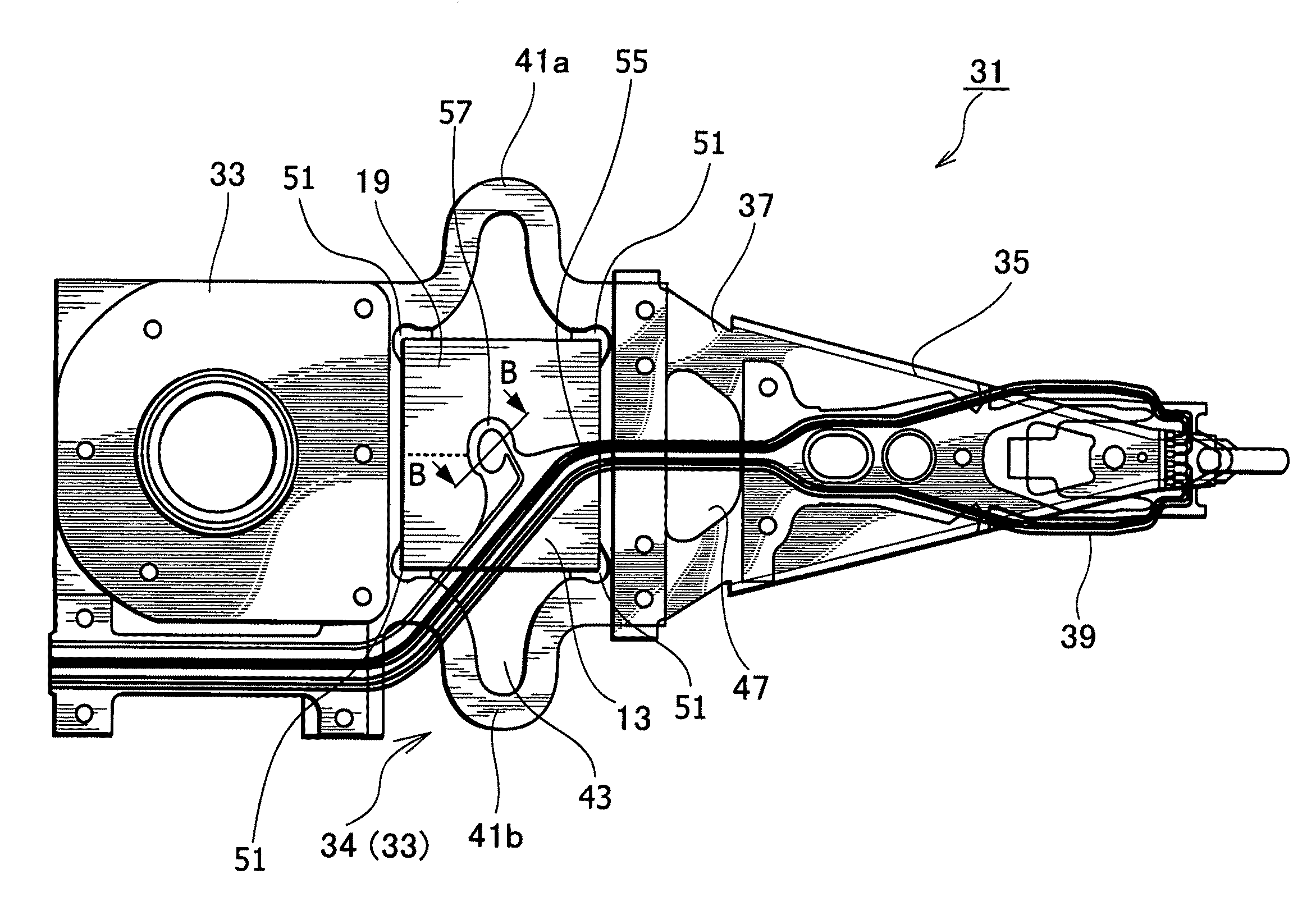

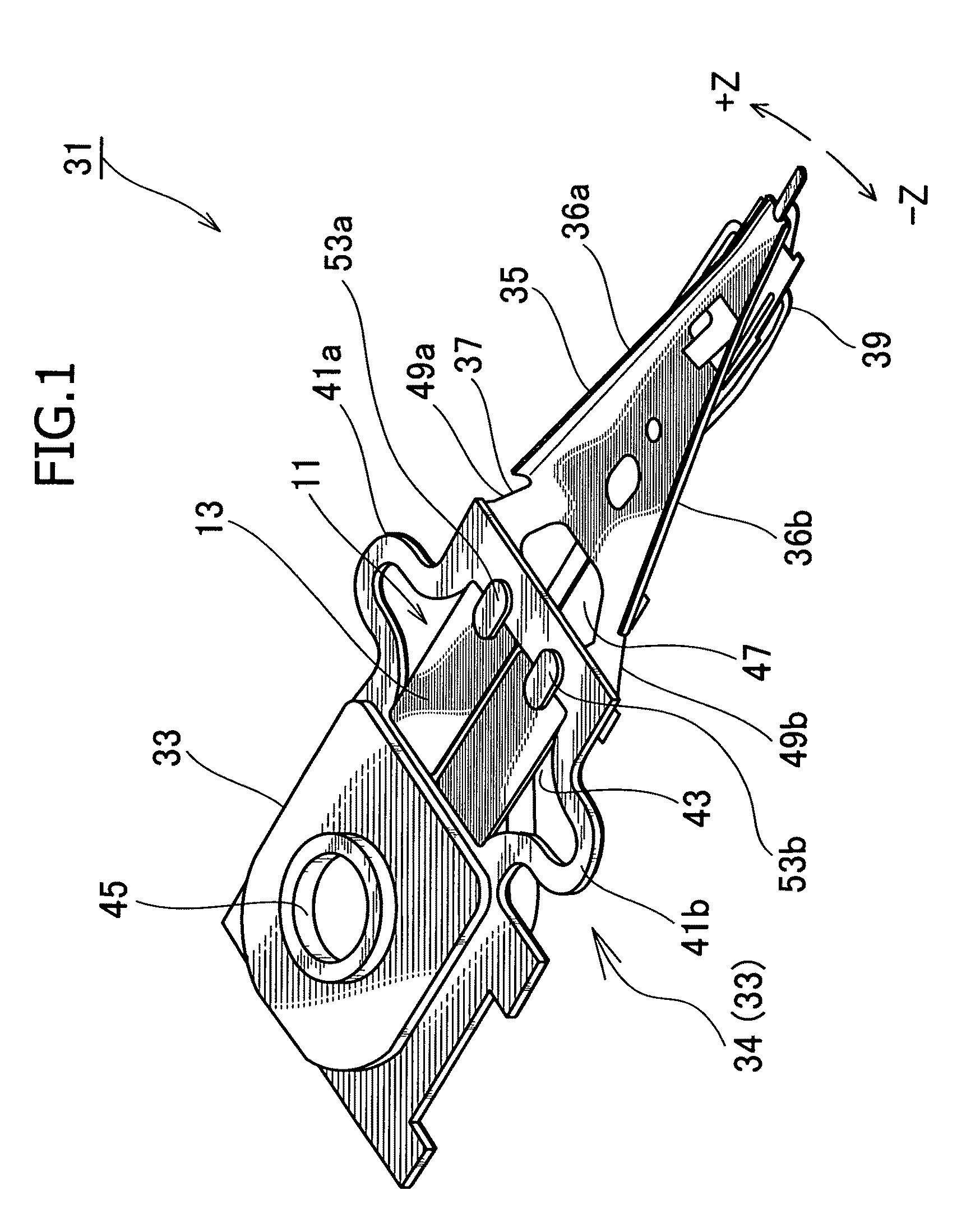

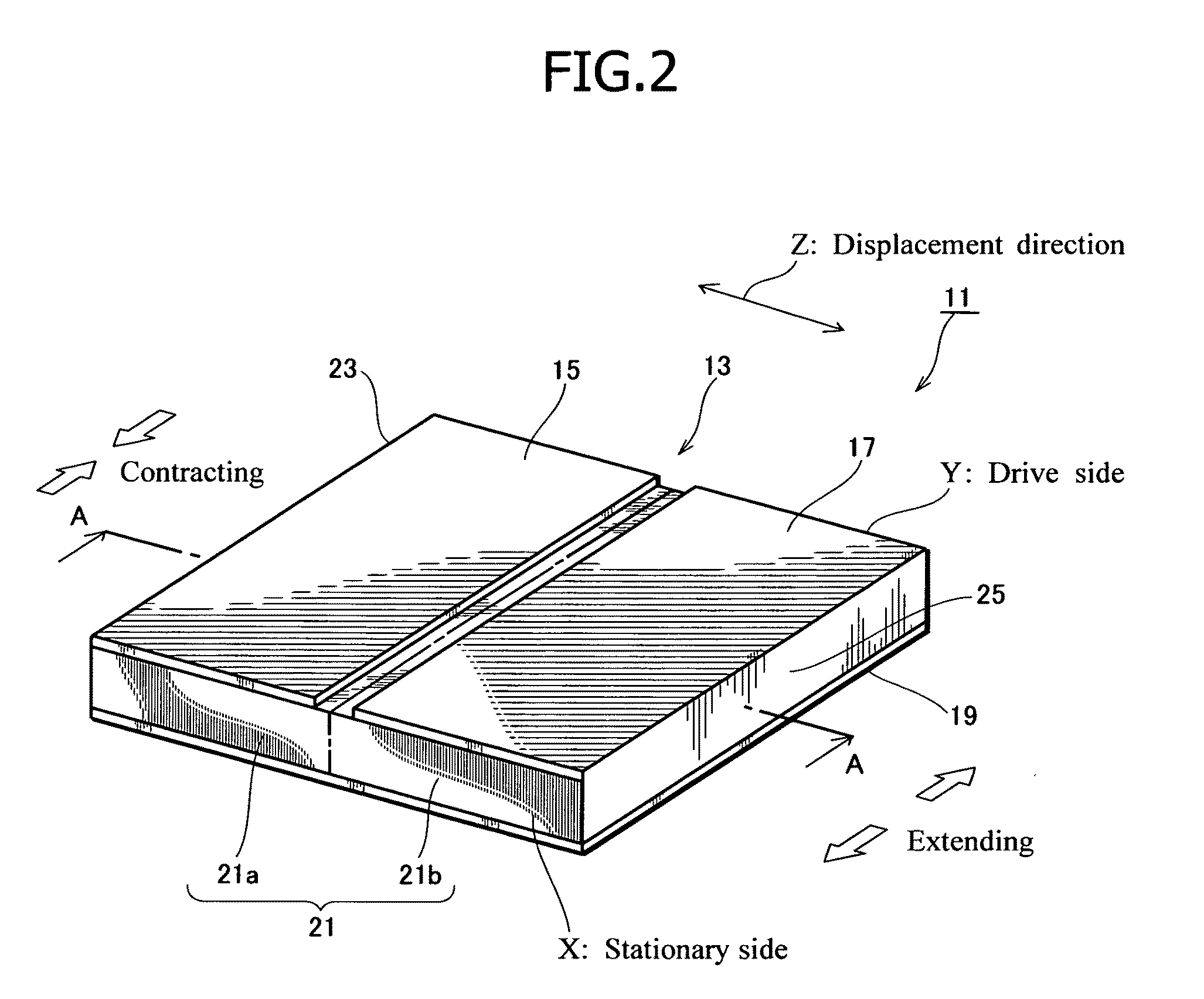

A piezoelectric element 13 has a common electrode 19 that receives electricity from a terminal 57. The terminal 57 has a through hole 67 and an electric insulating layer 61. The piezoelectric element 13 is arranged so that the common electrode 19 faces the electric insulating layer 61 of the terminal 57. A liquid stopper 69 is formed around the through hole 67 so as to come between the common electrode 19 and the terminal 57 when the common electrode 19 and terminal 57 are set to face each other. A liquid conductive adhesive 71 is injected into the through hole 67 to fill a gap defined by the liquid stopper 69 between the terminal 57 and the common electrode 19 and secure electric connection between the terminal 57 and the common electrode 19. This configuration improves the reliability of wiring to the piezoelectric element and prevents the piezoelectric element from being damaged.

Owner:NHK SPRING CO LTD

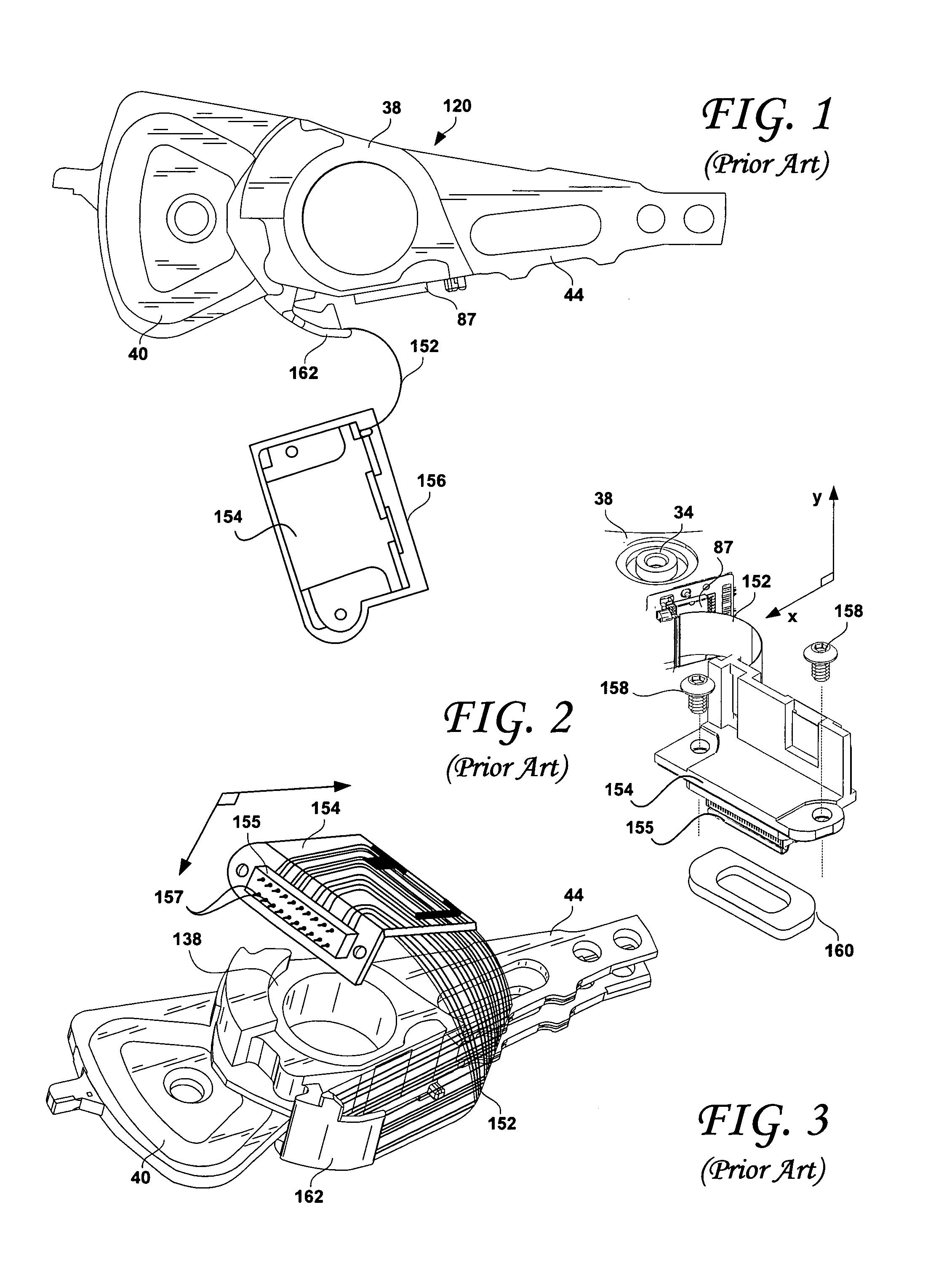

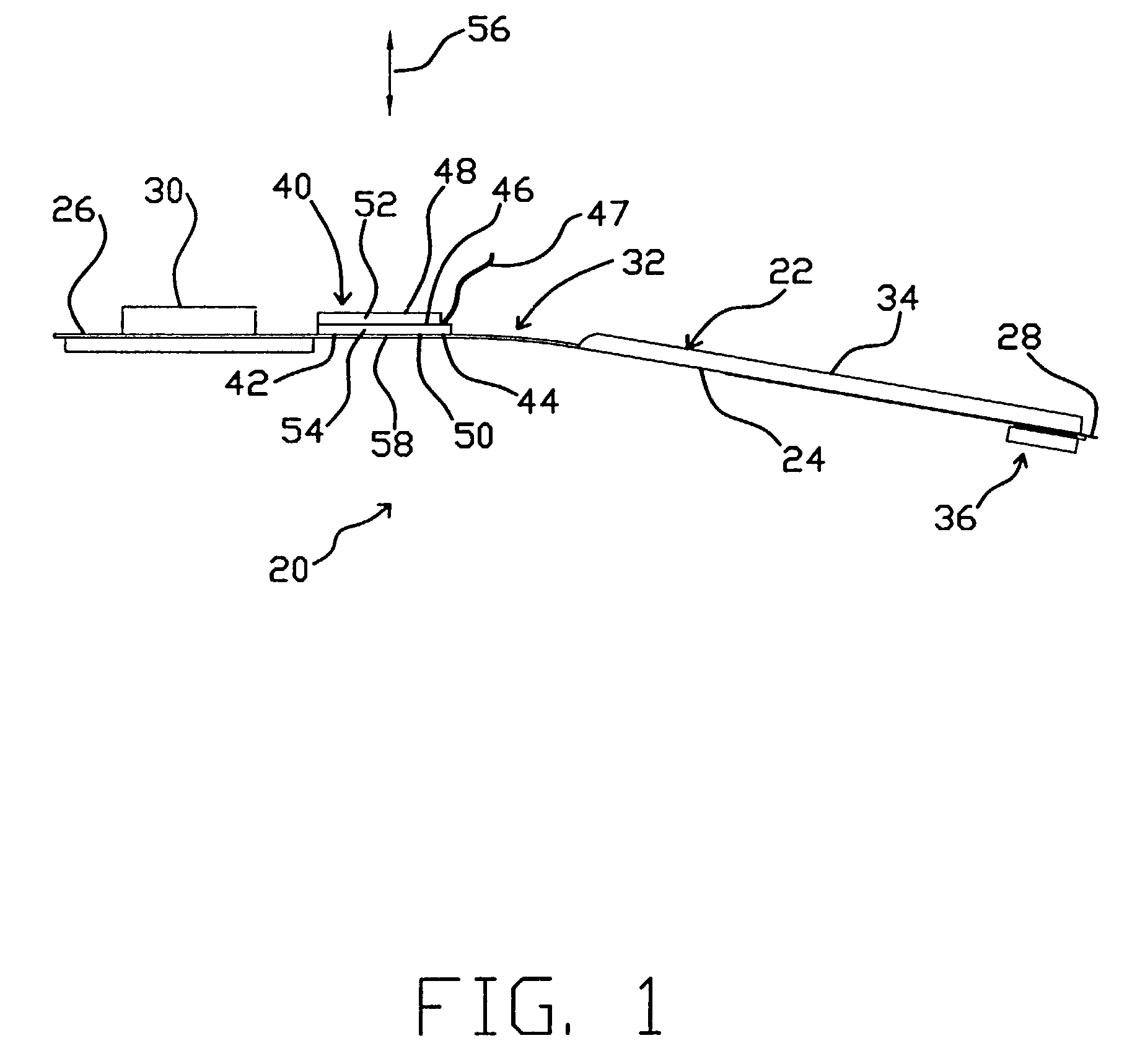

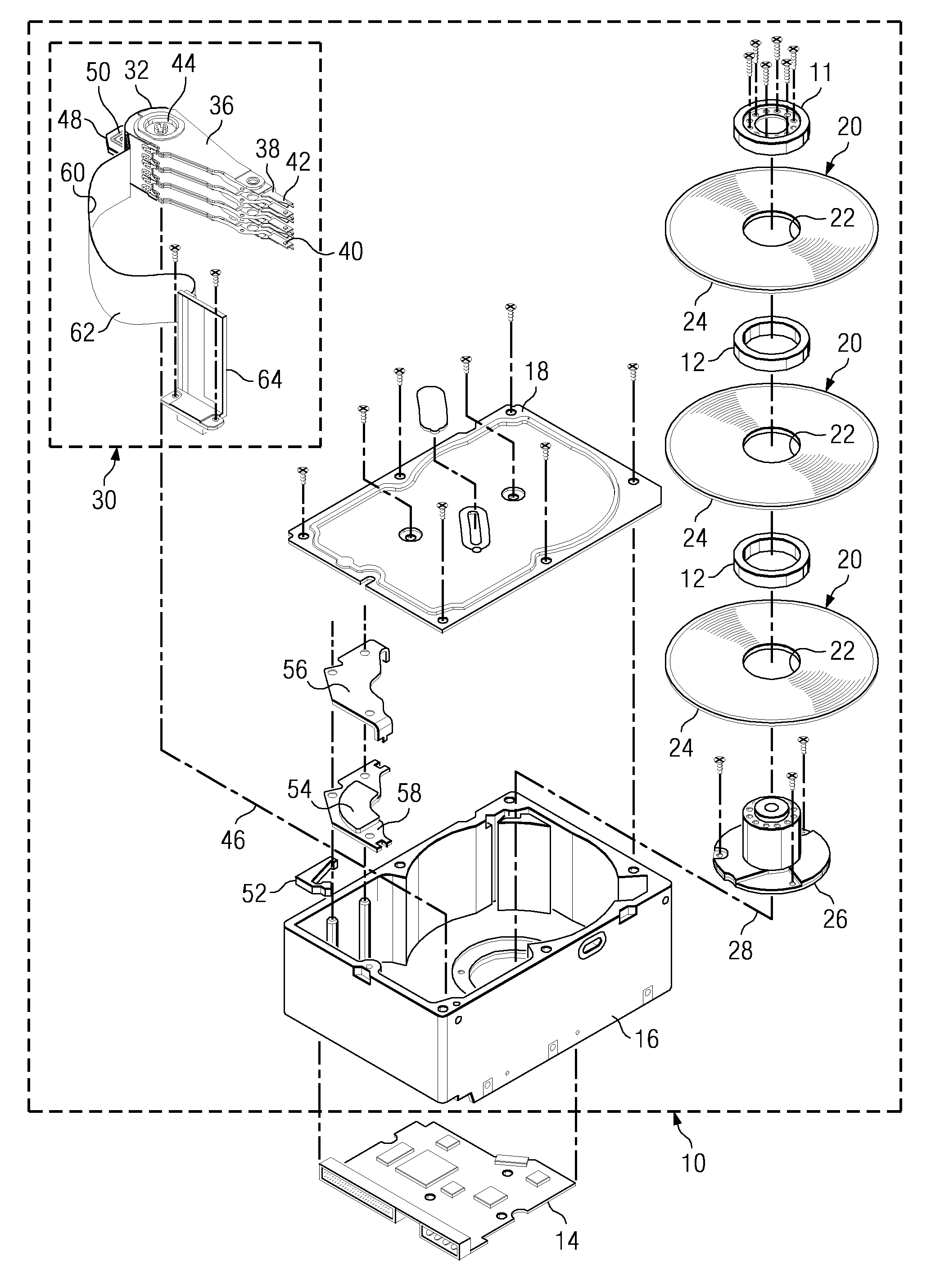

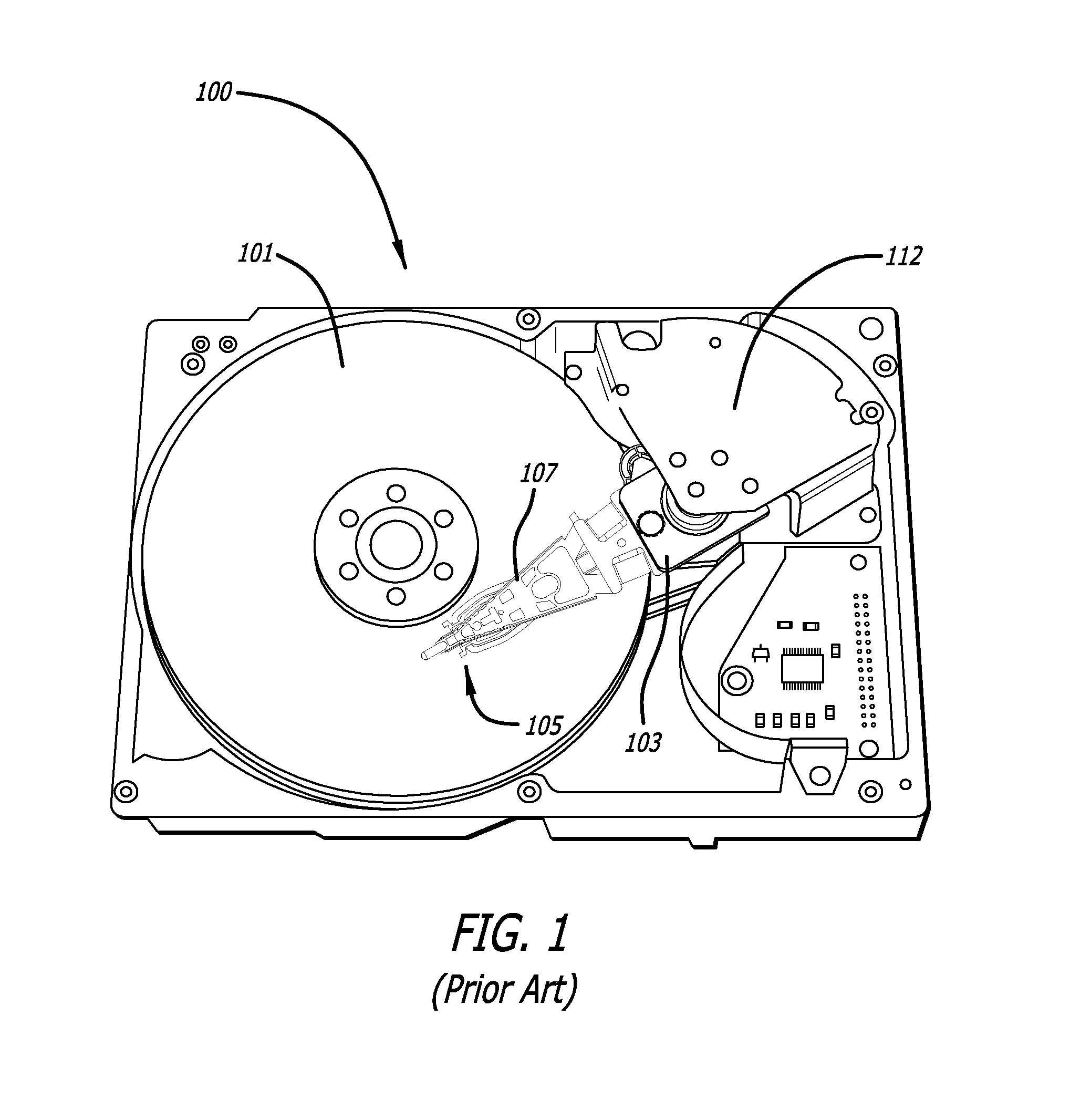

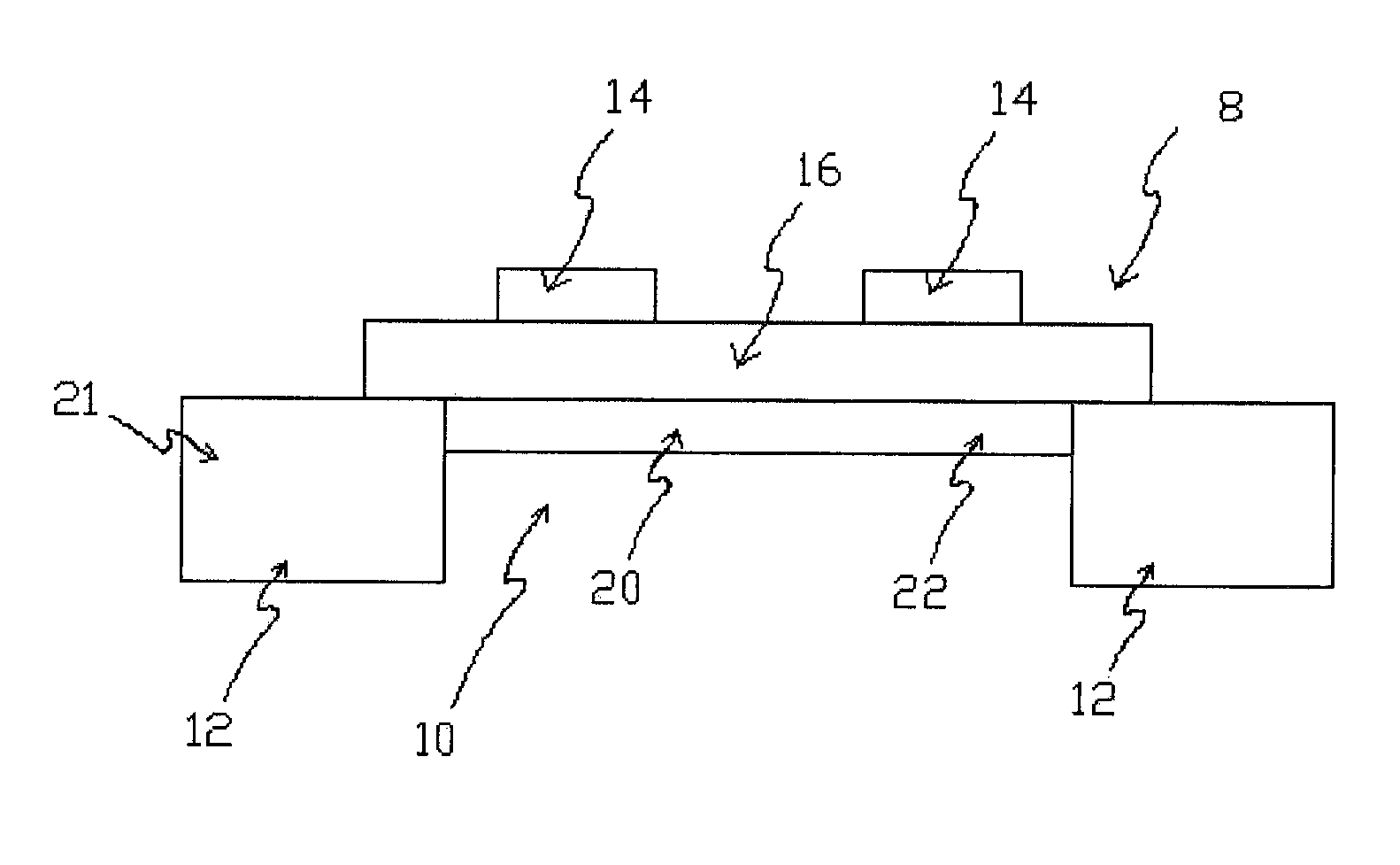

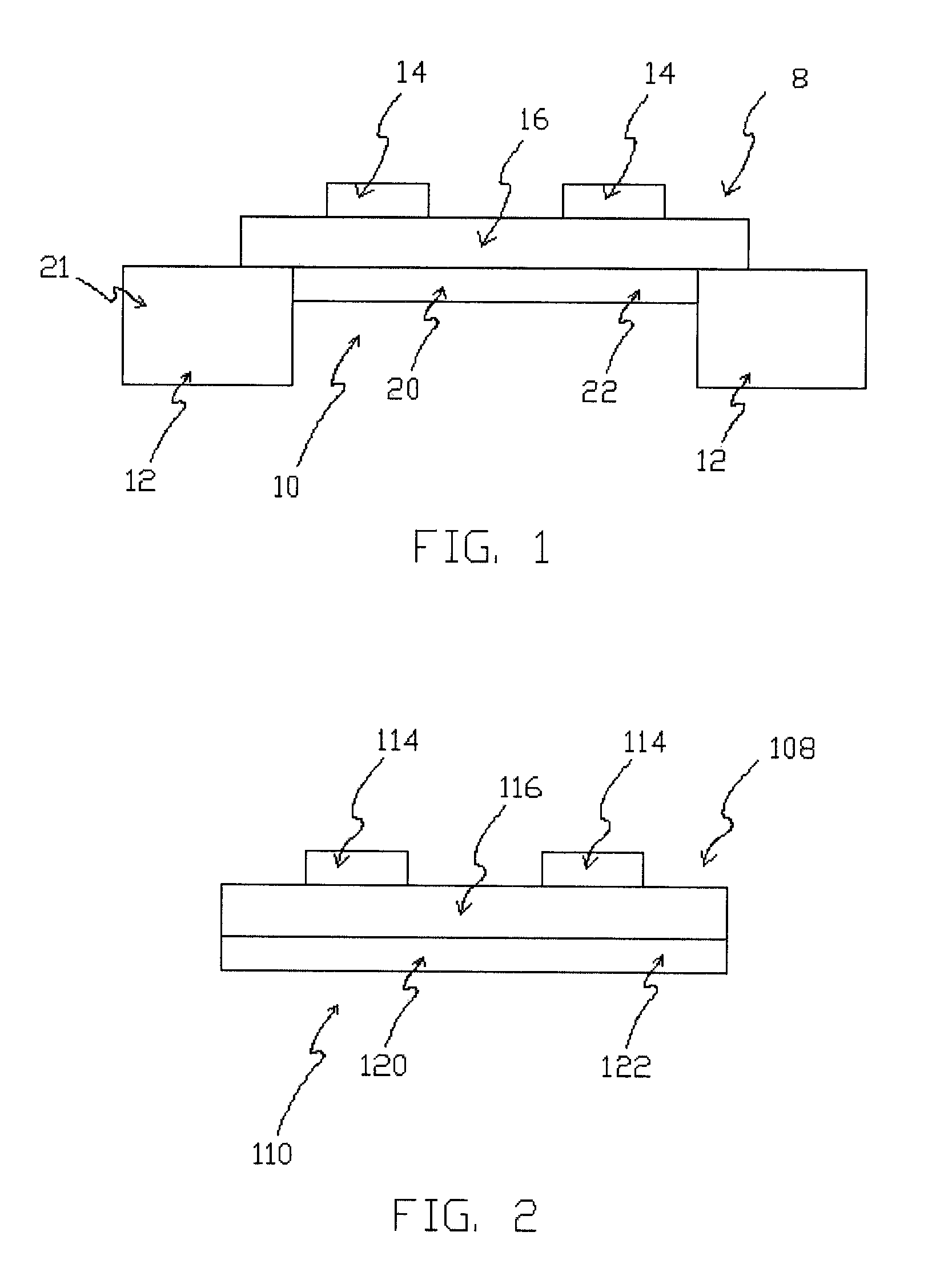

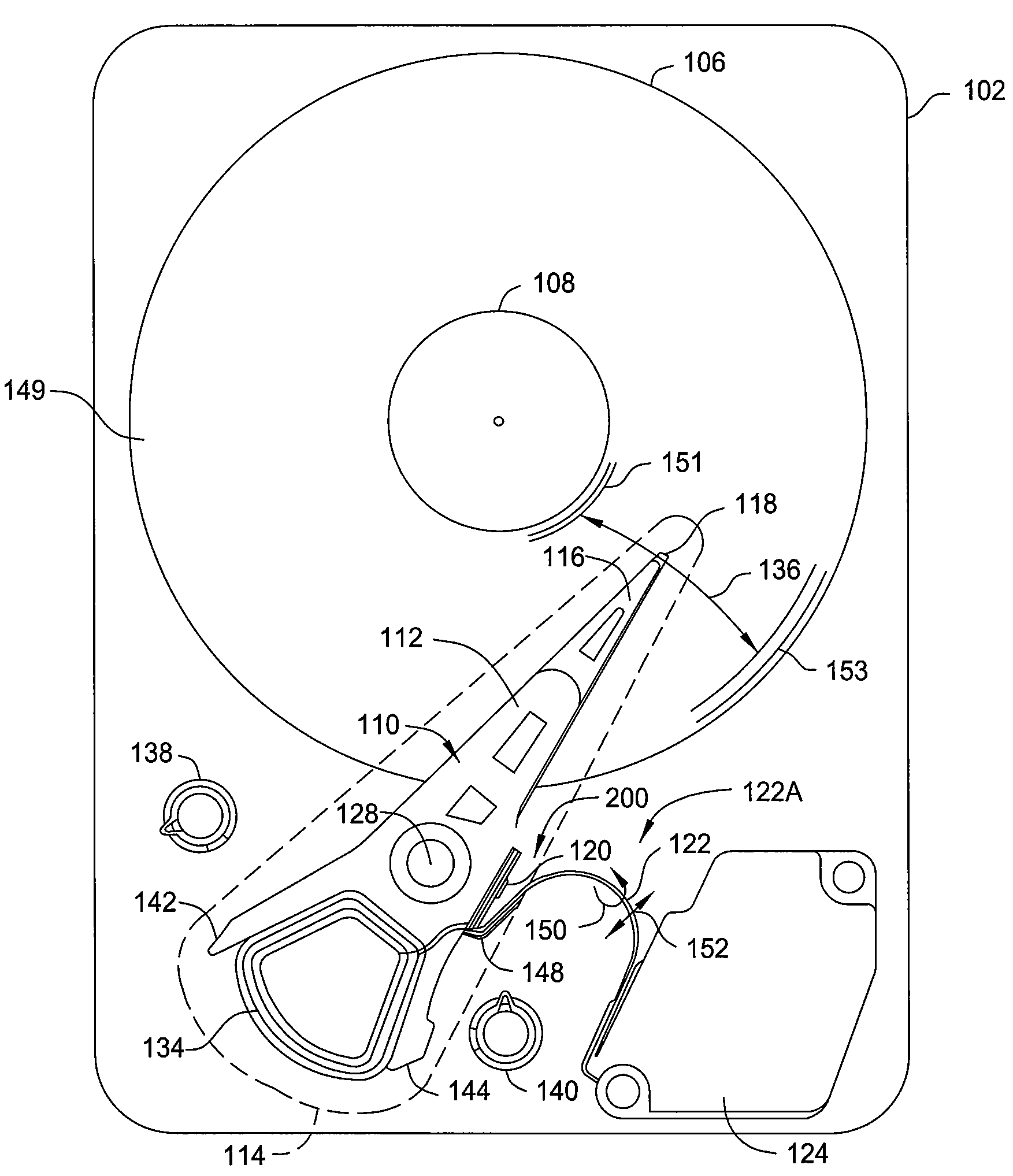

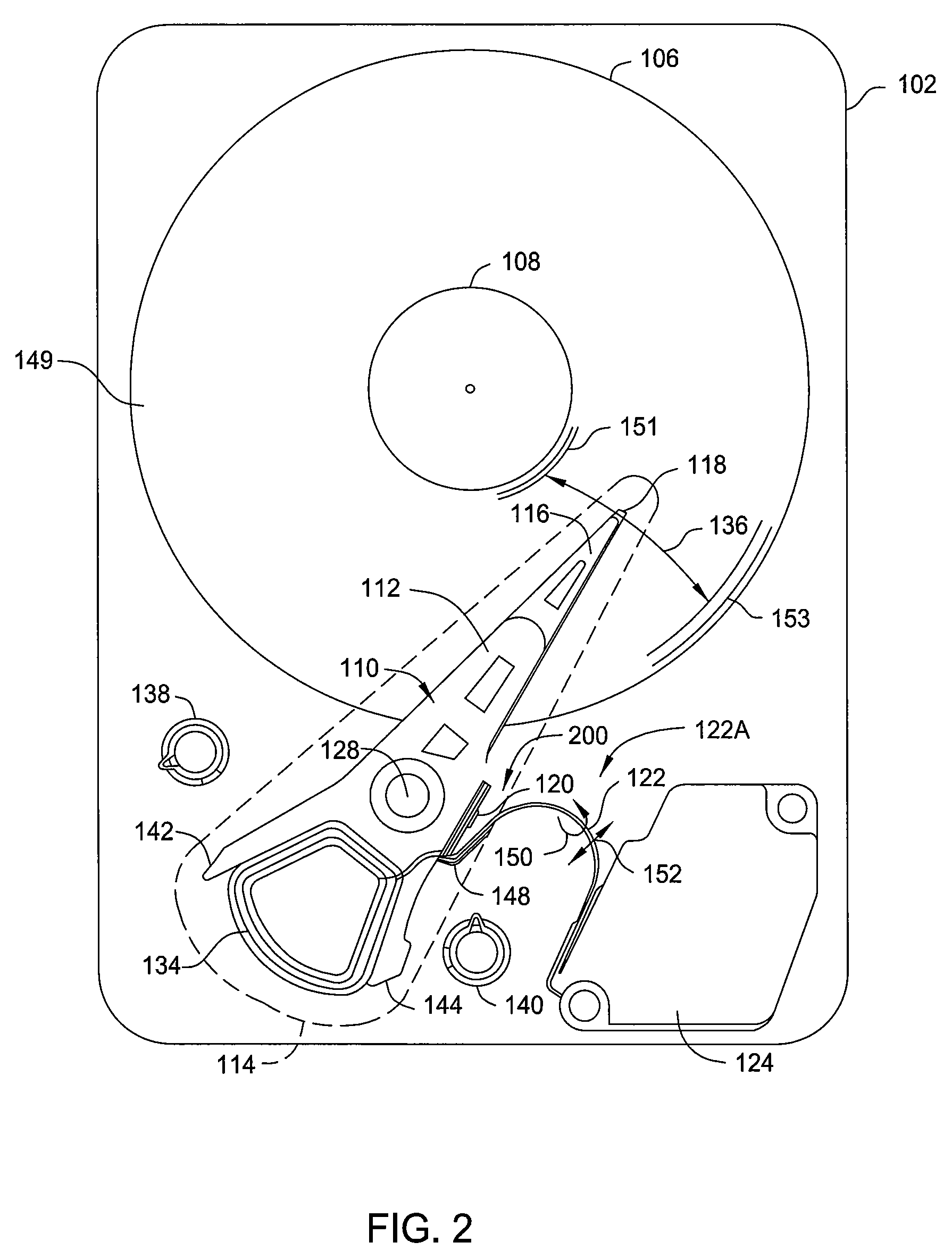

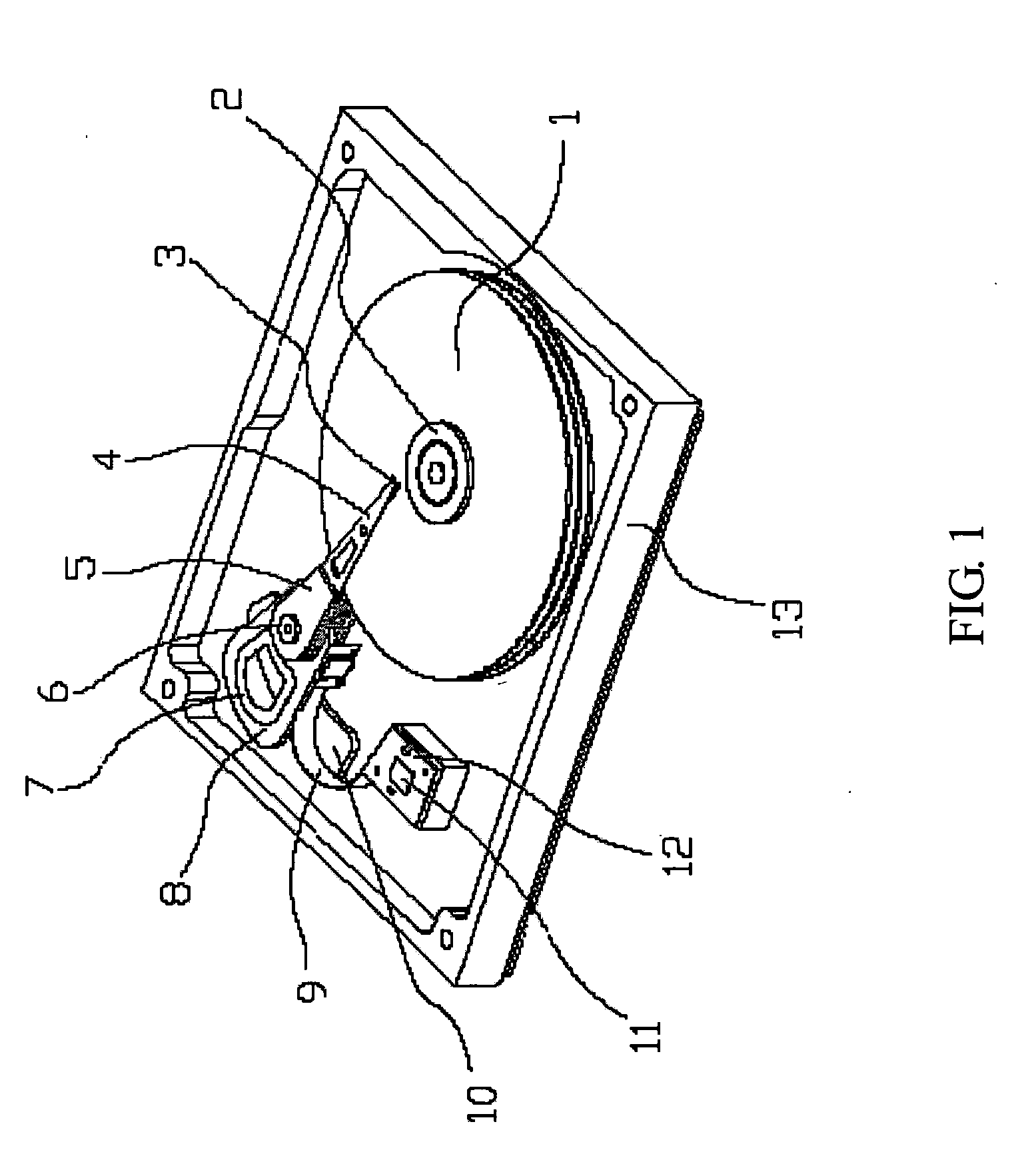

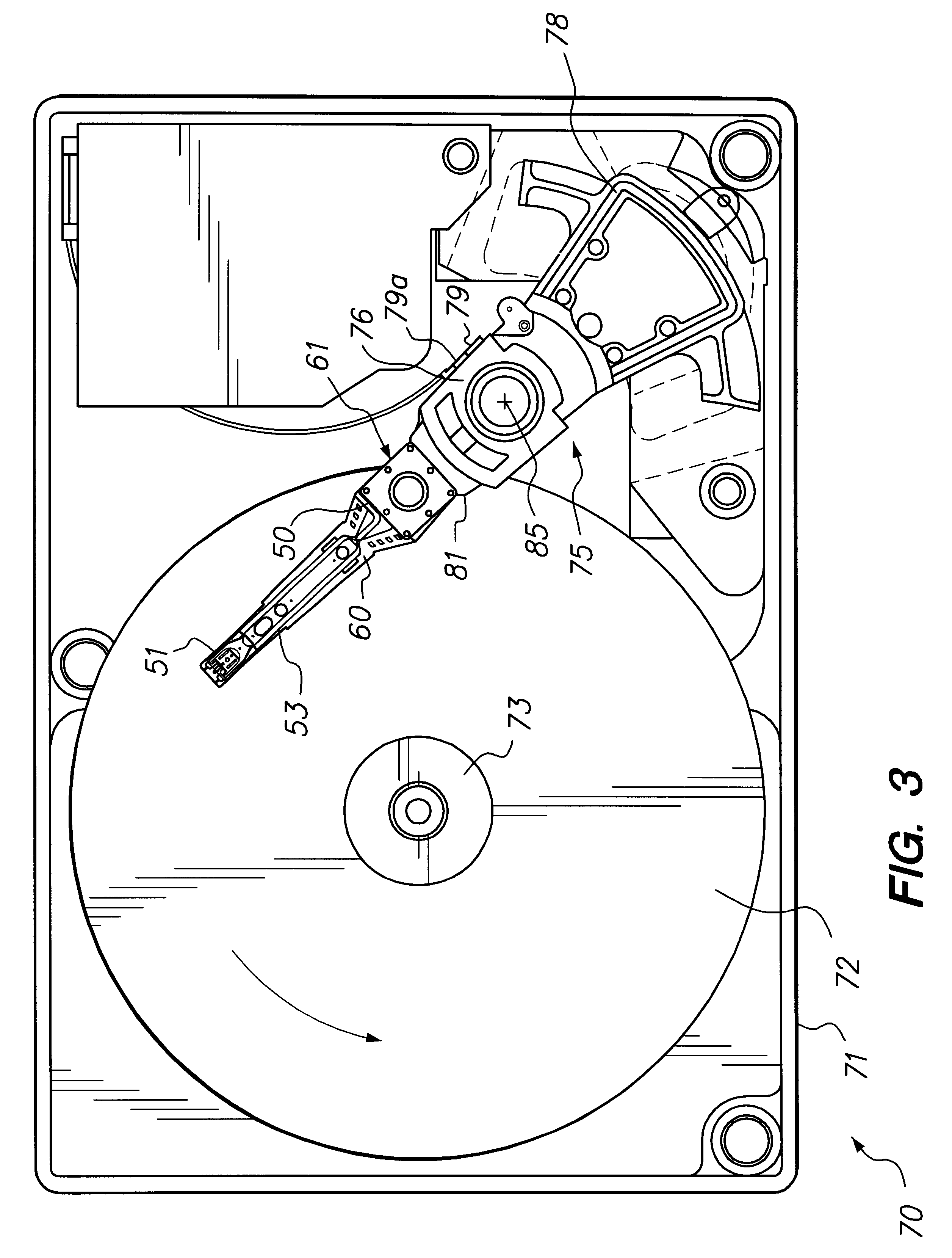

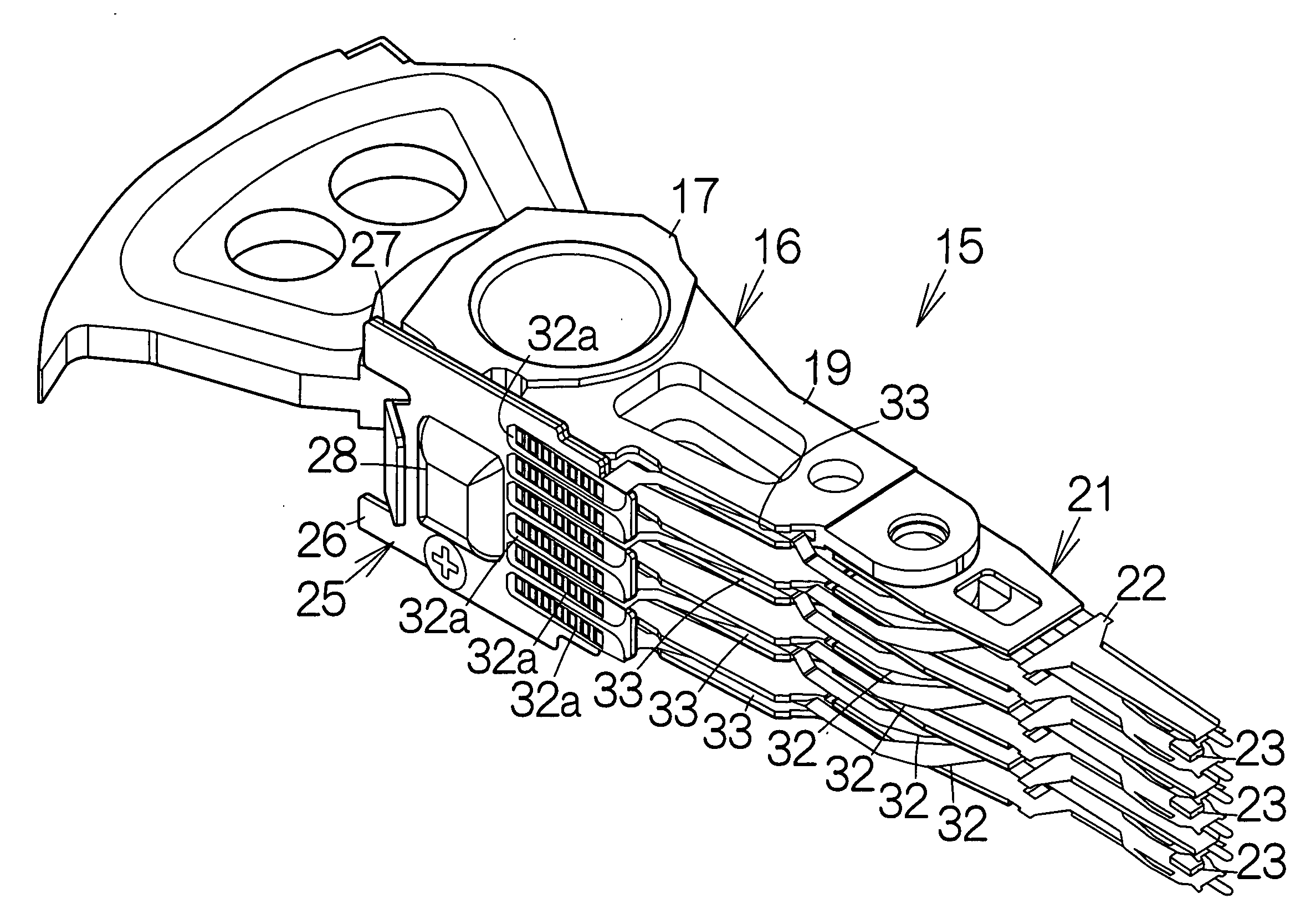

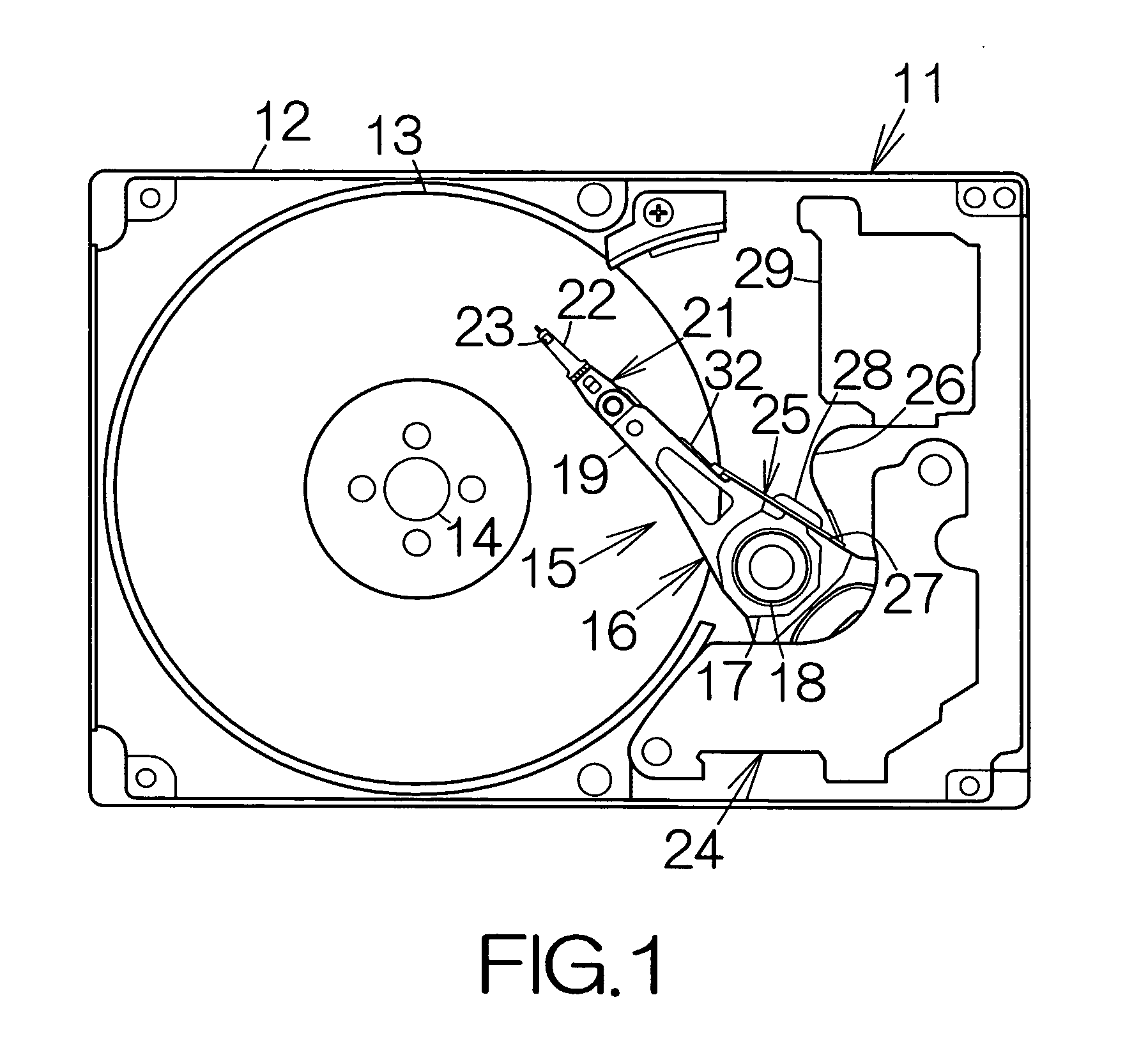

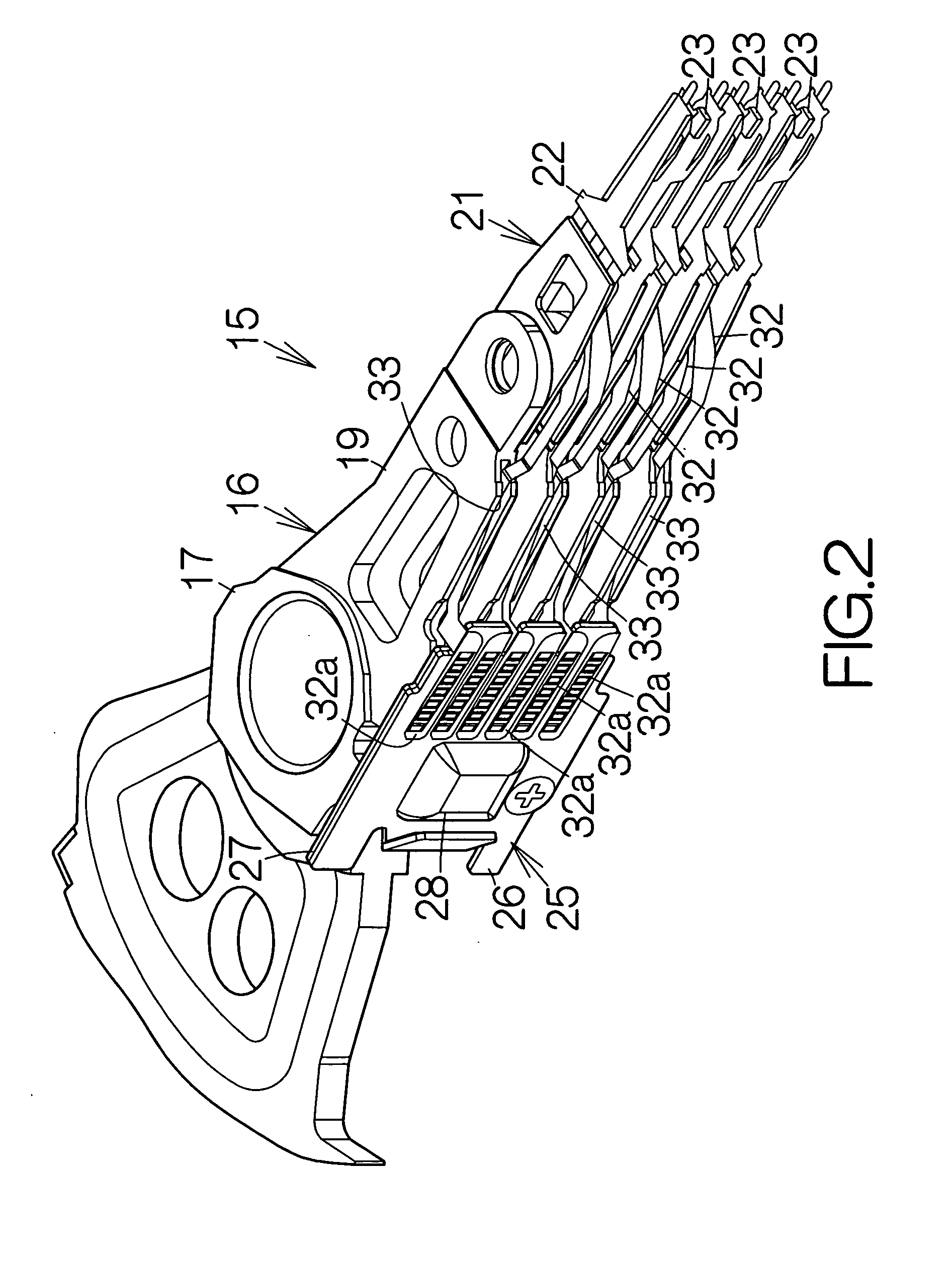

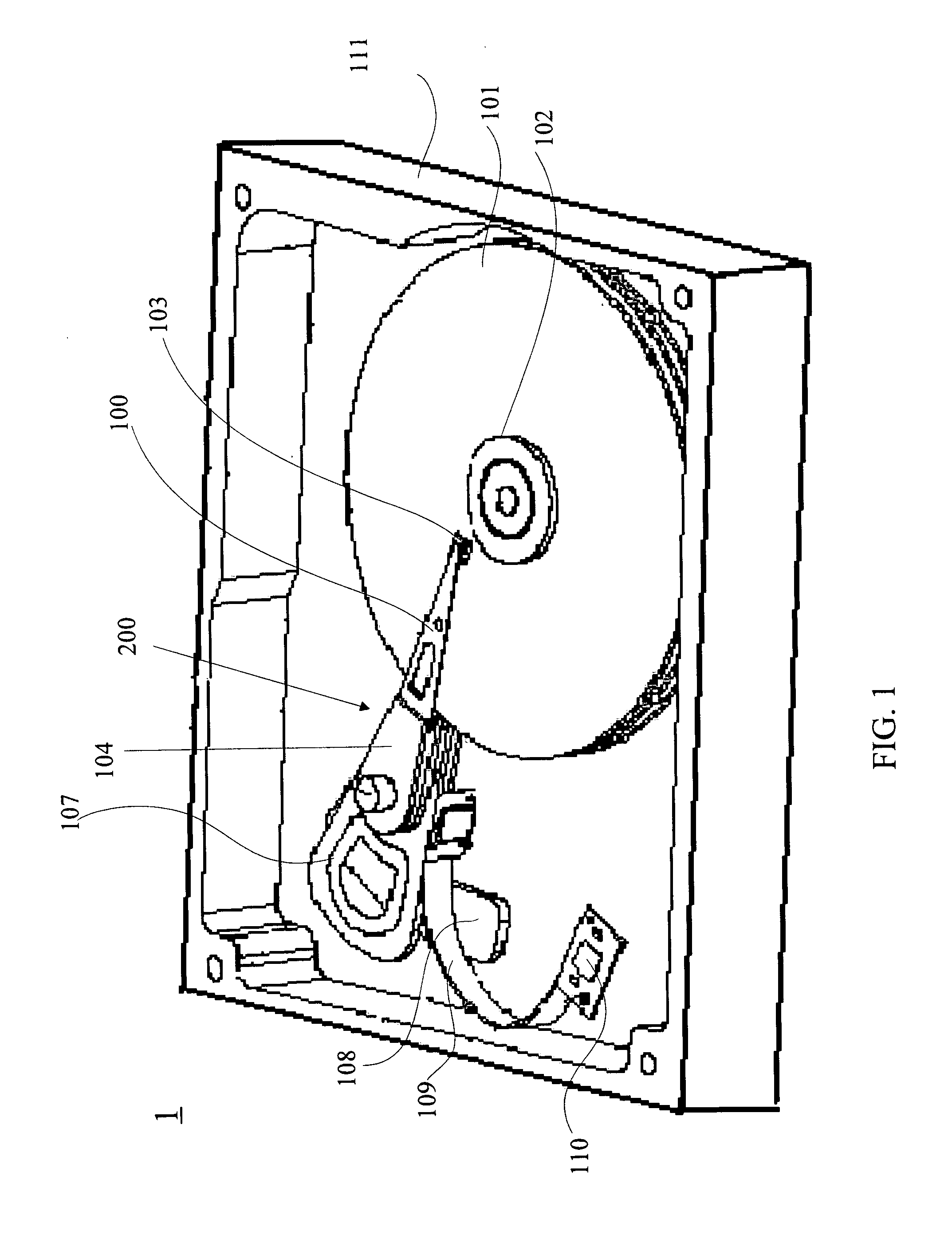

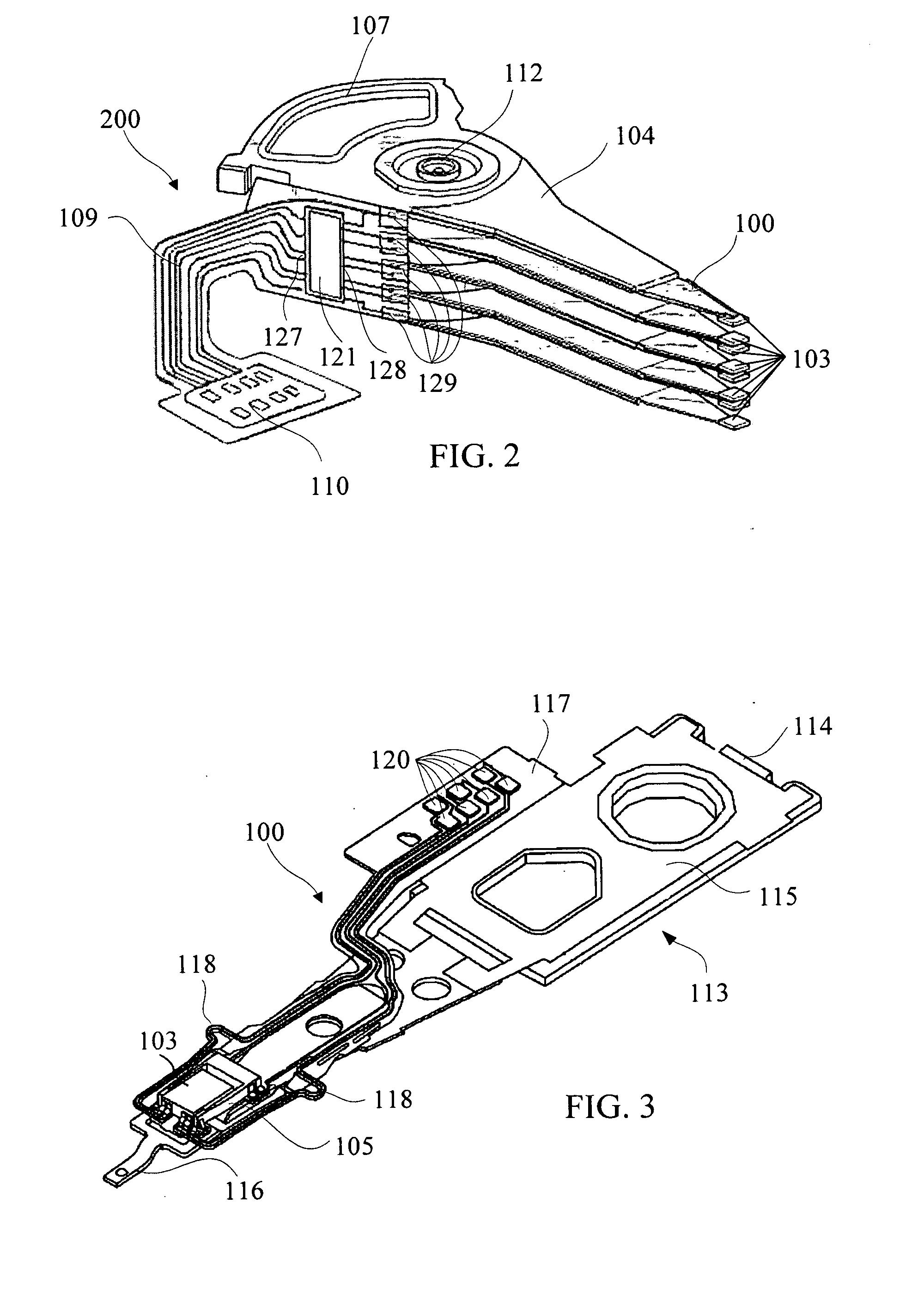

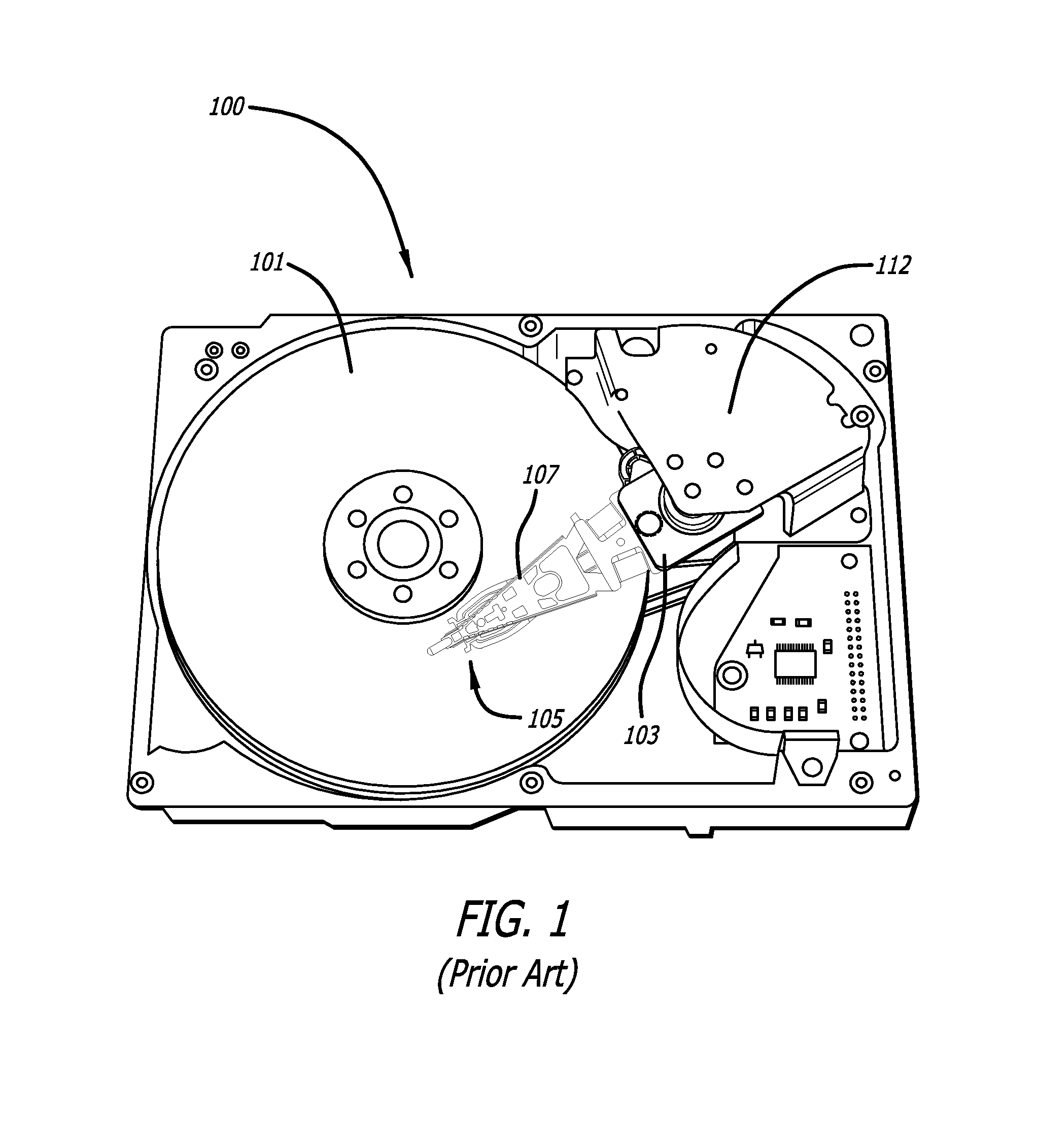

Disk drive including a base assembly having a flex-to-board edge connector

InactiveUS6934126B1Relieve pressureElectrical connection between head and armCarrier constructional parts dispositionEngineeringFlexible cable

A disk drive comprises a housing including a base; a disk rotatably attached to the base; a printed circuit board coupled to the base and including a plurality of circuit board pads; a head stack assembly pivotally coupled to the base about a pivot axis and a flex-to-board connector. The head stack assembly includes a head for reading and writing to the disk and a flex cable assembly that includes a flexible film including a plurality of conductive traces that are electrically coupled to the head. The flexible film includes a connecting portion in which each of the plurality of conductive traces defines a trace pad. Each trace pad is disposed on a surface of the flexible film that is generally parallel to the pivot axis. The flex-to-board connector is attached to the base and is configured to couple to the connecting portion of the flexible film and to maintain the surface of the flexible film on which the trace pads are disposed in an orientation that is generally parallel to the pivot axis. The flex-to-board connector includes a plurality of conductive fingers, each configured to electrically connect one of the trace pads to a corresponding one of the plurality of circuit board pads.

Owner:WESTERN DIGITAL TECH INC

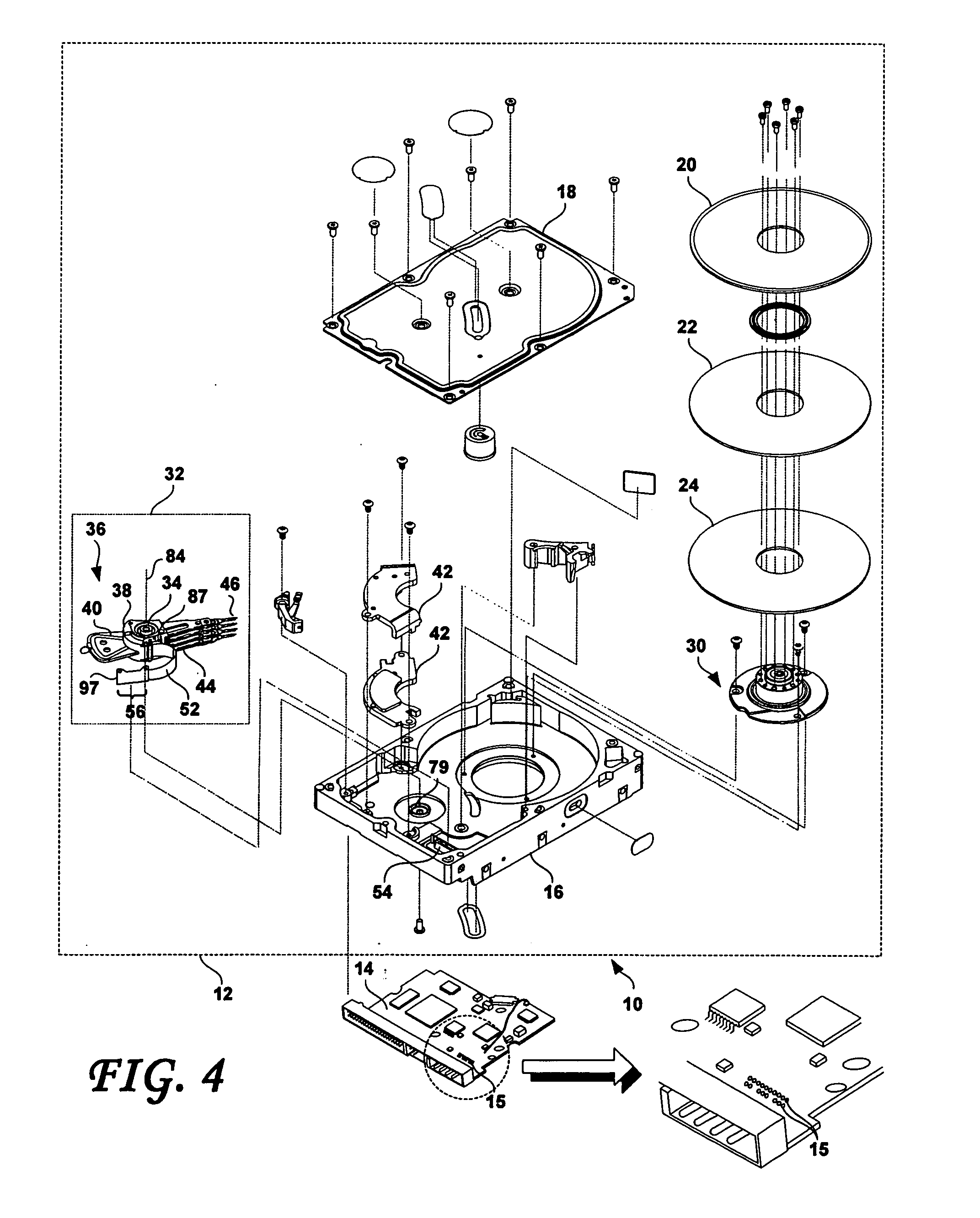

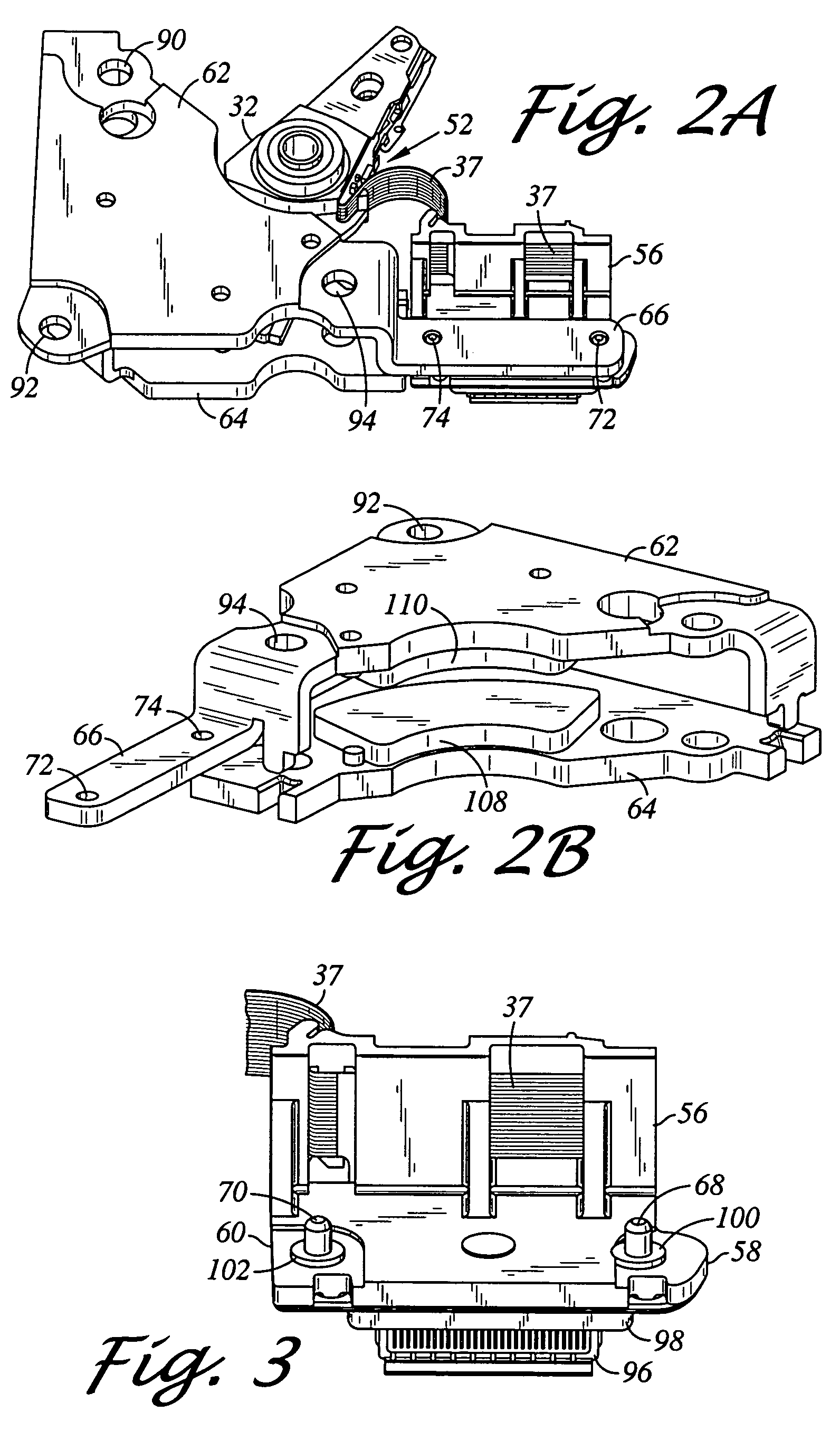

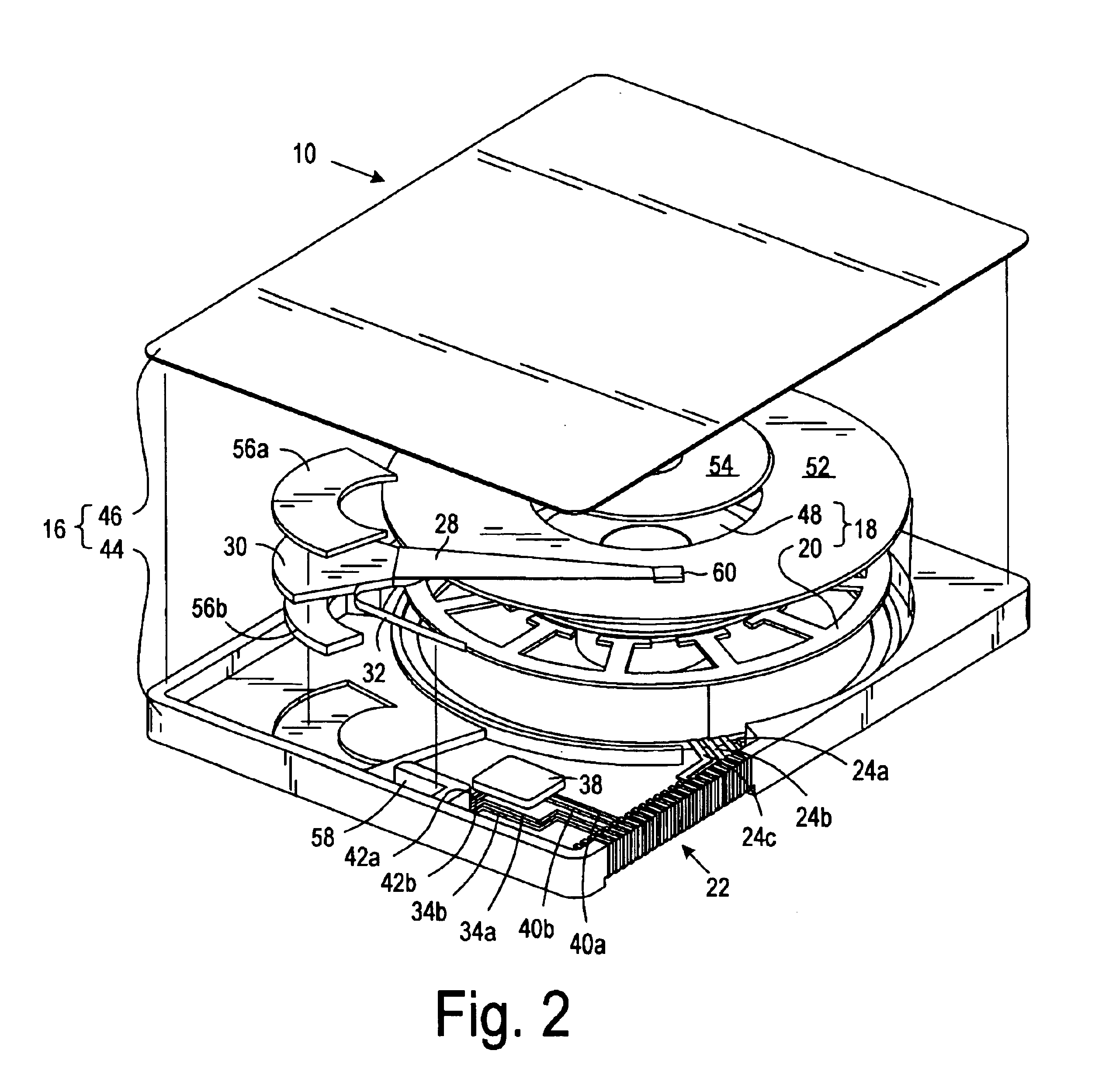

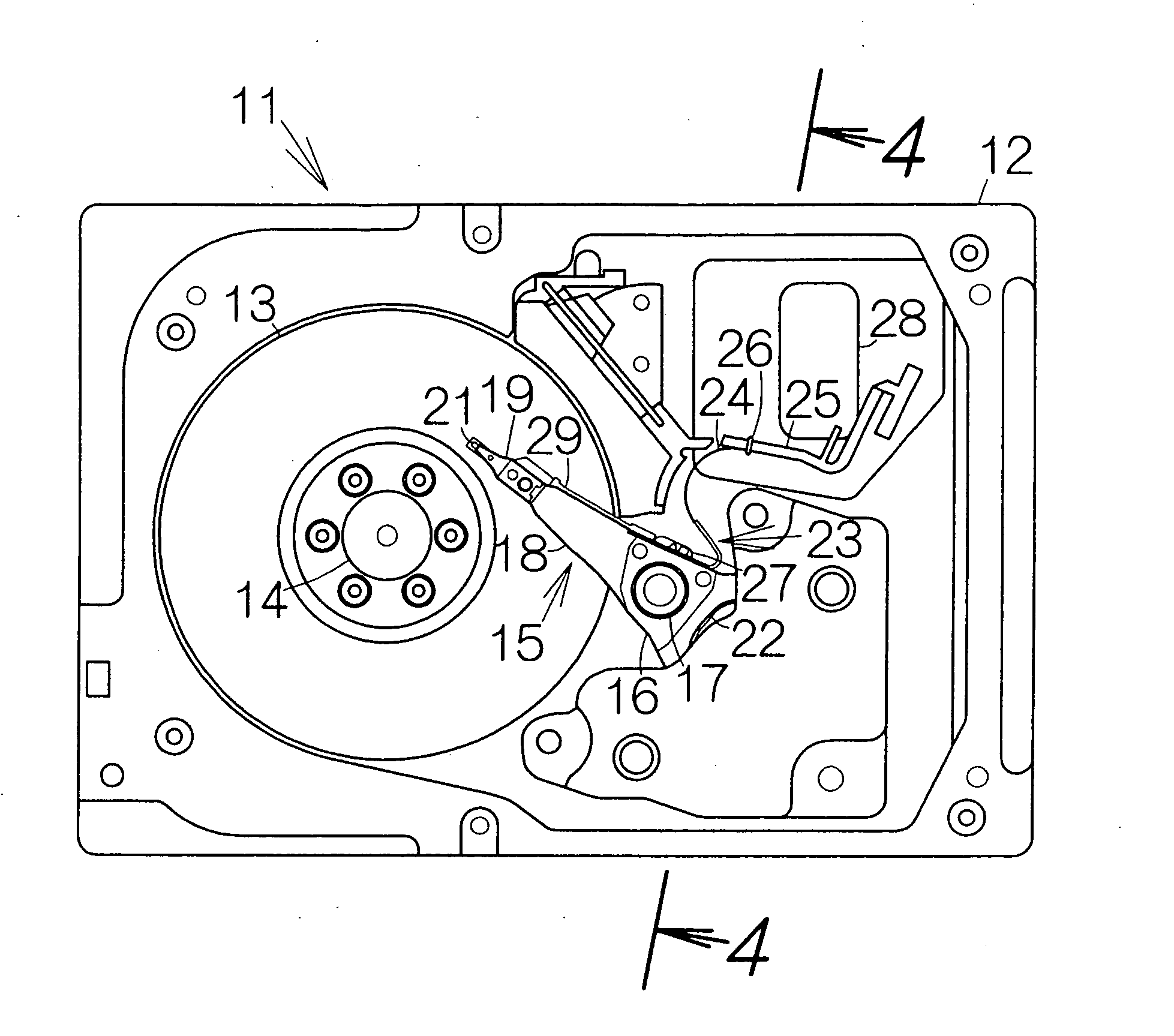

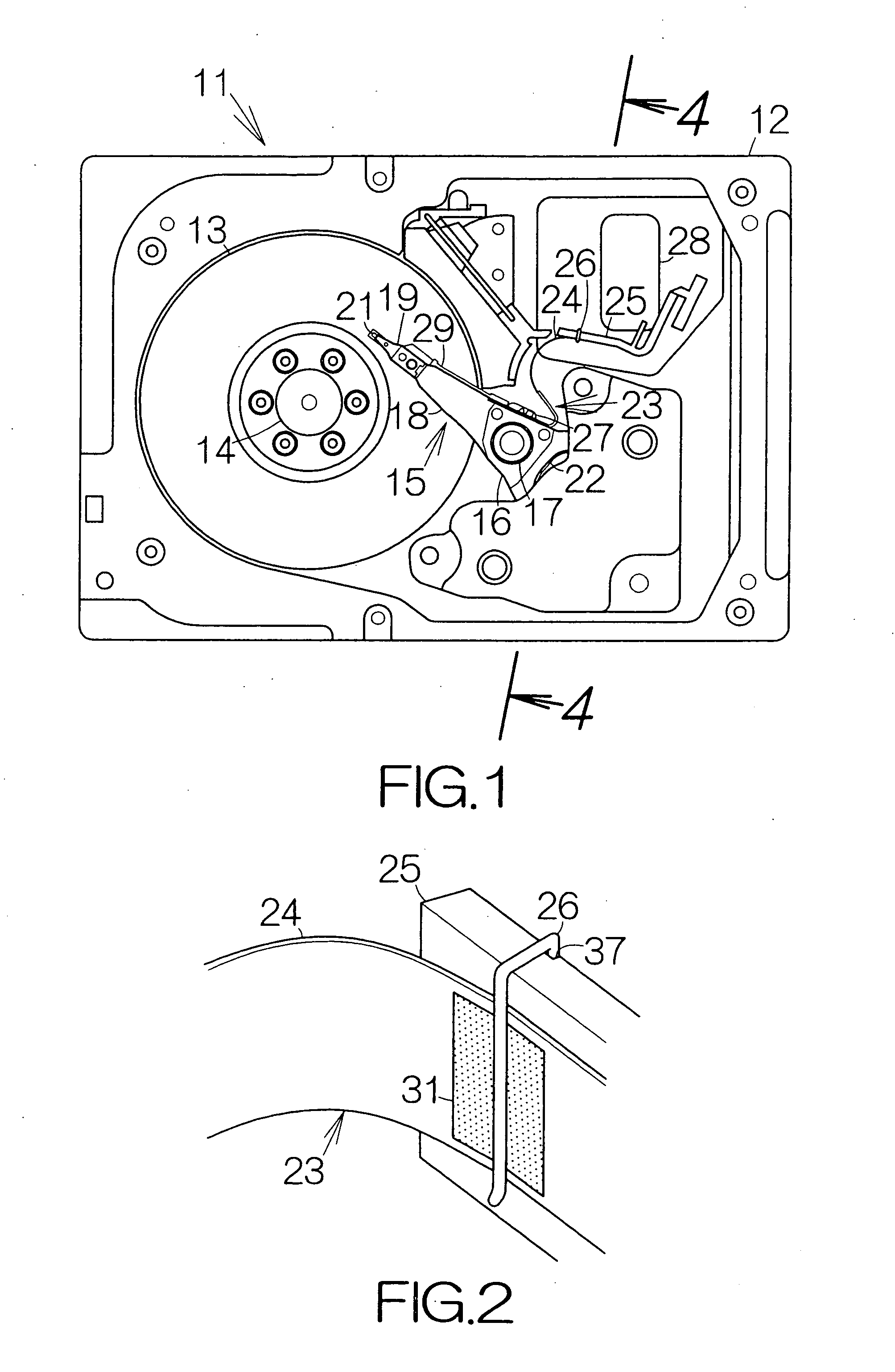

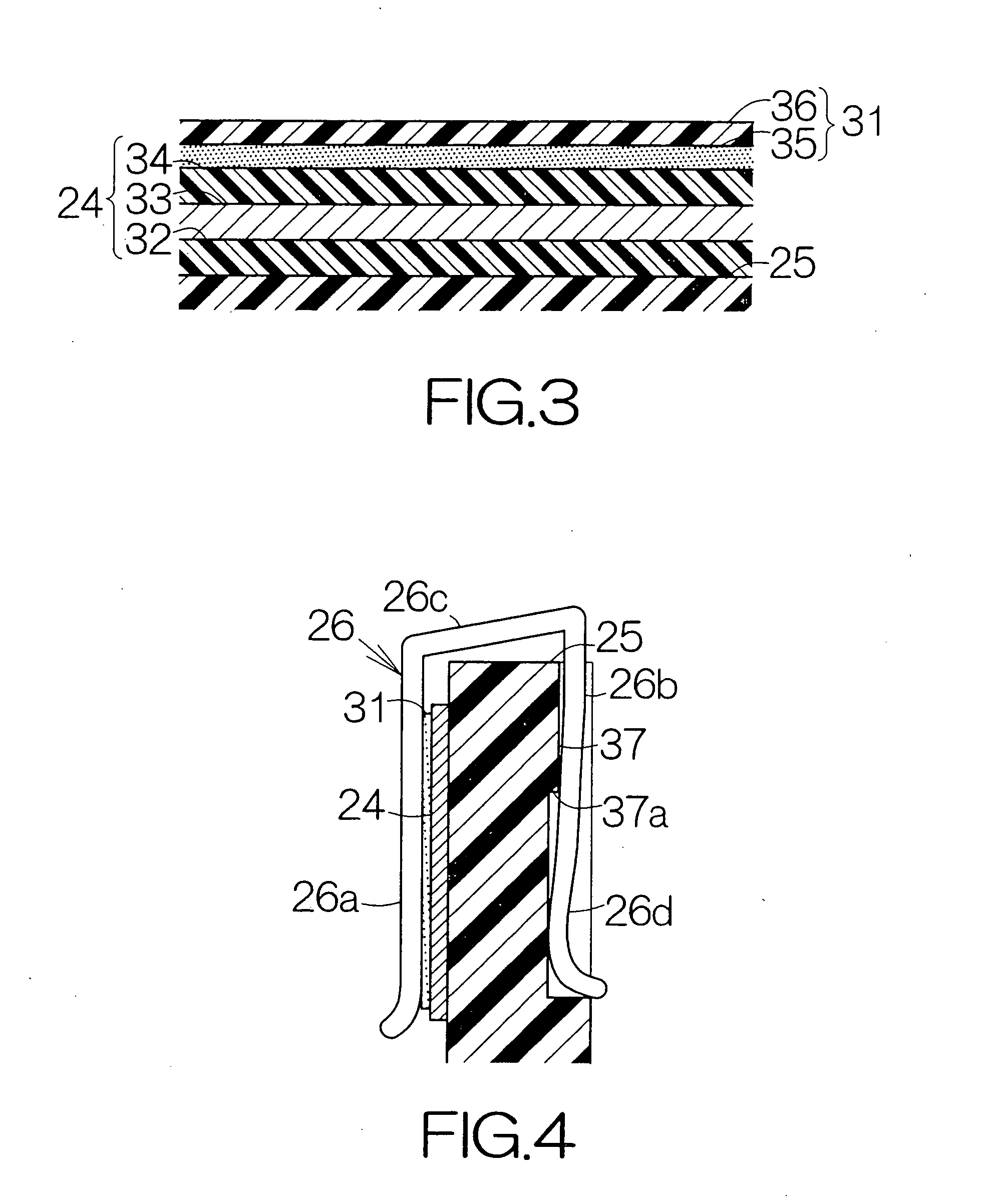

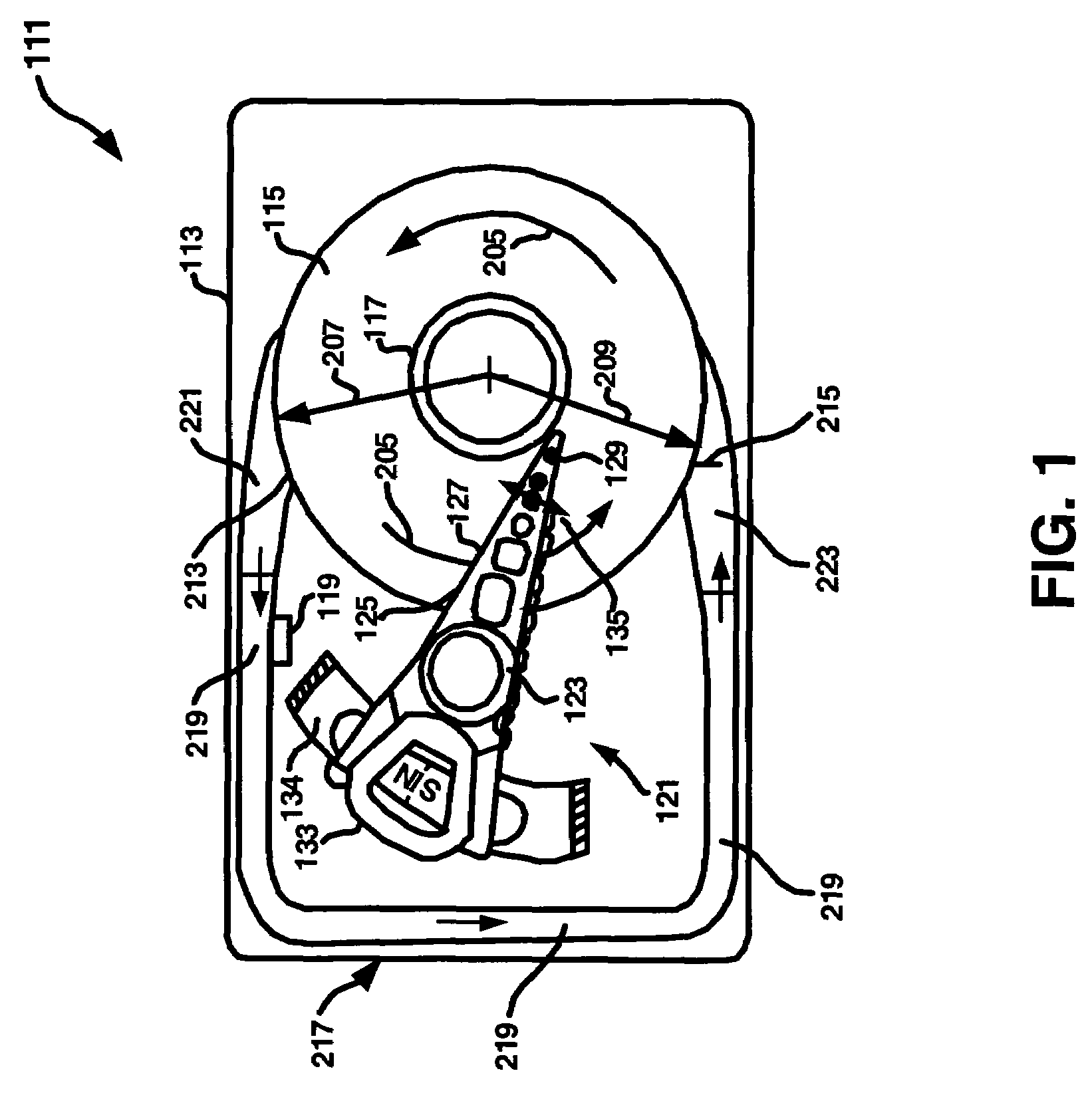

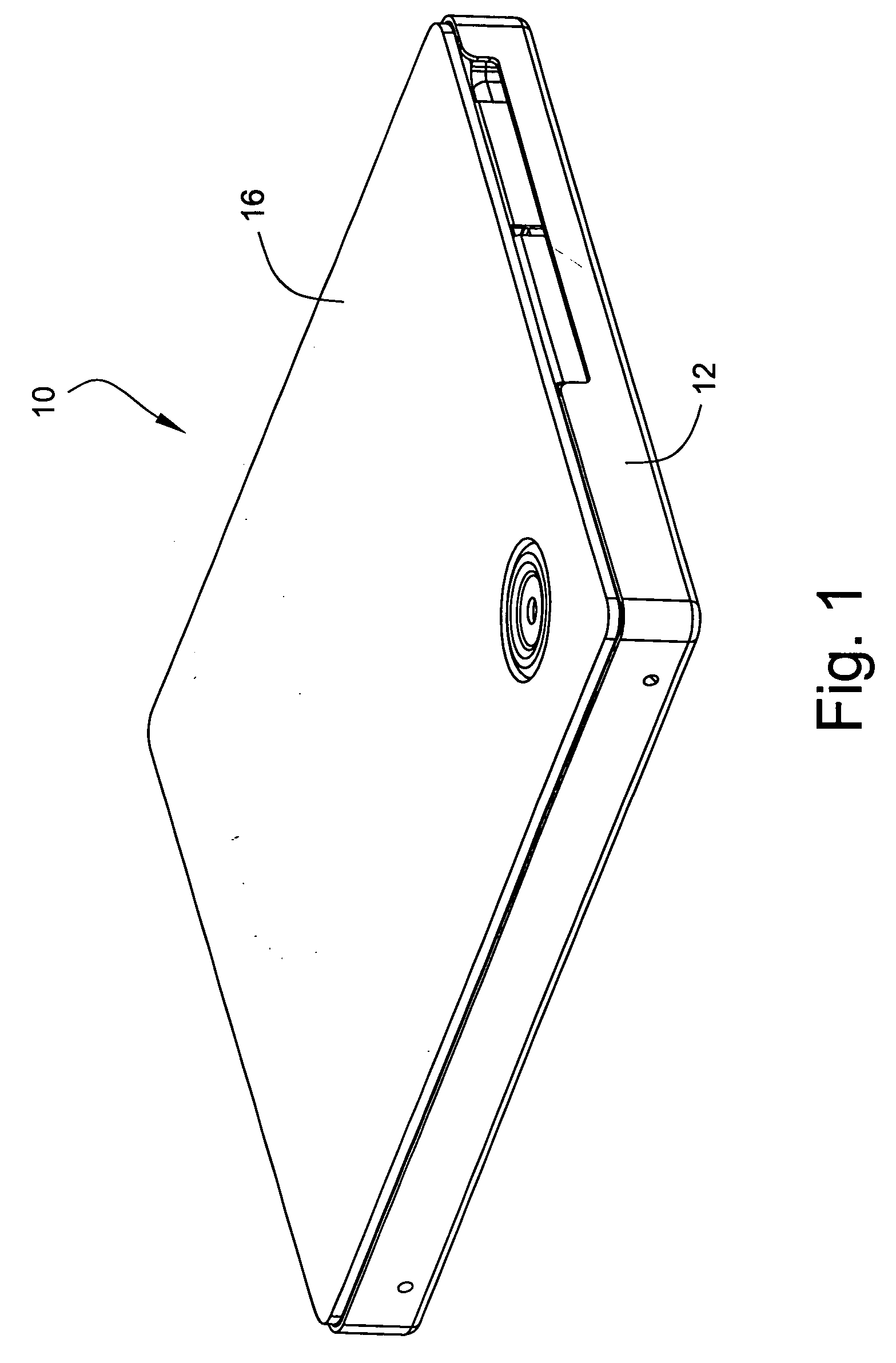

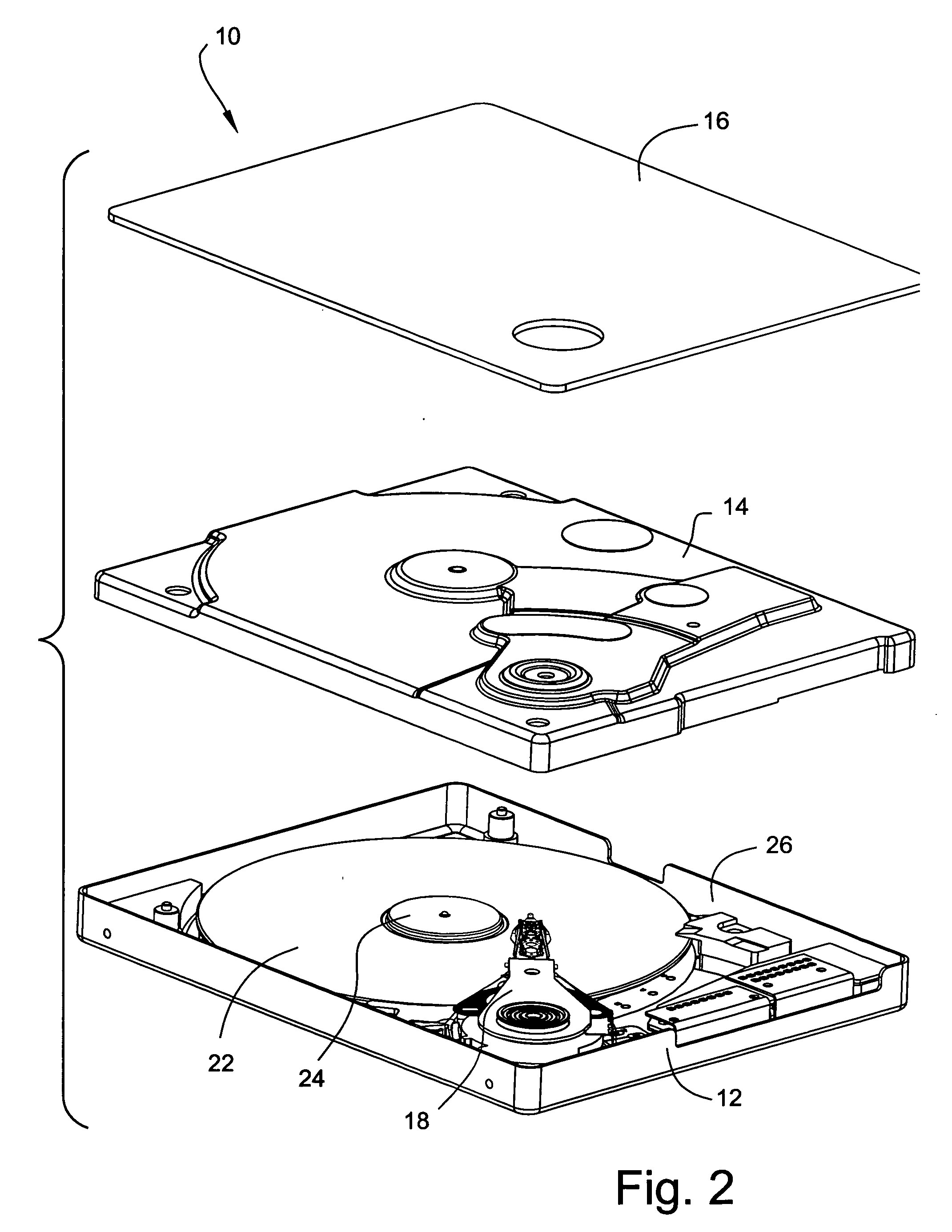

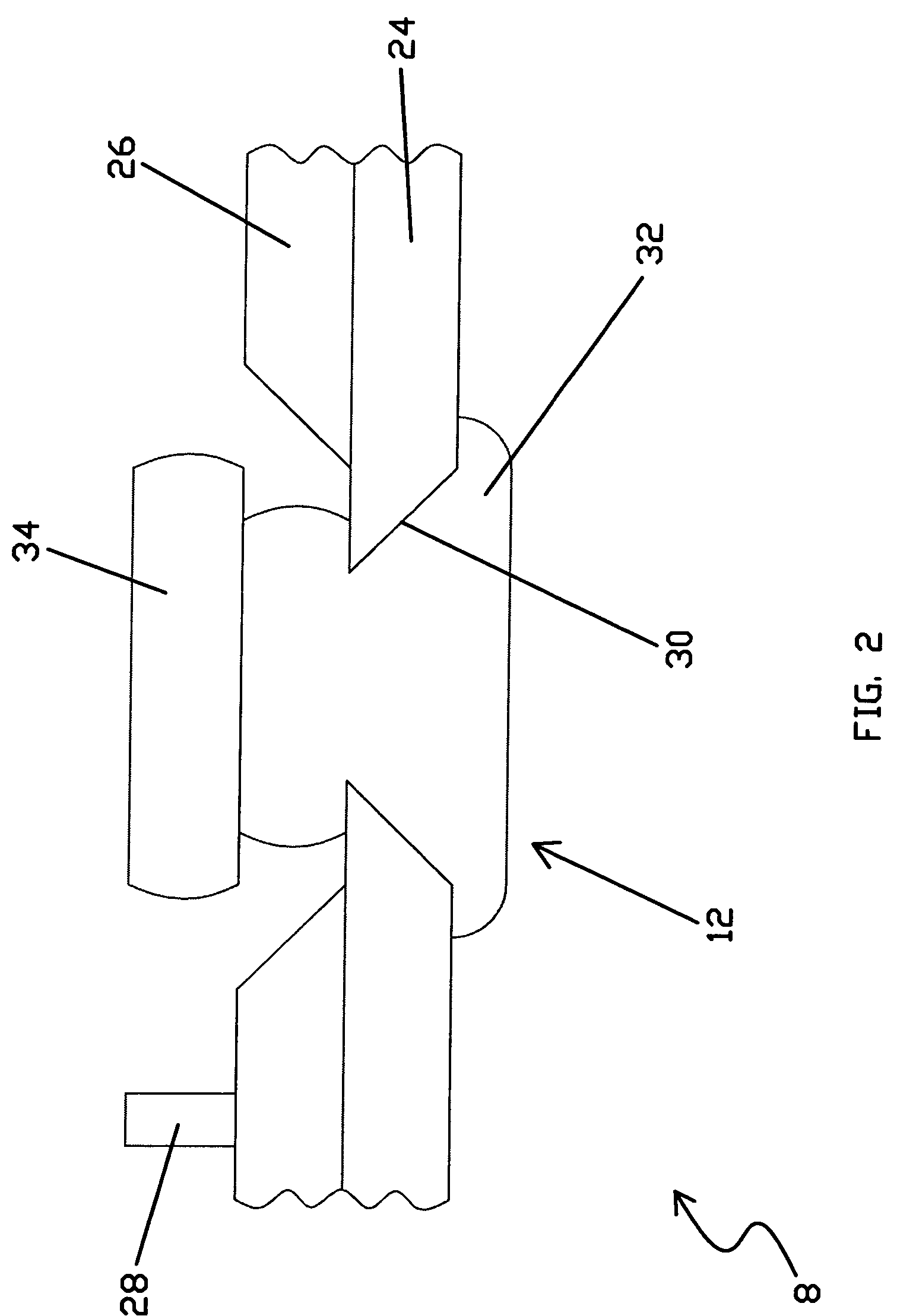

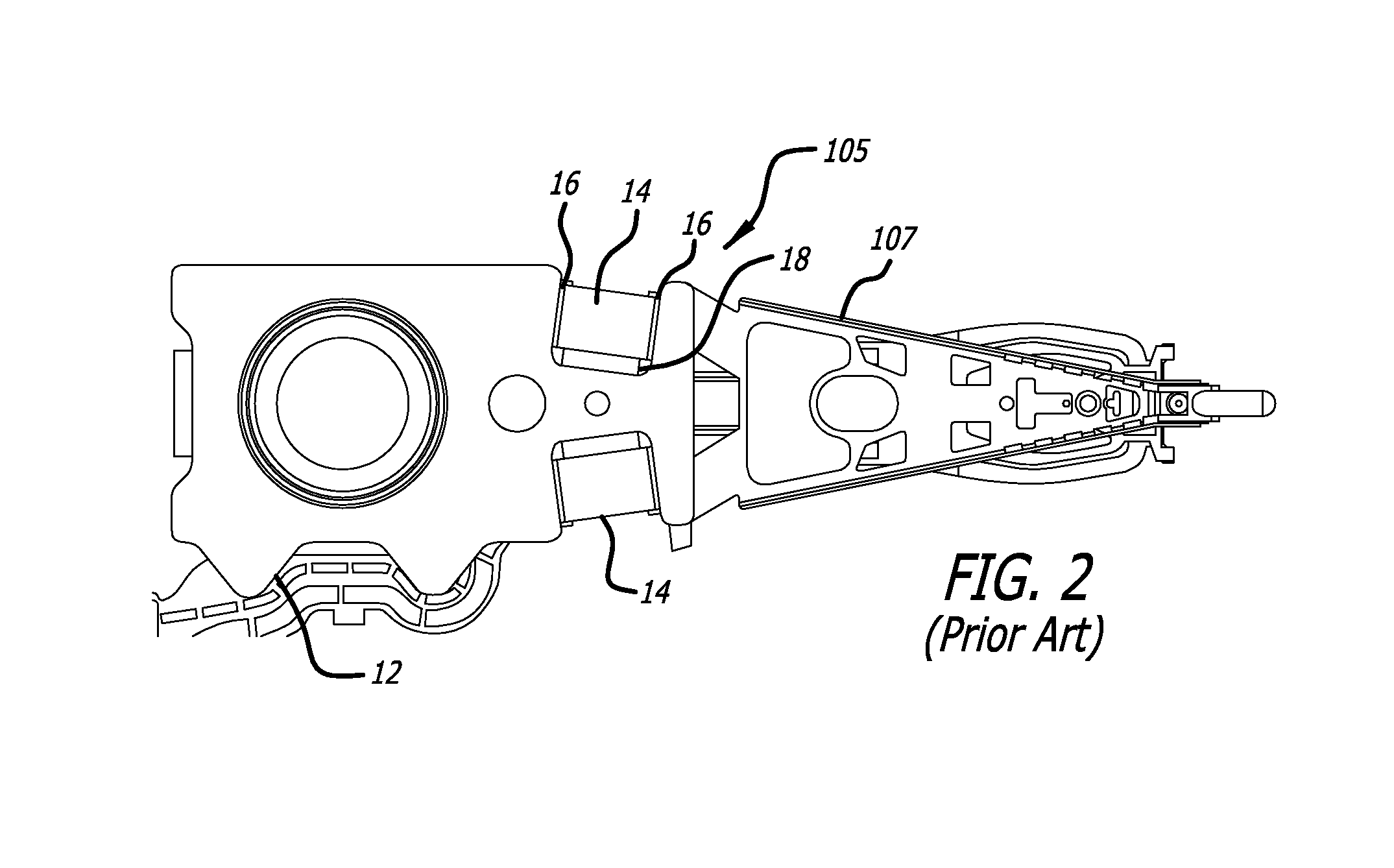

Disk drive having a VCM plate which includes an integrally formed elongated protrusion for securing a flex bracket to the disk drive base

InactiveUS6970329B1Record information storageElectrical connection between arm and supportFlexible circuitsEngineering

A disk drive includes a disk drive base, a spindle motor attached to the disk drive base, a disk supported by the spindle motor, and a head stack assembly coupled to the disk drive base. The head stack assembly includes an actuator body, a coil portion cantilevered from the actuator body, an actuator arm cantilevered from the actuator body in an opposite direction from the actuator arm, a flex circuit cable having an electrical connector end, and a flex bracket for clamping the electrical connector end of the flex circuit cable to the disk drive base, the flex bracket having first and second ends being spaced-apart along a width of the disk drive. The disk drive further includes an upper voice coil motor plate and a lower voice coil motor plate, the voice coil motor plates secured to the disk drive base, one of the voice coil motor plates having an integrally formed elongated protrusion extending from the voice coil motor plate for contacting and securing the flex bracket to the disk drive base, the elongated protrusion extending from the first end to proximate the second end, wherein the flex bracket is secured to the disk drive base free of using any fastener.

Owner:WESTERN DIGITAL TECH INC

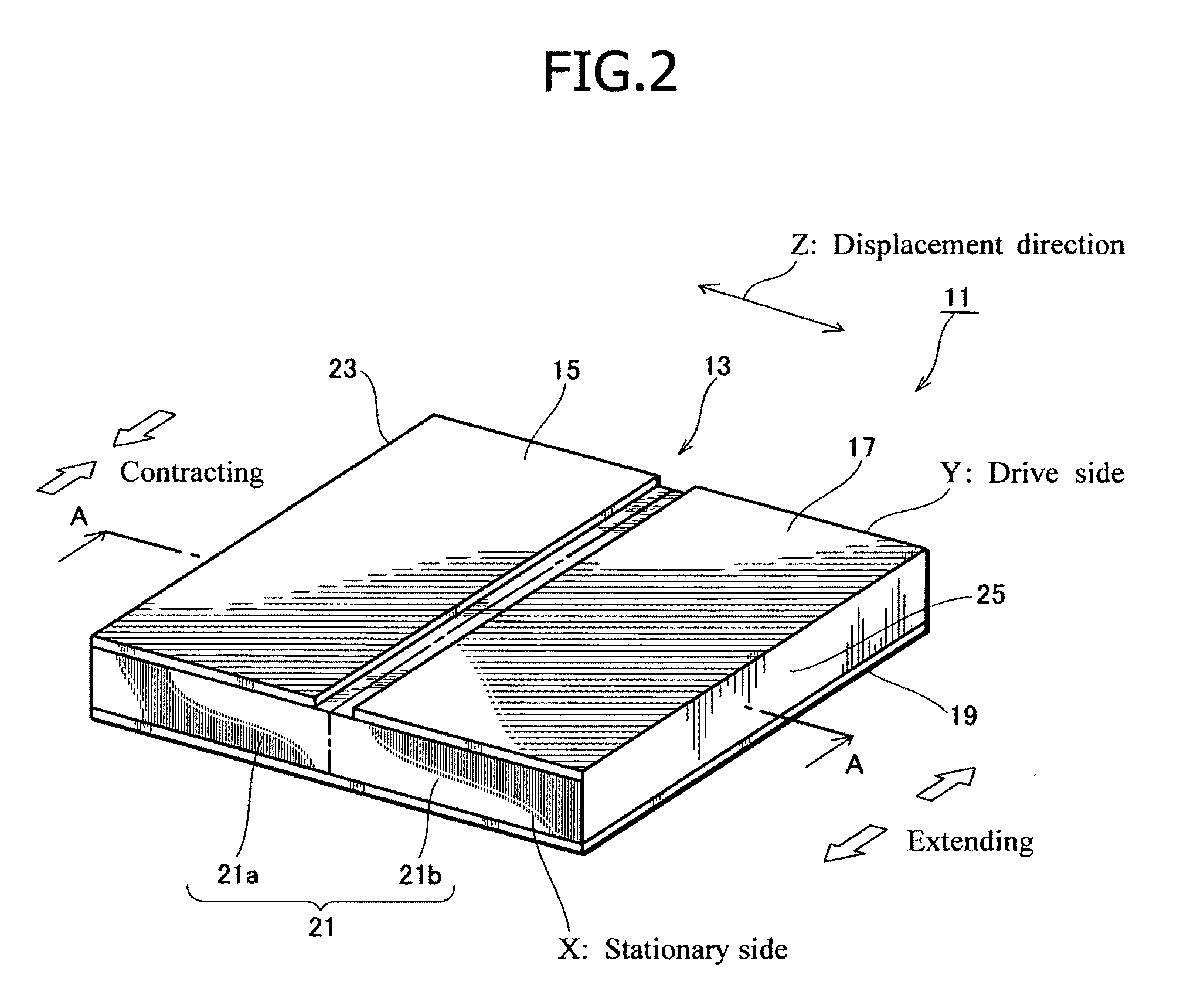

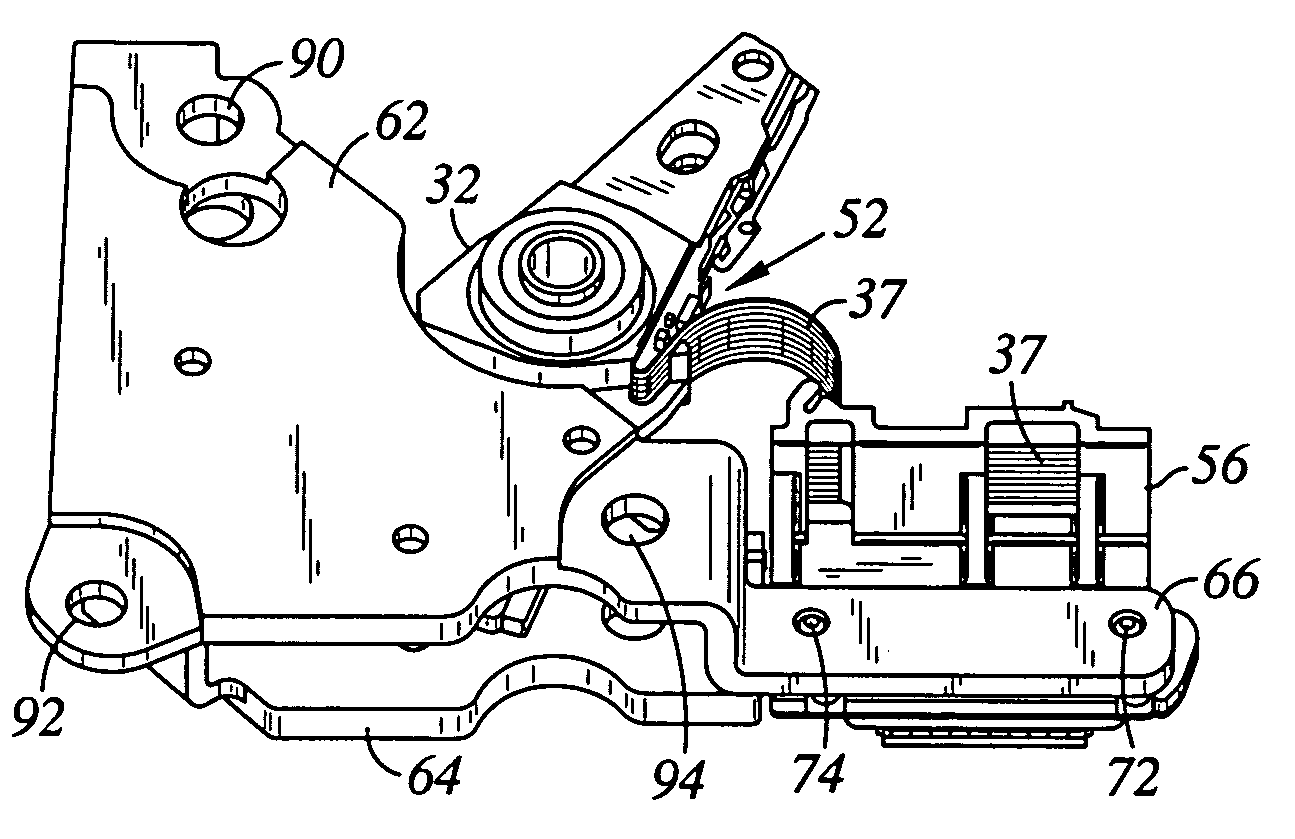

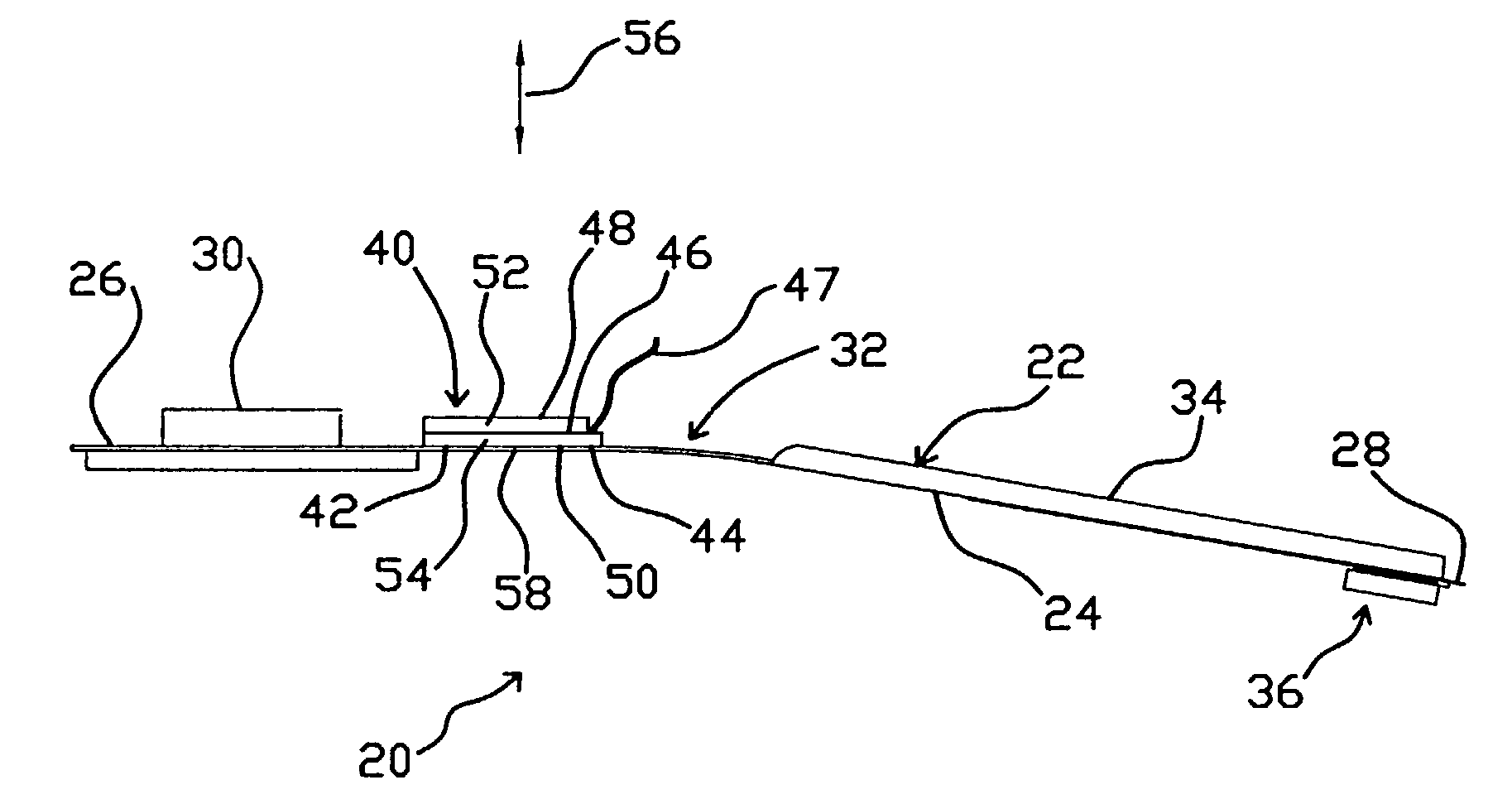

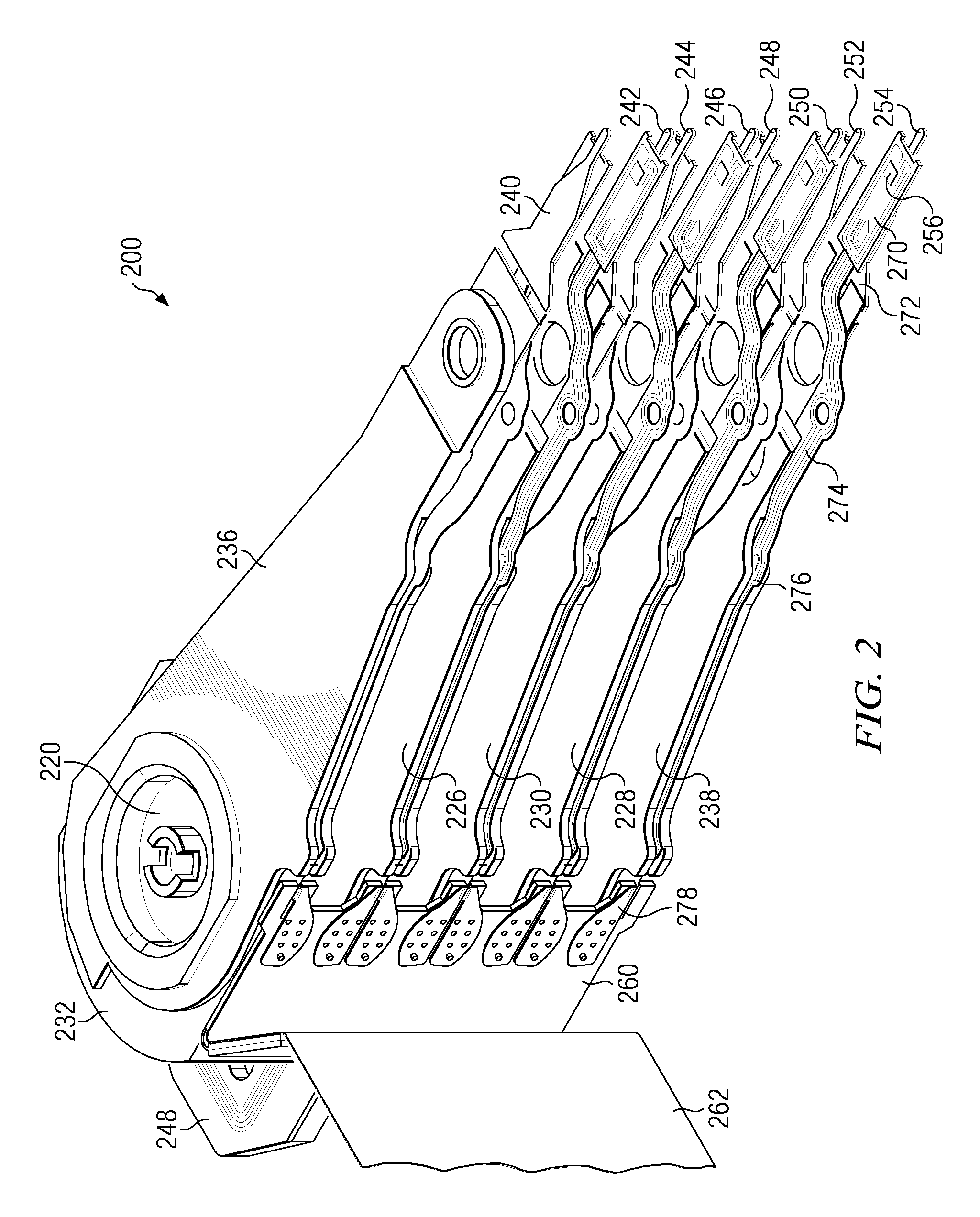

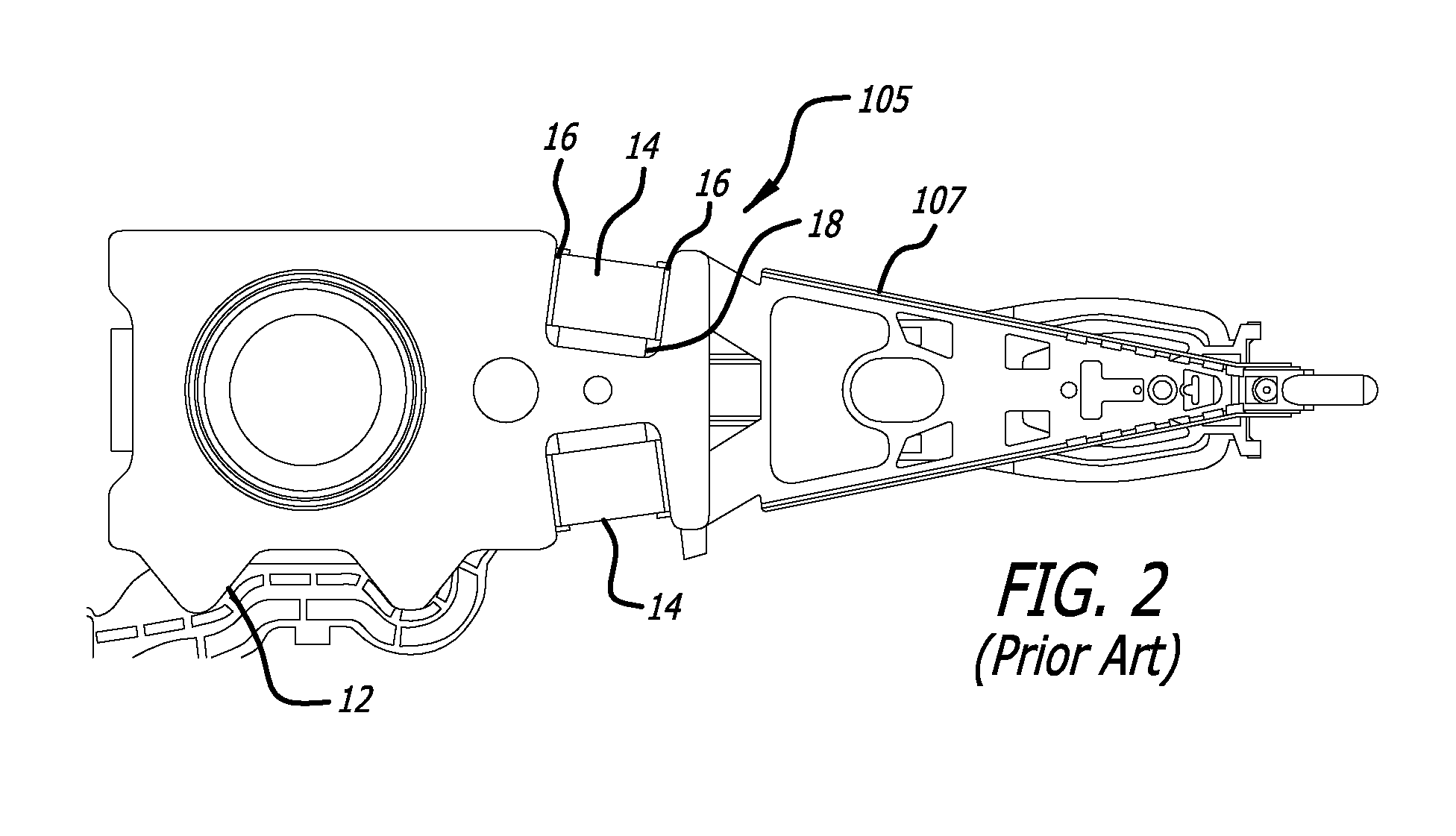

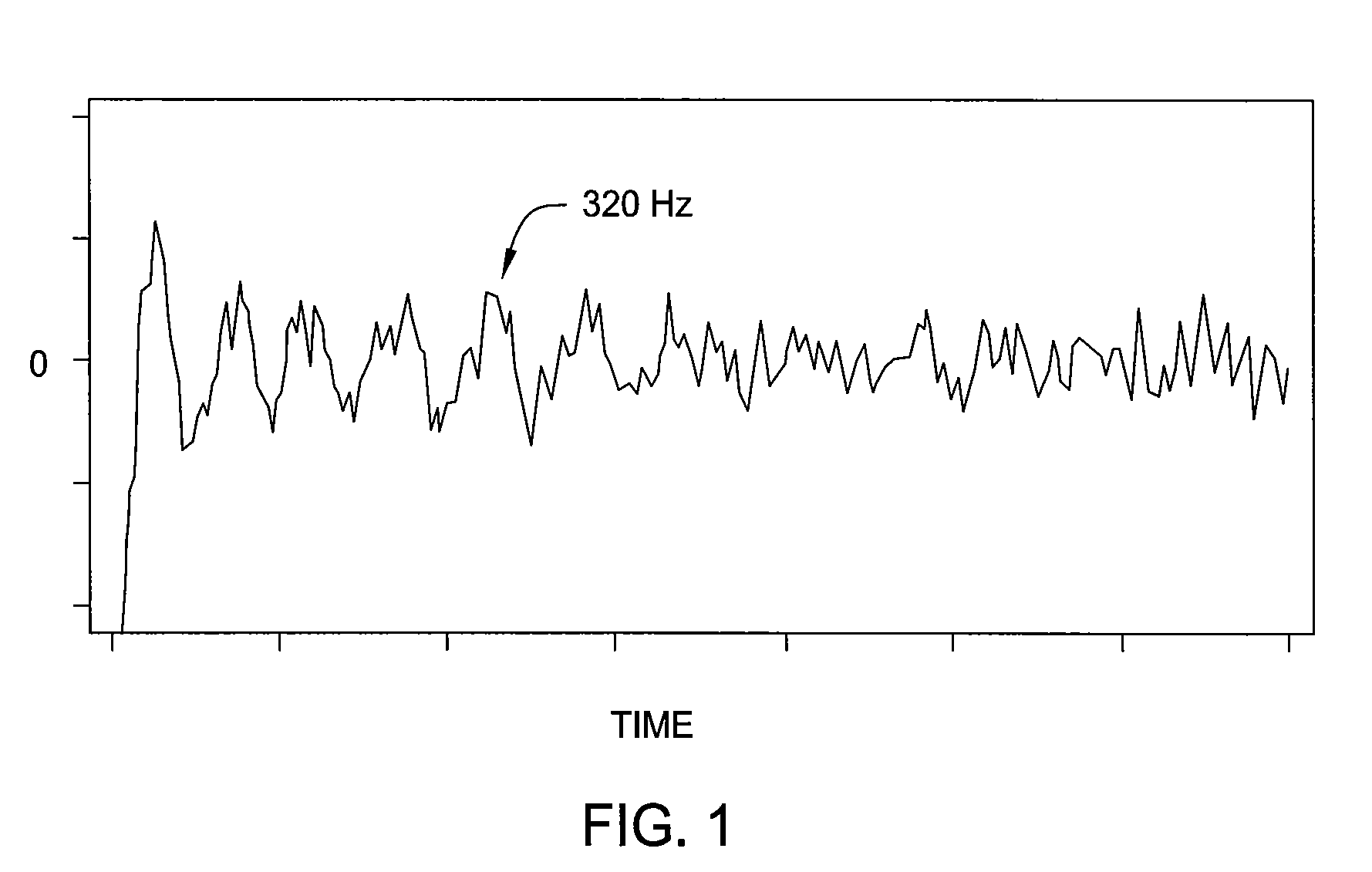

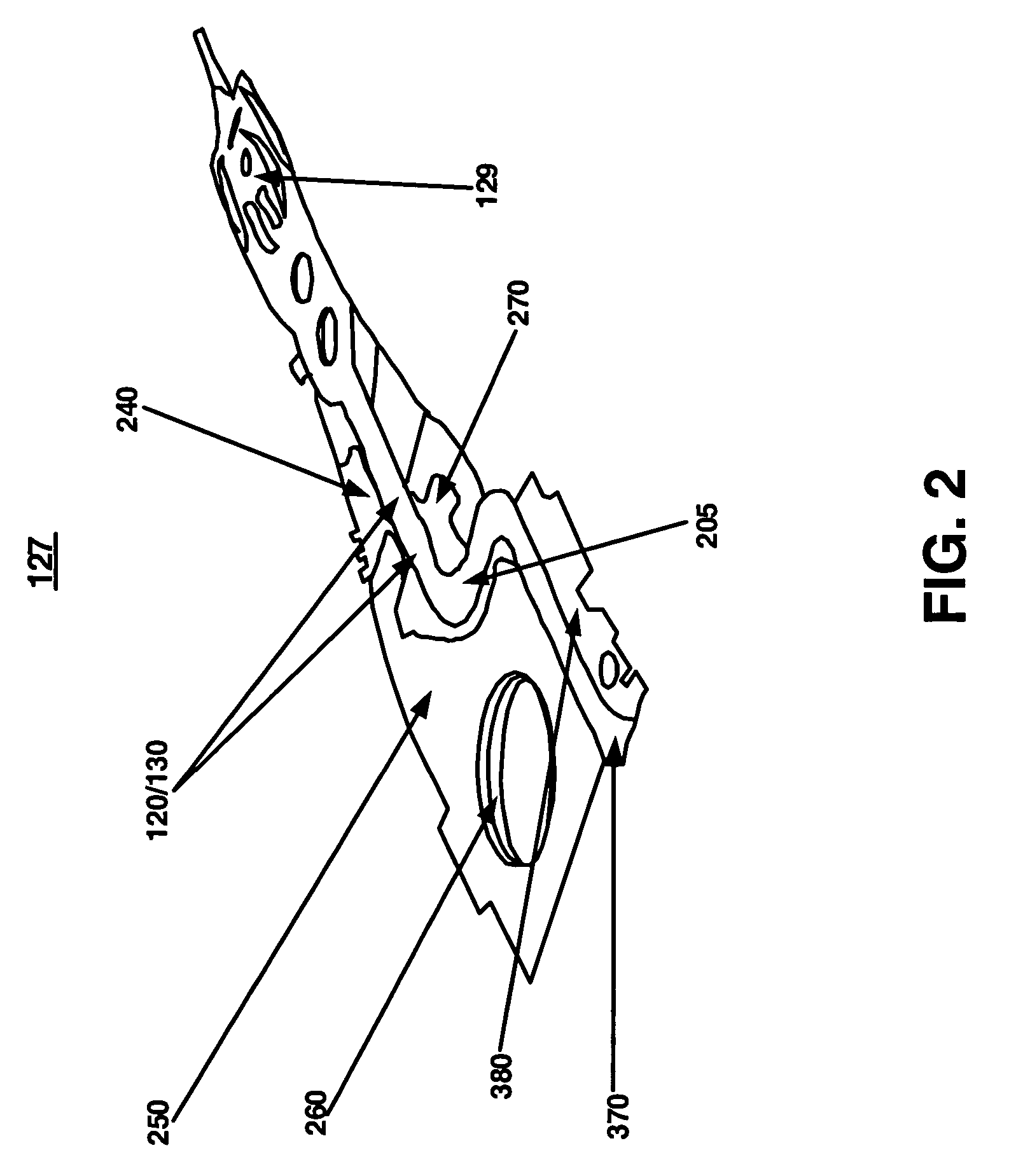

Method for actively controlling the gram load on a disk drive suspension assembly

InactiveUS7082670B2Large range of motionOptimization rangePrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyElectricityControl system

A method and apparatus for actively controlling the gram load on a disk drive suspension assembly and to a disk drive using the present disk drive suspension assembly. The gram load can be actively changed by changing the applied voltage to one or more multi-layer piezoelectric actuators attached to the head suspension. The active gram control system allows the gram load to be changed on a non-permanent basis and to control the gram load to a much finer scale than can be accomplished using conventional techniques. By attaching the first and second ends of the piezoelectric actuator to discrete locations on the load beam, while the portion of the piezoelectric actuator between the first and second ends remains unattached to the load beam, a force non-parallel to the load beam can be applied to the head suspension.

Owner:HUTCHINSON TECH

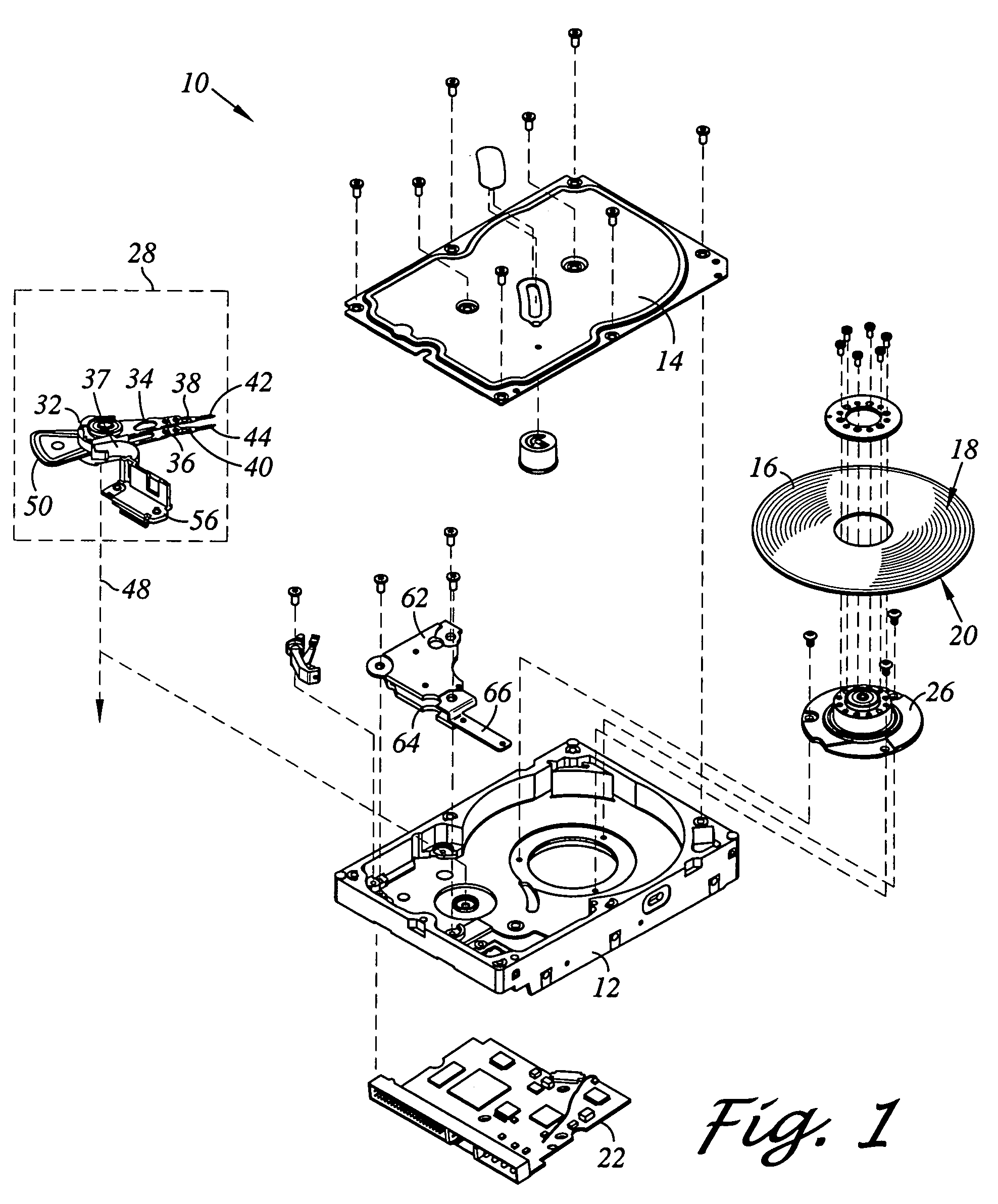

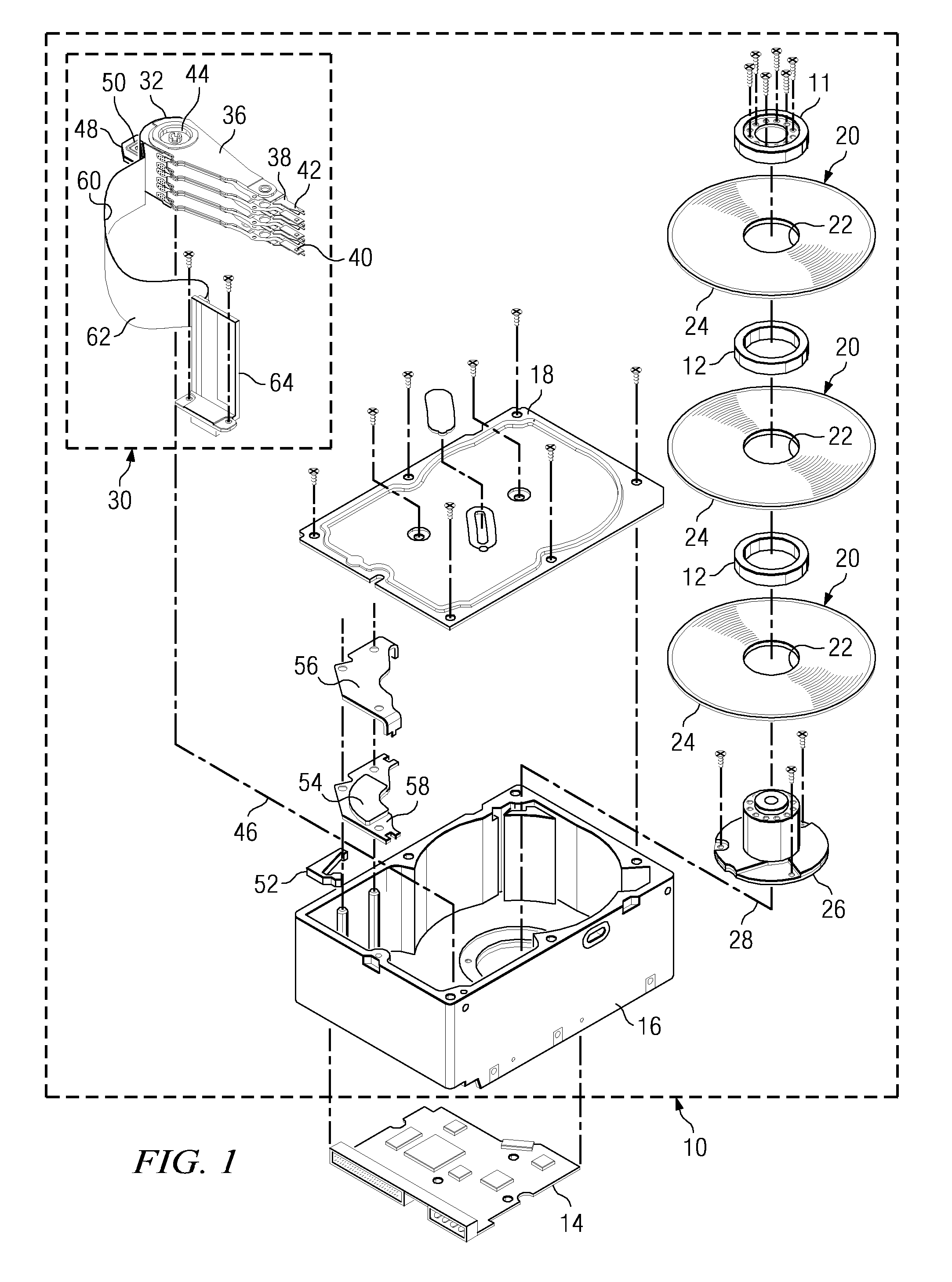

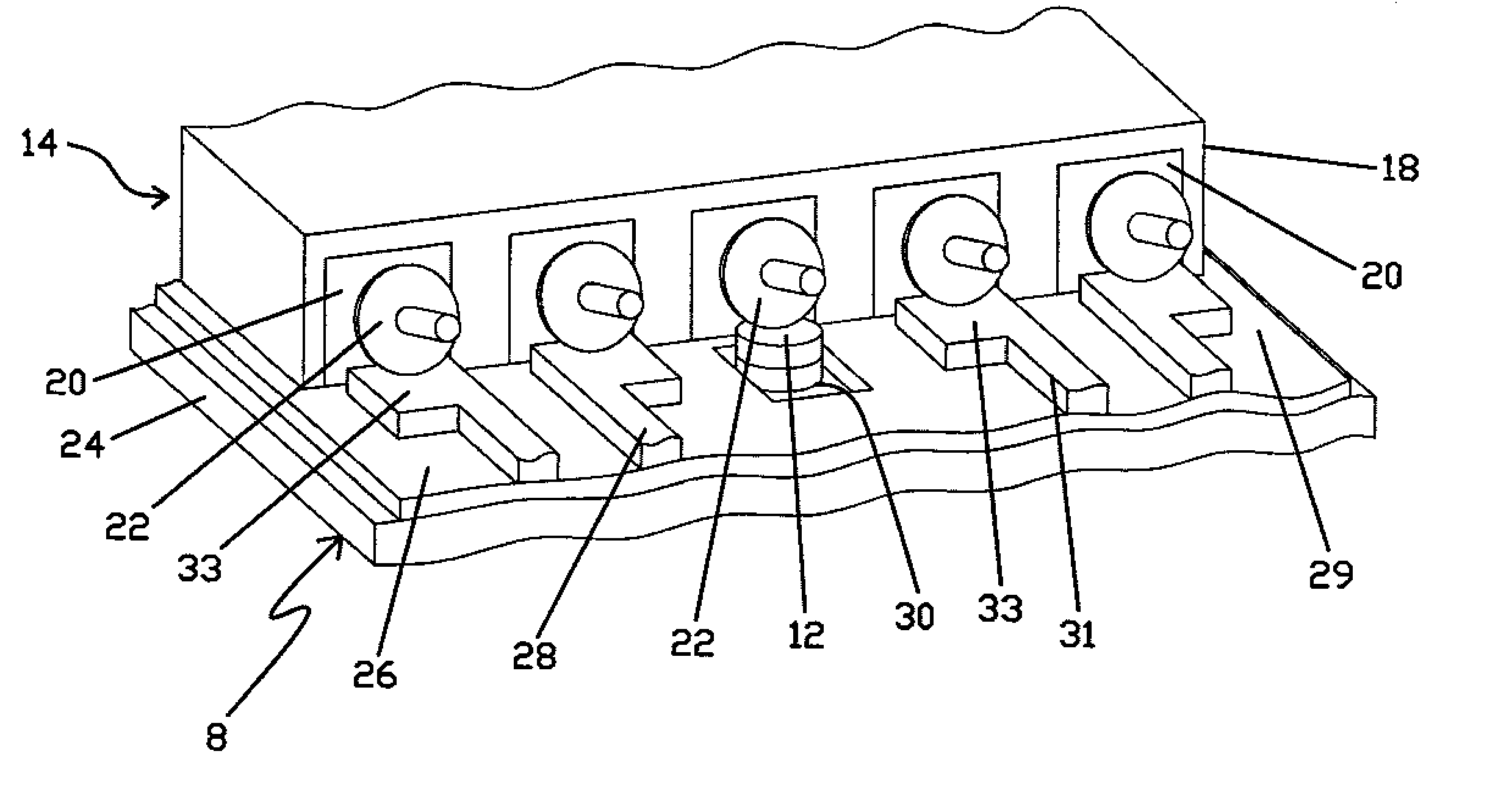

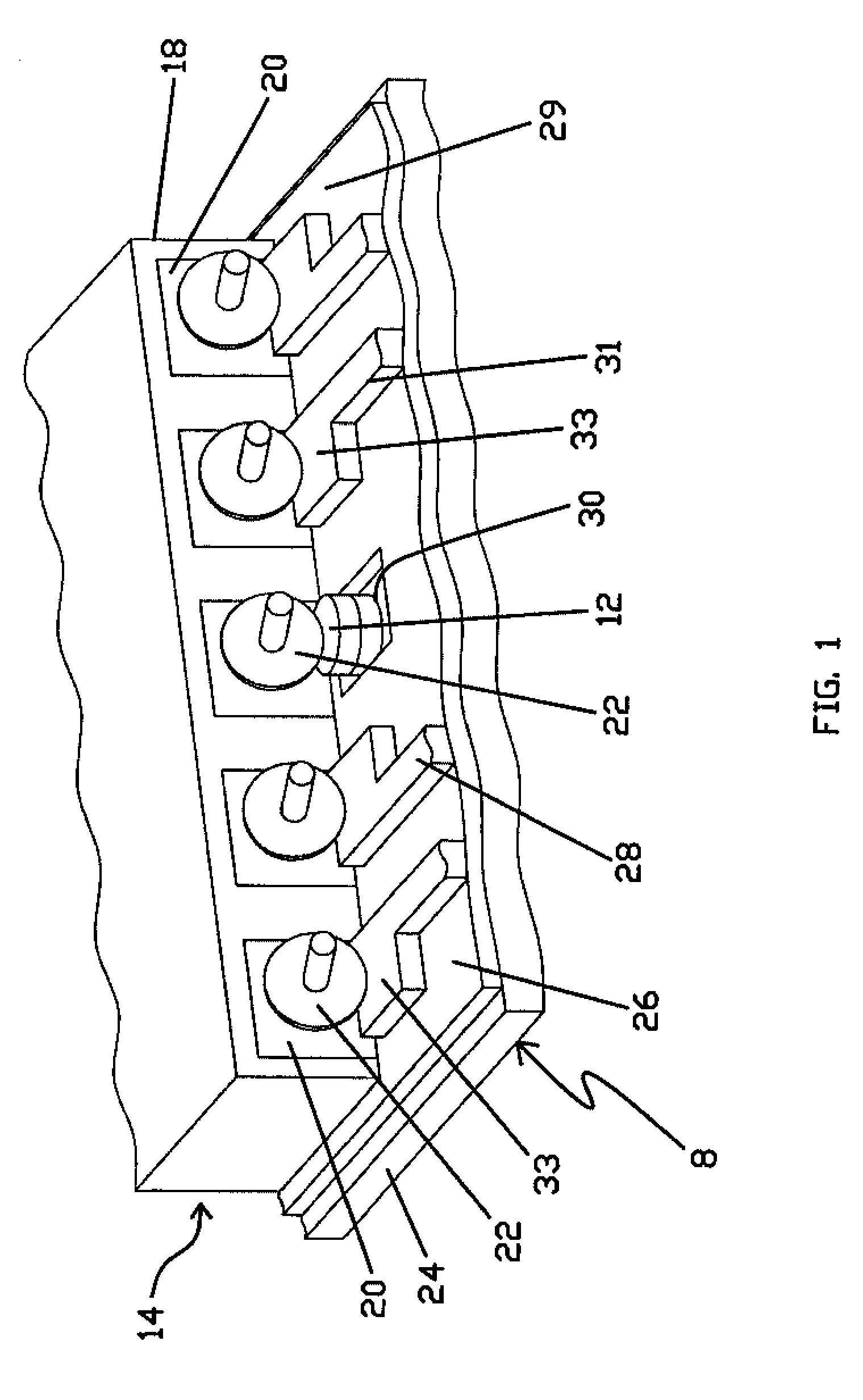

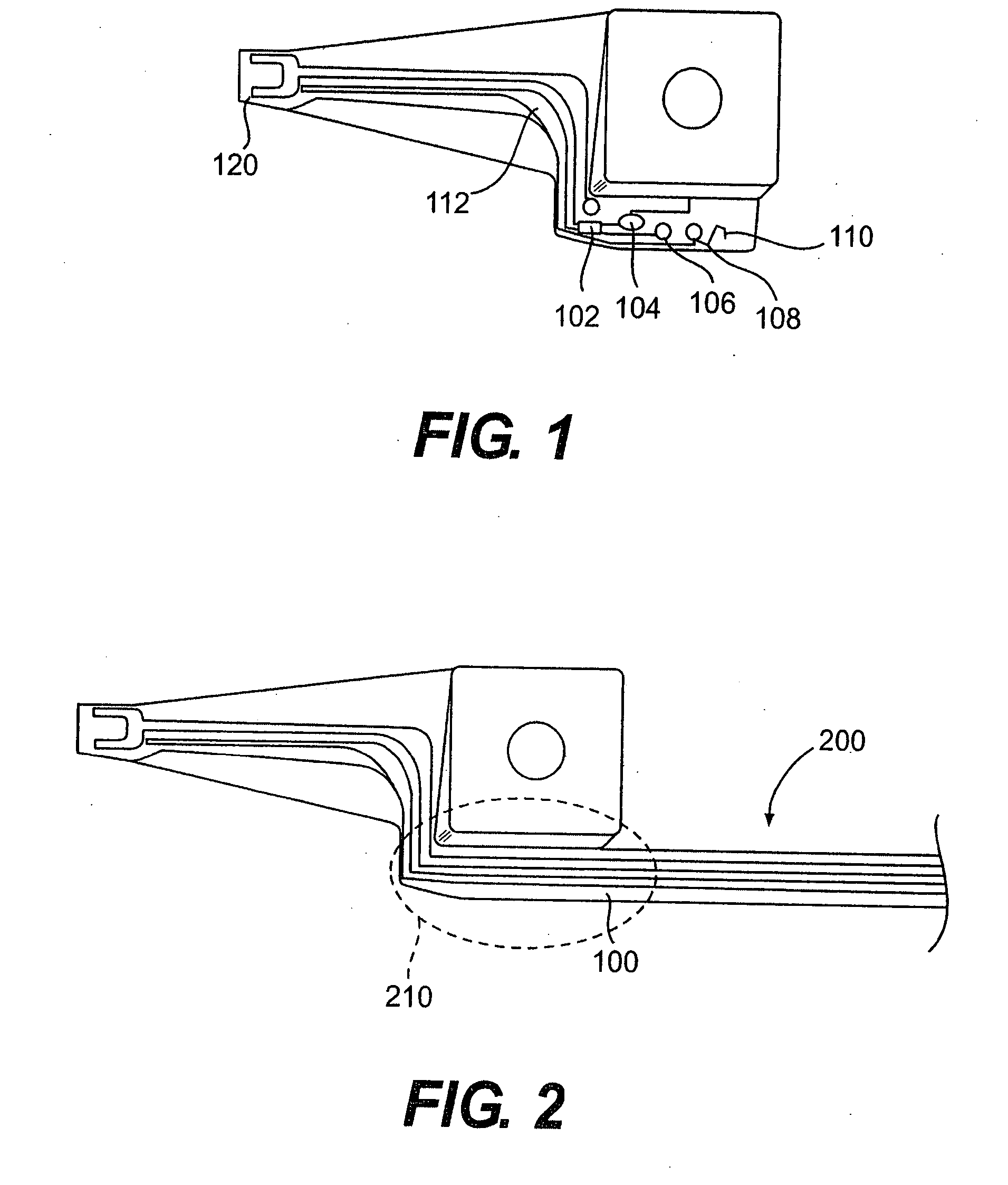

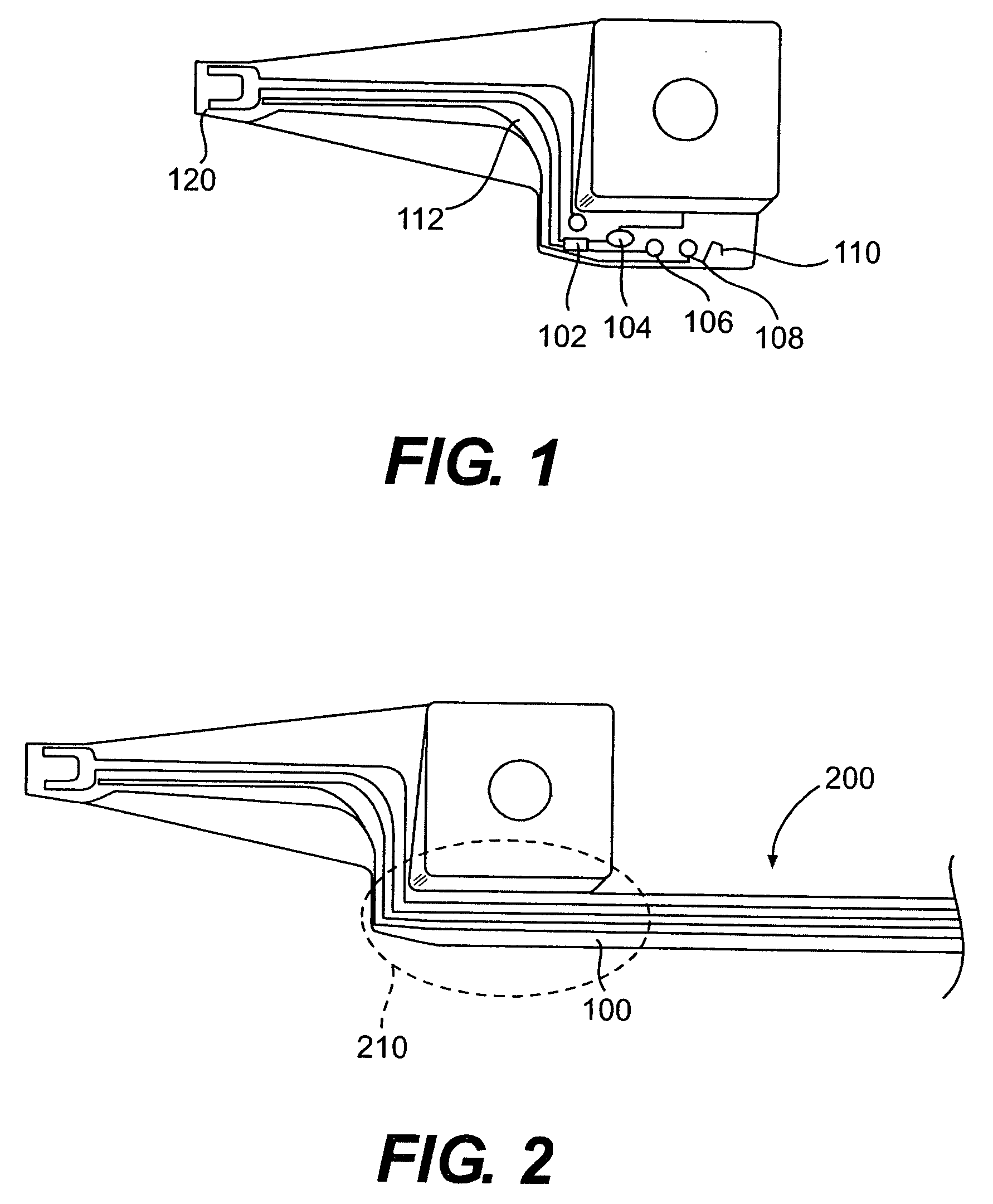

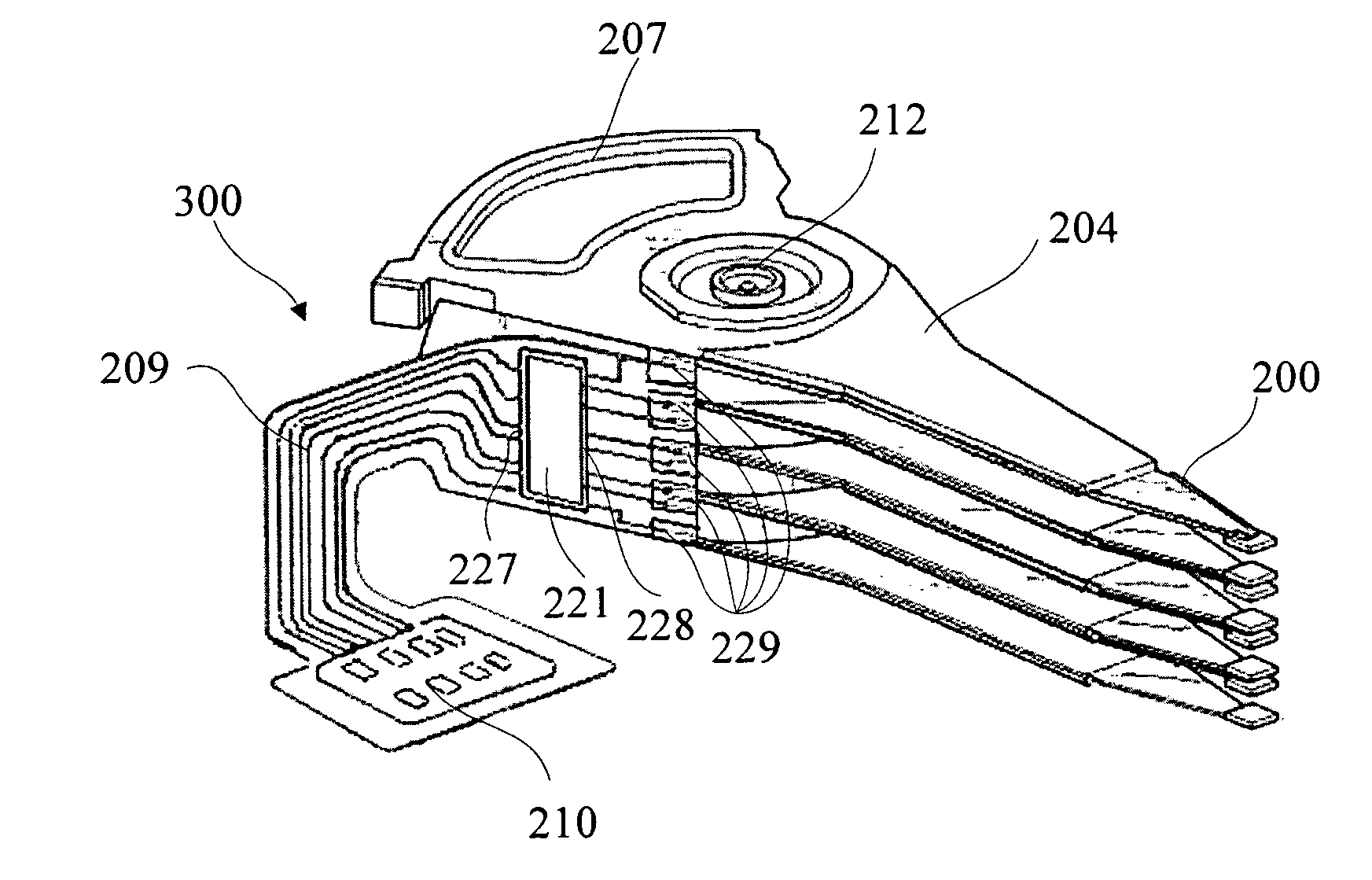

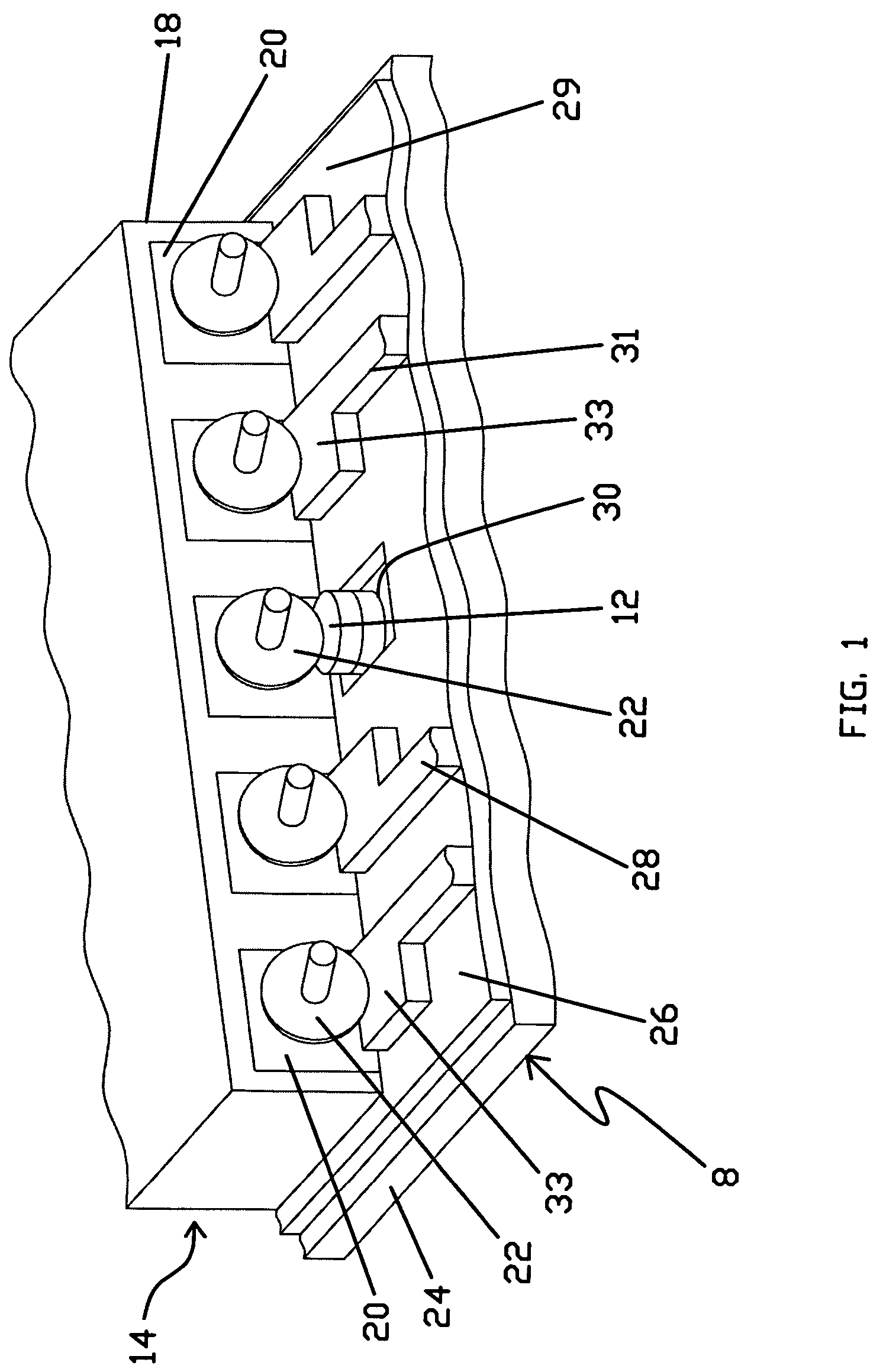

Head stack assembly with suspension tails extending into interfering slits in a flexible printed circuit

ActiveUS8068314B1Record information storageElectrical connection between arm and supportActuatorControl theory

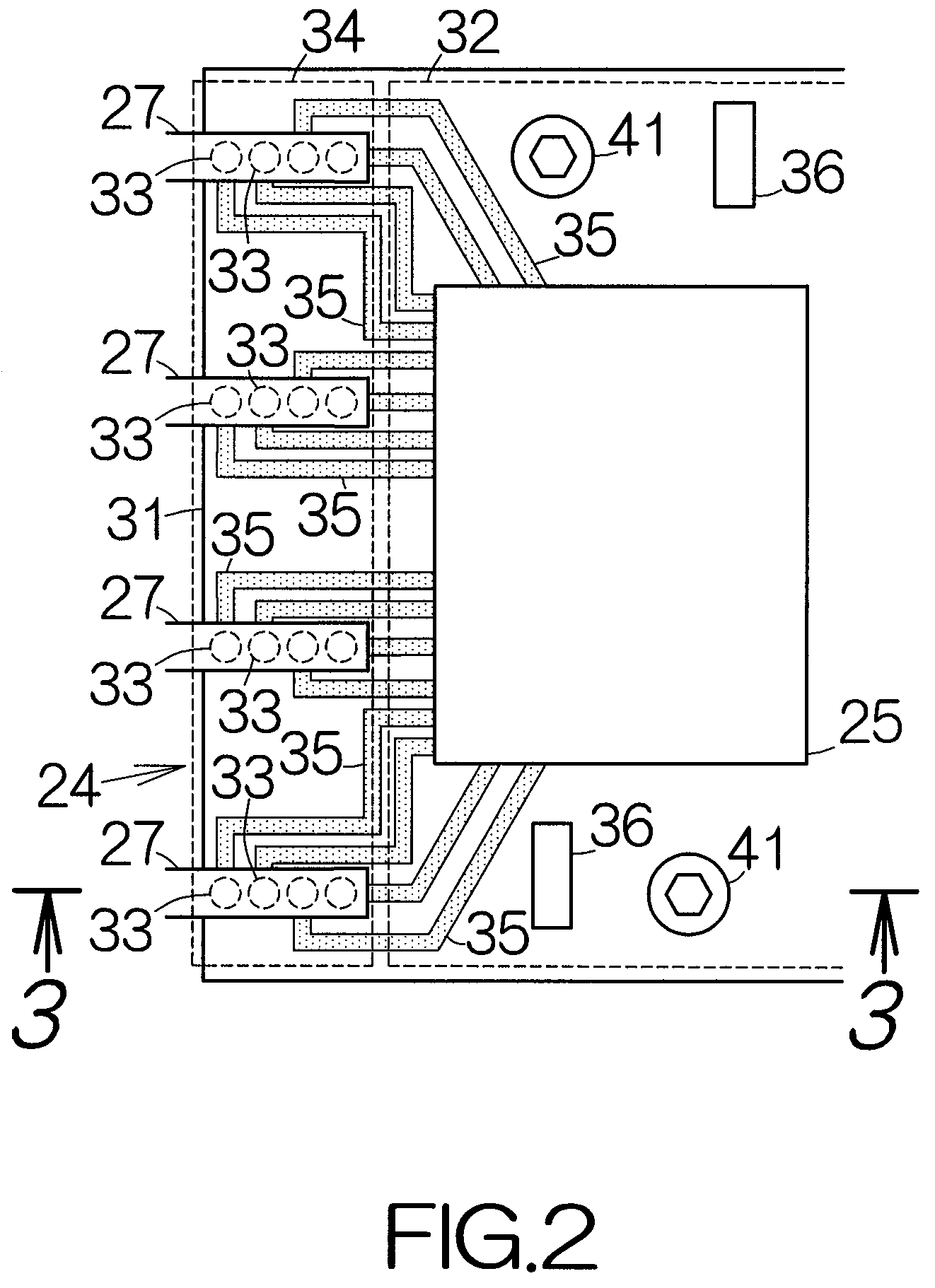

A novel head stack assembly (HSA) is disclosed and claimed. The HSA includes an actuator including an actuator body and an actuator arm extending from the actuator body, and a flexible printed circuit (FPC) adjacent the actuator body. The FPC includes a slit therethrough. A head gimbal assembly (HGA) is attached to the actuator arm. The HGA includes a load beam, a laminated flexure attached to the load beam, and a head attached to the laminated flexure. The laminated flexure has a flexure tail that includes an intermediate region that is disposed adjacent the actuator arm, and a terminal region that is electrically connected to the FPC. The terminal region is substantially orthogonal to the intermediate region. The intermediate region of the flexure tail extends into the slit, interferes with the slit, and contacts and deforms the FPC adjacent the slit.

Owner:WESTERN DIGITAL TECH INC

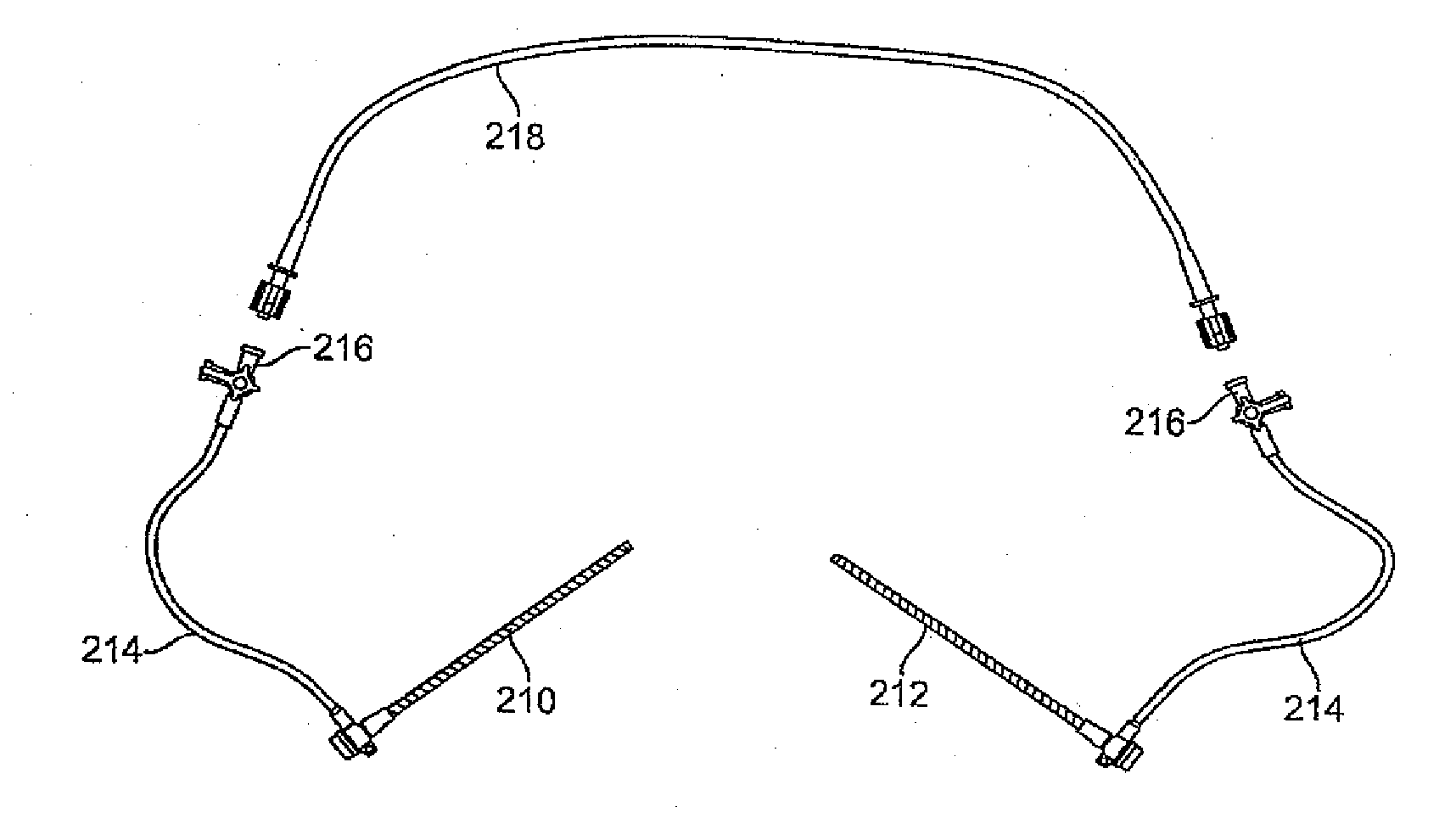

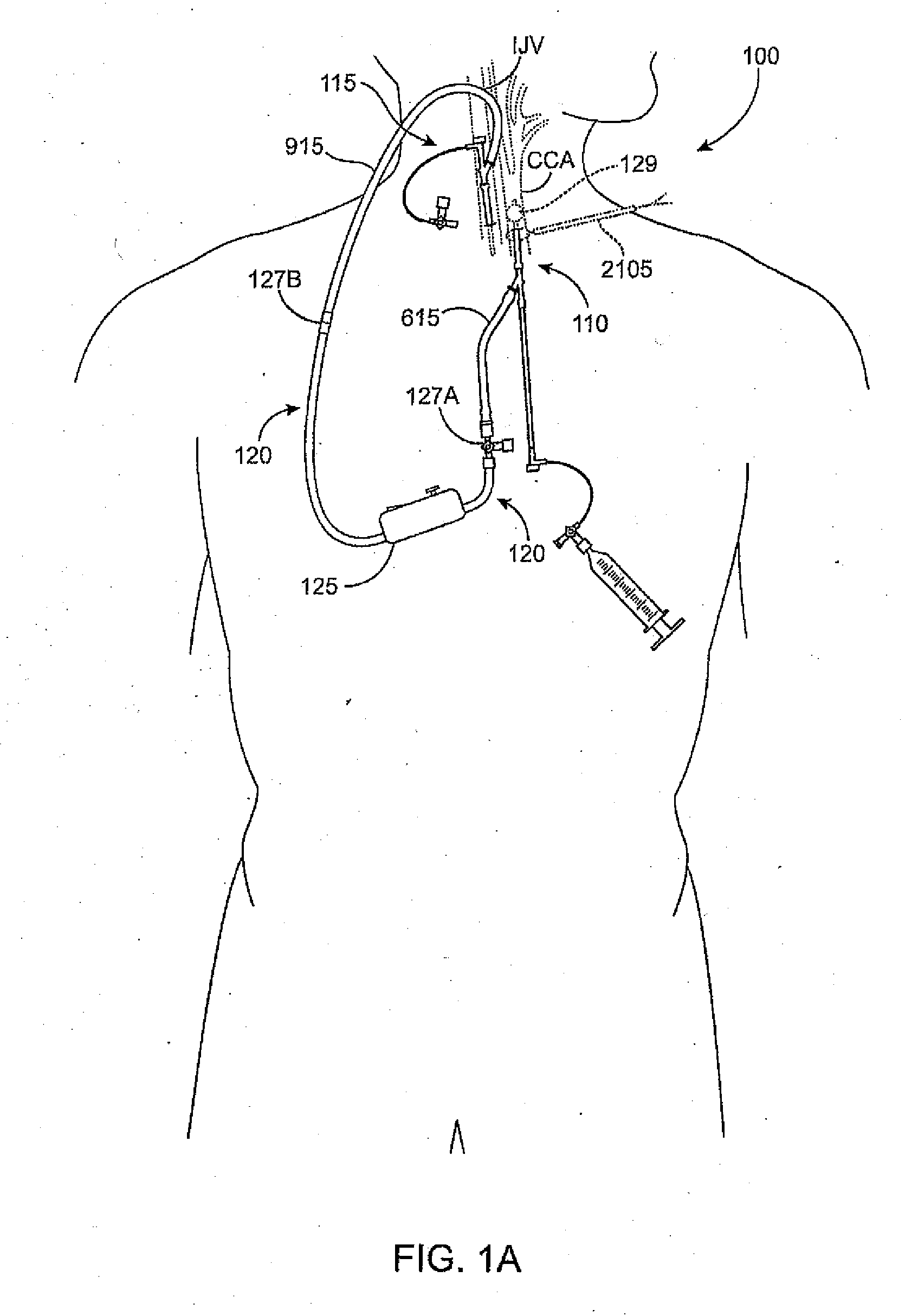

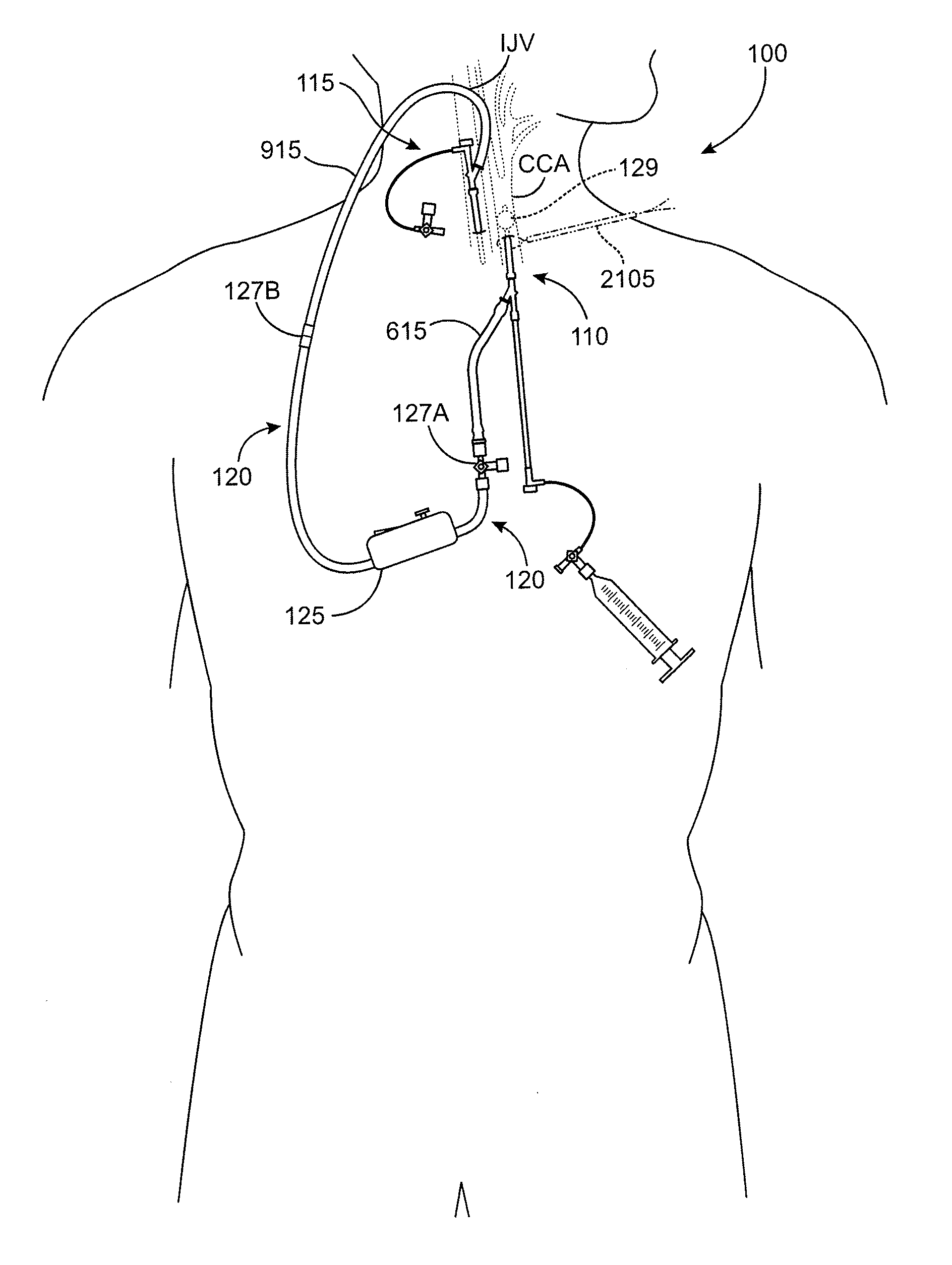

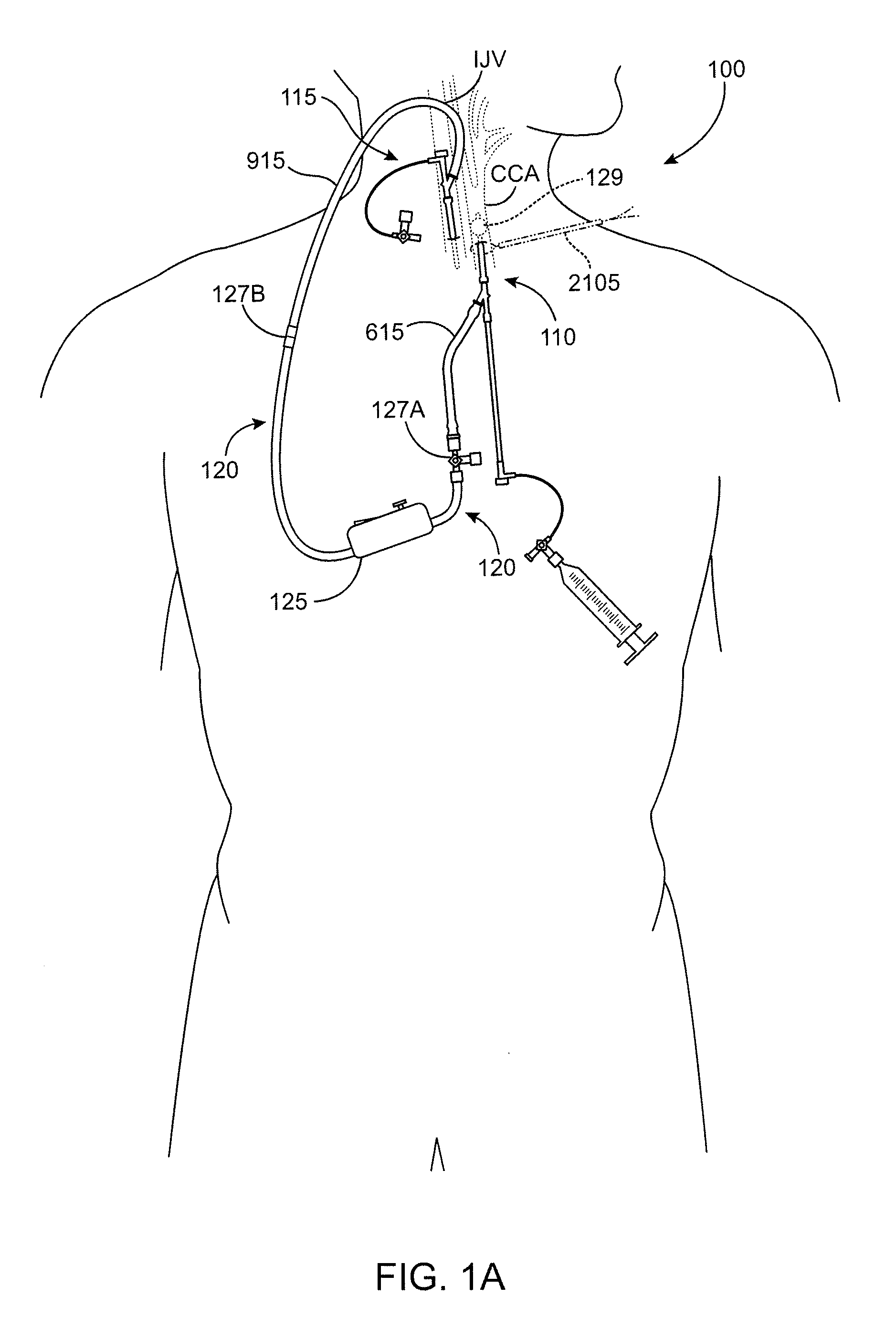

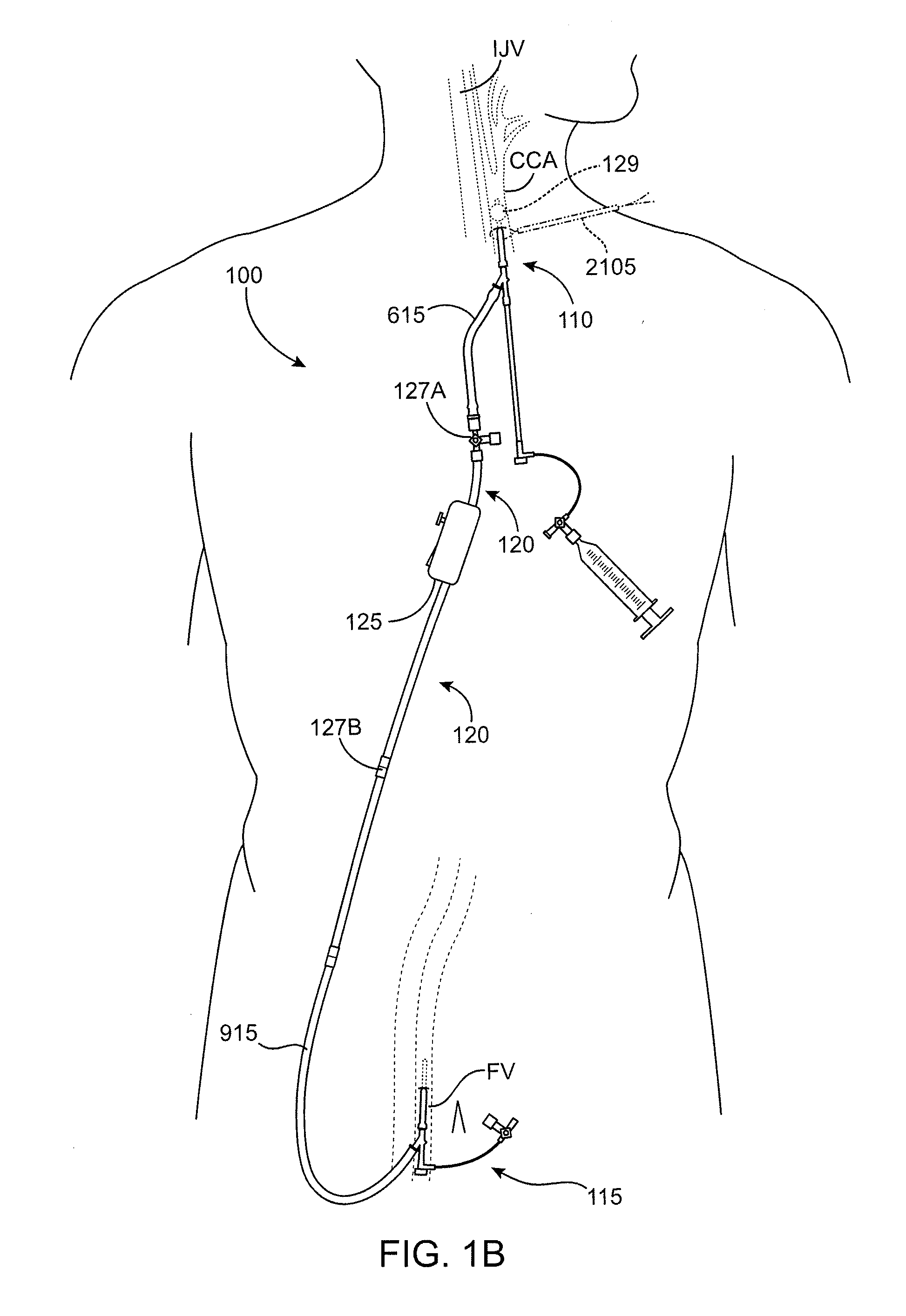

Methods and systems for establishing retrograde carotid arterial blood flow

ActiveUS20110166497A1Limit and prevent releasePromote blood circulationOther blood circulation devicesHaemofiltrationVeinFlow diverter

Interventional procedures on the carotid arteries are performed through a transcervical access while retrograde blood flow is established from the internal carotid artery to a venous or external location. A system for use in accessing and treating a carotid artery includes an arterial access device, a shunt fluidly connected to the arterial access device, and a flow control assembly coupled to the shunt and adapted to regulate blood flow through the shunt between at least a first blood flow state and at least a second blood flow state. The flow control assembly includes one or more components that interact with the blood flow through the shunt.

Owner:SILK ROAD MEDICAL

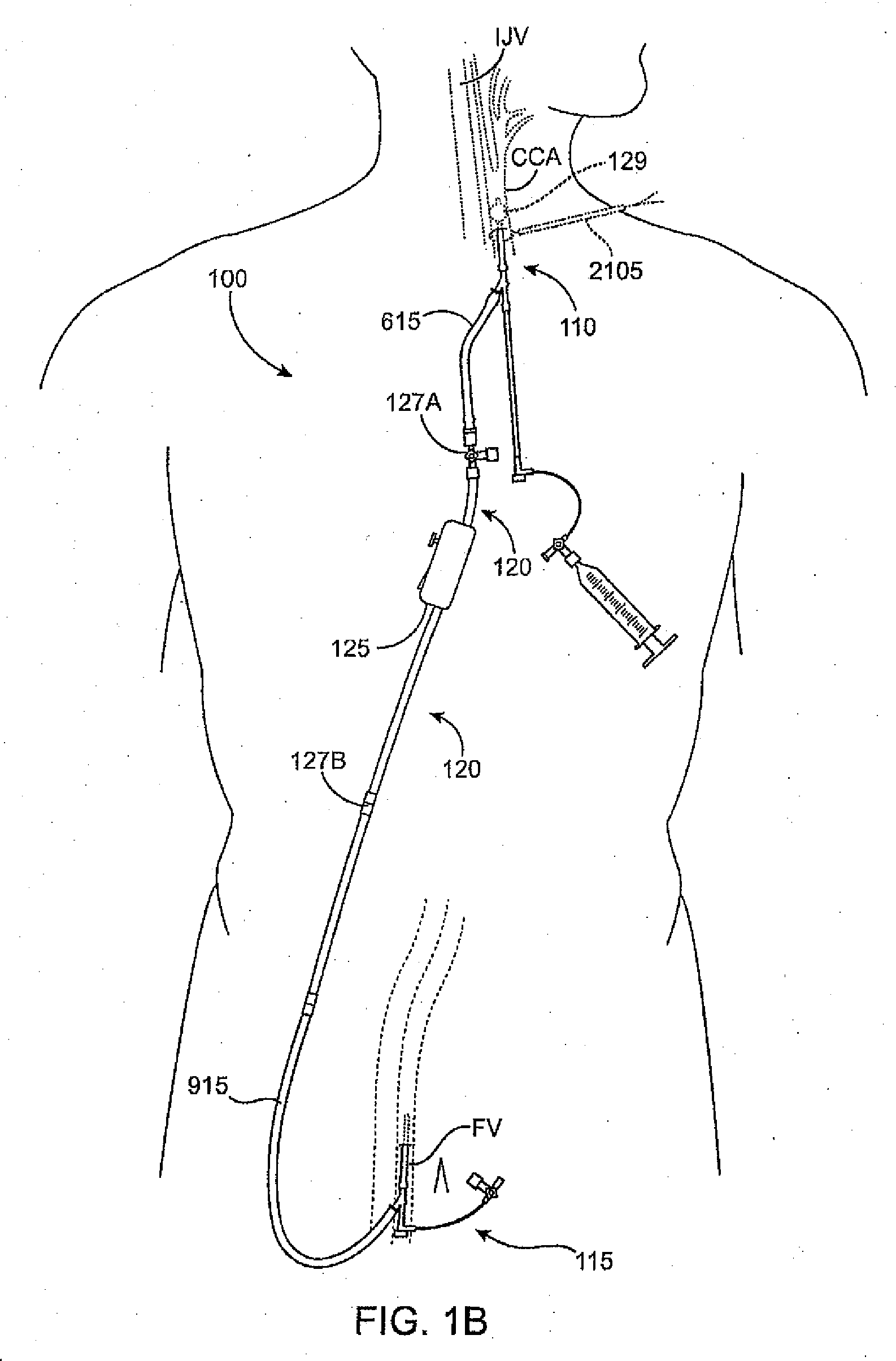

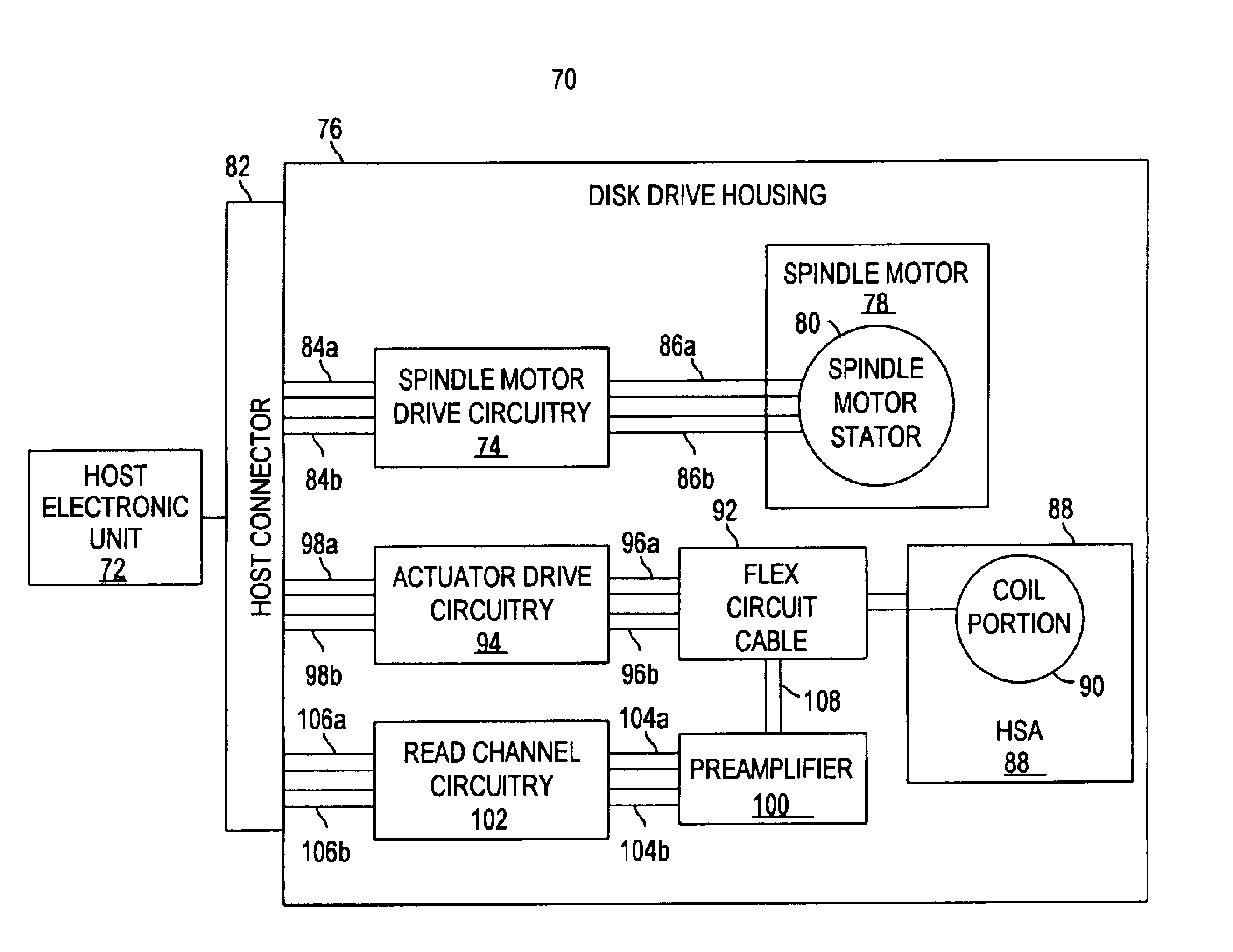

Disk drive including electrical traces integrally formed upon disk drive housing

InactiveUS6839199B1Carrier constructional parts disposition3D rigid printed circuitsElectricityMotor drive

A disk drive for use with a host electronic unit including spindle motor drive circuitry. The disk drive includes a disk drive housing, and a spindle motor rotatably attached to the disk drive housing. The spindle motor includes a stator. The disk drive further includes a host connector attached to the disk drive housing which is operably connectable to the spindle motor drive circuitry for receiving electrical signals from the spindle motor drive circuitry for controlling the spindle motor. The disk drive further includes a stator electrical trace integrally formed upon the disk drive housing from the stator to the host connector for electrically connecting the stator and the host connector.

Owner:WESTERN DIGITAL TECH INC

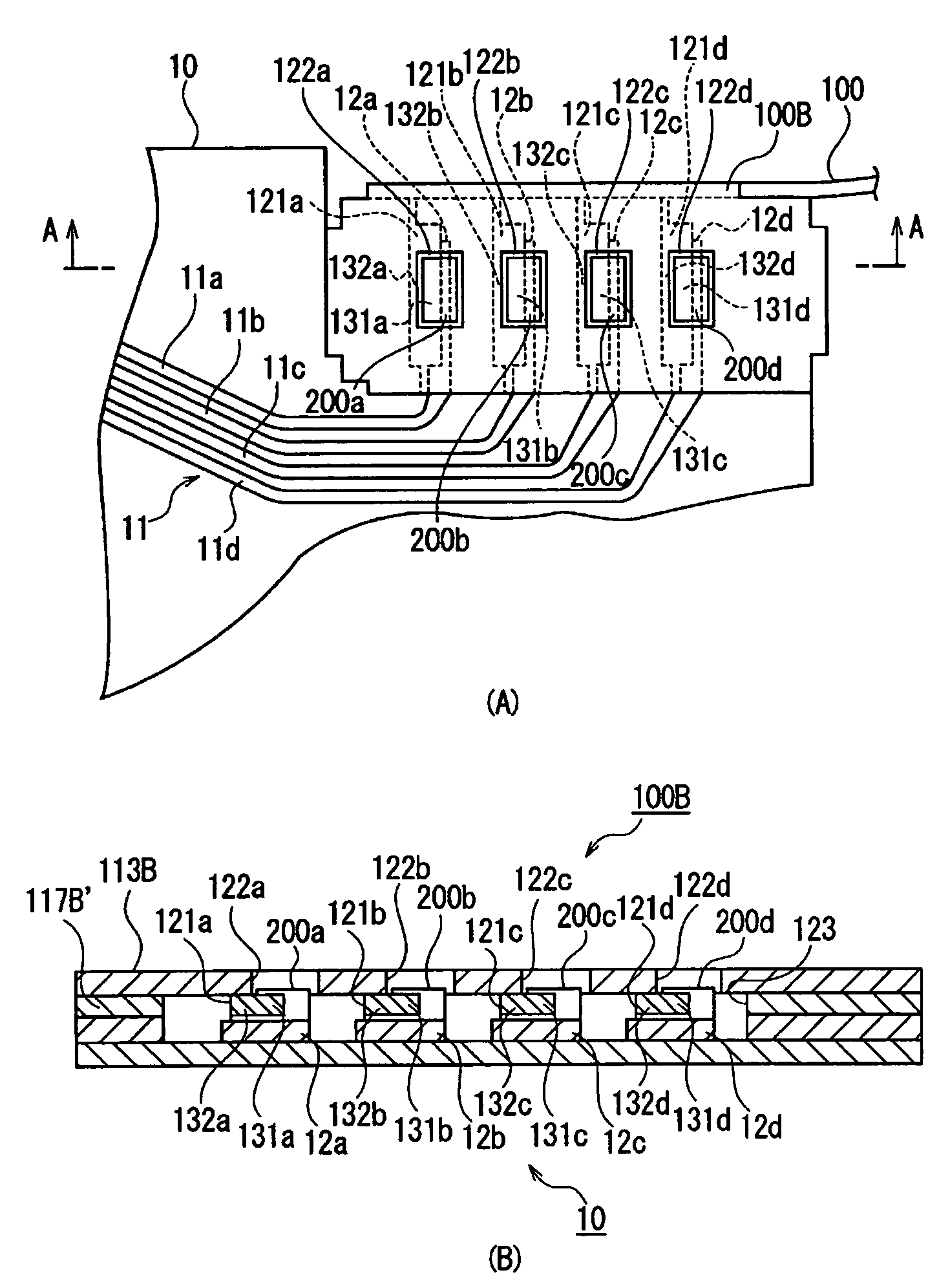

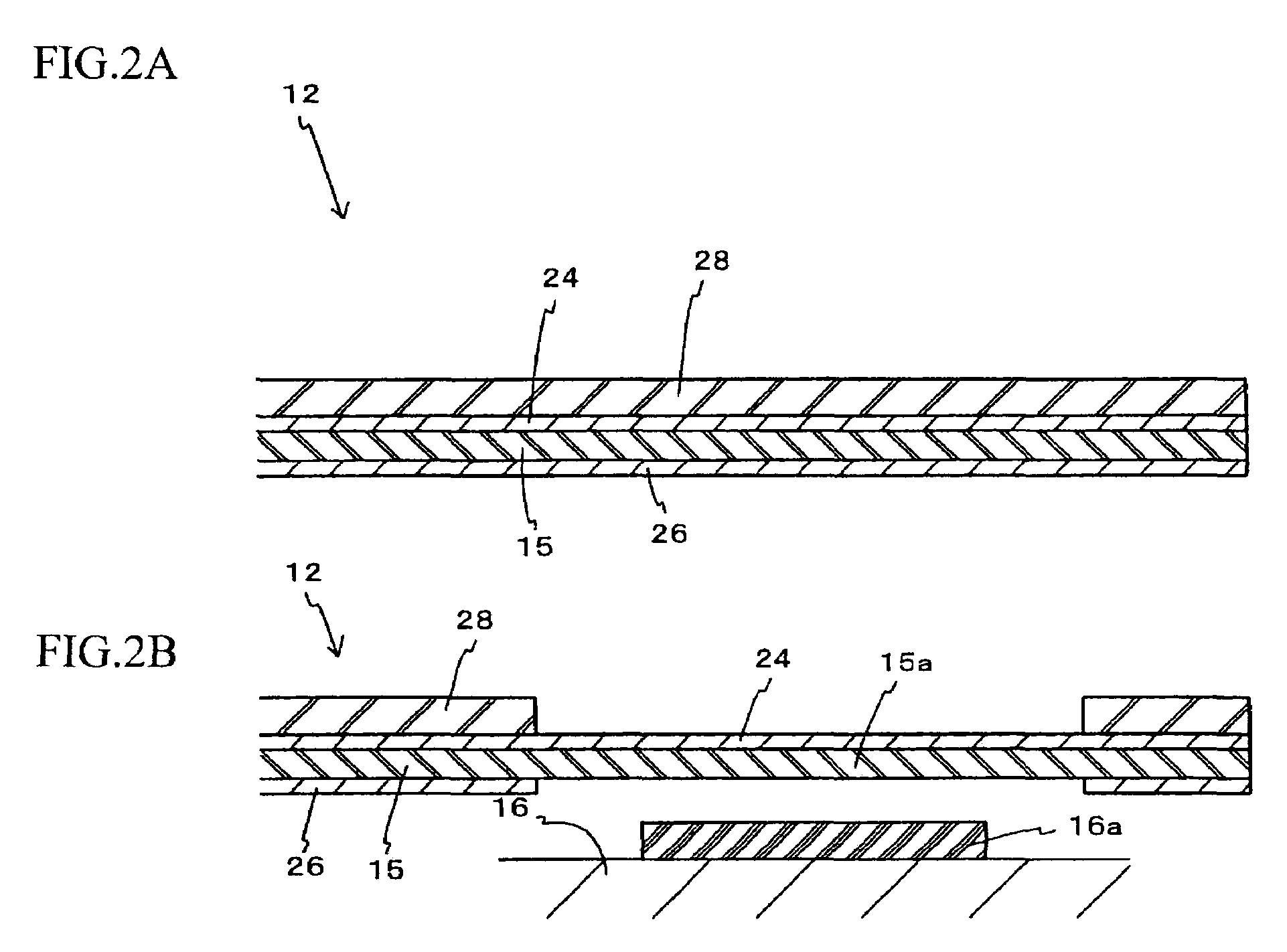

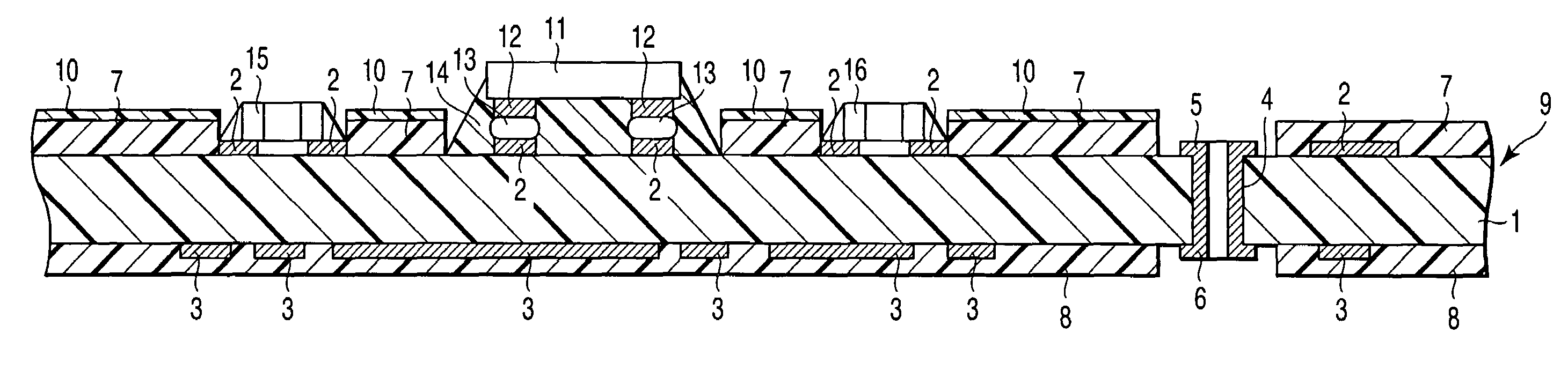

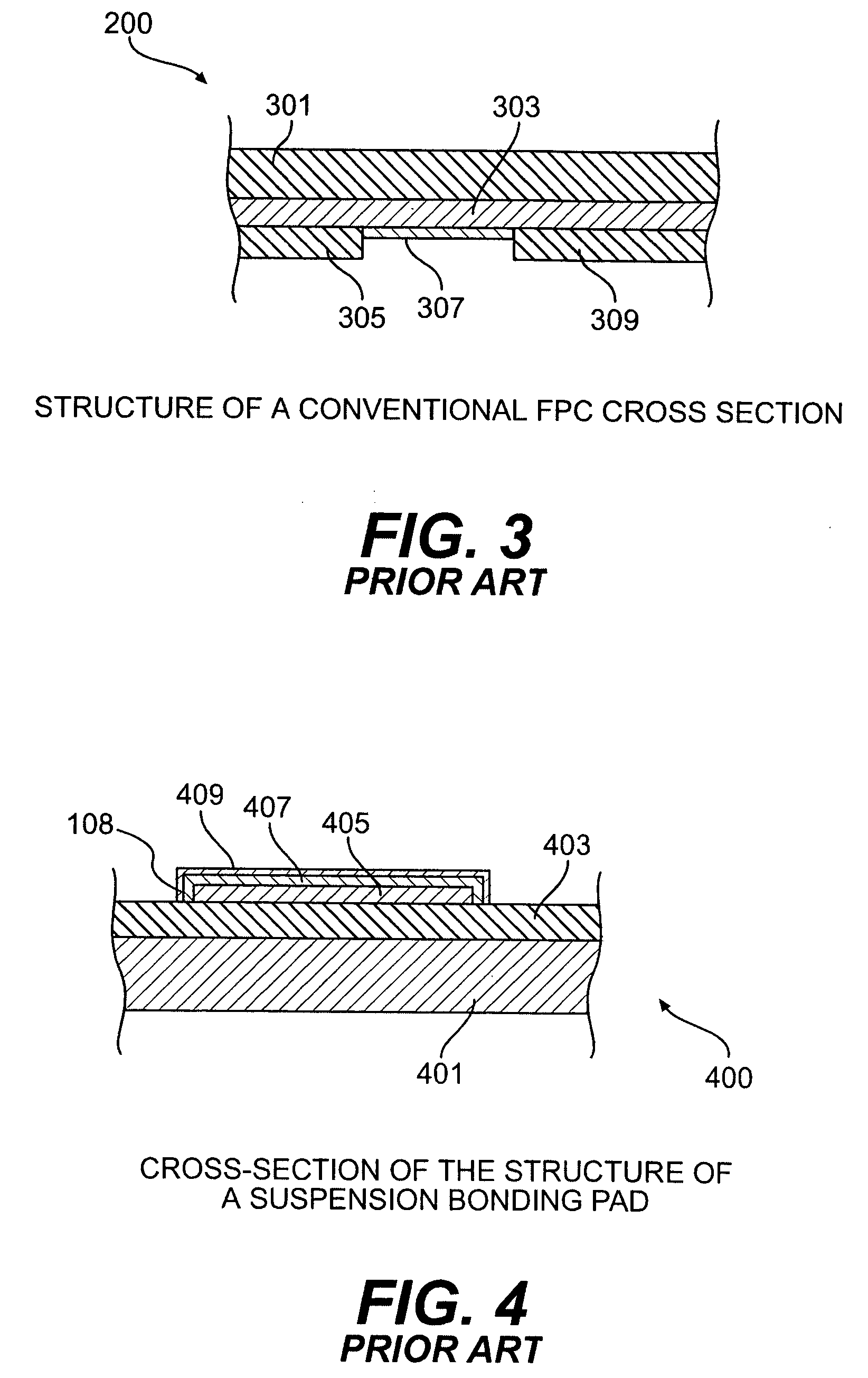

Magnetic disk drive, wiring connection structure and terminal structure

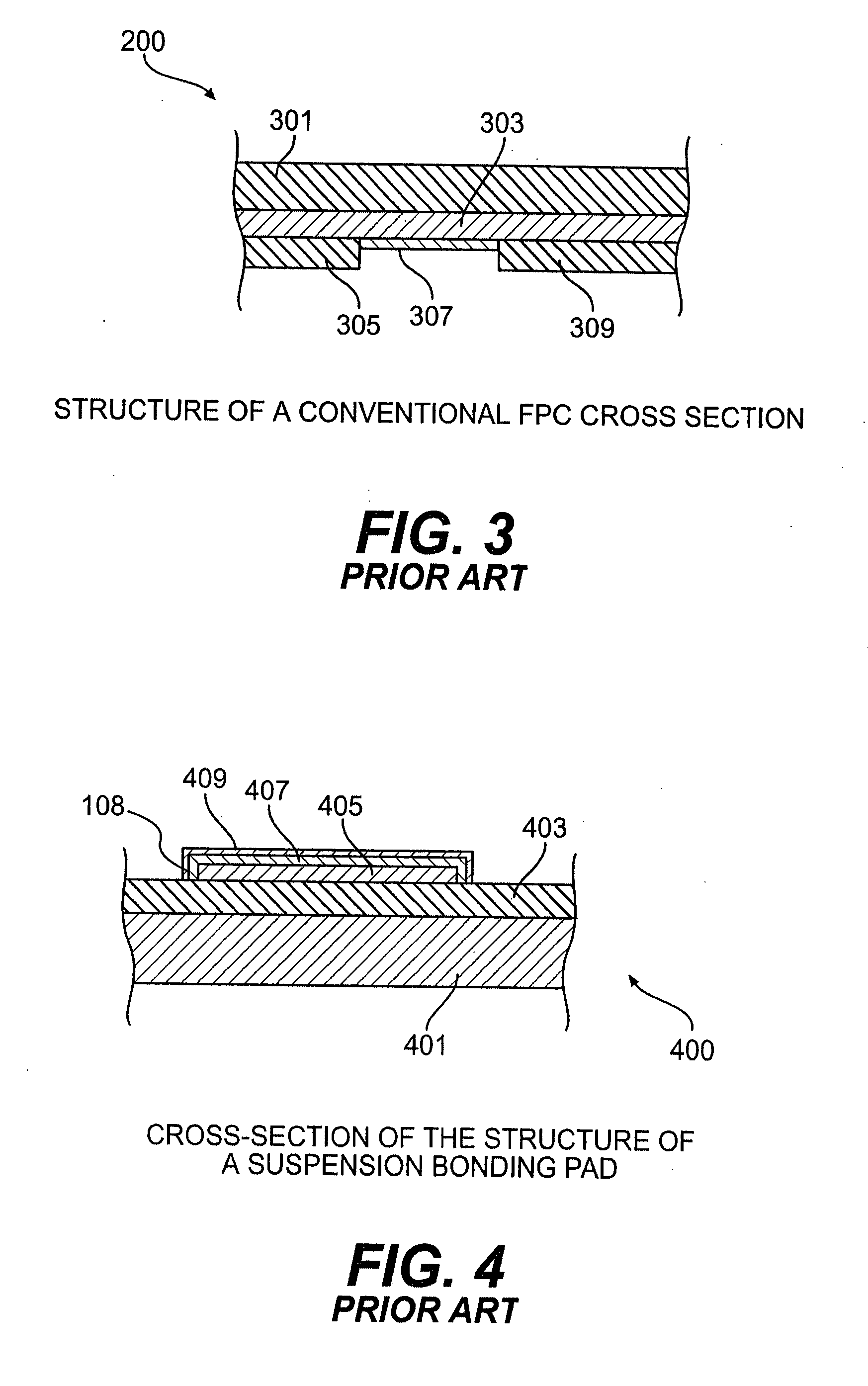

InactiveUS7372669B2Avoid crackingEasy to solvePrinted circuit aspectsRecord information storageElectrical conductorFlexible electronics

Terminals of a flexible printed circuit board and terminals of a wiring trace in a head suspension assembly are to be connected with each other by soldering without causing a soldering defect. In an embodiment, a terminal structure of a multi-connector in a wiring trace which includes an insulating layer and a conductor pattern portion formed on a surface of the insulating layer is provided with exposed portions of terminals exposed from apertures formed in part of the insulating layer and is also provided with lining portions adjacent to the exposed portions in a longitudinal direction of the conductor pattern portion and bonded to the insulating layer. Even if terminals of the multi-connector are cracked when soldered, not only conductivity is ensured, but also it is possible to strengthen the terminals, because the lining portions of the terminals are bonded to the insulating layer.

Owner:WESTERN DIGITAL TECH INC

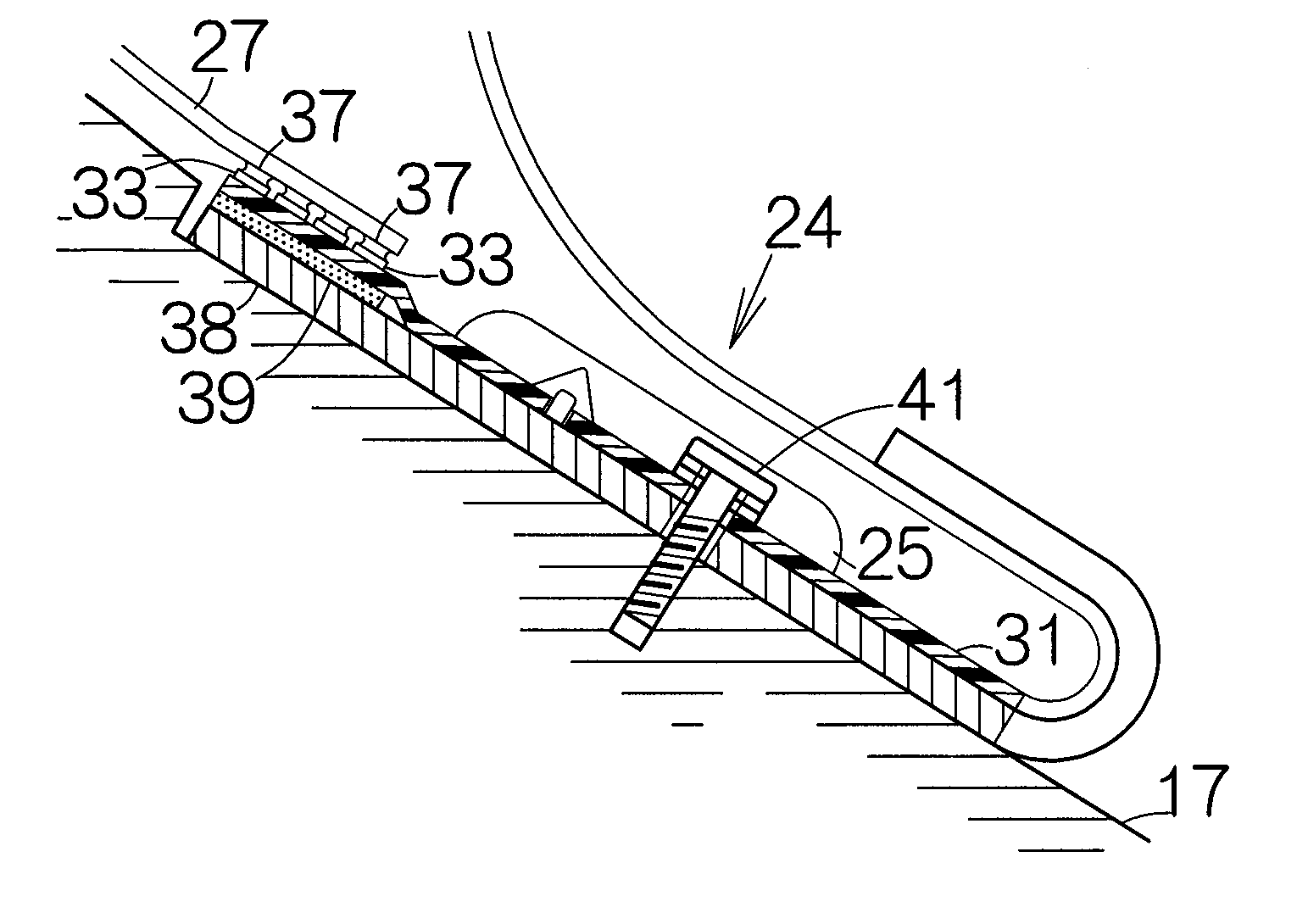

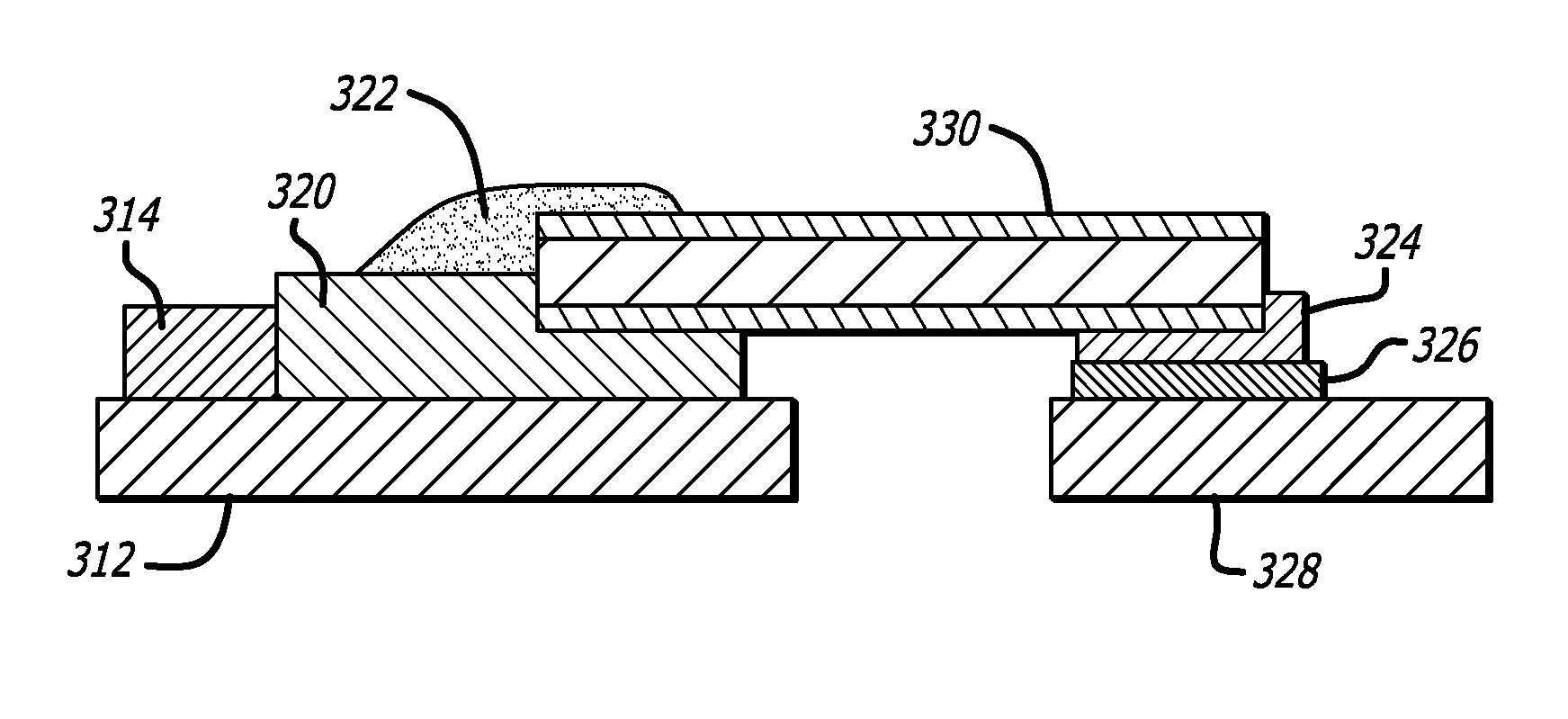

Hard drive suspension microactuator with restraining layer for control of bending

ActiveUS9117468B1Reduce and eliminate and changeIncrease distanceArm with actuatorsPiezoelectric/electrostriction/magnetostriction machinesHard disc driveElectrical connection

A PZT microactuator such as for a hard disk drive has a restraining layer bonded on its side that is opposite the side on which the PZT is mounted. The restraining layer comprises a stiff and resilient material such as stainless steel. The restraining layer can cover all of the top of the PZT, or most of the top of the PZT with an electrical connection being made to the PZT where it is not covered by the restraining layer. The restraining layer reduces bending of the PZT as mounted and hence increases effective stroke length, or reverses the sign of the bending which increases the effective stroke length of the PZT even further.

Owner:MAGNECOMP

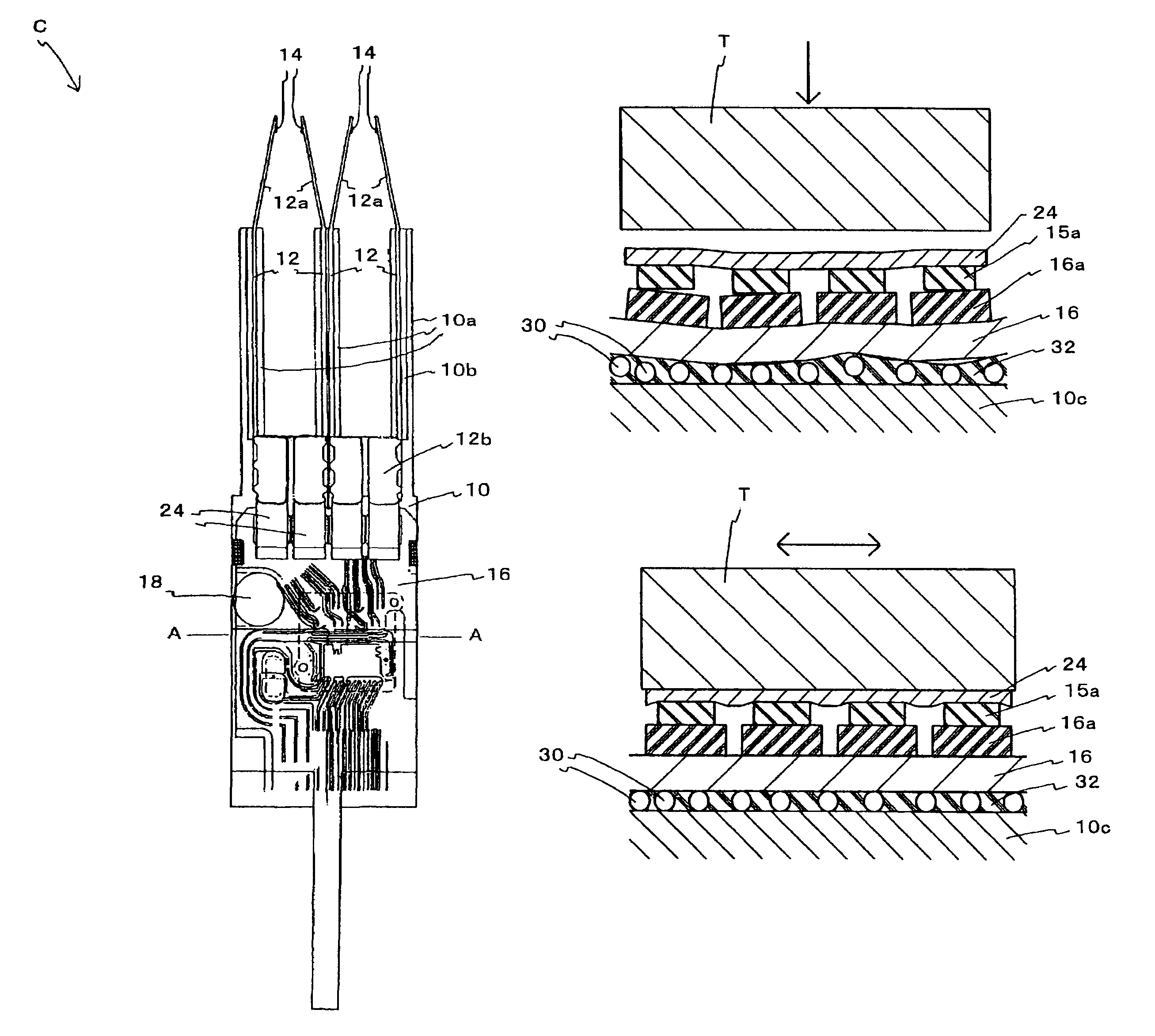

Carriage assembly of a hard disk drive

InactiveUS7385788B2Improve liquidityDeformation of the adhesive layer is facilitatedLaminating printed circuit boardsPrinted circuit aspectsHard disc driveAdhesive

A carriage assembly of a hard disk drive is constructed so that the bonding of flying leads of a long tail suspension circuit board and bonding terminals of a flexible printed circuit board can be carried out uniformly and reliably, and the problem of the flying leads breaking when the flying leads are pulled off the bonding terminals does not occur. The flexible printed circuit board is attached to a reinforced part by an adhesive in which spacers with a substantially equal particle diameter are mixed, and the flying leads and the bonding terminals are bonded together by ultrasonic bonding by applying ultrasonic vibration in a state where the flying leads are pressed onto the bonding terminals. In addition, an insulating film is provided on an opposite surface of the flying leads to the surface bonded to the bonding terminals, and during the ultrasonic bonding, ultrasonic vibration is applied in a state where the flying leads are pressed via the insulating film onto the bonding terminals.

Owner:TOSHIBA STORAGE DEVICE CORP

High conductivity ground planes for integrated lead suspensions

ActiveUS7710687B1Improve conductivityHigh materialElectrical connection between head and armRecord information storageGround planeHigh conductivity

An integrated lead flexure or suspension including an insulating layer, a plurality of traces on the insulating layer and a stainless steel base layer on the side of the insulating layer opposite the traces. The traces are free of a conductive shield layer on the side opposite the insulating layer. One or more voids extend through the stainless steel layer below the traces. The voids are filled with a high conductivity metal layer.

Owner:HUTCHINSON TECH

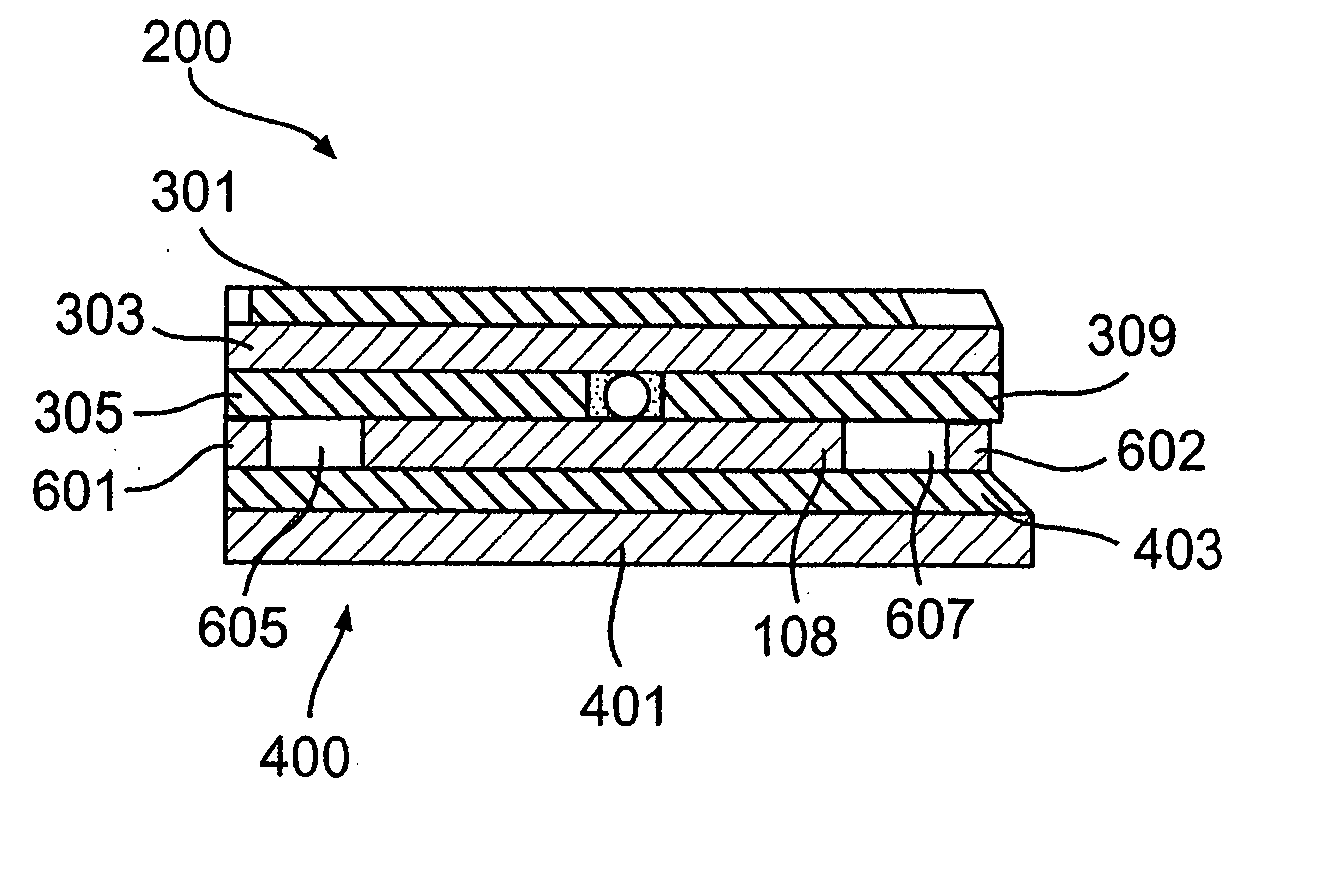

Method for forming an electrical interconnect to a spring layer in an integrated lead suspension

A method for forming an electrical interconnect to the spring metal layer in an integrated lead suspension or suspension component of the type having a multi-layer structure including a spring metal layer and a conductor layer separated by a dielectric insulator layer. The method includes forming an aperture through at least one of either the spring metal and conductor layers, and optionally through the dielectric layer, at an interconnect site. A first mass of malleable conductive metal is inserted into the aperture. The mass of metal is then coined to form a stud that engages at least the spring metal layer at the interconnect site.

Owner:HUTCHINSON TECH

Disk Drive Assembly Having Flexible Support for Flexible Printed Circuit Board

InactiveUS20100188778A1Reduce the amount requiredReduce vibrationCircuit bendability/stretchabilityPrinted circuit aspectsExit angleEngineering

A disk drive assembly includes a movable assembly having a mounting arm, a stationary electronics module, a flexible printed circuit board (PCB) electrically connecting the movable assembly to the stationary electronics module, and a flexible support sandwiched between the flexible PCB and the mounting arm. The flexible support is attached to the mounting arm and the flexible PCB, and extends past the mounting arm of the movable assembly. The flexible support is flexible enough to flex with the flexible PCB but has sufficient rigidity so that an exit point and an exit angle of the flexible PCB can vary during movement of the movable assembly. In addition, the flexible PCB is attached to the flexible support through an adhesive layer that damps vibrations in the flexible PCB.

Owner:KK TOSHIBA

Flexible printed circuit board unit contributing to reliable soldering and suppression of increased temperature

InactiveUS6992864B2Avoid deformationUndesirable limitationElectrical connection between head and armApparatus for flat record carriersConductive materialsFlexible electronics

A thermal component is mounted on the front surface of an isolator sheet within a first specific area. A thermally-conductive material is located on the back surface of the isolator sheet on the back of the first specific area. An electrically-conductive material is located on the front surface of the isolator sheet within a second specific area. A thermally-insulating material is located on the back surface of the isolator sheet on the back of the second specific area. The flexible printed circuit board unit of this type allows heat of the thermal component to efficiently radiate from the thermally-conductive material. An increase in temperature can be suppressed in the thermal component. Heat can reliably stay in the electrically-conductive material when a solder material is applied to the surface of the electrically-conductive material. The solder material is allowed to reliably fuse.

Owner:FUJITSU LTD

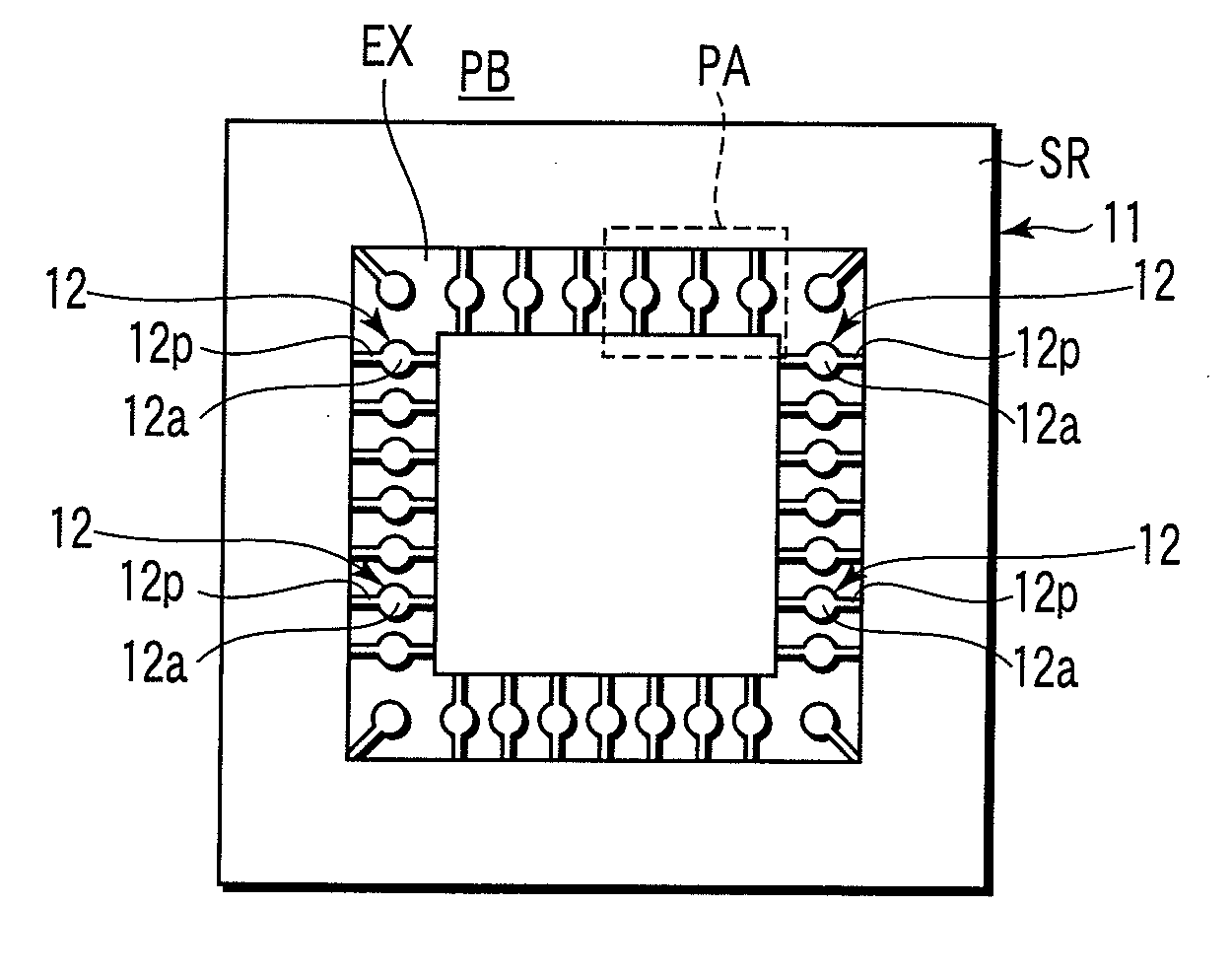

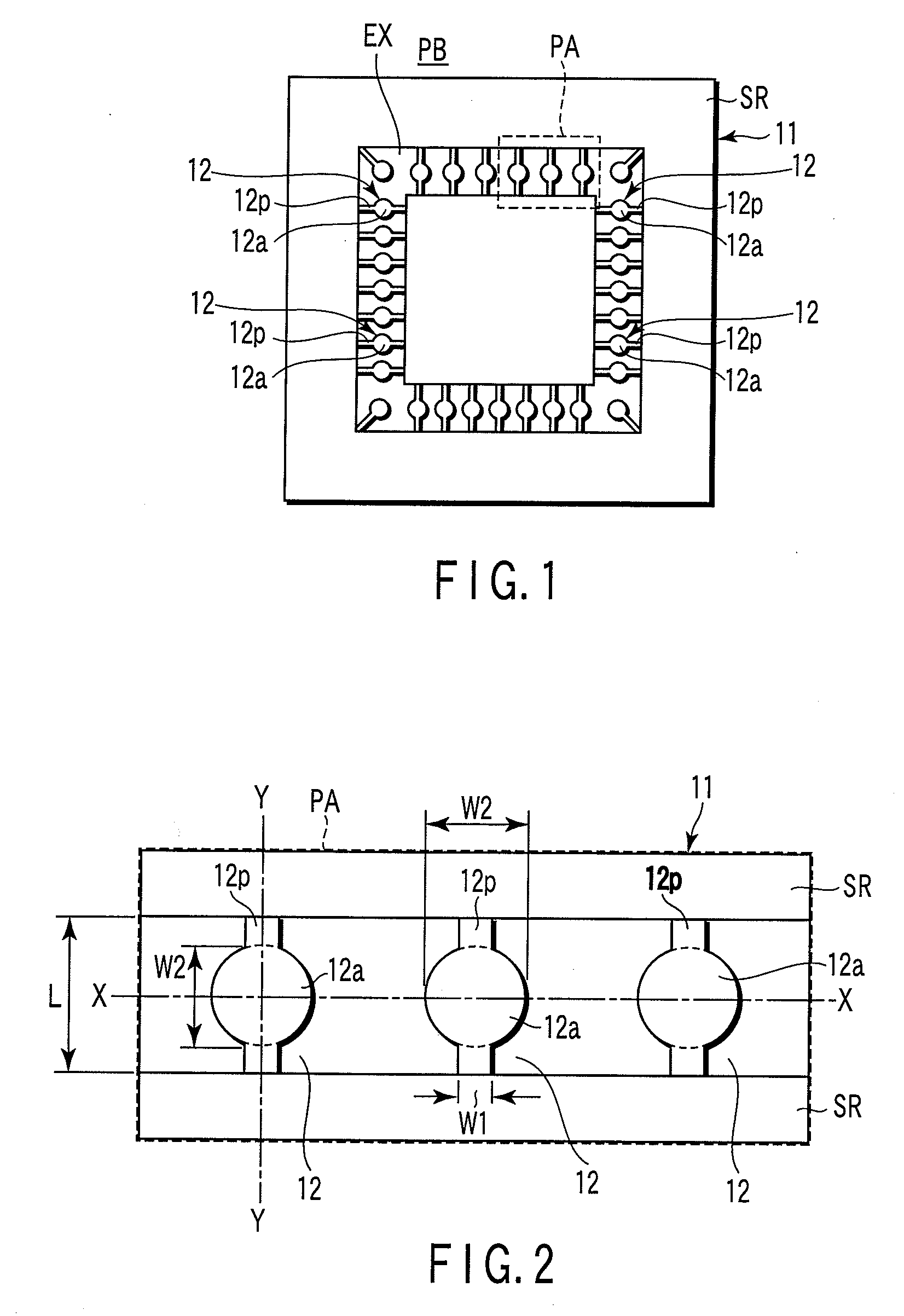

Module substrate and disk apparatus

InactiveUS20060103030A1Dielectric materialsSemiconductor/solid-state device detailsElectrical and Electronics engineeringMagnetic disks

A module substrate includes an insulating substrate, a circuit pattern formed on at least a main surface of the insulating substrate, a protection film formed on the main surface of the insulating substrate including the circuit patter such as to expose a mount region of the circuit pattern, an active element part mounted on the mount region of the circuit pattern, a fluororesin film formed on the protection film at least in a vicinity of the mount region of the active element part, and an underfill filled between the active element part and the mount region of the circuit pattern.

Owner:KK TOSHIBA

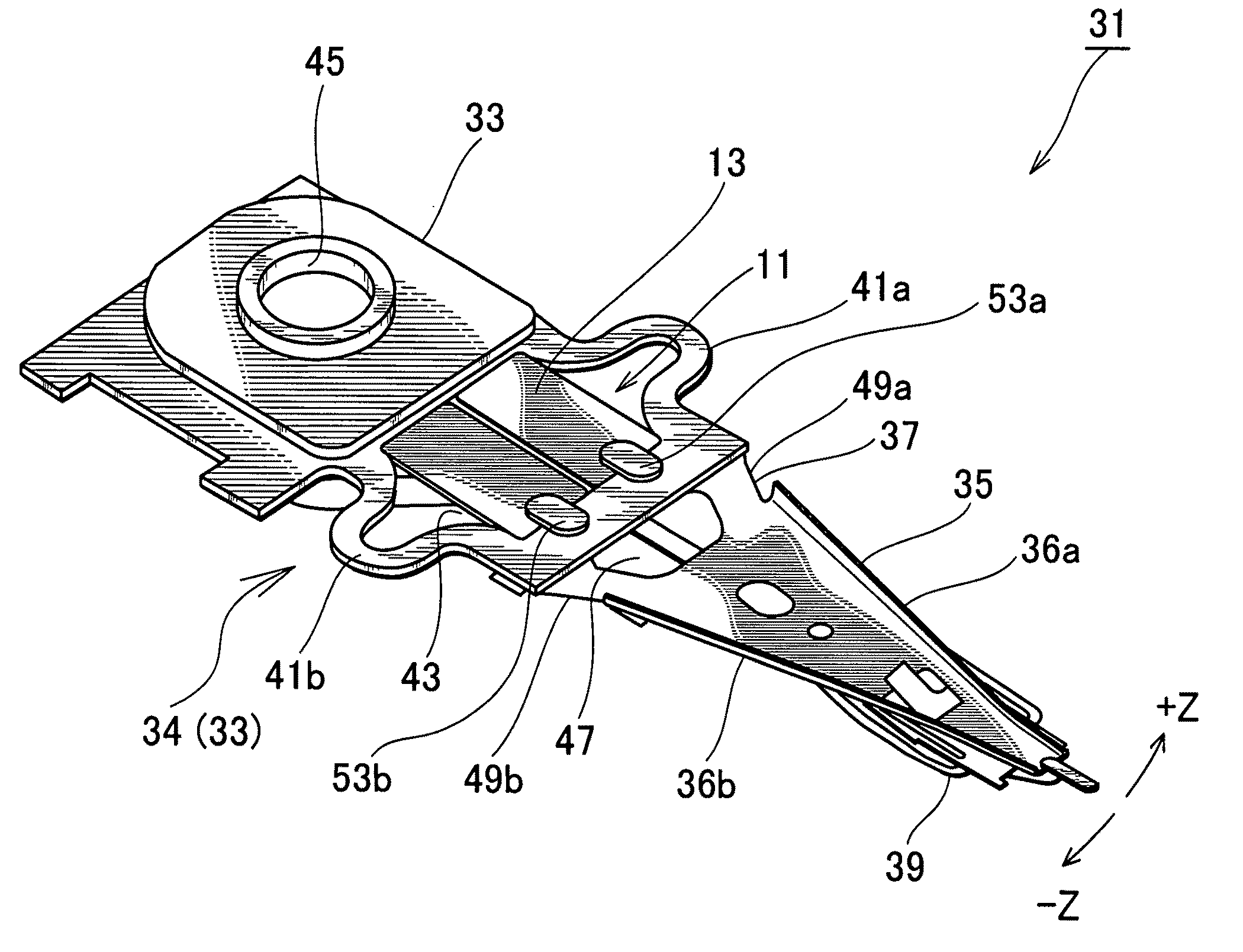

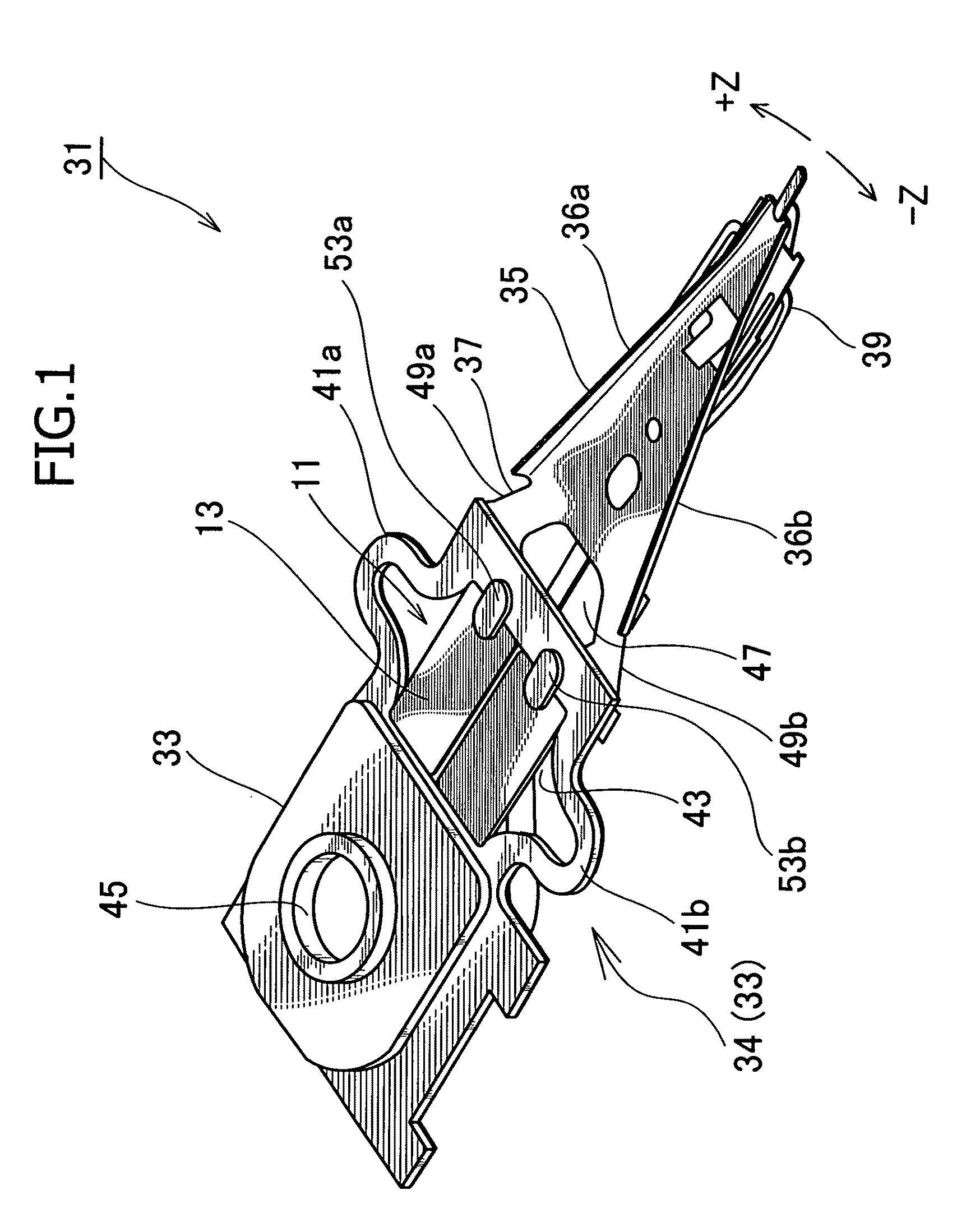

Electrical connecting structure for piezoelectric element, piezoelectric actuator, head suspension, and electrical connecting structure for conductive part

ActiveUS8199442B2Without deteriorating productivity and reliabilityAccurate wiringTrack finding/aligningArm with actuatorsElectricityAdhesive

A piezoelectric element 13 has a common electrode 19 that receives electricity from a terminal 57. The terminal 57 has a through hole 67 and an electric insulating layer 61. The piezoelectric element 13 is arranged so that the common electrode 19 faces the electric insulating layer 61 of the terminal 57. A liquid stopper 69 is formed around the through hole 67 so as to come between the common electrode 19 and the terminal 57 when the common electrode 19 and terminal 57 are set to face each other. A liquid conductive adhesive 71 is injected into the through hole 67 to fill a gap defined by the liquid stopper 69 between the terminal 57 and the common electrode 19 and secure electric connection between the terminal 57 and the common electrode 19. This configuration improves the reliability of wiring to the piezoelectric element and prevents the piezoelectric element from being damaged.

Owner:NHK SPRING CO LTD

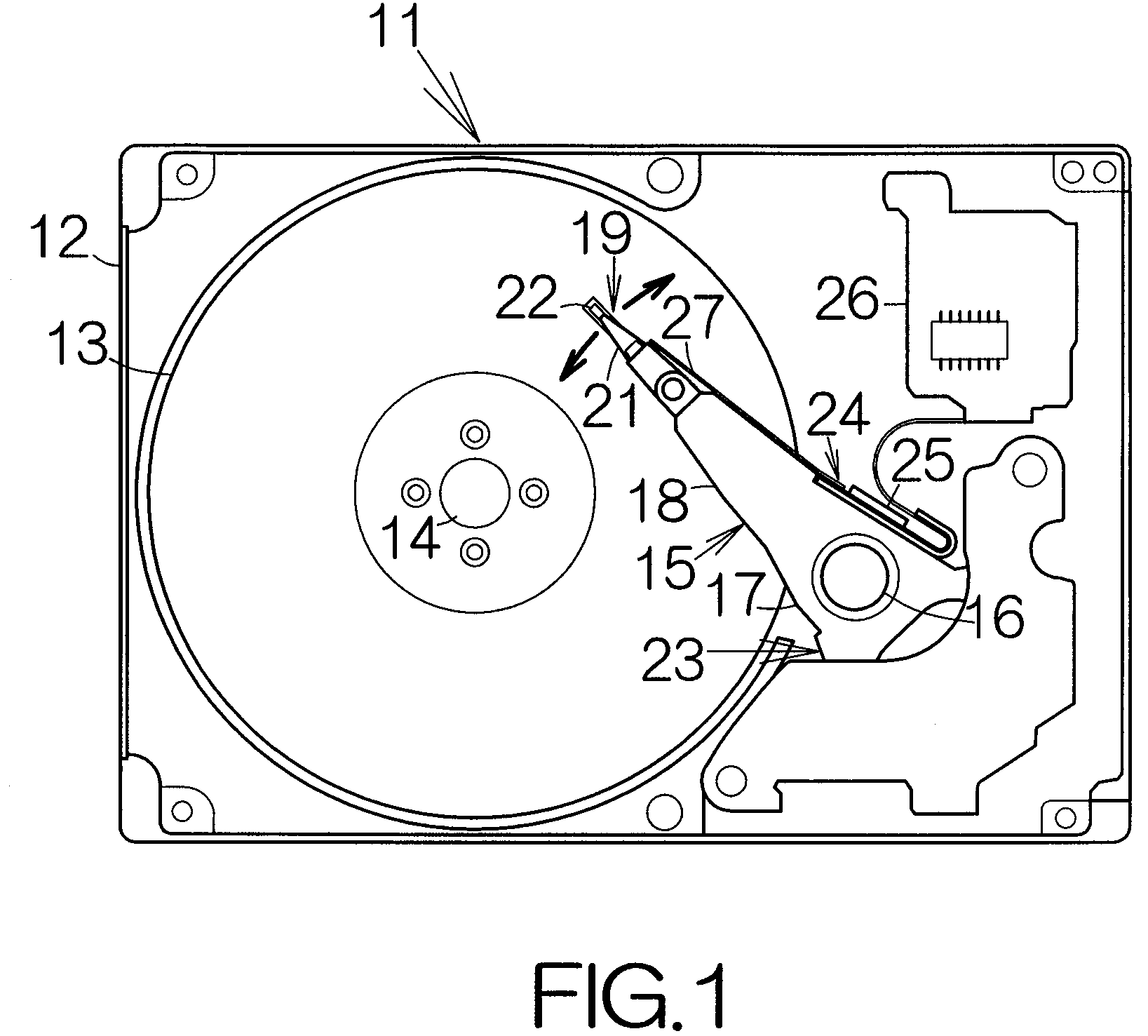

Recording disk drive capable of suppressing vibration of flexible printed circuit board

InactiveUS20070153427A1Vibration of flexibleImprove accuracyLaminating printed circuit boardsRecord information storageResidual vibrationEngineering

A fixing member is spaced from a head actuator by a predetermined distance. A flexible printed circuit board extends at least from the head actuator to the fixing member. The flexible printed circuit board is superposed on the surface of the fixing member. A viscoelastic layer and a protecting layer are overlaid on the surface of the flexible printed circuit board. A clip clips all the fixing member, the flexible printed circuit board, the viscoelastic layer and the protecting layer together. When a head slider is positioned, the head actuator changes its attitude relative to a recording disk. The inertial force based on the rotation causes the first flexible printed circuit board to vibrate when the actuator block stops rotating. The viscoelastic layer serves to absorb this residual vibration of the first flexible printed circuit board. Vibration of the flexible printed circuit board can be suppressed.

Owner:FUJITSU LTD

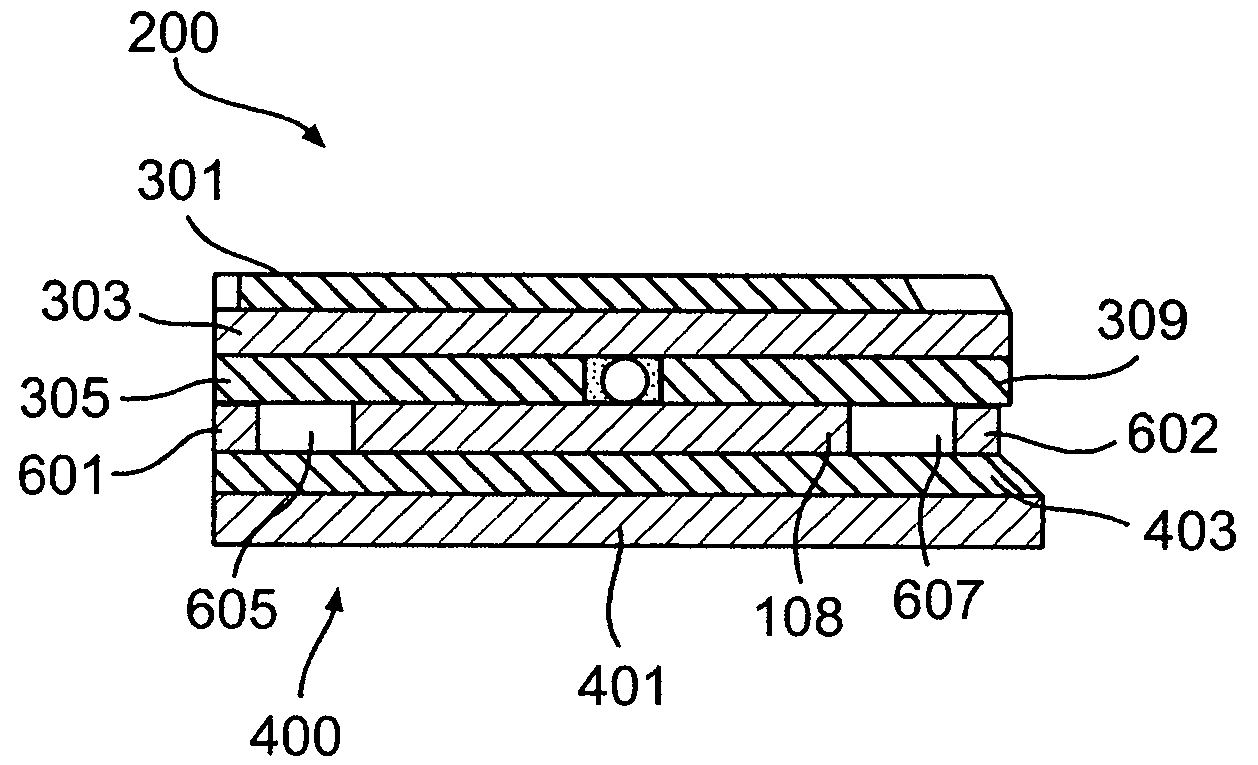

Novel bonding structure for a hard disk drive suspension using anisotropic conductive film

InactiveUS20070246251A1Reduce difficultyAvoid bondingPrinted circuit assemblingDriving/moving recording headsHard disc driveAnisotropic conductive film

A plurality of bonding structures and their forming methods for bonding a FPC to a bonding pad, in particular a bonding pad of a wireless suspension in a head gimbal assembly, using anisotropic conductive adhesive; such structures eliminate the spring-back force in typical anisotropic bonding to ensure durable bonding. At the same time, these structures also allow for reworkability under which the bonded parts can be separated easily.

Owner:SHIRAISHI MASASHI +1

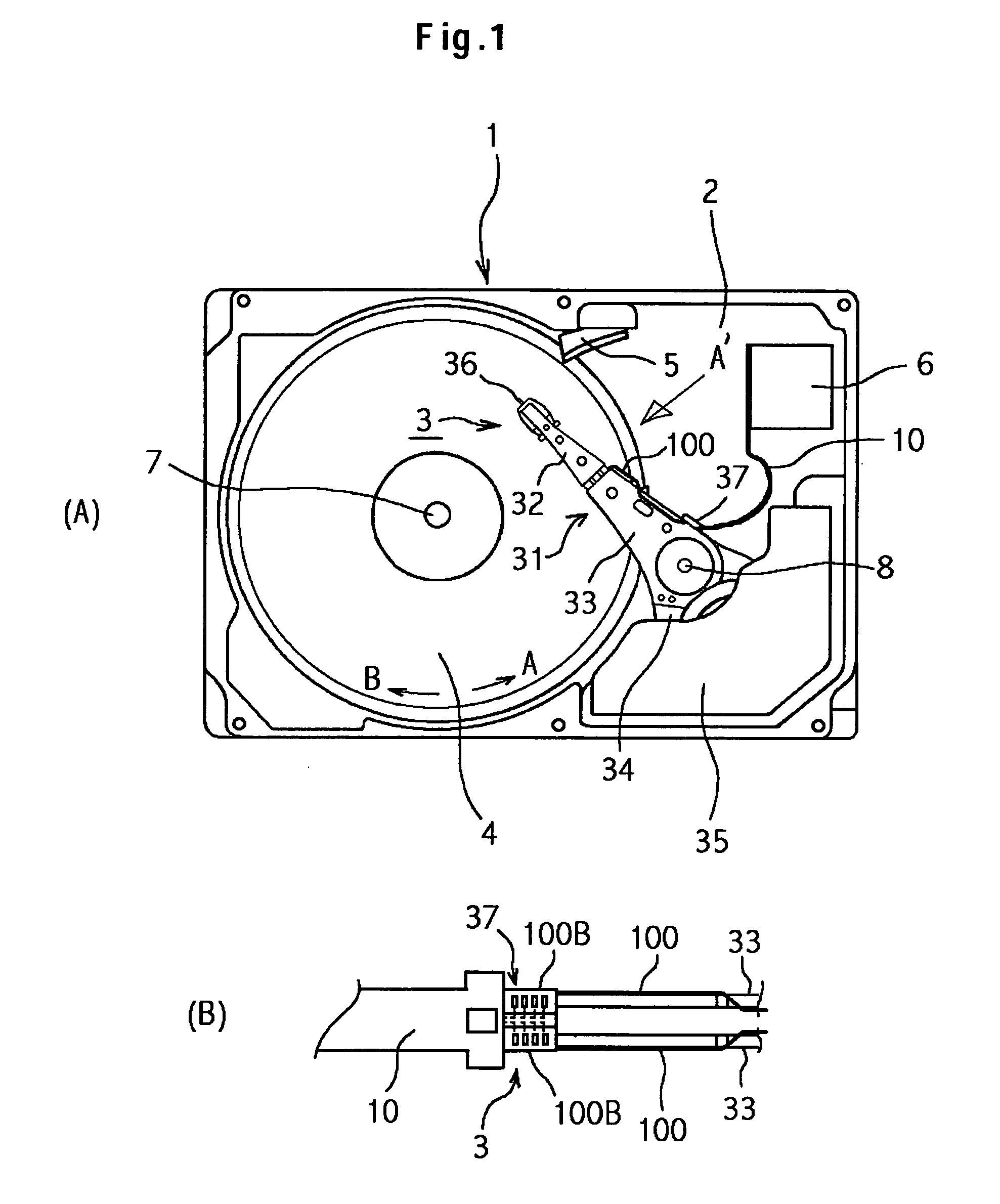

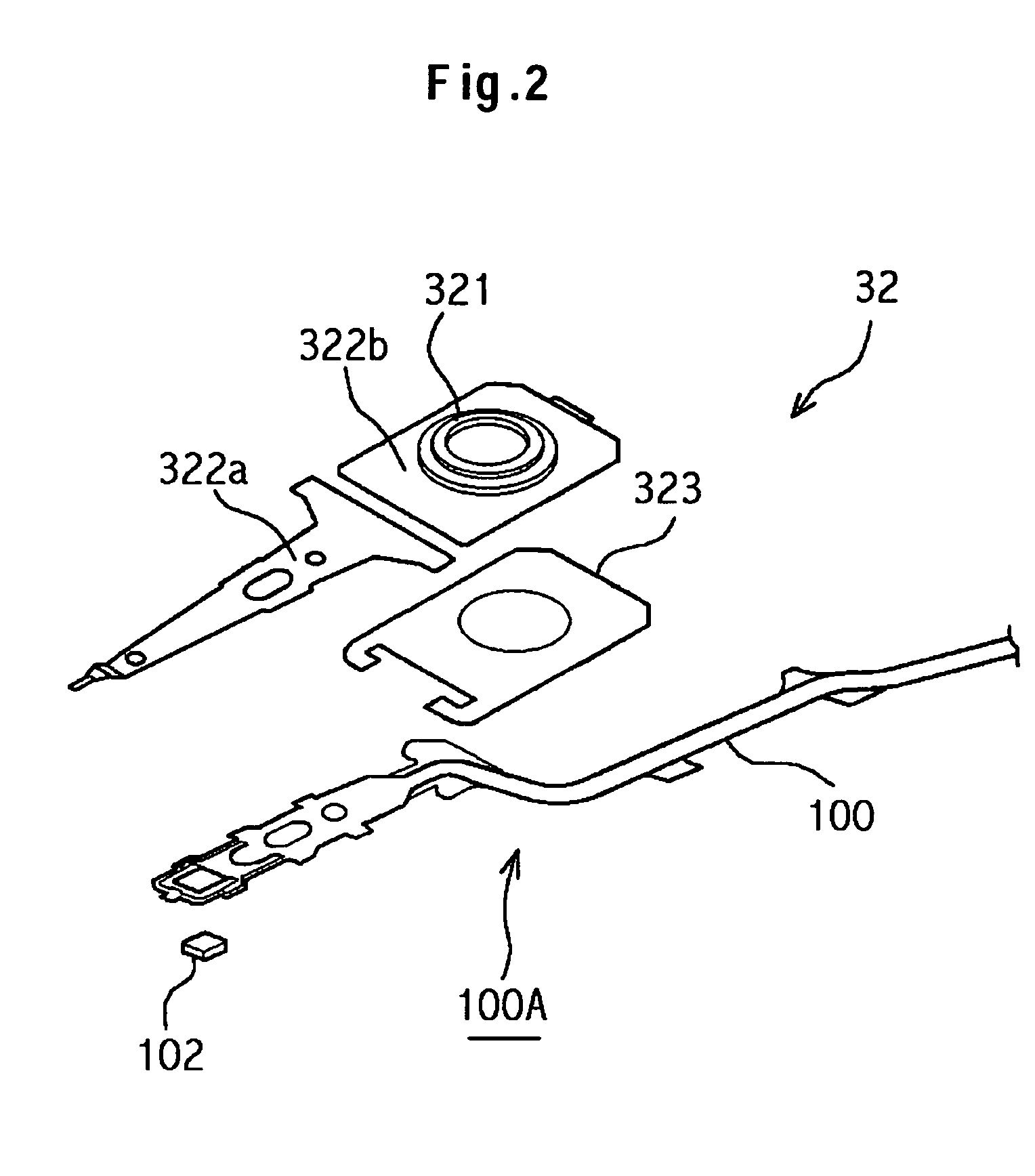

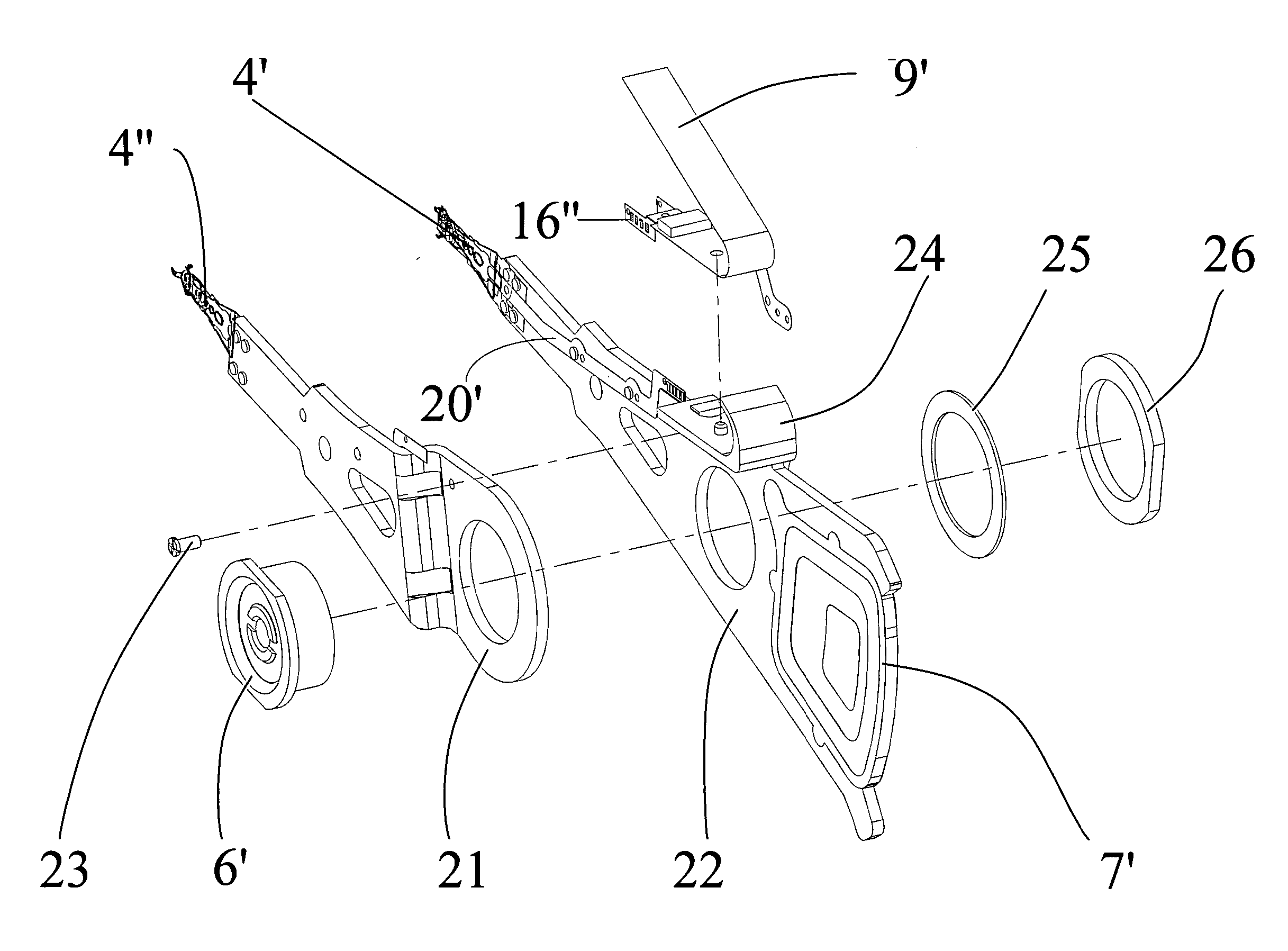

Head stack assembly and manufacturing thereof

InactiveUS20050243472A1Convenient and safe manufacturingConvenient and safe manufacturing methodPrinted circuit assemblingPrinted circuit aspectsEpoxyAnisotropic conductive film

A method for manufacturing a head stack assembly (HSA) of a disk drive unit includes including the steps of: forming a head arm assembly (HAA) having an overmolded suspension flexure cable thereon and a flexible printed circuit assembly; and bonding the suspension flexure cable with the flexible printed circuit assembly by conductive epoxy to attain an electrical connection therebetween. In the invention, the conductive epoxy is preferably anisotropic conductive film. Forming the head arm assembly further comprises forming a drive arm, and overmolding a suspension, a bracket, and a voice coil thereonto. Also, the method may further include a step of forming another HAA as a part of the HSA. In addition, a structure of the HSA is also disclosed in the present invention.

Owner:SAE MAGNETICS (HK) LTD

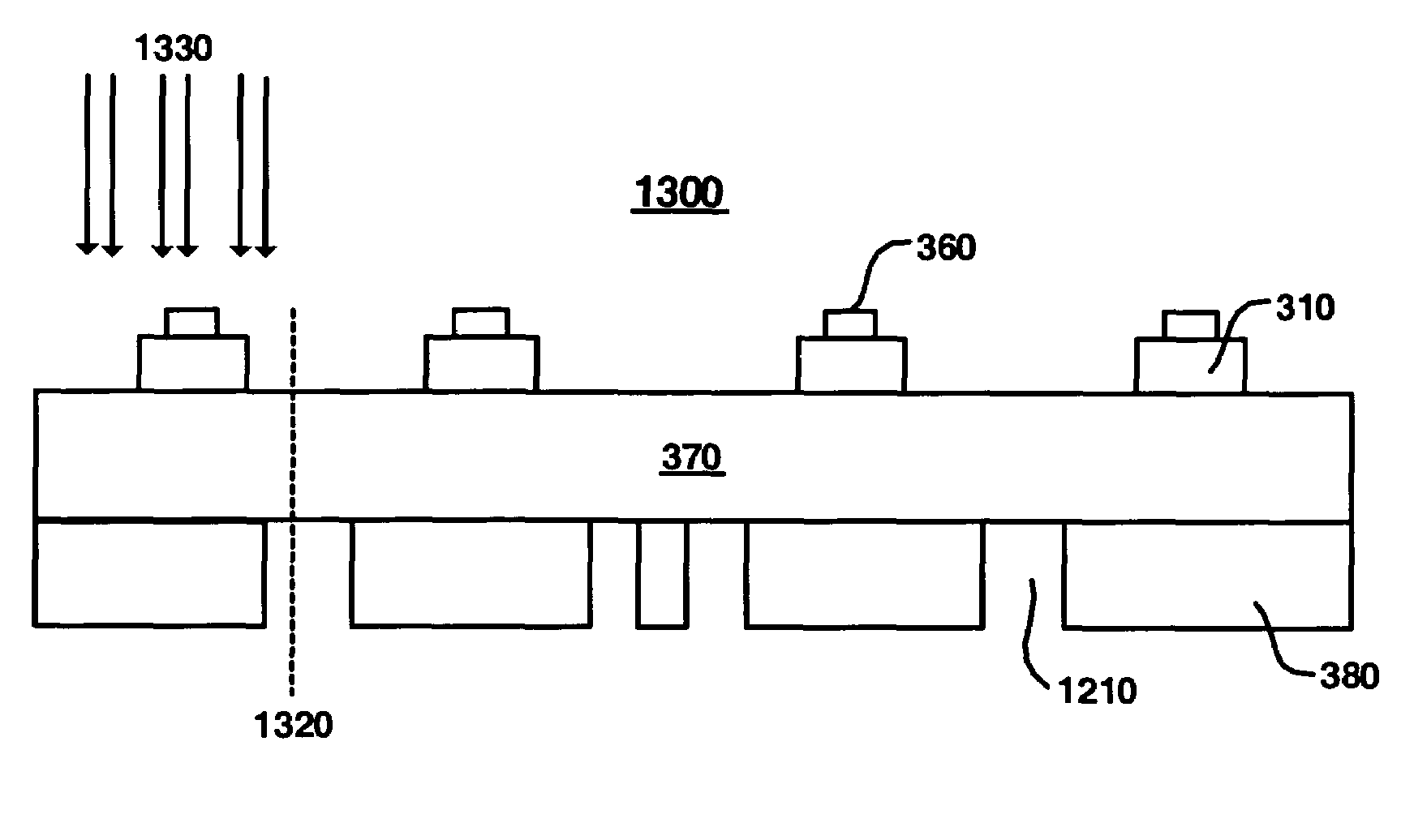

Printed-wiring board, method for forming electrode of the board, and hard disk device

InactiveUS20080099235A1Electrically conductive connectionsDriving/moving recording headsResistDevice material

According to one embodiment, there is provided a printed-wiring board on which an electrode for a semiconductor device bonding in a flip-chip-mounting manner is formed by an exposed part of a wiring pattern defined by a solder resist coating film, wherein the electrode includes an expanded section spreading in a line width direction of the wiring pattern to form the electrode.

Owner:KK TOSHIBA

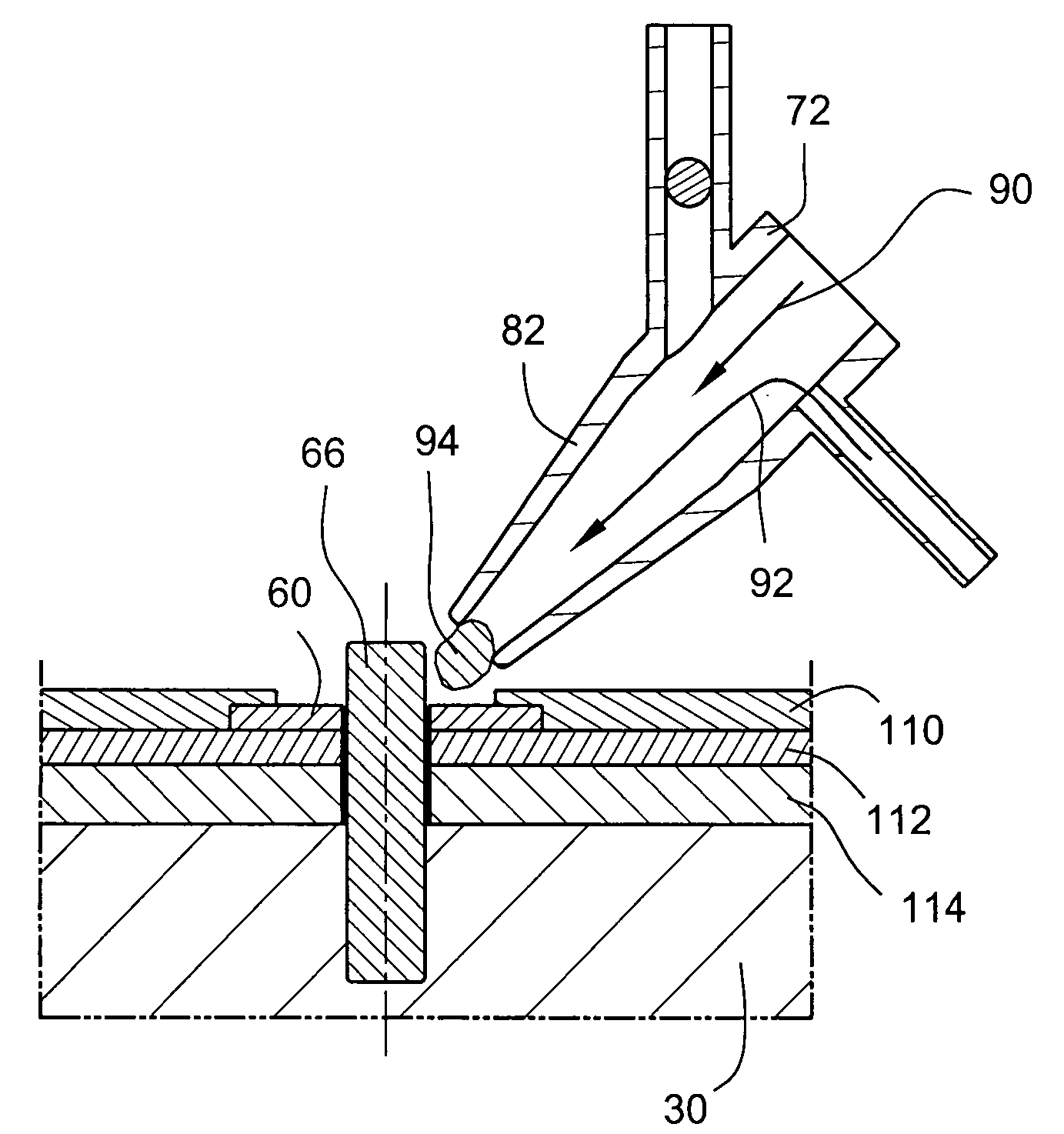

Method and apparatus for reducing heat absorption around solder pads on an electrical lead suspension

ActiveUS7450346B2Reduce heat gainElectrical connection between head and armFinal product manufactureElectricitySolder paste

An apparatus and method for reducing heat absorption around solder pads on an electrical lead suspension (ELS). The method provides a base-metal layer having at least one opening. A dielectric layer is also provided above the base-metal layer, the dielectric layer covering a portion of the base-metal layer and at least one of the openings in the base-metal layer. A signal conductive layer is provided above dielectric layer. The signal conductive layer carries at least one solder pad portion, wherein the solder pad portion is placed above the portion of the dielectric layer such that the solder pad portion does not align with the at least one opening in the base-metal layer. In so doing, the heat absorption with respect to the base-metal layer is reduced.

Owner:WESTERN DIGITAL TECH INC

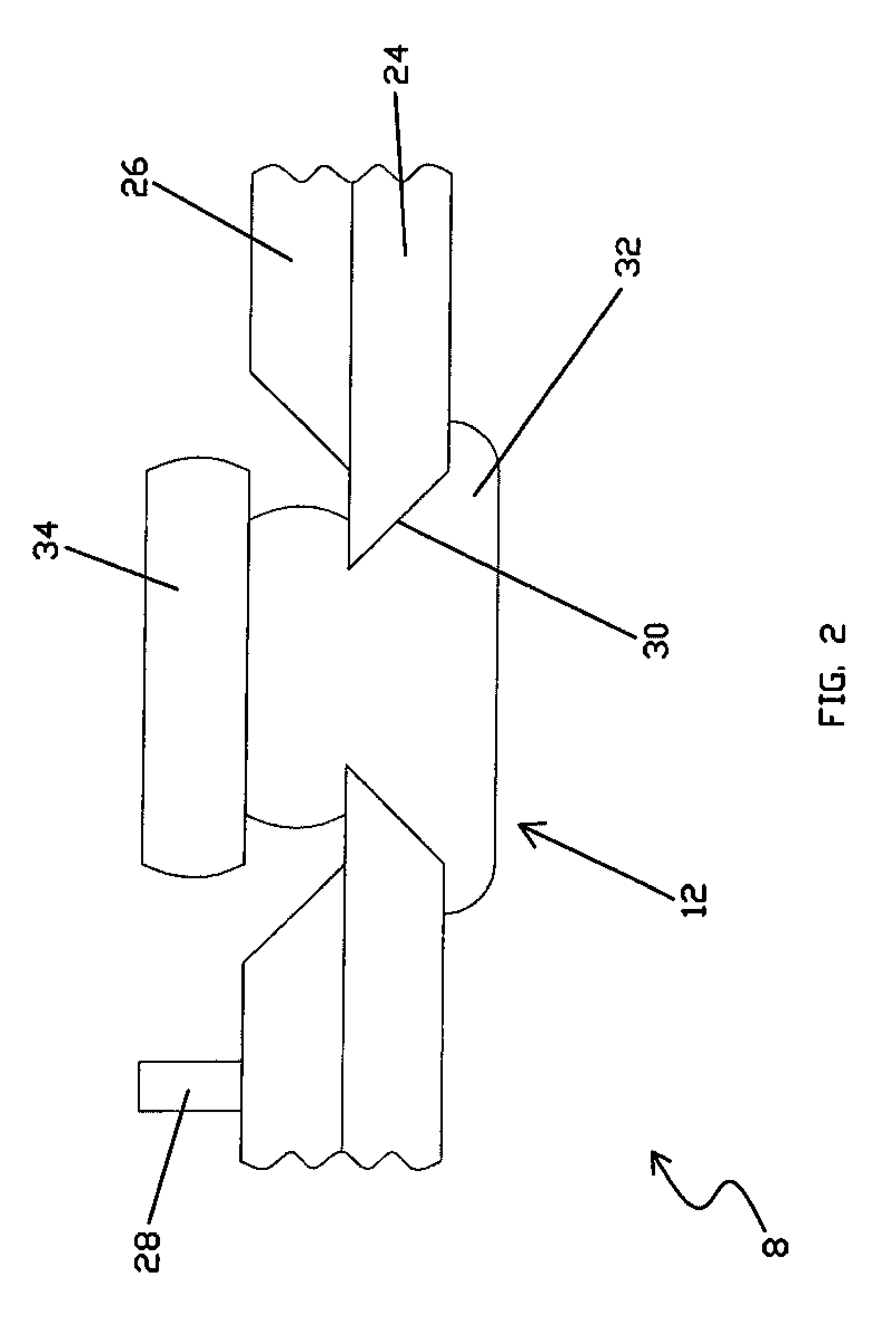

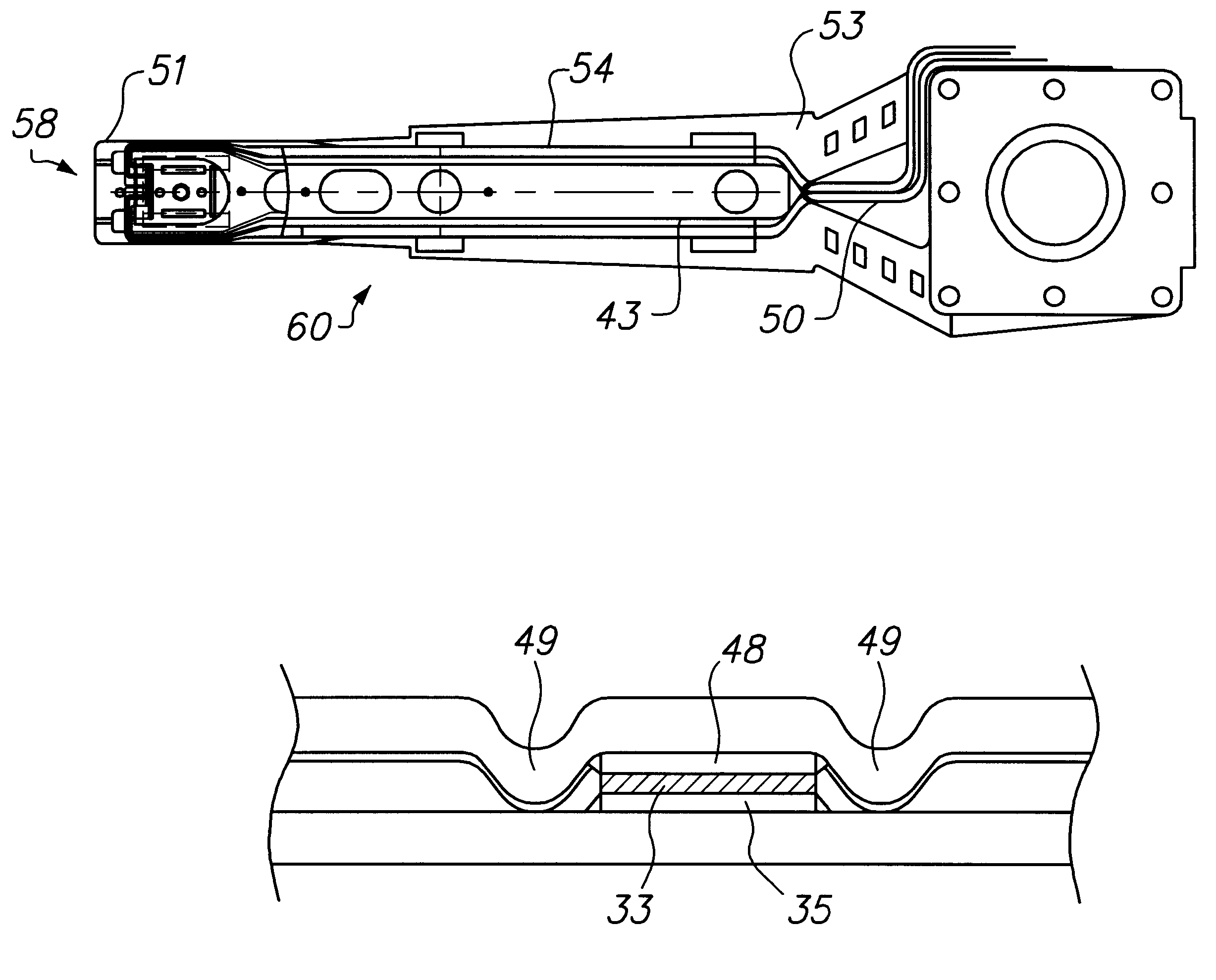

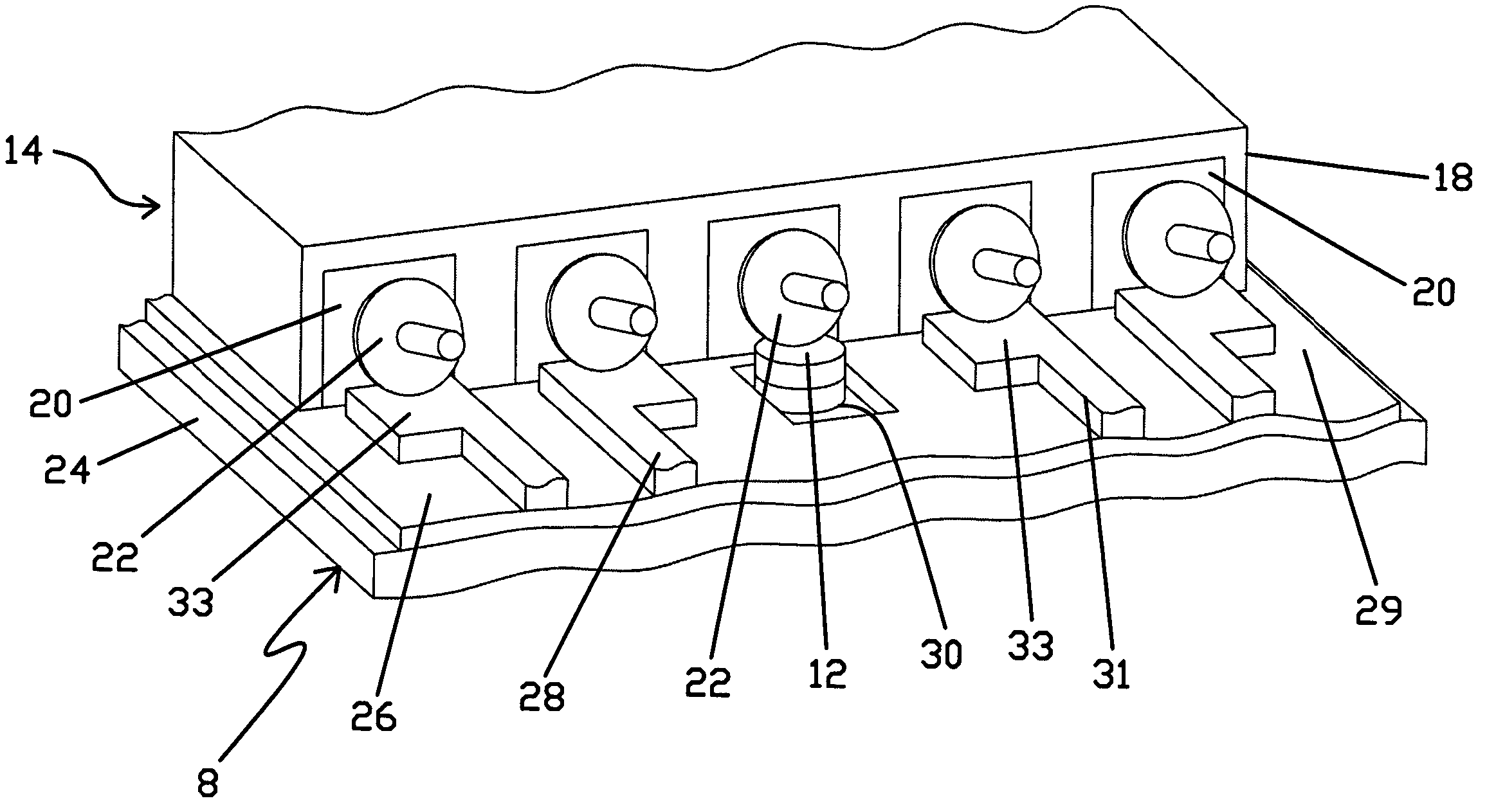

Mechanically formed standoffs in a circuit interconnect

InactiveUS6246548B1Low costReliable connectorPrinted circuit assemblingElectrical connection between head and armIntegrated circuit interconnectBonding process

Mechanically formed standoffs in a disk drive integrated circuit interconnect reduces the cost of manufacturing and improves the reliability of the electrical interconnections thereof. Connection pads defined along the interconnect are bonded with bonding pads of a signal producing source and a signal processing source. The standoffs provide mechanical stops during the bonding process, enabling sufficient bonding material to form between bonding areas. The standoffs are mechanically formed with a punch and die assembly either directly through a bonding pad predefined along traces on the interconnect or adjacent the bonding pad. The standoffs formed through the bonding pads are covered with solder or other electrically conductive bonding material.

Owner:MAXTOR

Methods and systems for establishing retrograde carotid arterial blood flow

Interventional procedures on the carotid arteries are performed through a transcervical access while retrograde blood flow is established from the internal carotid artery to a venous or external location. A system for use in accessing and treating a carotid artery includes an arterial access device, a shunt fluidly connected to the arterial access device, and a flow control assembly coupled to the shunt and adapted to regulate blood flow through the shunt between at least a first blood flow state and at least a second blood flow state. The flow control assembly includes one or more components that interact with the blood flow through the shunt.

Owner:SILK ROAD MEDICAL

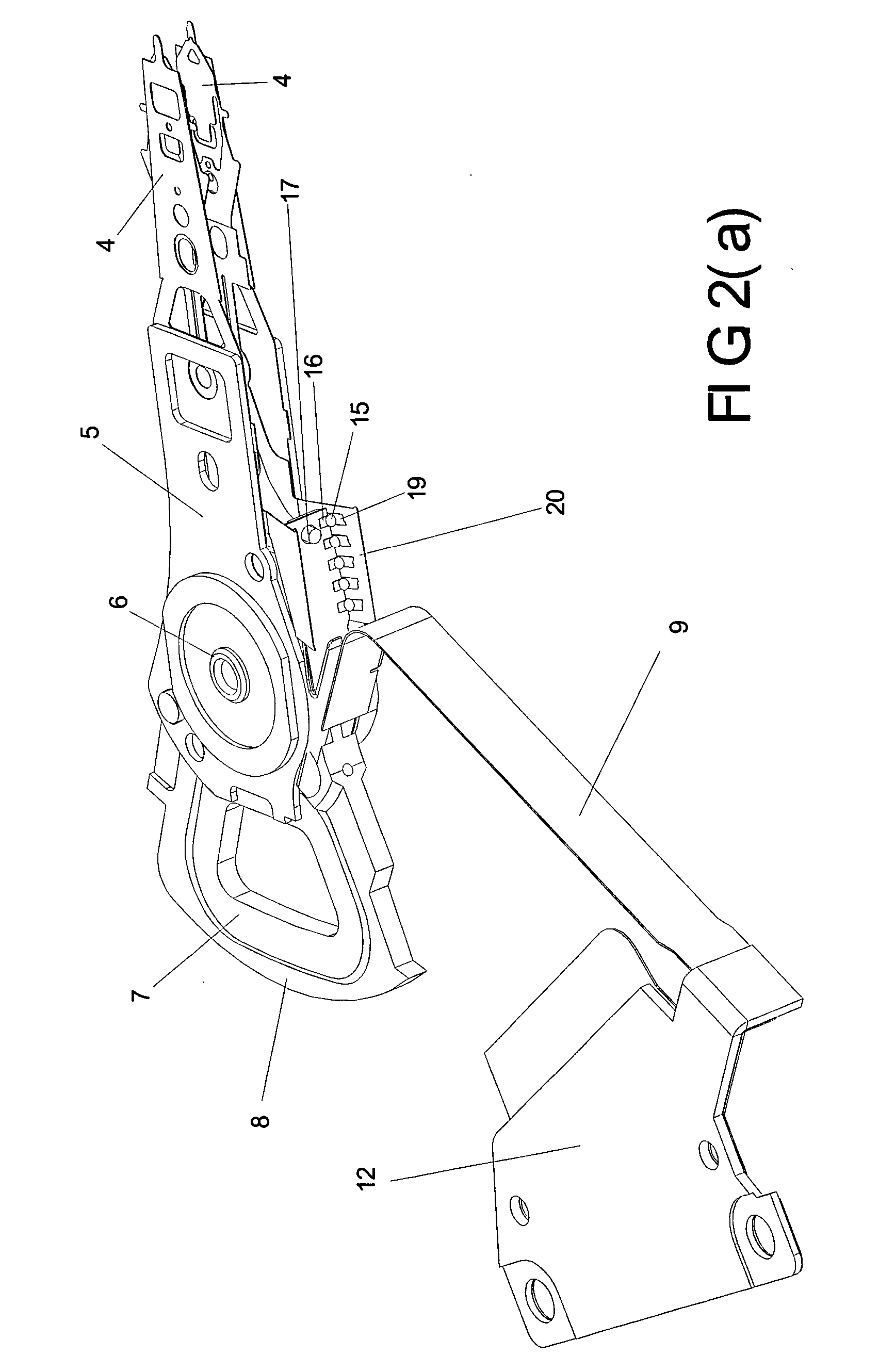

Carriage assembly and storage medium drive

InactiveUS20070279807A1Easy alignmentSimple wayPrinted circuit aspectsRecord information storageElectrical and Electronics engineering

A first flexible printed wiring board is attached to the supported end of a carriage. First terminals are exposed on the first flexible printed wiring board. A second flexible printed wiring board extending from a head slider toward the supported end of the carriage. The second flexible printed wiring board is overlaid on the first flexible printed wiring board. Second terminals are exposed on the second flexible printed wiring board. The second terminals are bonded to the first terminals. A step defines a wall surface facing the edge of the second flexible printed wiring board on the first flexible printed wiring board. A depression is defined on the first flexible printed wiring board. The second flexible printed wiring board is received in the depression, the second terminal can accurately be positioned on the first terminal in a facilitated manner.

Owner:FUJITSU LTD

Module substrate and disk apparatus

InactiveUS7327040B2Dielectric materialsSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

A module substrate includes an insulating substrate, a circuit pattern formed on at least a main surface of the insulating substrate, a protection film formed on the main surface of the insulating substrate including the circuit patter such as to expose a mount region of the circuit pattern, an active element part mounted on the mount region of the circuit pattern, a fluororesin film formed on the protection film at least in a vicinity of the mount region of the active element part, and an underfill filled between the active element part and the mount region of the circuit pattern.

Owner:KK TOSHIBA

Soldering device and method for forming electrical solder connections in a disk drive unit

InactiveUS20070075056A1Electrical connection between head and armPrinted circuit aspectsSolder ballEngineering

A soldering device for forming electrical solder connections in a disk drive unit includes a bond head, a laser unit, a pressurized gas supply, and a solder ball supply. The bond head includes a housing that provides a primary passage and two supplemental passages that communicate with the primary passage. The laser unit is operable to direct a laser beam through the primary passage. The pressurized gas supply is operable to deliver pressurized gas through one supplemental passage and into the primary passage. The solder ball supply is operable to deliver a single solder ball through the other supplemental passage and into the primary passage. The primary passage has a tapered configuration structured to maintain a solder ball within the primary passage to allow a laser beam from the laser unit to act upon the solder ball before the solder ball is discharged from the bond head by pressurized gas.

Owner:SAE MAGNETICS (HK) LTD

Bonding structure for a hard disk drive suspension using anisotropic conductive film

InactiveUS7205484B2Reduce difficultyAvoid high-temperature bonding requiredPrinted circuit assemblingDriving/moving recording headsHard disc driveAnisotropic conductive film

A plurality of bonding structures and their forming methods for bonding a FPC to a bonding pad, in particular a bonding pad of a wireless suspension in a head gimbal assembly, using anisotropic conductive adhesive; such structures eliminate the spring-back force in typical anistropic bonding to ensure durable bonding. At the same time, these structures also allow for reworkability under which the bonded parts can be separated easily.

Owner:SAE MAGNETICS (HK) LTD

Flexible printed cable, head stack assembly with the same and manufacturing method thereof

InactiveUS20090207529A1Protect electrical connectionsElectrical connection between head and armRecord information storageElectricityMicro actuator

A HSA includes a plurality of HGAs and an FPC. The FPC includes a connector for connecting with a control system, a voltage trace and a ground trace. A common voltage end of the voltage trace has a plurality of first voltage pads and a plurality of second voltage pads arranged adjacent to the corresponding first voltage pads respectively and electrically isolated from the respective first voltage pads. Each of the second voltage pads connects with the micro-actuator of the corresponding HGA. A common ground end of the ground trace has a plurality of micro-actuator ground pads, each of which connects with a micro-actuator of the corresponding HGA. The second voltage pads and the corresponding first voltage pads are connected with each other after the micro-actuator are tested. The invention also discloses a manufacturing method of the HSA.

Owner:SAE MAGNETICS (HK) LTD

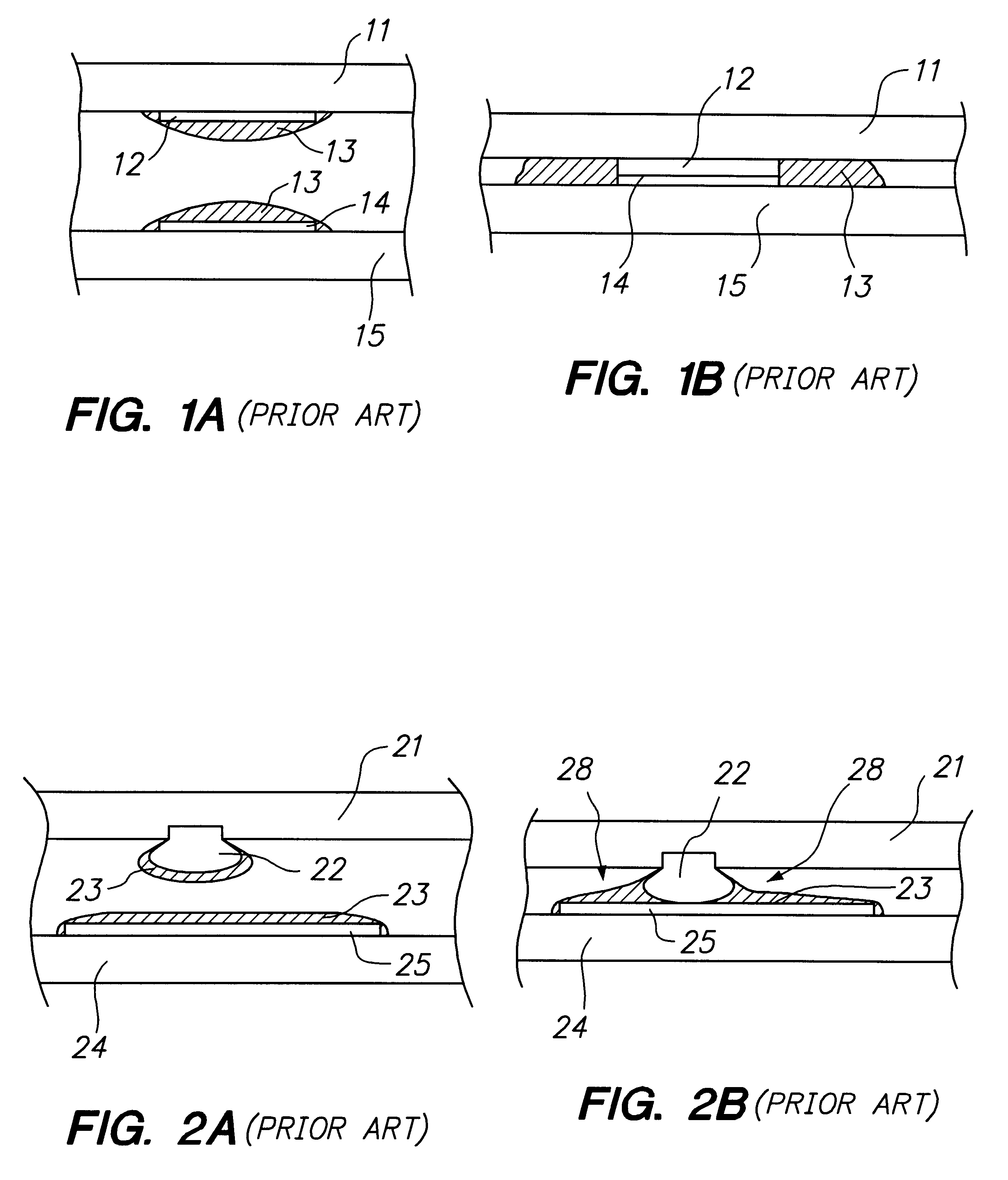

Coined ground features for integrated lead suspensions

InactiveUS20050195528A1Quality improvementPrinted circuit aspectsFluid-dynamic spacing of headsElectricityEngineering

A method for forming an electrical interconnect to the spring metal layer in an integrated lead suspension or suspension component of the type having a multi-layer structure including a spring metal layer and a conductor layer separated by a dielectric insulator layer. The method includes forming an aperture through at least one of either the spring metal and conductor layers, and optionally through the dielectric layer, at an interconnect site. A first mass of malleable conductive metal is inserted into the aperture. The mass of metal is then coined to form a stud that engages at least the spring metal layer at the interconnect site. One embodiment of the invention is used to form a bond pad stud that is free from contact with the conductor layer. Another embodiment is used to form an electrical interconnect stud that electrically connects the spring metal and conductor layers. The invention can also be used to mount integrated lead flexures to load beams.

Owner:HUTCHINSON TECH

Assembly of DSA suspensions using microactuators with partially cured adhesive, and DSA suspensions having PZTs with wrap-around electrodes

ActiveUS9406314B1Simple processSimplifies electrical connectionsTrack finding/aligningPiezoelectric/electrostrictive device manufacture/assemblyElectricityDual stage

A method of assembly a dual stage actuated suspension includes either applying an adhesive to a microactuator motor and then B-staging, it or applying an adhesive that has already been B-staged such as in film adhesive form, then assembling it to a microactuator and then finishing the adhesive cure. The method allows greater control over how much adhesive is used, and greater control over spread of that adhesive, than traditional liquid epoxy dispense methods. Additionally, a suspension is provided that has a wrap-around electrode such that both the driving voltage and the ground, which are normally connected at different sides of a PZT, can be connected at the same side of the PZT, thus simplifying electrical connections to the PZT.

Owner:MAGNECOMP

Popular searches

Piezoelectric/electrostrictive/magnetostrictive devices Support for heads Apparatus modification to store record carriers Undesired vibrations/sounds insulation/absorption Casings/cabinets/drawers details Hermetically-sealed casings Track changing/selection Piezoelectric/electrostrictive transducers Medical devices Occulders

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com