Combustor of a gas turbine engine

a gas turbine engine and combustor technology, applied in the direction of machines/engines, mechanical equipment, lighting and heating apparatus, etc., can solve the problems of carbon monoxide formation at the periphery of the combustor, and the inability to obtain the maximum cooling potential from the available mass of cooling air while still maintaining low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

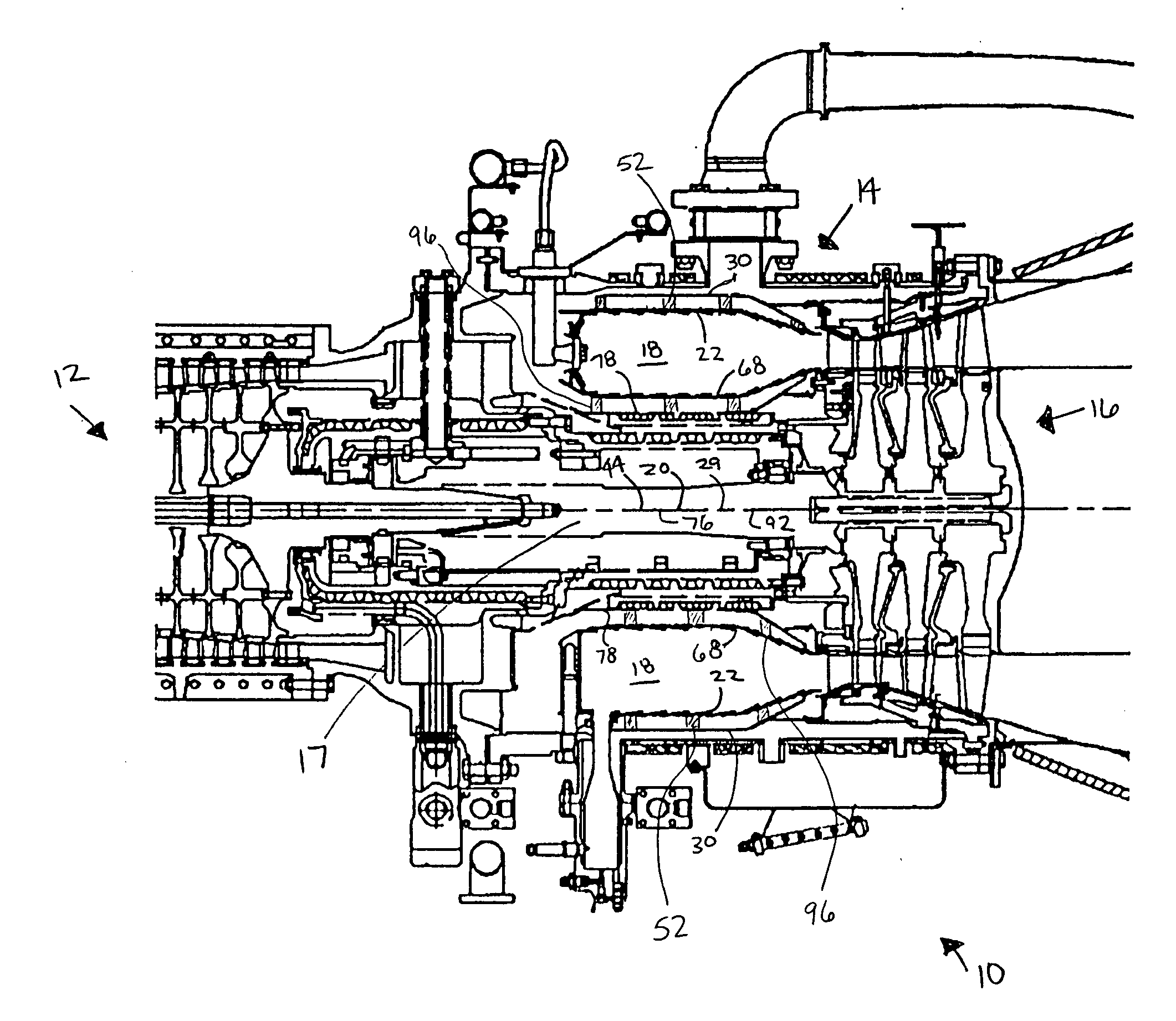

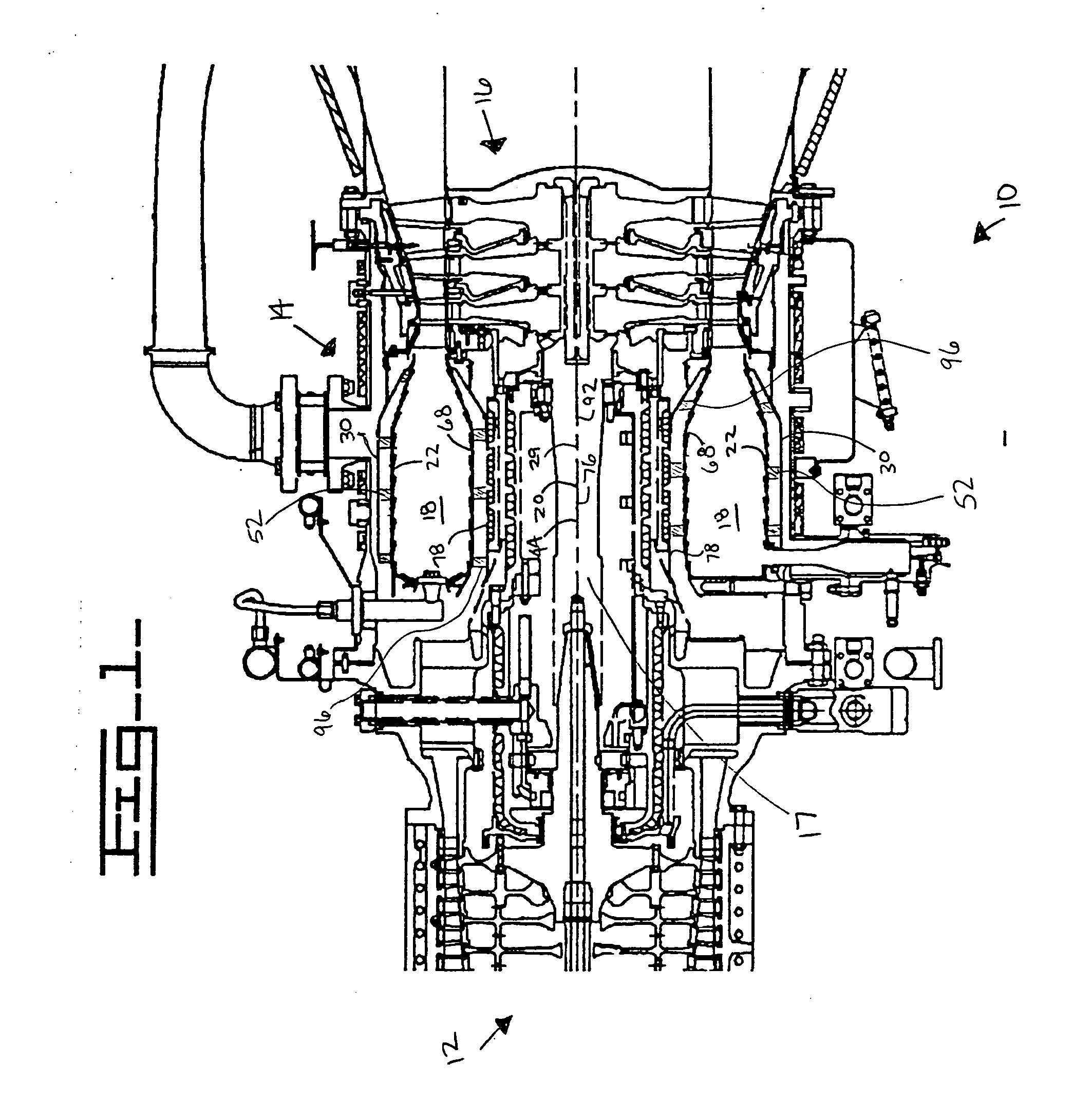

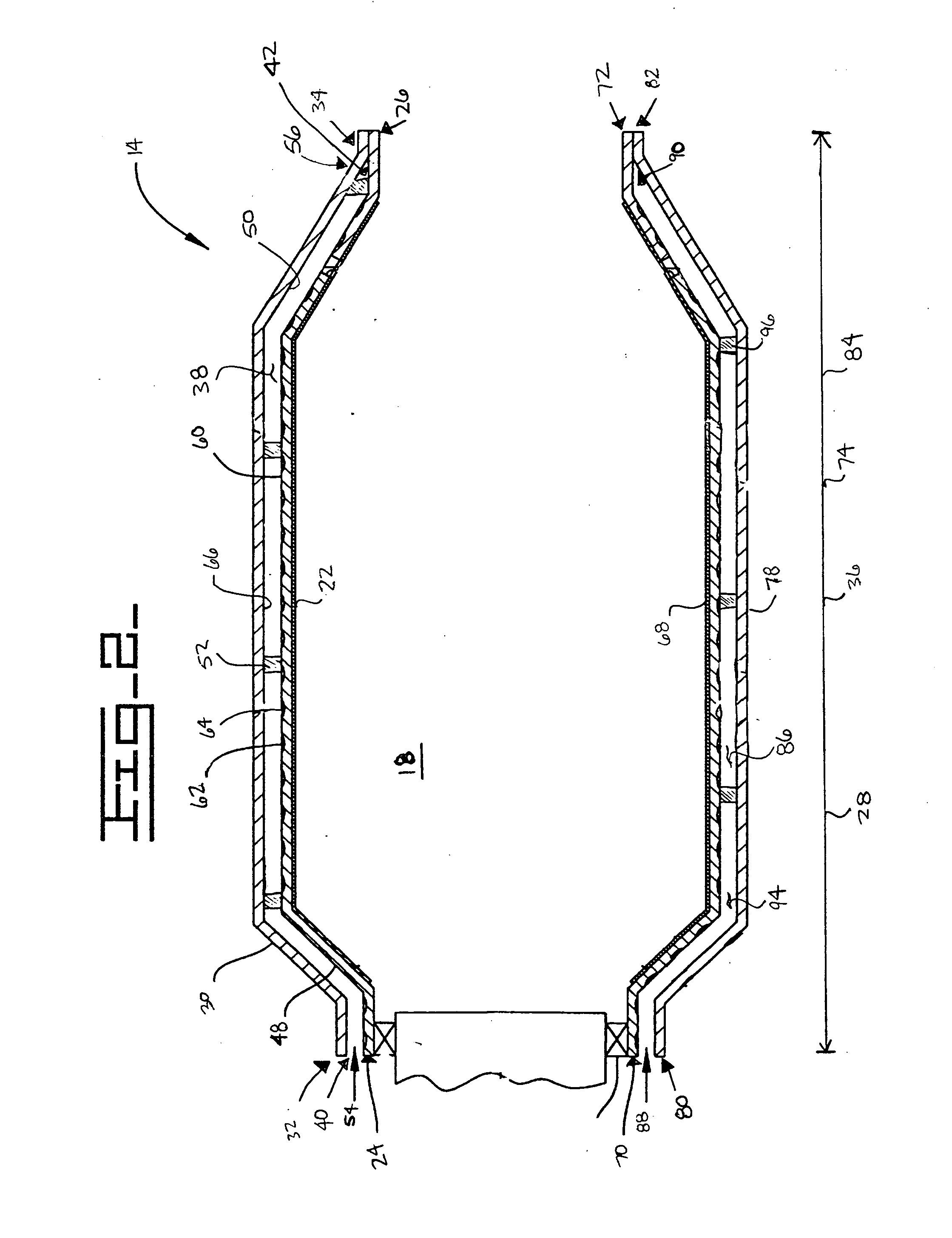

[0014] Referring to FIG. 1, an embodiment of a gas turbine engine 10 is shown having a compressor 12, a combustor 14, and a turbine 16. The combustor 14 is in fluid communication with the compressor 12, and the turbine 16 is in fluid communication with the combustor 14. The turbine 16 is connected to the compressor 12 via a force-transmitting device 17, such as a shaft or gear system. The combustor 14 defines a combustion zone 18 of the gas turbine engine 10. In the embodiment of FIG. 1, the combustor 14 of the gas turbine engine 10 is an annular combustor and has a central axis 20. However, in other embodiments, the combustor 14 may be tubular with a single can, tubular with multiple cans, tuboannular, or any other configuration known in the art. In the embodiment of FIG. 1, the combustor 14 is generally in the shape of a cylinder joined to a conical frustum. However, the combustor 14 may approximate any other shape or combination of shapes, such as a cylinder, an elliptic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com