Method and apparatus for guiding side edges of continuously running web

a technology of side edges and continuous running webs, applied in the direction of web handling, manufacturing tools, transportation and packaging, etc., can solve the problems of difficulty in shifting side edges in directions other than outward direction, and difficulty in continuously making articles each having a high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

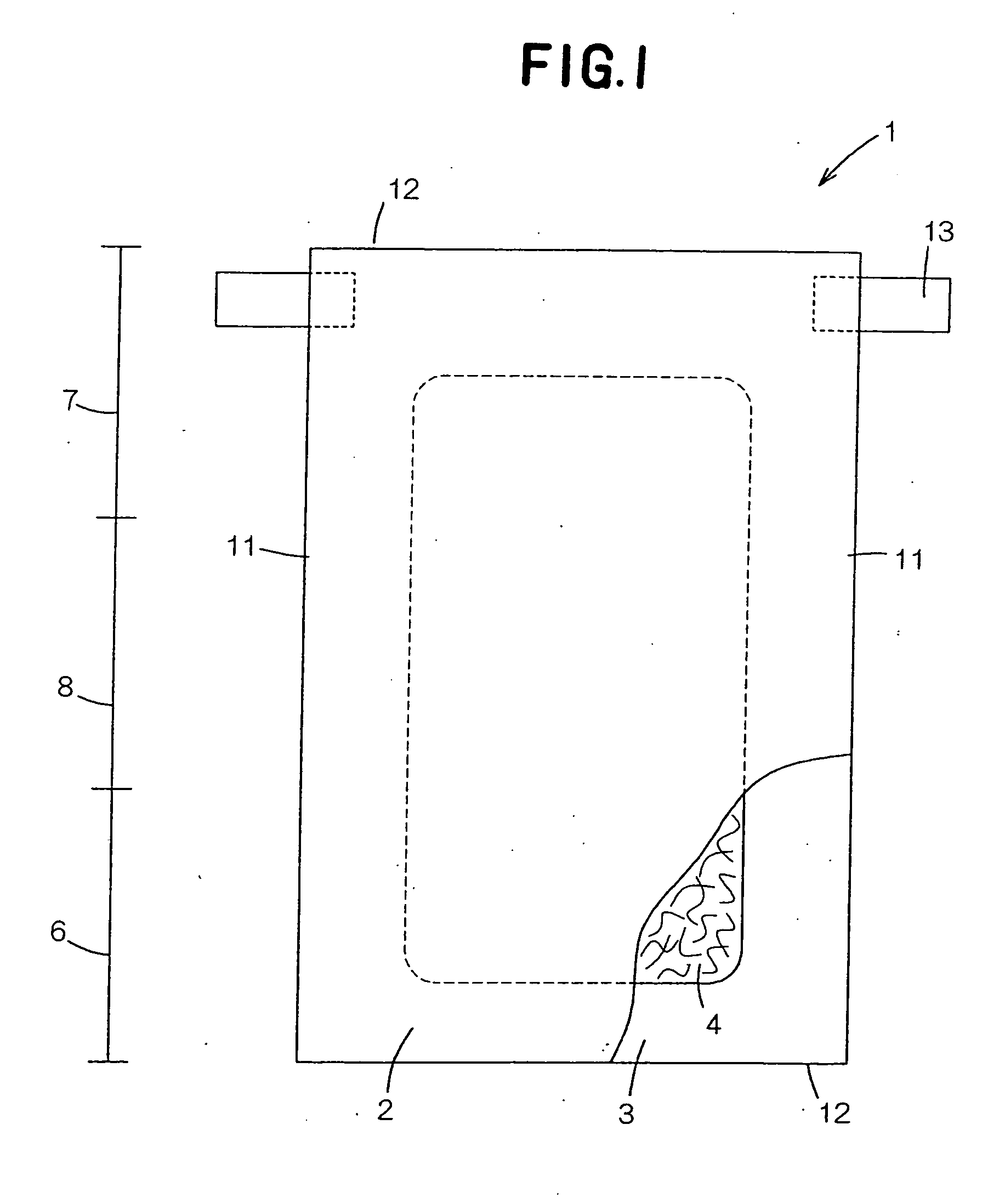

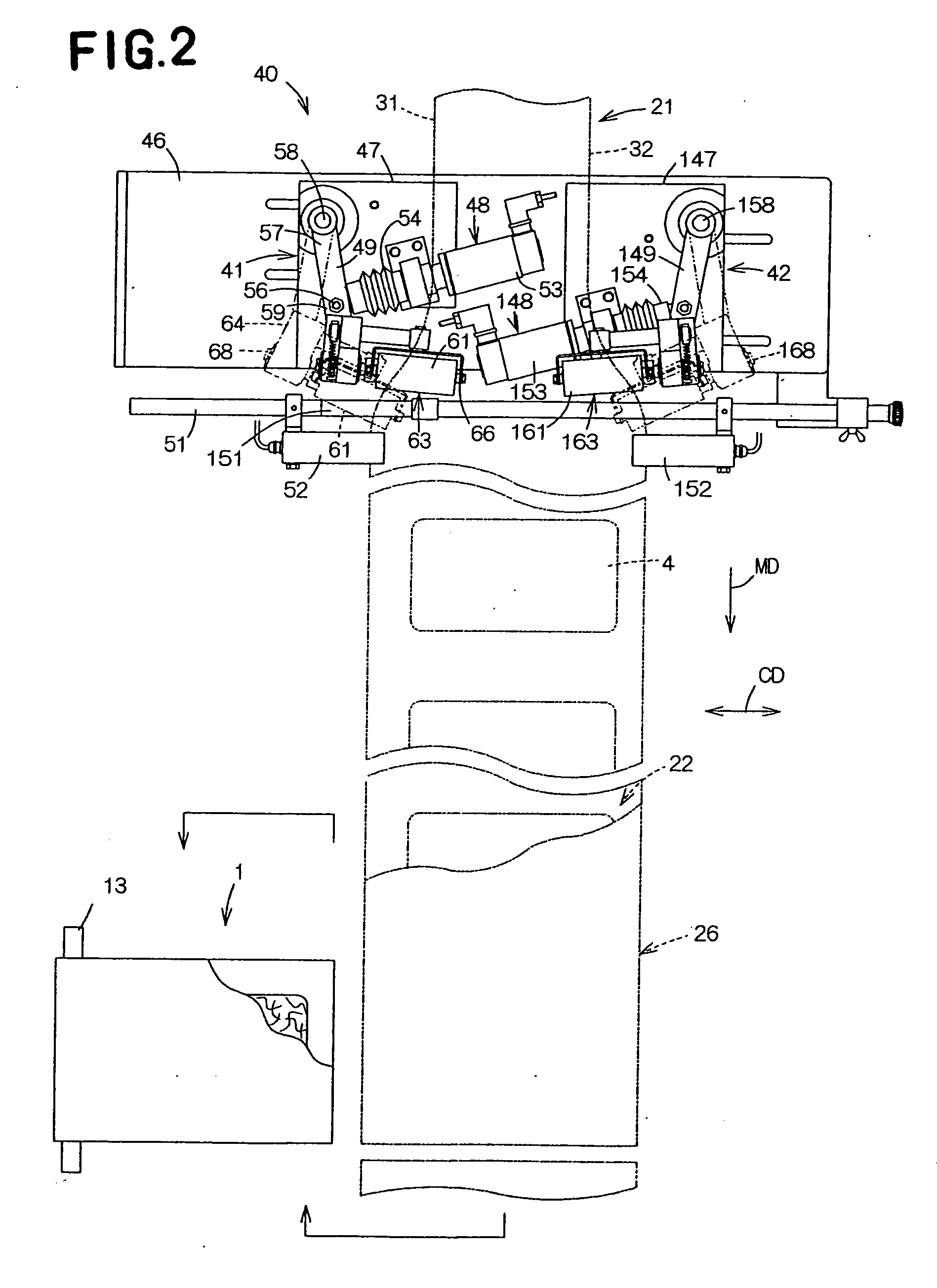

[0032] Details of a method and an apparatus according to the present invention will be more fully understood from the description given hereunder with reference to the accompanying drawings.

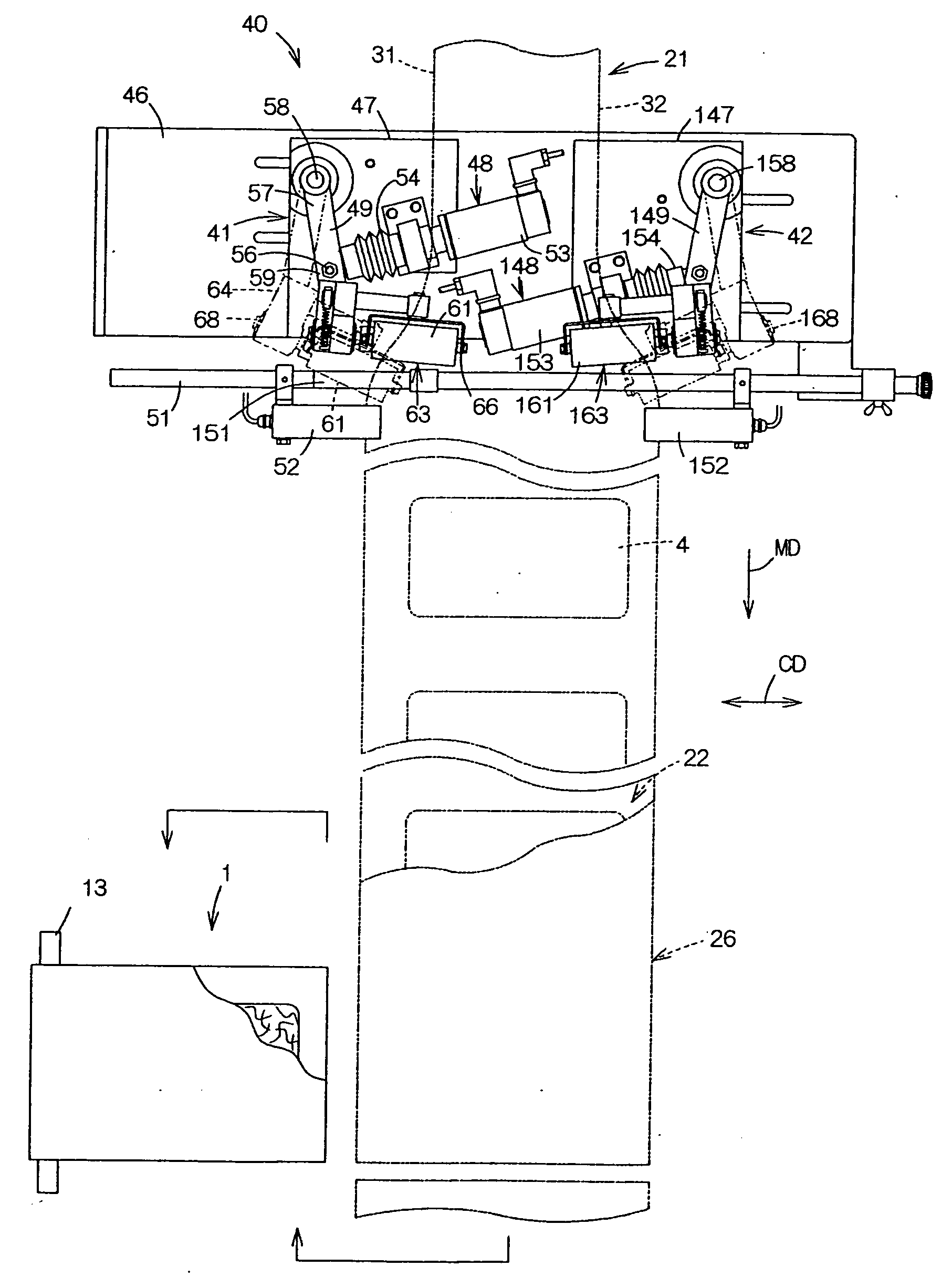

[0033] A disposable diaper 1 shown by FIG. 1 in a plan view as partially broken away is a product obtained by a method and an apparatus according to the present invention. This diaper 1 comprises a liquid-pervious topsheet 2, a liquid-impervious backsheet 3 and a liquid-absorbent core 4 interposed between these sheets 2, 3. The diaper 1 has a in- and outward direction (longitudinal direction as viewed in FIG. 1) and a waist-surrounding direction (transverse direction as viewed in FIG. 1). The diaper 1 is peripherally contoured by a pair of side edges 11 extending parallel to each other in the in- and outward direction and a pair of ends extending parallel to each other in the waist-surrounding direction. As viewed in the in- and and outward direction, the diaper 1 is composed of a front waist re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com