Device for wrapping groups of filter segments with a wrapping material for producing multi-segment filters of the tobacco industry and multi-segment filter production device

a technology of filter segments and wrapping materials, which is applied in the direction of tobacco smoke filters, cigar manufacture, etc., can solve the problems of large financial expenditure, low variability in the production of multi-filters, and the production of multi-segment filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In the following description of the figures, in part the same elements are labeled with the same reference numbers so that a repeated introduction has been omitted.

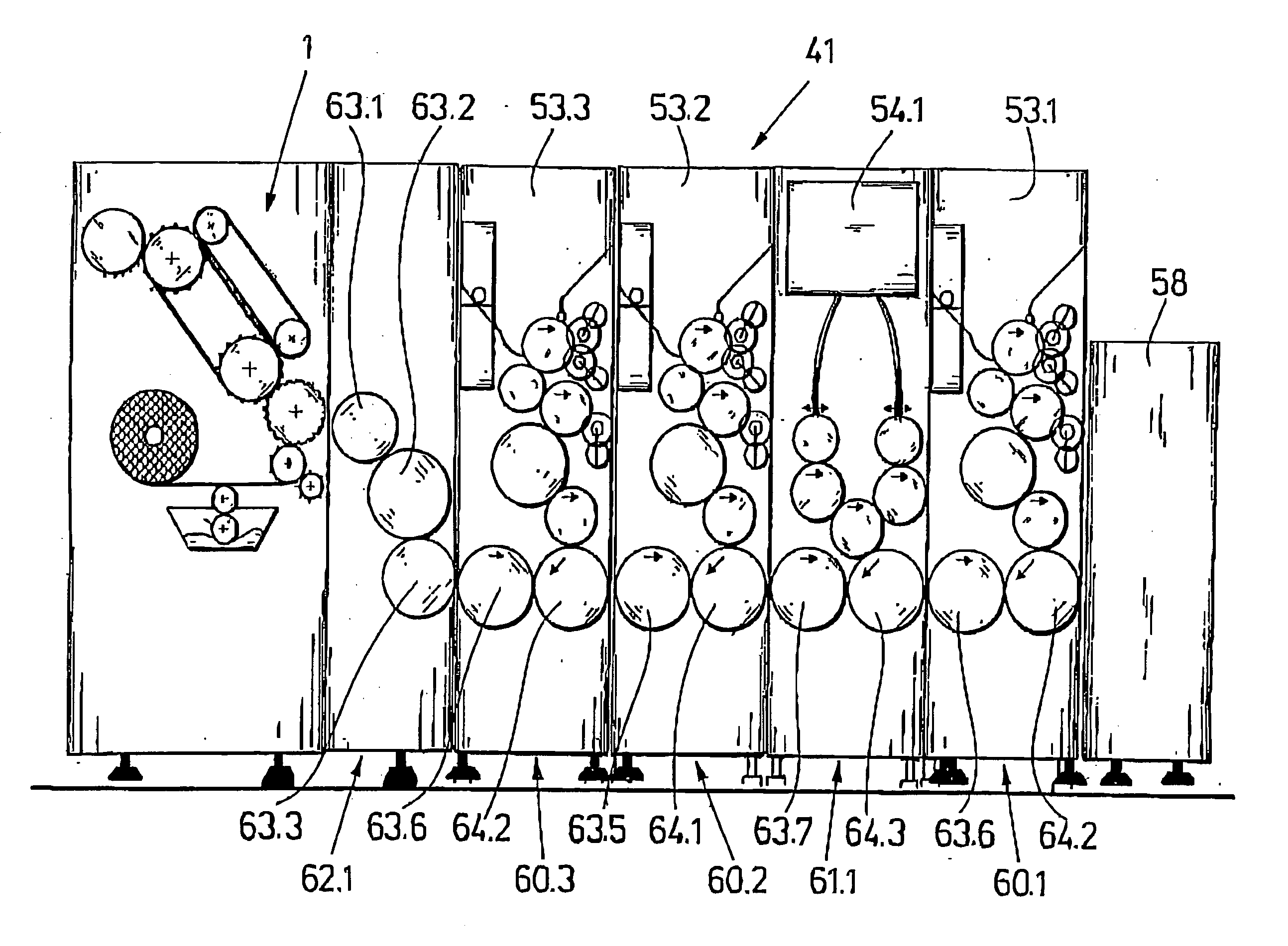

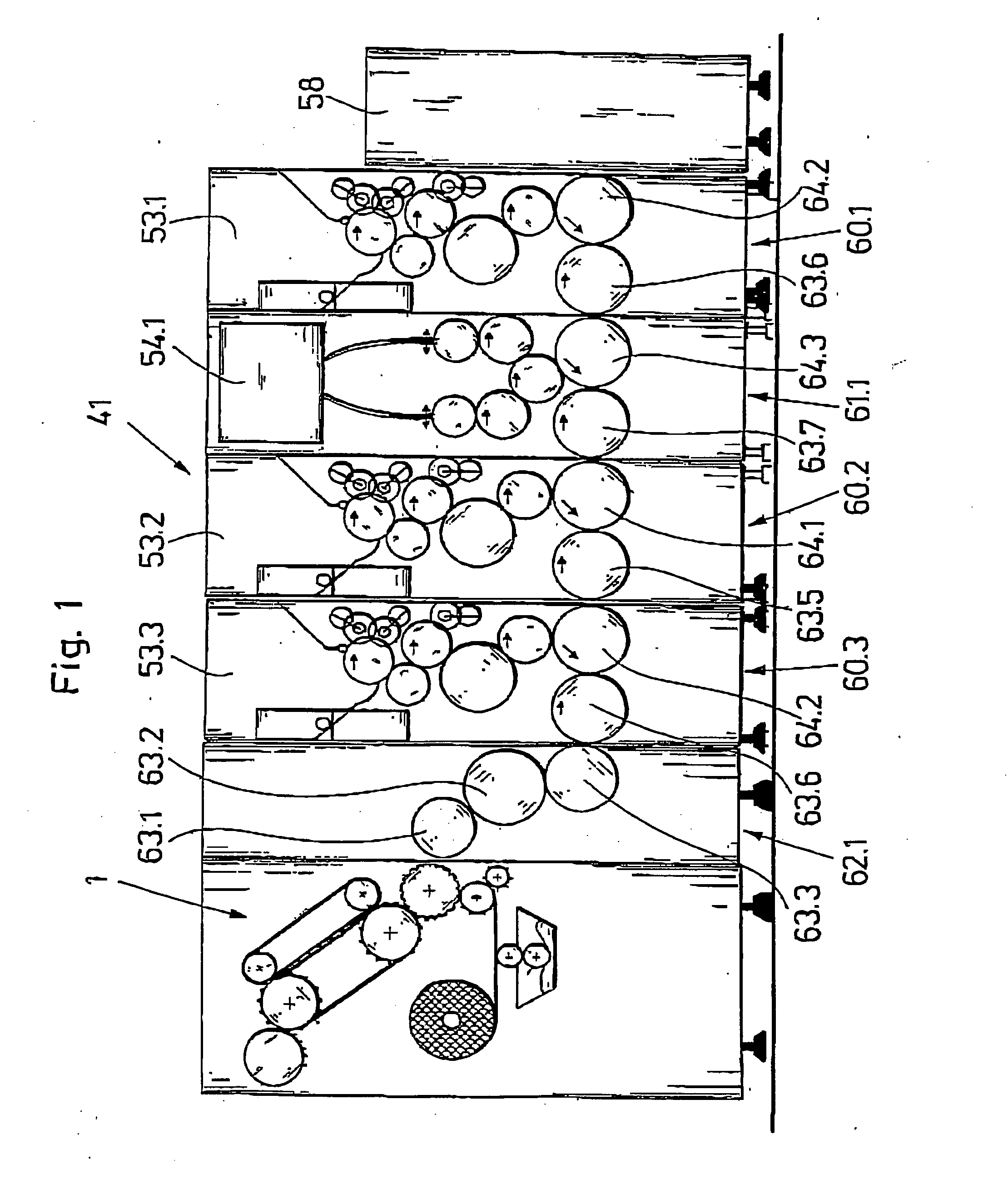

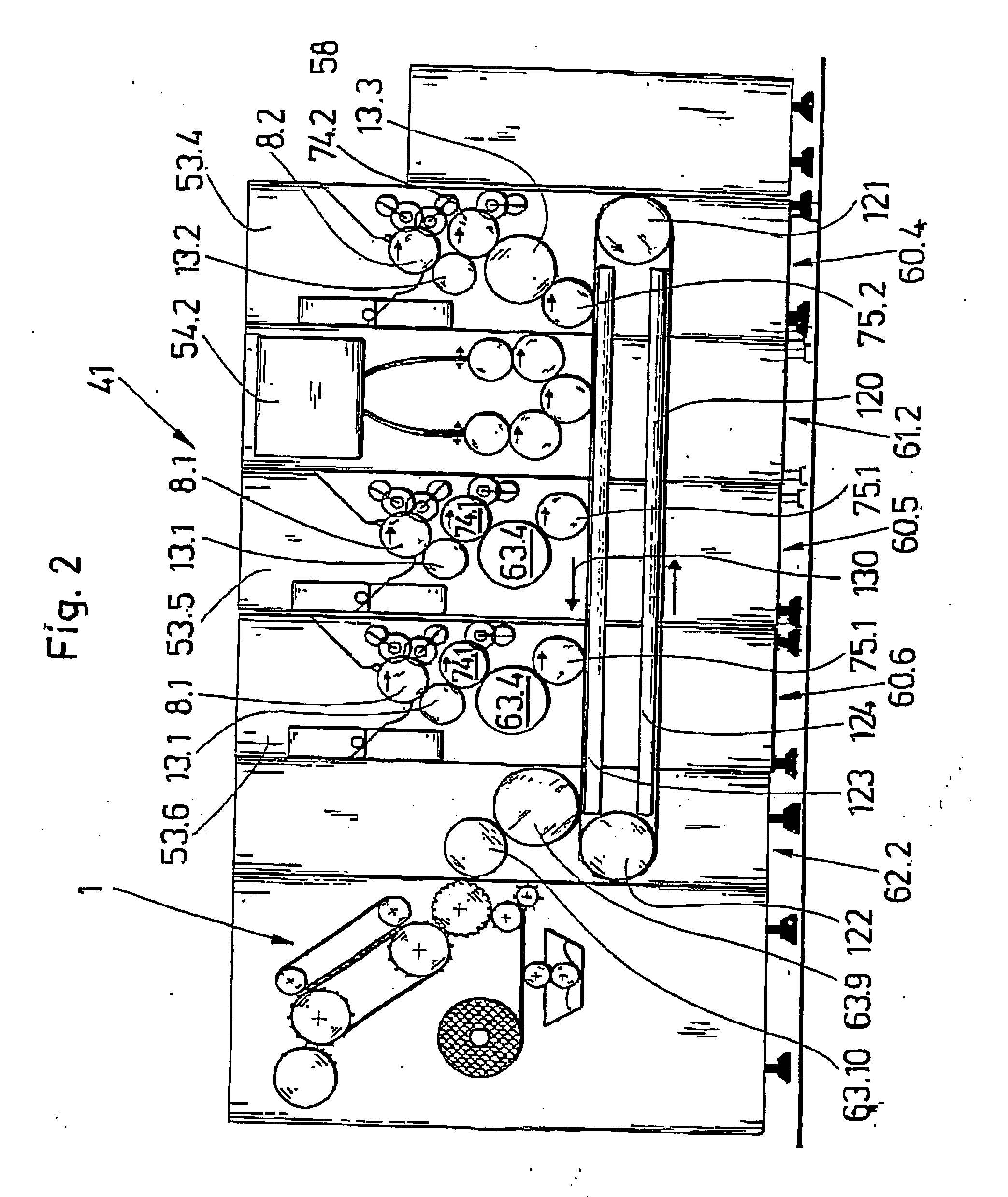

[0059] A multi-segment filter production device according to the invention with a device according to the invention for assembling groups of filter segments to produce multi-segment filters is shown in FIG. 1.

[0060] This is hereby a group-forming device 41, whereby, however, respectively independent functional units 60.1-60.3, and 61.1 are used. The functional units 60.2 and 60.3 are soft element units by way of which two individual filter segments are fed (FIG. 5a), the functional unit 60.1 is a soft element unit by way of which an individual filter plug or an individual filter segment of double unit length is fed, and the functional unit 61.1 is a hard element unit. Storage containers 53.1-53.3 and 54.1 are respectively provided in the functional units, whereby, naturally, a soft element storage container 53.1-53...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com