Release device and method of manufacturing, installing and operating the same

a technology of release device and release plate, which is applied in the direction of curtain suspension device, curtain accessories, screens, etc., can solve the problems of reducing the span length of the device, reducing the width of the device, and undesirable transverse runners, so as to achieve minimal deflection and high versatility. , the effect of minimal deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

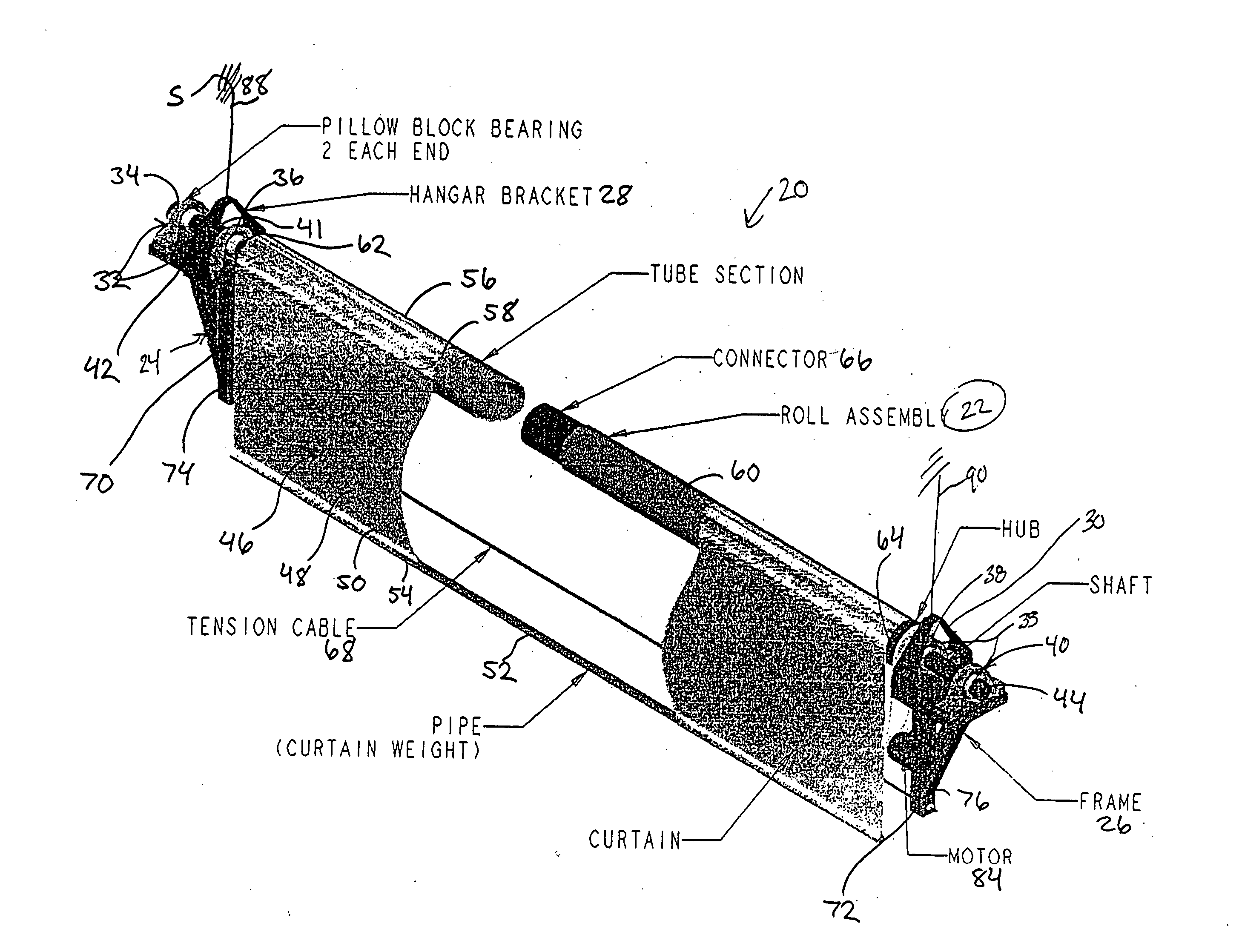

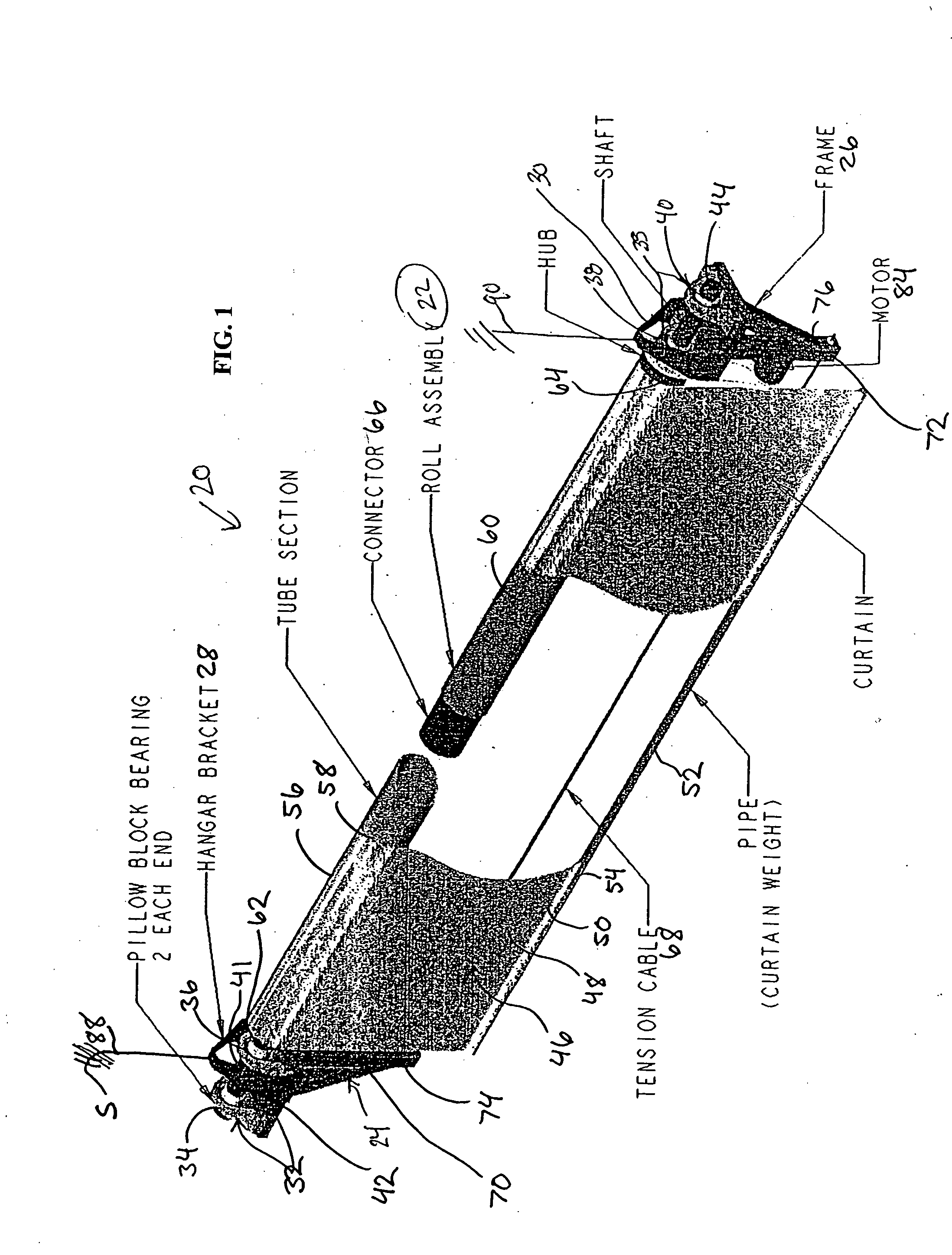

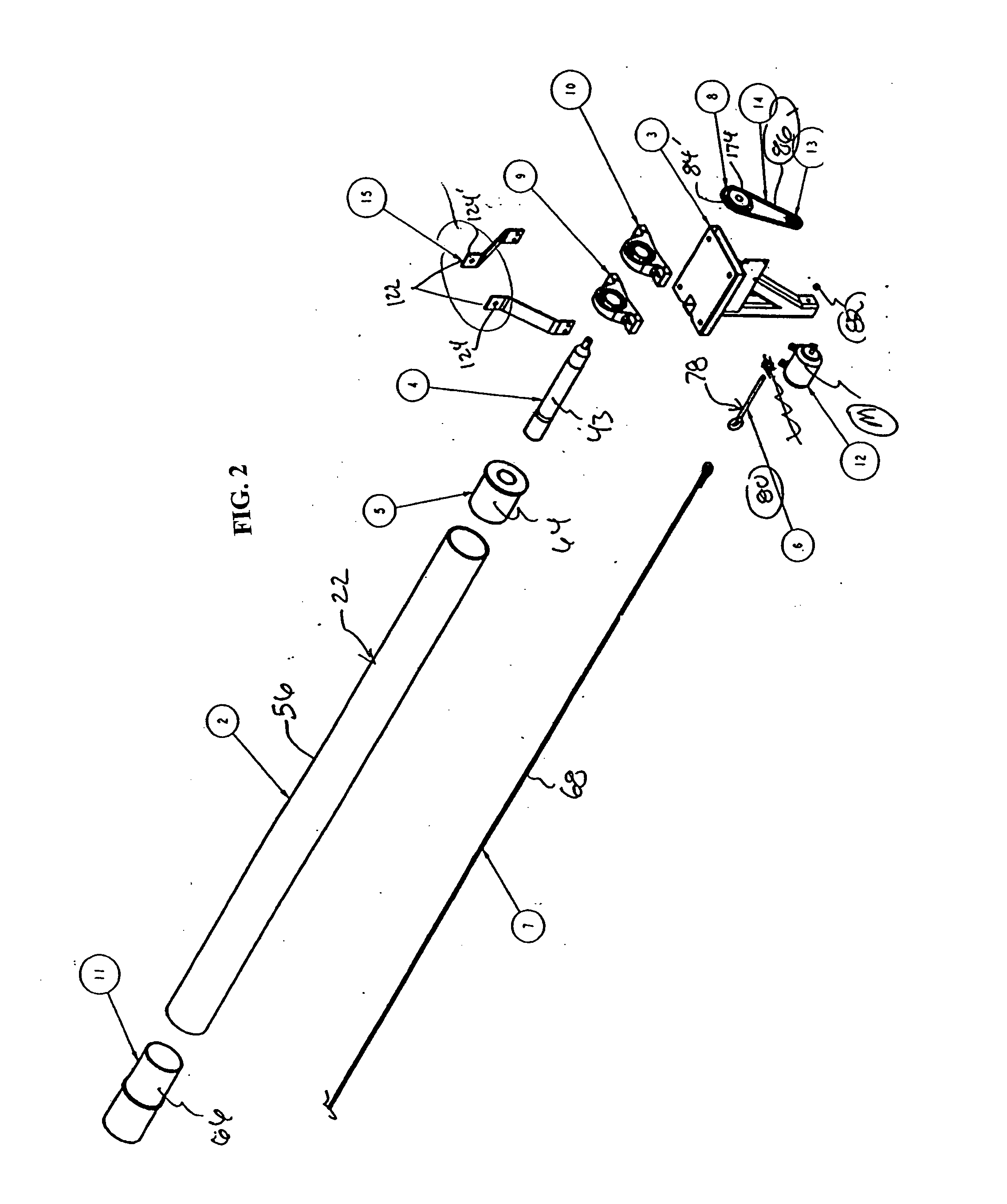

[0036]FIG. 1 illustrates, in perspective, a preferred embodiment of a release device 20 in the form of a roll drop device (hereafter referred to as roll drop device 20) which is well suited for use as a roll drop such as for theatrical banners (e.g., curtains) acoustic banners, sun and environmental control banners, advertising banners, etc. Roll drop device 20 comprises roll assembly 22 which is supported at opposite ends by first frame 24 and second frame 26. First frame 24 is connected with first support connector (e.g., a first hanger bracket assembly) 28, while second frame 26 is connected with second support connector (e.g., a second hanger bracket assembly) 30. As explained in greater detail below, first frame 24 supports bearing assembly 32 (e.g., a bearing set 34, 36) and second frame 26 supports bearing assembly 33 (e.g., a second bearing set 38, 40). The first and second bearing assemblies are shown arranged on the frames to receive the “exposed” shaft ends 42 and 44 of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com