Flapper valve for a toilet tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

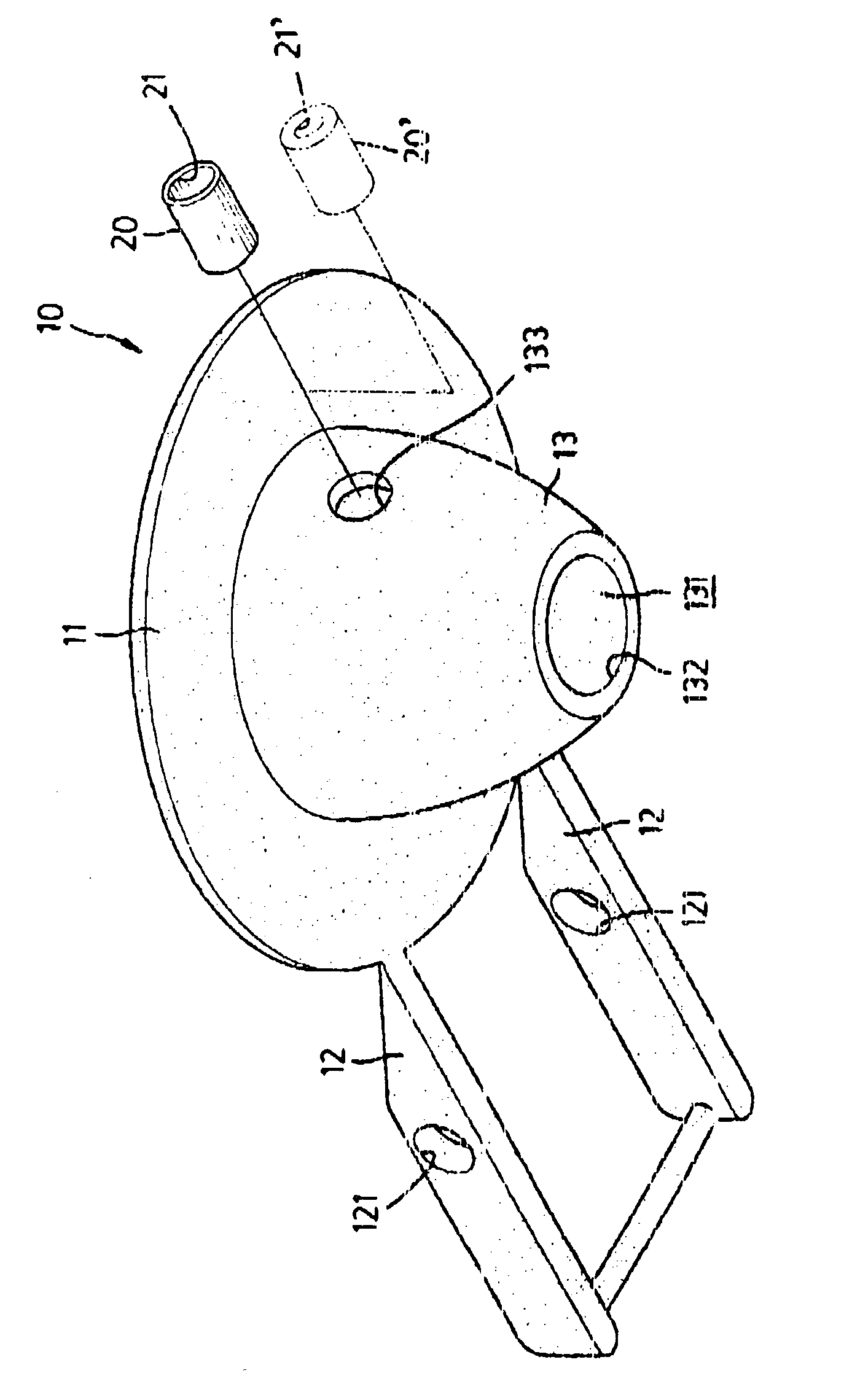

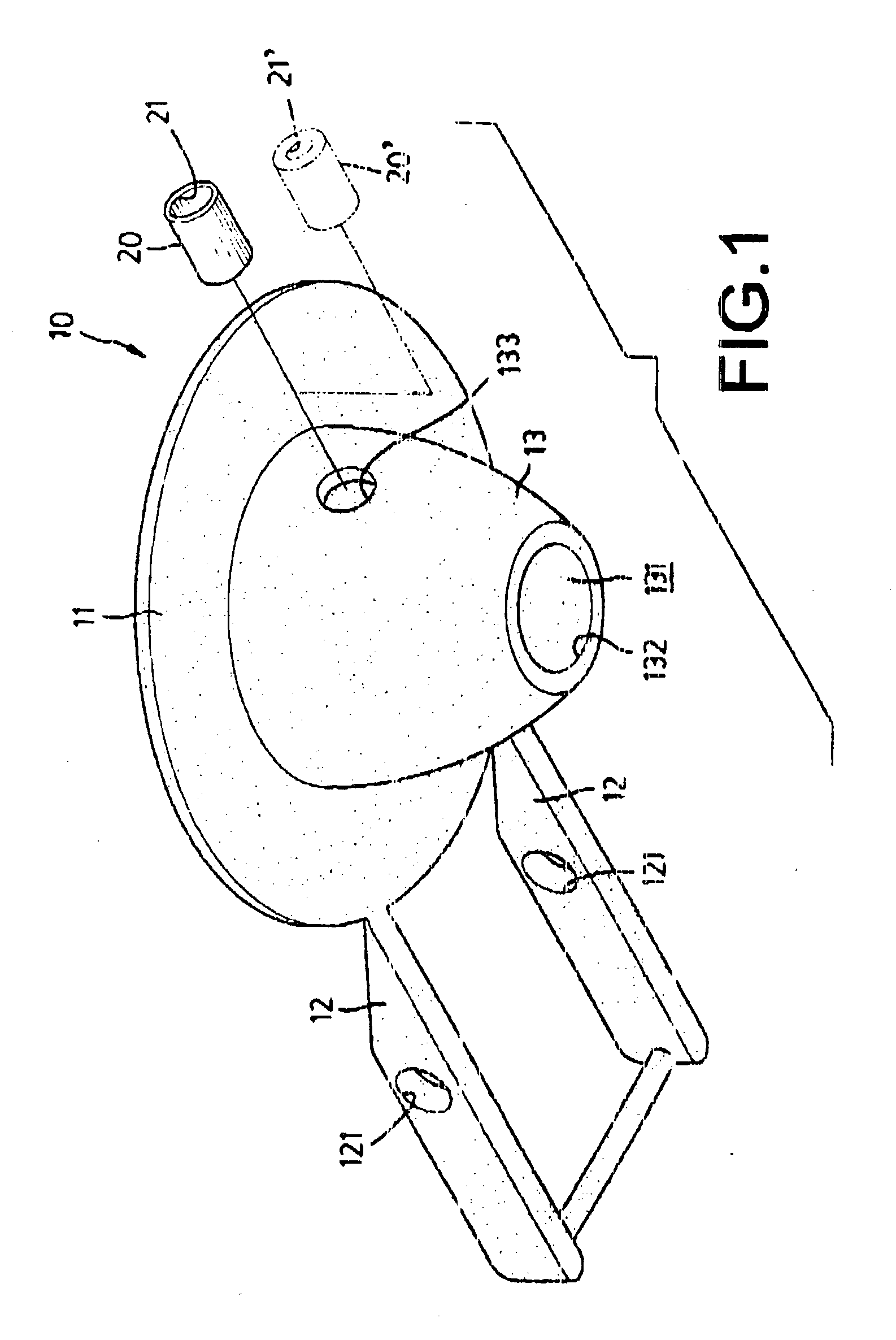

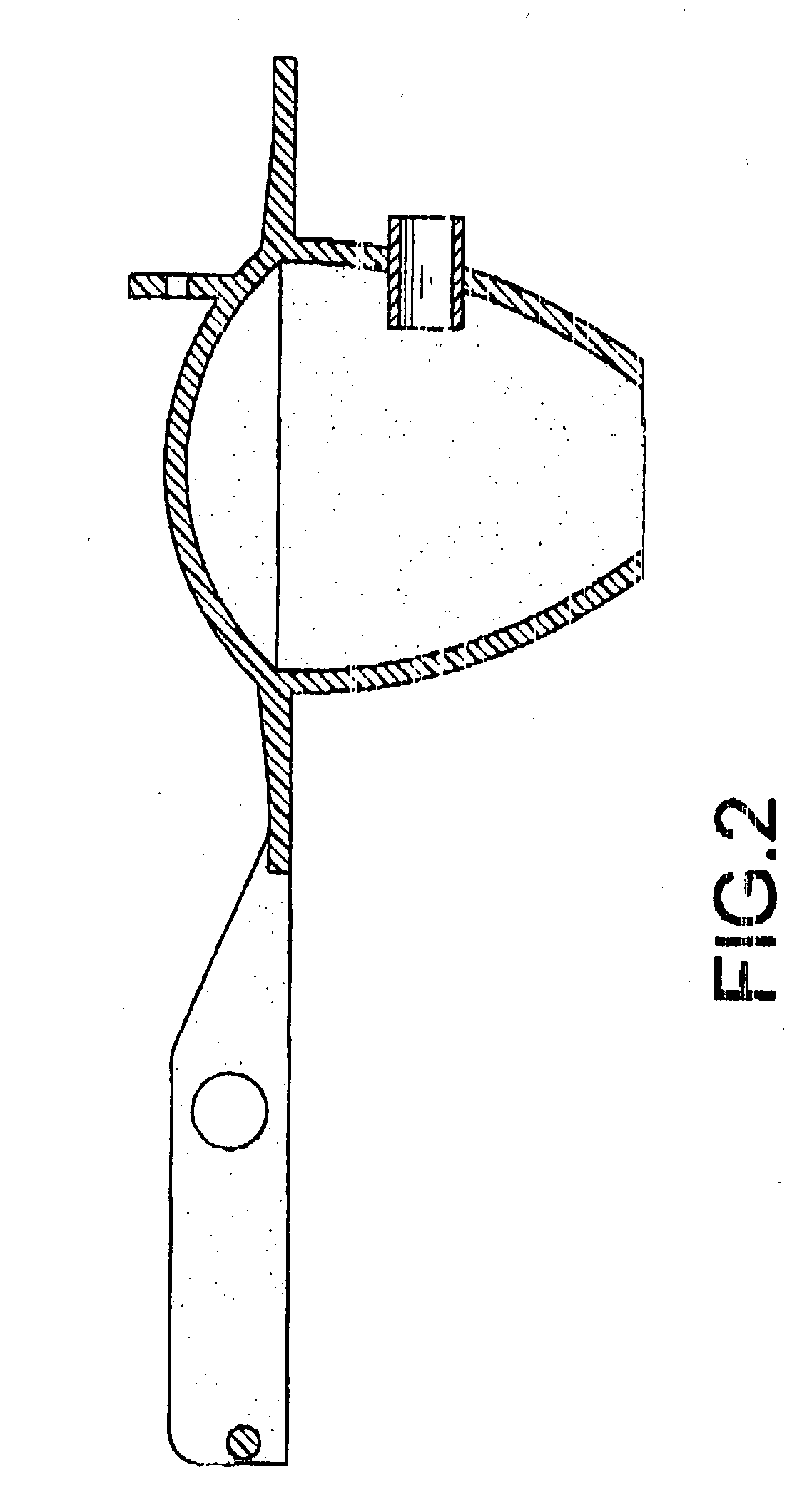

[0017] With reference to FIGS. 1 and 2, a flapper valve (10) in accordance with the present invention for a toilet tank comprises an annular flange (11), a cone (13) and an airflow controlling member (20). The annular flange (11) is pivotally connected to in overflow pipe (not shown) in the toilet tank and closes a top opening of a drain pipe (not shown) in the toilet. In practice two arms (12) extend from the flange (11) in parallel, and each arm (12) has a mounting hole (121) to pivotally receive a stub (not shown) mounted on the overflow pipe. With the engagements of the mounting holes (121) in the arms (12) and the stubs on the overflow pipe, the annular flange (11) is pivotally connected to the overflow pipe.

[0018] The cone (13) is hollow and protrudes from the bottom of the annular flange (11). The cone (13) has a chamber (131) and an opening (132) defined in the bottom of the cone (13) and communicating with the chamber (131). A vent (133) is defined in the periphery of the c...

third embodiment

[0024] With reference to FIGS. 5 and 6, the airflow controlling member (40) comprises a plug (41) and a disk (42). The plug (41) is received in the vent (133). A bore (411) is defined in the plug (41), and a ventage (412) is defined through the plug (41) and communicates with the chamber (131) in the cone (13). The disk (42) is moveably mounted on the plug (41) and corresponds to the ventage (412) in the plug (41). A shaft (421) protrudes from the disk (42) and is moveably inserted into the bore (411) in the plug (41) so as to moveably combine the disk (42) with the plug (41). A gap (not numbered) is defined between the plug (41) and the disk (42).

[0025] In such an embodiment, the air in the chamber (131) can be discharged from the ventage (412) in the plug (41) and the gap between the plug (41) and the disk (42). When the disk (42) is moved relative to the plug (41) the gap between the plug (41) and the disk (42) is changed. Accordingly, the discharging rate of the air is adjustabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com