Laminate packaging for ice cream cones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

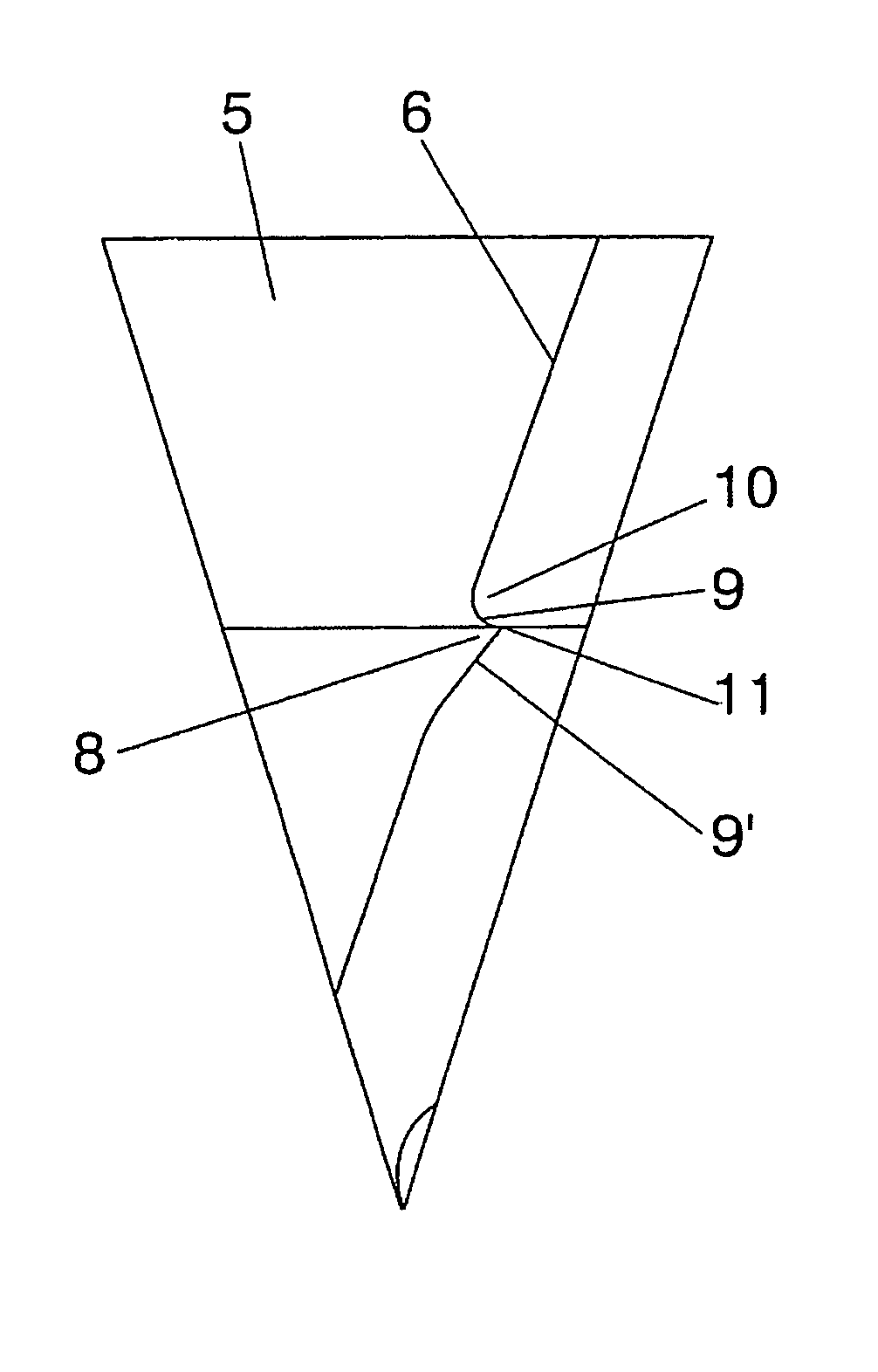

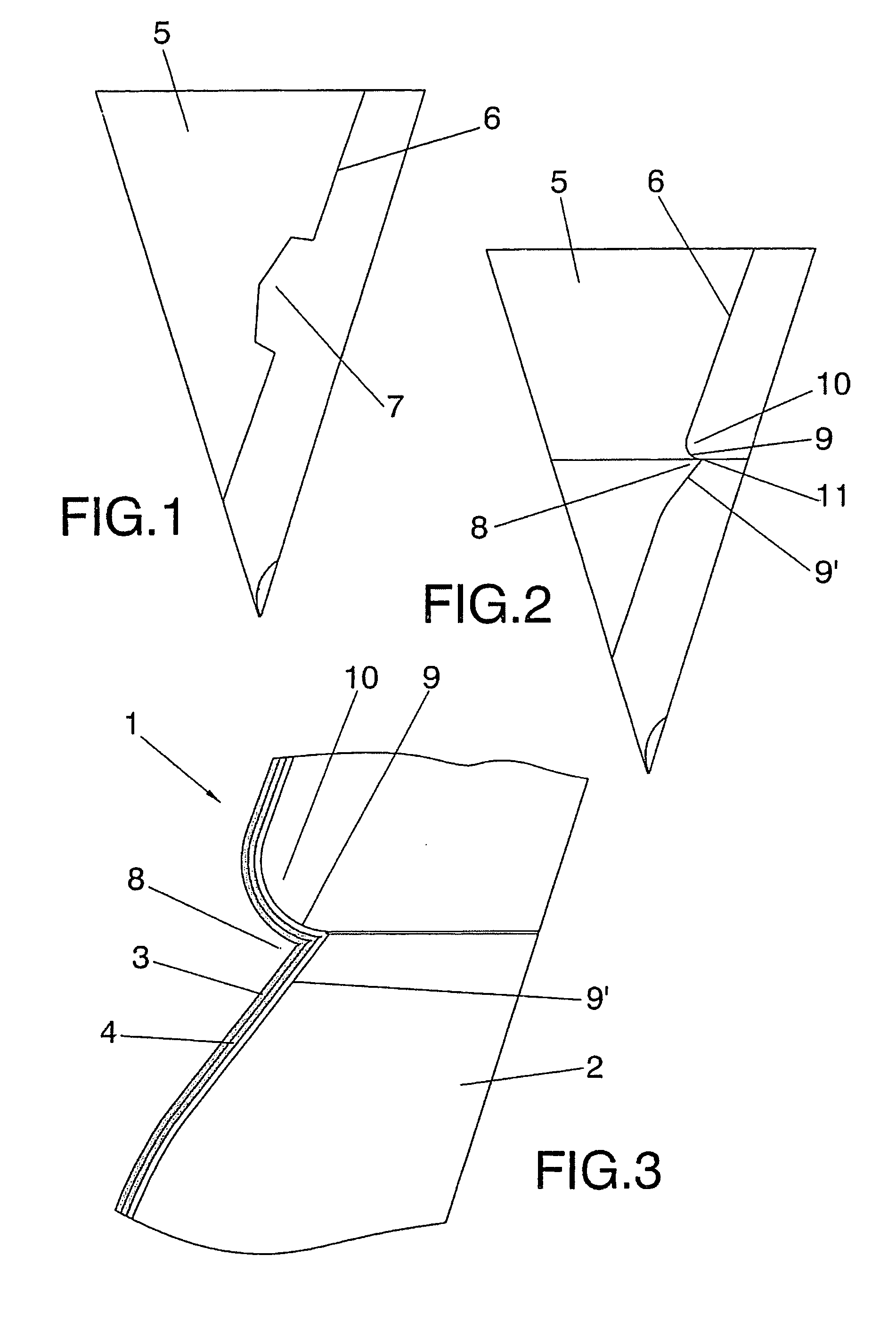

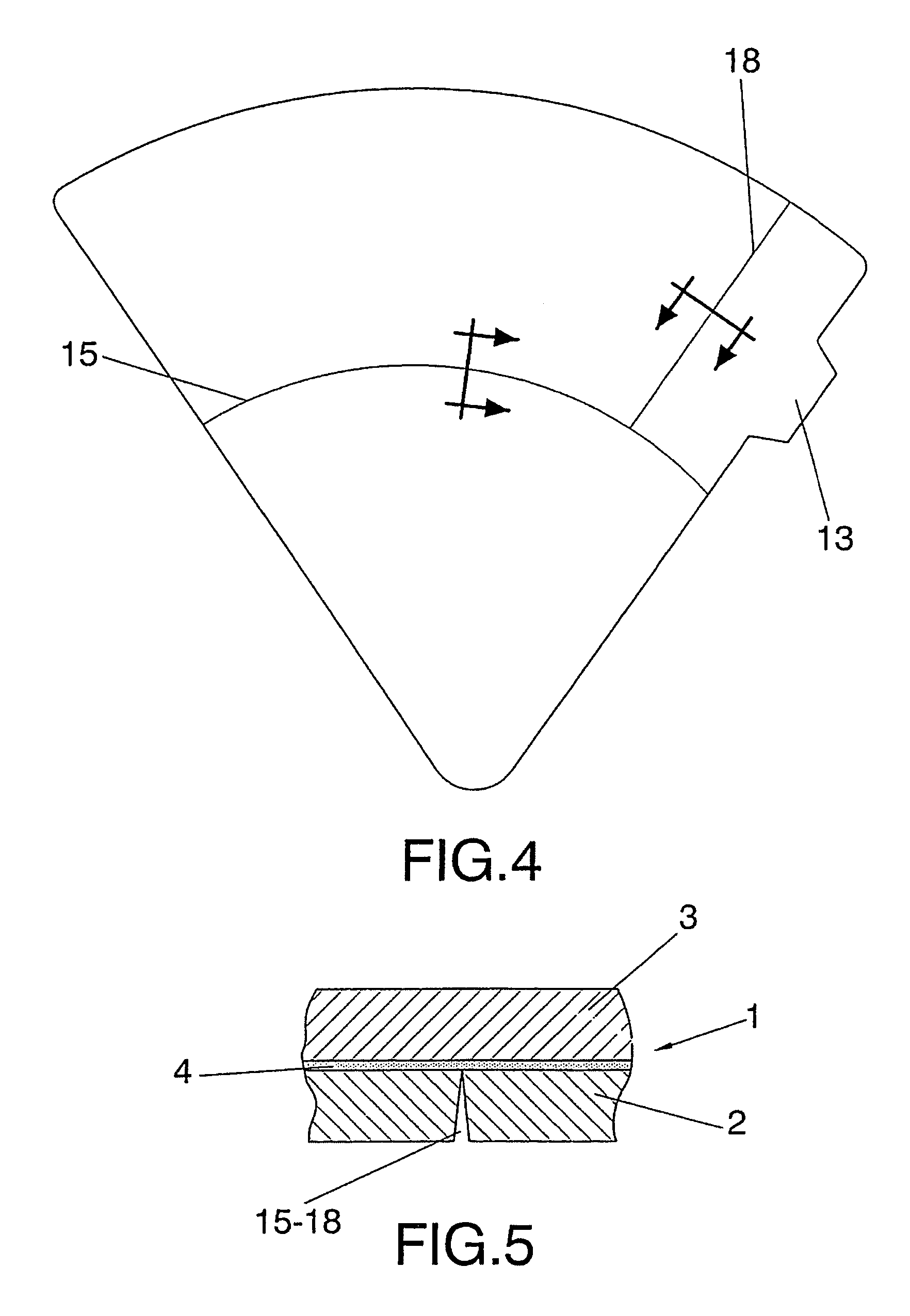

[0010] The wrapping which the invention discloses has been conceived and structured in order to resolve in a fully satisfactory manner the problem described above, in the aspects mentioned.

[0011] To this end, in a more specific way and in accordance with the invention, in the laminar body constituting the wrapping the classic projecting tab has been suppressed, and has been replaced by an angular seam, which in the first place supposes a substantial saving in material, since the layered sheet with which one starts for obtaining the wrapping can be shorter, specifically in the measure corresponding to the width of the traditional tab and of length coincident with the generatrix of the cone.

[0012] Moreover, the gripping tab of the cone for tearing is defined by one of the sides of the angular seam, specifically that nearest the mouth of the cone, whereby this tab, by not being projecting outwards, cannot be separated accidentally or unwittingly from the cone itself, whereby the risk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com