Method and apparatus for tire pressure monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

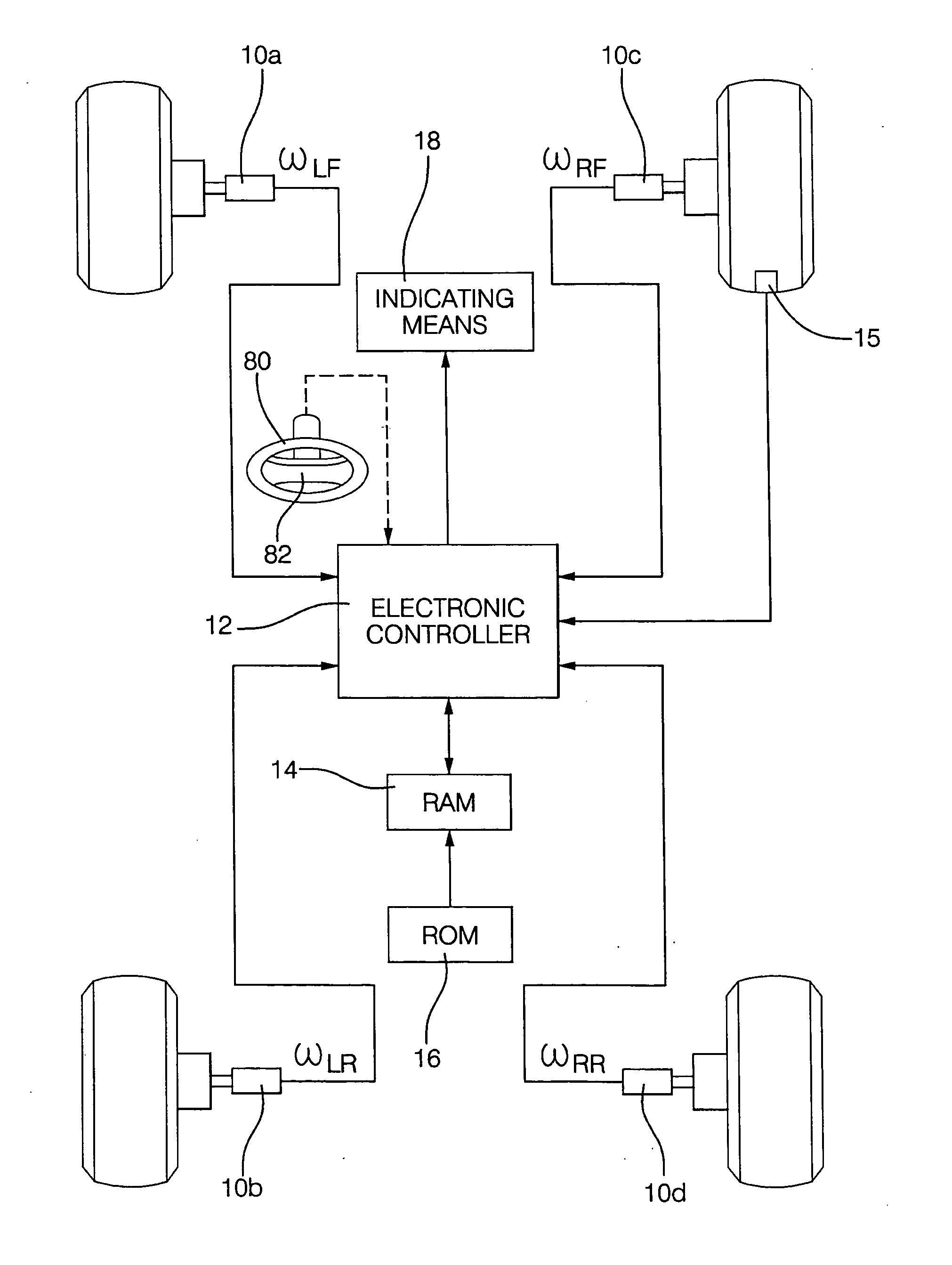

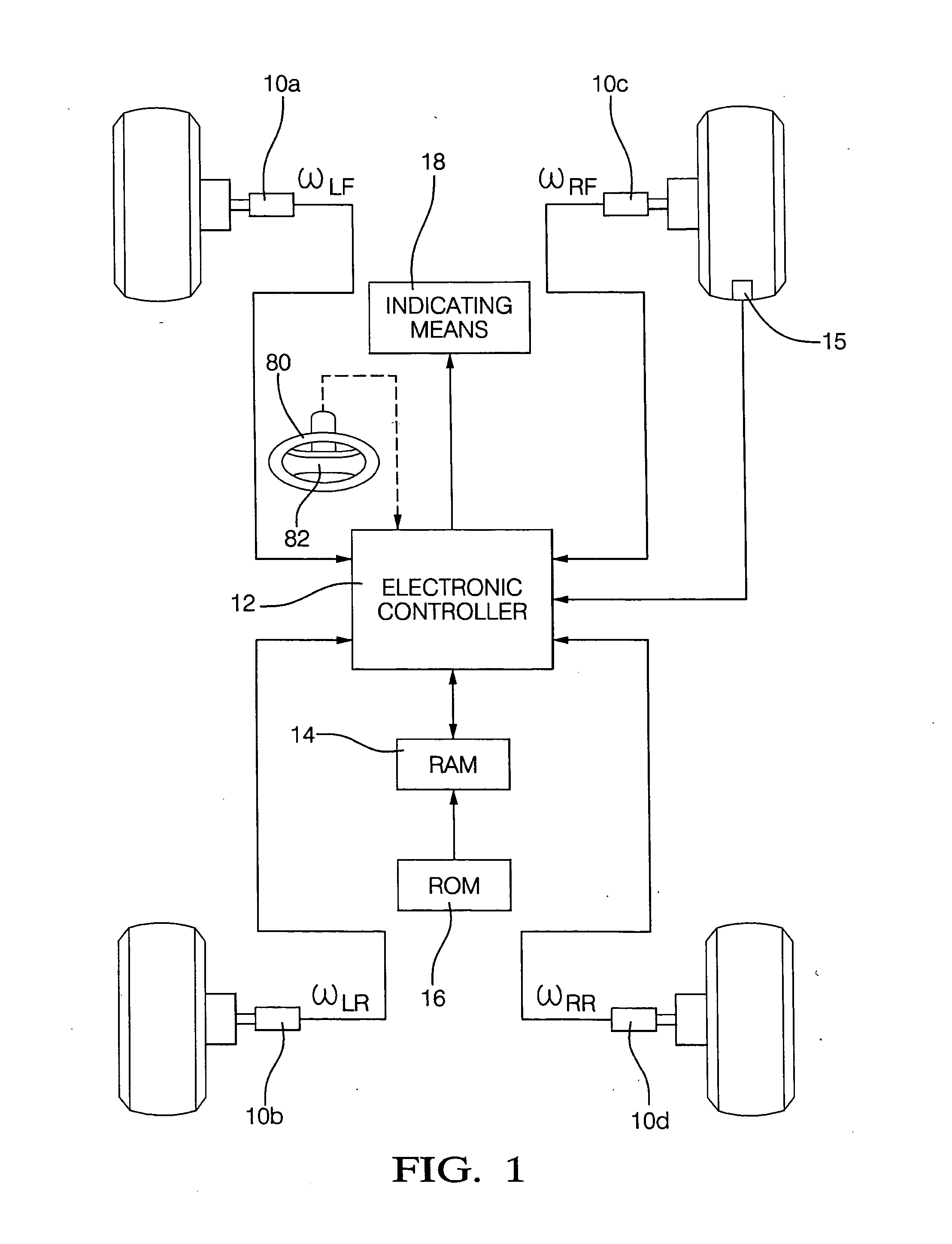

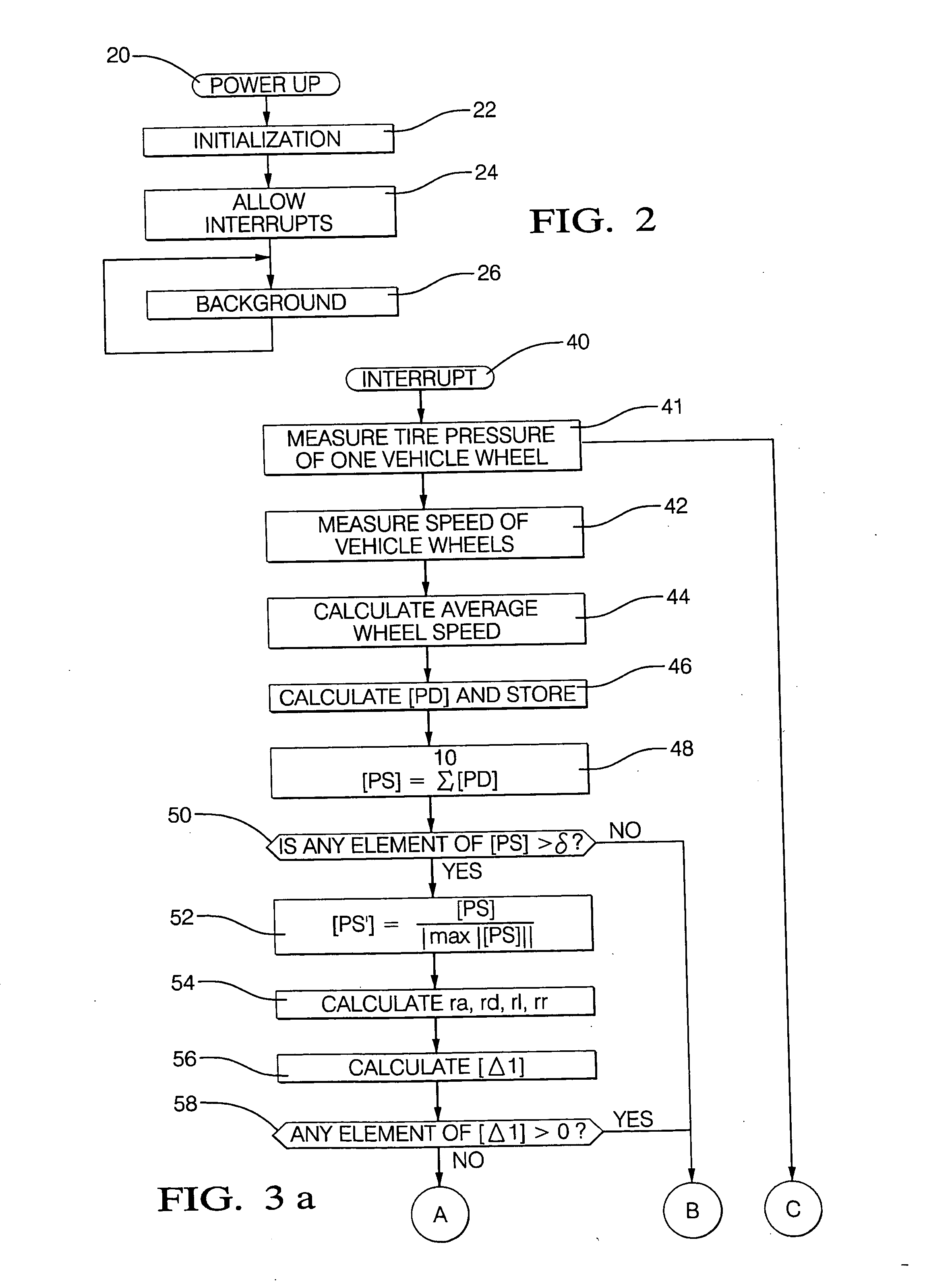

The inflation pressure of conventional automotive tires is related to the tire radius in that, to an extent, increasing the tire pressure increases the radius. Further, tire radius is related to tire rotation speed in that, for a given vehicle speed, the tire rotation speed will increase as the tire radius decreases. Accordingly, by relating the tire (wheel) speed of the vehicle tires to each other, all of which are subject to a common vehicle speed, information on the tire radius and thus on the individual tire inflation pressure is made available.

Vehicles are available that already have the necessary hardware for constant monitoring of wheel speed of each of the vehicle's wheels. Accordingly, to implement a system that determines tire pressure status purely on wheel speed information may be relatively inexpensive, as generally only an algorithm to interpret the already available wheel speed data, and perhaps a low pressure indicating means is needed.

Unfortunately, wheel speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com