PDA diagnosis of thermostats

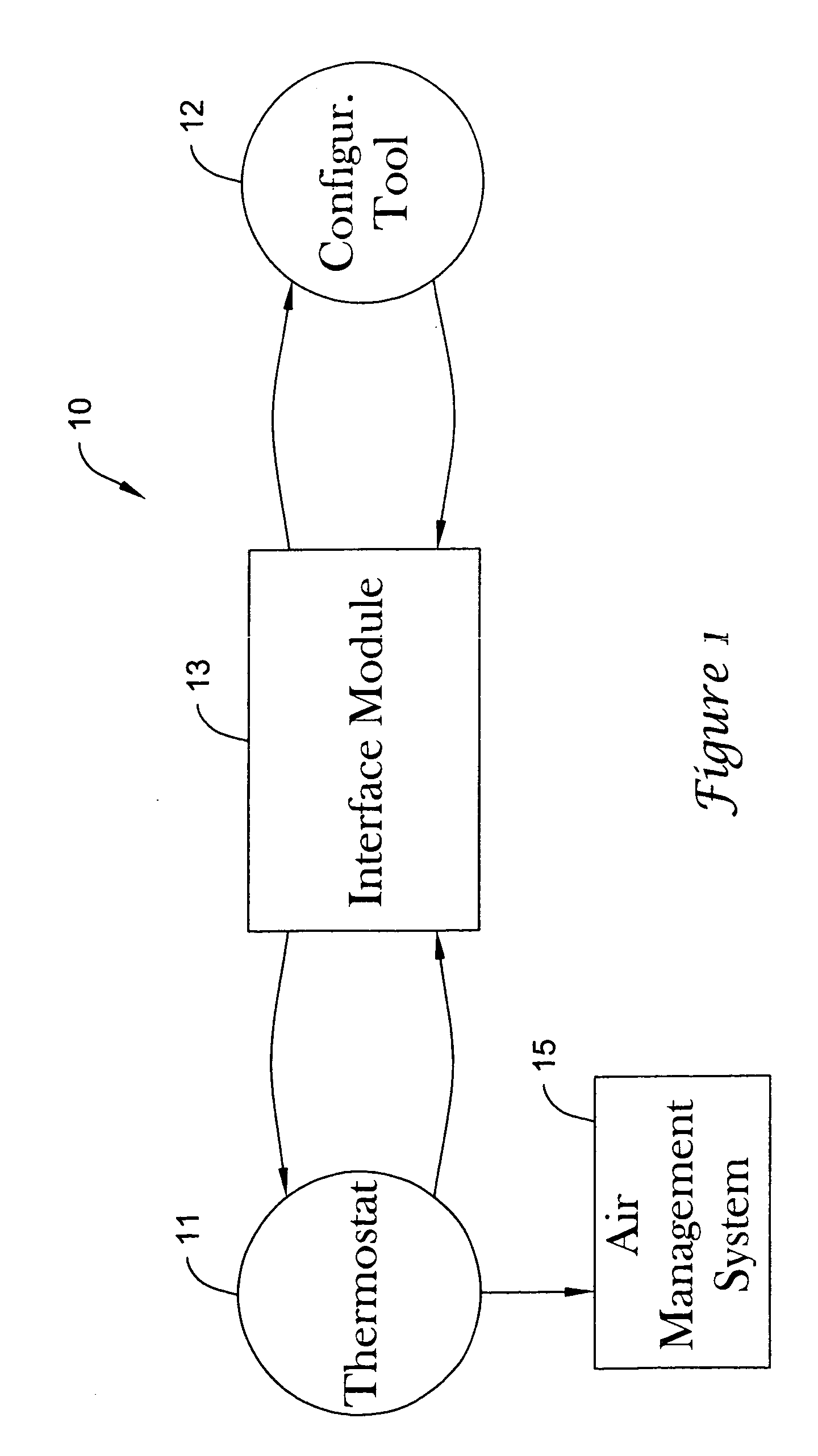

a thermostat and thermostat technology, applied in the field of thermostats, can solve the problems of time-consuming and confusing thermostat system maintenance, frustration with adjusting and operating those kinds of systems, complex and confusing controls in many commercial and residential places, etc., and achieves the effect of less expertise, less time and inconvenience, and less complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

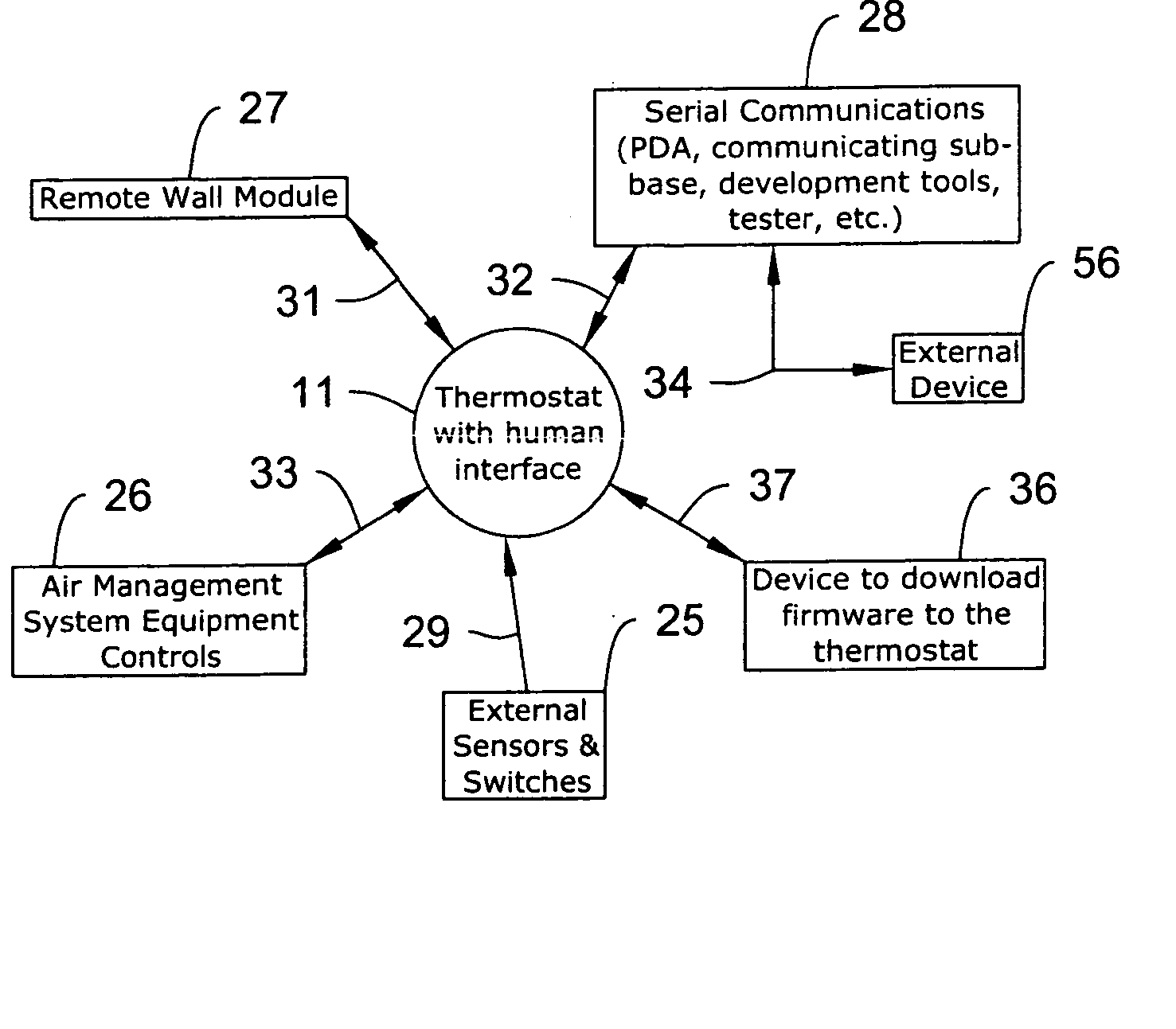

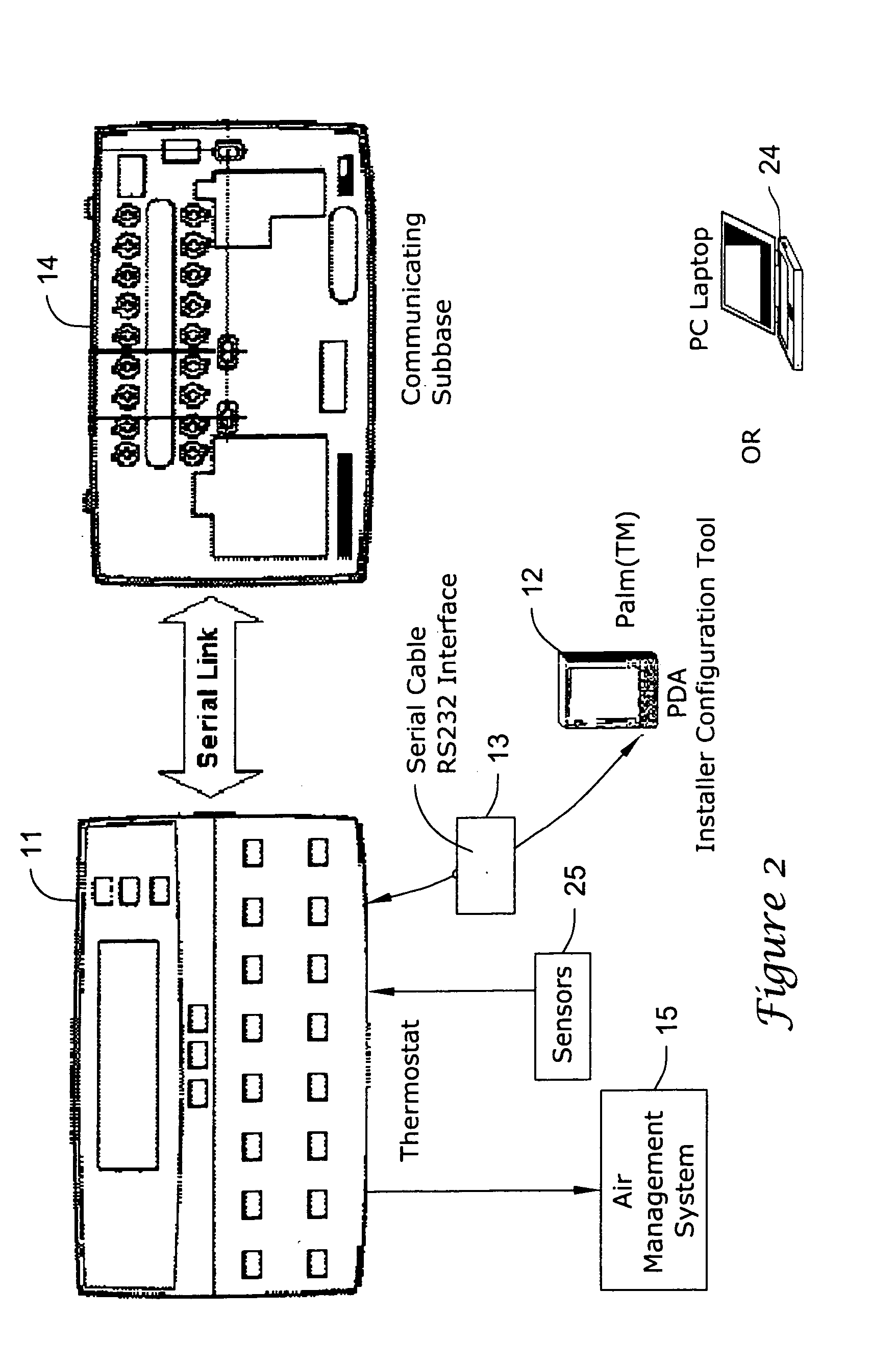

Method used

Image

Examples

Embodiment Construction

”, which may result in the next screen as illustrated in FIG. 4c. Here, one may click “Downld”, which may bring a screen as shown in FIG. 4d. Then one may click “OK” to connect the PDA serial port to the T7350 thermostat. On the other hand, one may configure a new arrangement and then connect in FIGS. 5a, 5b and 5c. One may click a “New Config” on the opening screen of FIG. 5a and enter the new configuration name and its description on the next screen in FIG. 5b. The thermostat may be configured clicking the “Next” button to navigate it for entering the new configuration selections, features and settings. Clicking the “DownLd” button may result in the screen of FIG. 5c for the opportunity of serially connecting the PDA 12 port to thermostat 11.

FIGS. 6a through 6c relate to connecting and modifying the existing configuration. On the opening screen of FIG. 6a, one may click “Upload Config” and get the connecting screen in FIG. 6b where one may connect the PDA to the thermostat by clic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com