Surgical suturing instrument and method of use

a surgical and suture technology, applied in the field of medical suturing instruments, can solve the problems of system not providing sufficient flexibility in regard to the appropriate type of suture stitch to be applied, device not allowing sufficient flexibility in regard to the amount of tension, system not allowing sufficient flexibility in all situations,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Overview

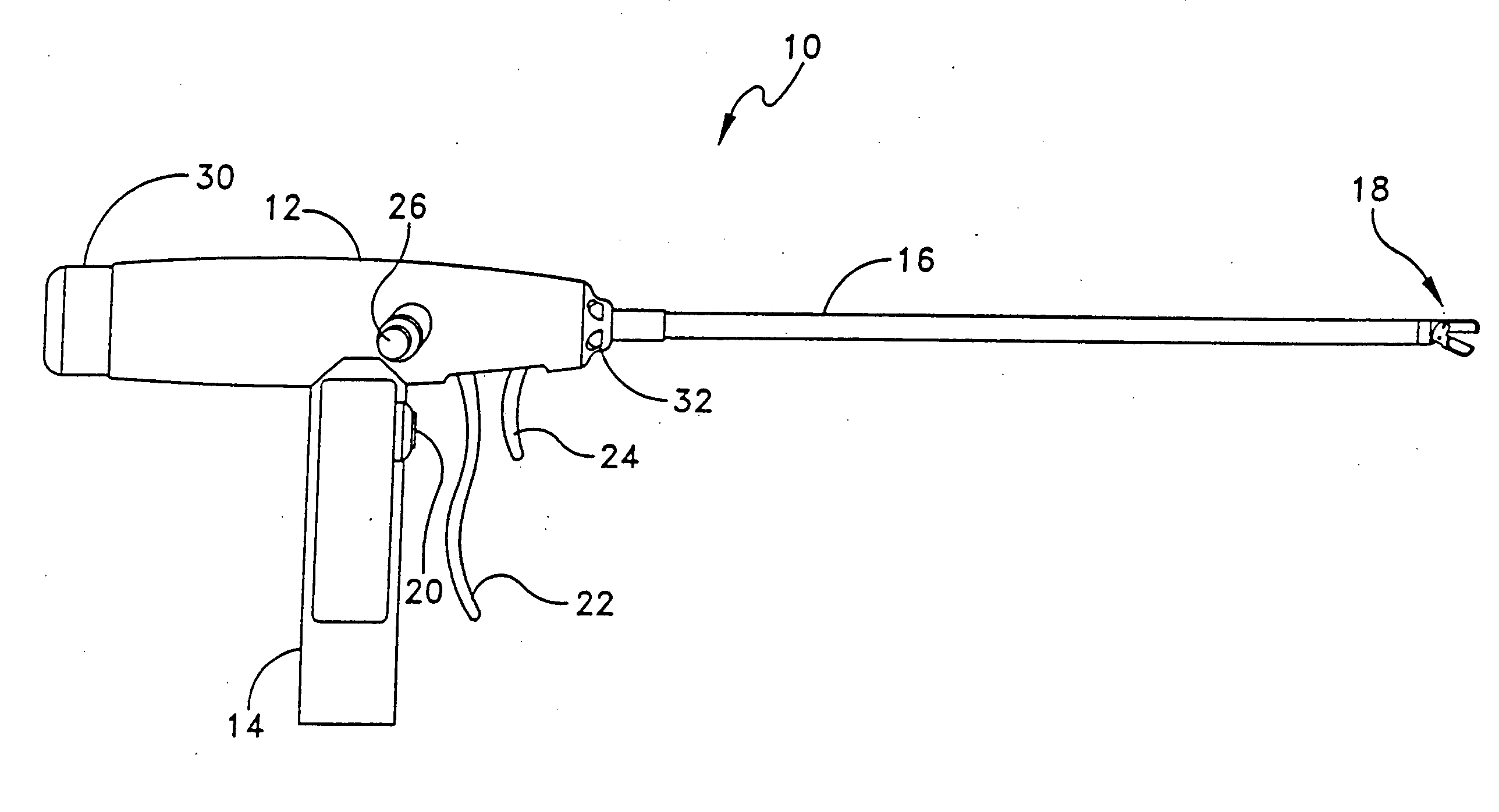

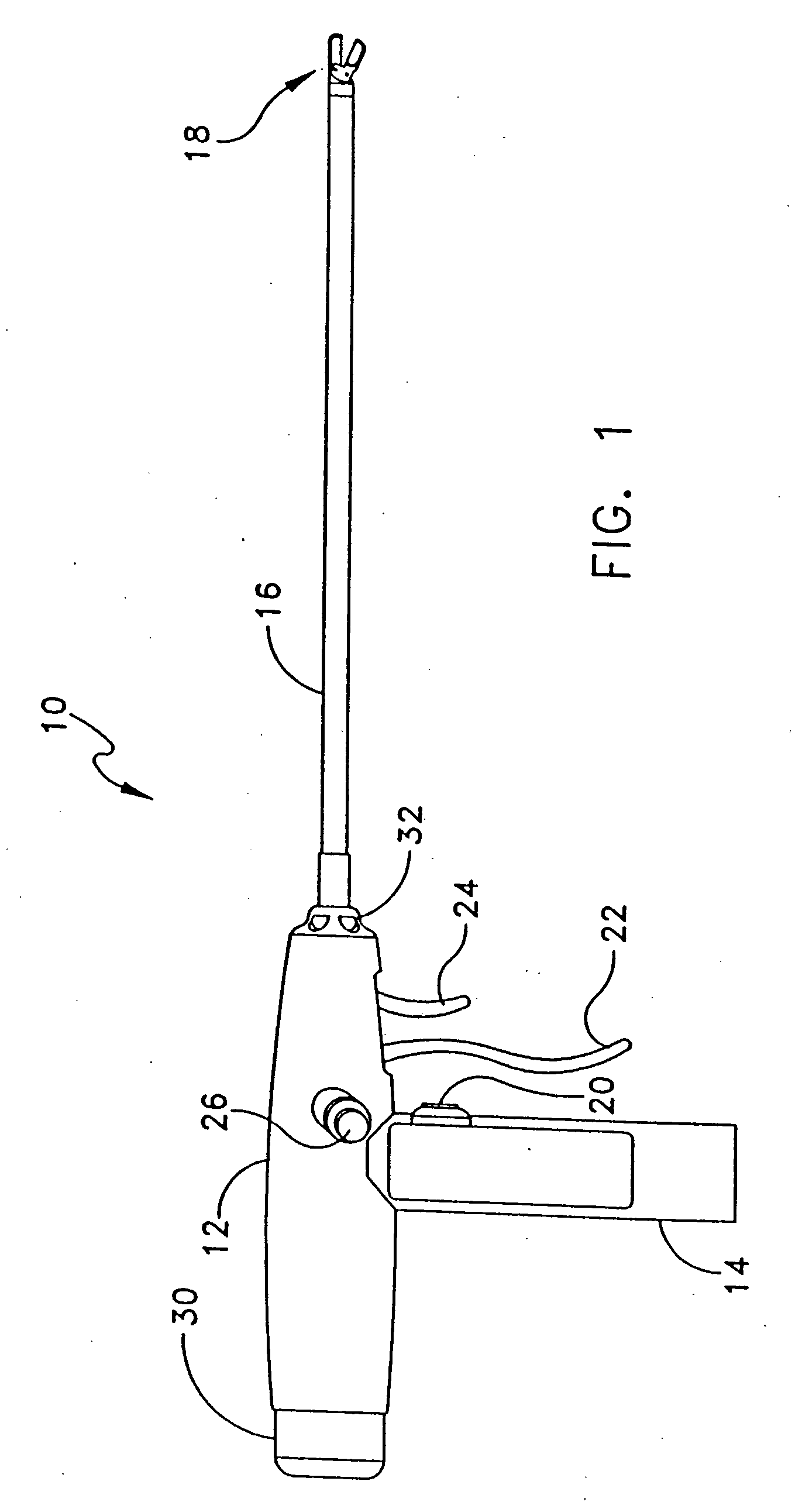

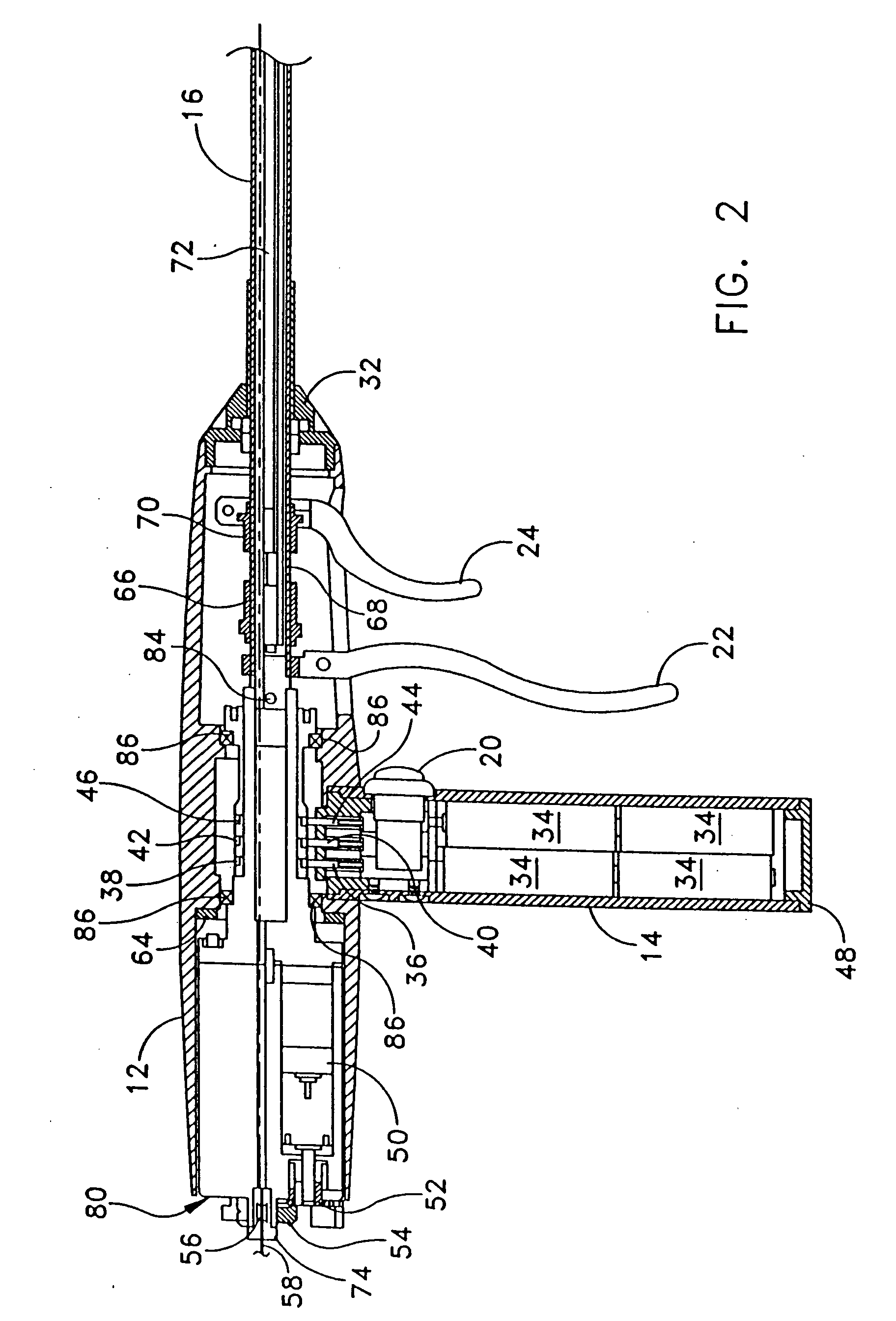

[0078] Looking first at FIG. 1, there is shown a suturing instrument 10 which comprises a preferred embodiment of the present invention. Suturing instrument 10 includes a housing 12, a handle 14, a shaft 16 and an end effector 18. Suturing instrument 10 also includes a wire advance button 20, a jaw closing actuator 22, a wire cutting actuator 24, a left-thumb-actuated rotation button 26, and a right-thumb-actuated rotation button 28 (FIG. 3). Suturing instrument 10 also includes a wire supply cartridge 30, as well as a shaft retaining nut 32. Shaft retaining nut 32 allows shaft 16 to be dismounted from the remainder of the device for cleaning purposes.

[0079] As will be discussed in further detail below, generally during use, suture wire (comprising wire formed of metal or any other suitable material having the required flexibility and stiffness) is drawn from a winding in wire supply cartridge 30 and is pushed through housing 12 and shaft 16 to end effector 18, which inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com