Phase-change structural insulated panels and walls

a technology of structural insulation and insulated panels, applied in the field of structural insulation panels and walls, can solve the problems of increasing the flammability of the boards, reducing the permeability of the boards to water vapor, and wasting engineering and design time, and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

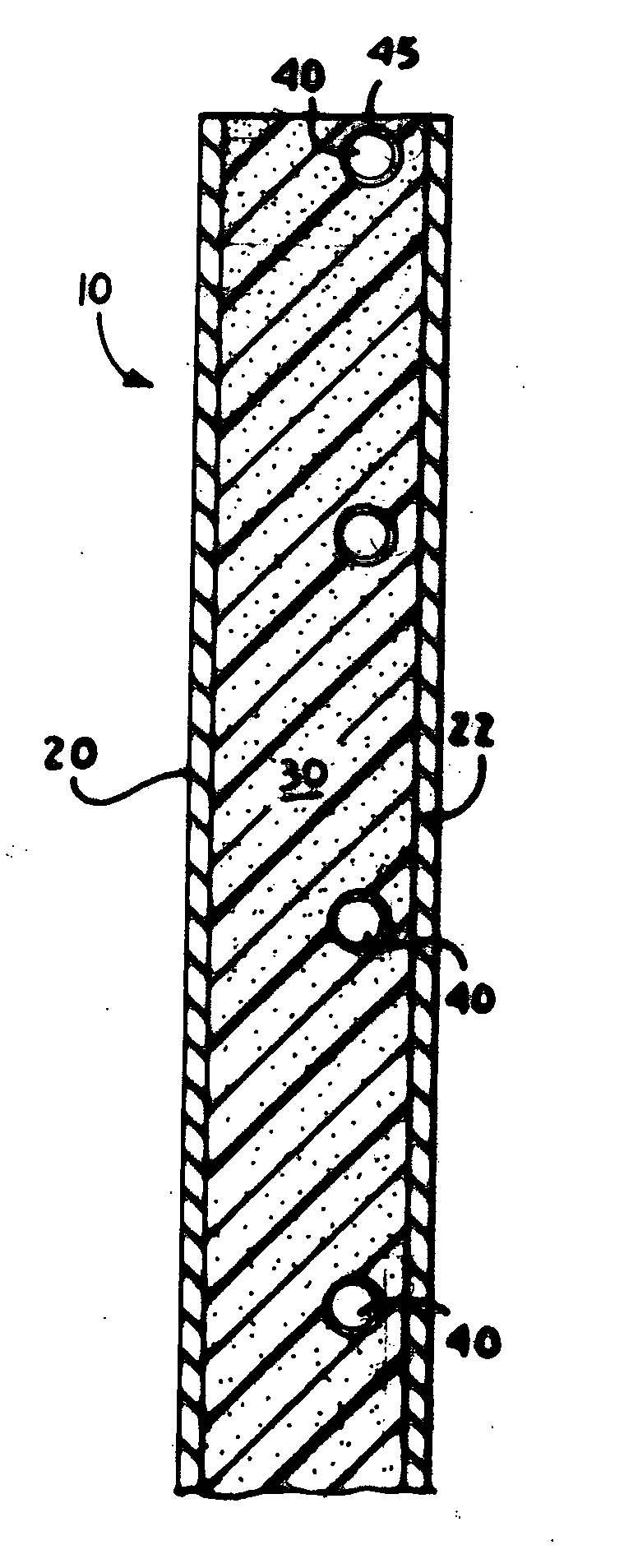

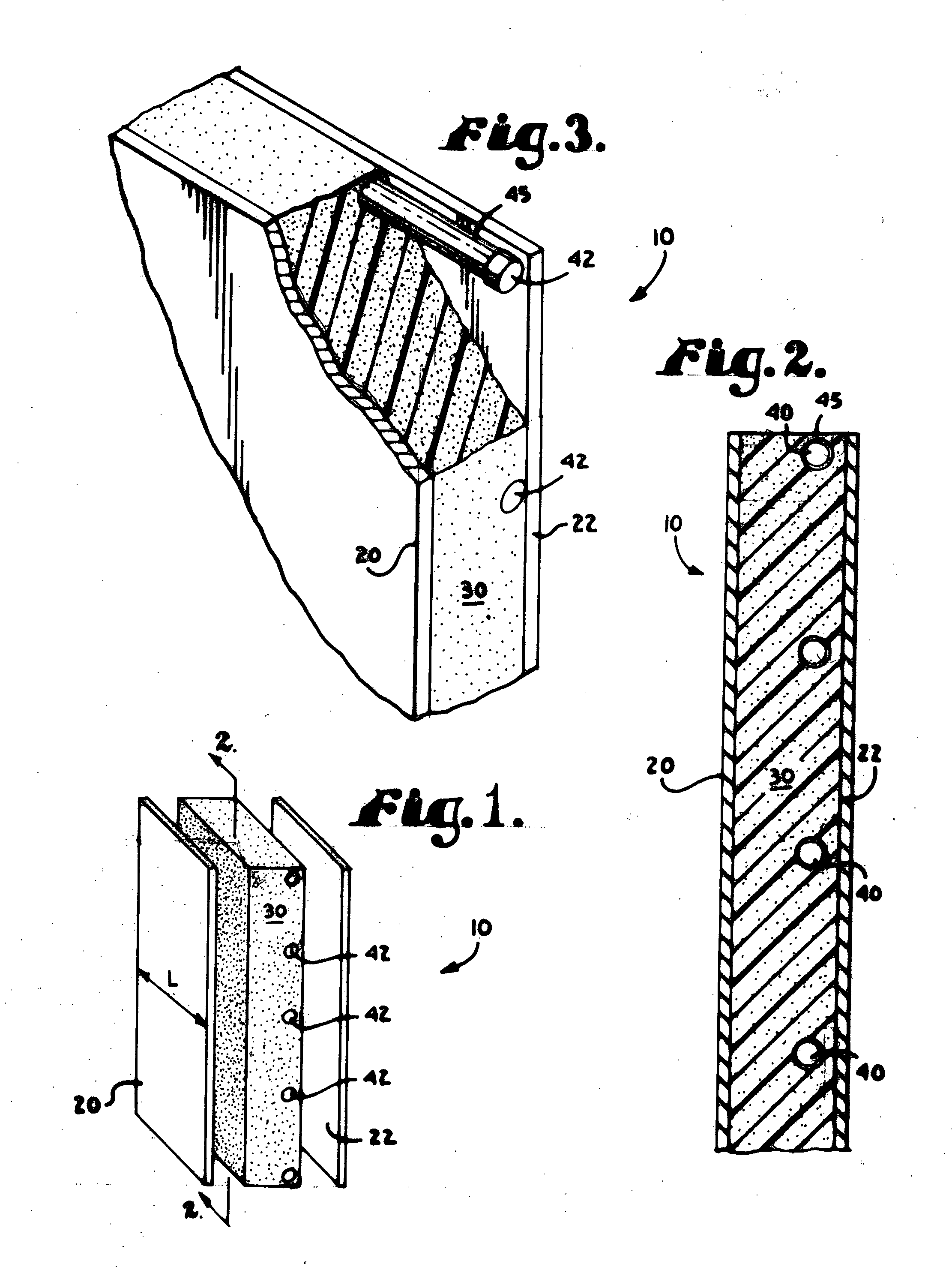

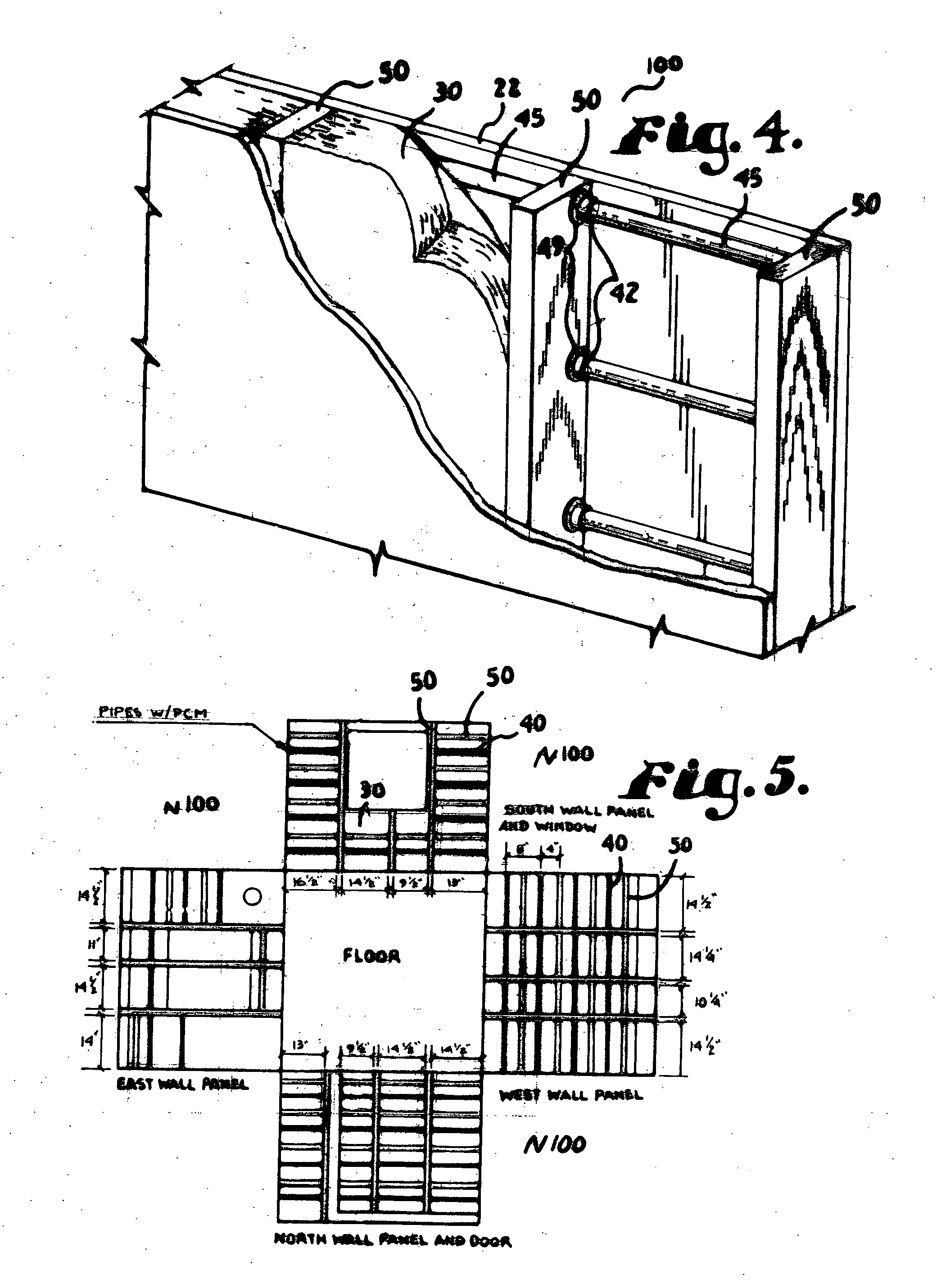

[0020] Referring to FIGS. 1-2, a structural panel in accordance with the present invention is shown. Structural panel 10 includes first and second sheathings 20 and 22 disposed on and affixed to opposed outer surfaces of a generally planar, insulating core 30. One or more PCMs 40 are macroencapsulated between the sheathings 20, 22.

[0021] Various types of sheathings 20, 22 are known to those skilled in the art. The sheathing is preferably comprised of a rigid material such as gypsum or cementous composite, waferboard, metal, plywood, drywall, OSB, or an agricultural board product such as strawboard or wheatboard. Most preferably, the sheathing comprises OSB.

[0022] The sheathings 20, 22 of the present invention are of any suitable thickness. The sheathing preferably has a thickness between about 0.125 to 3 inches (7.18 mm to 7.62 cm), more preferably between about 0.25 to 2 inches (6.35 mm to 5.08 cm), and most preferably about 0.5 to 0.75 inches (1.27 to 1.91 cm). Common commercial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com