Web-enabled configurable quality data collection tool

a configurable quality and data collection technology, applied in the field of vehicle design and manufacture, can solve the problems of inability to collect data from more than a nominal number of vehicles of a particular model, limited system data, and inability to provide data in real-time to a diagnostic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

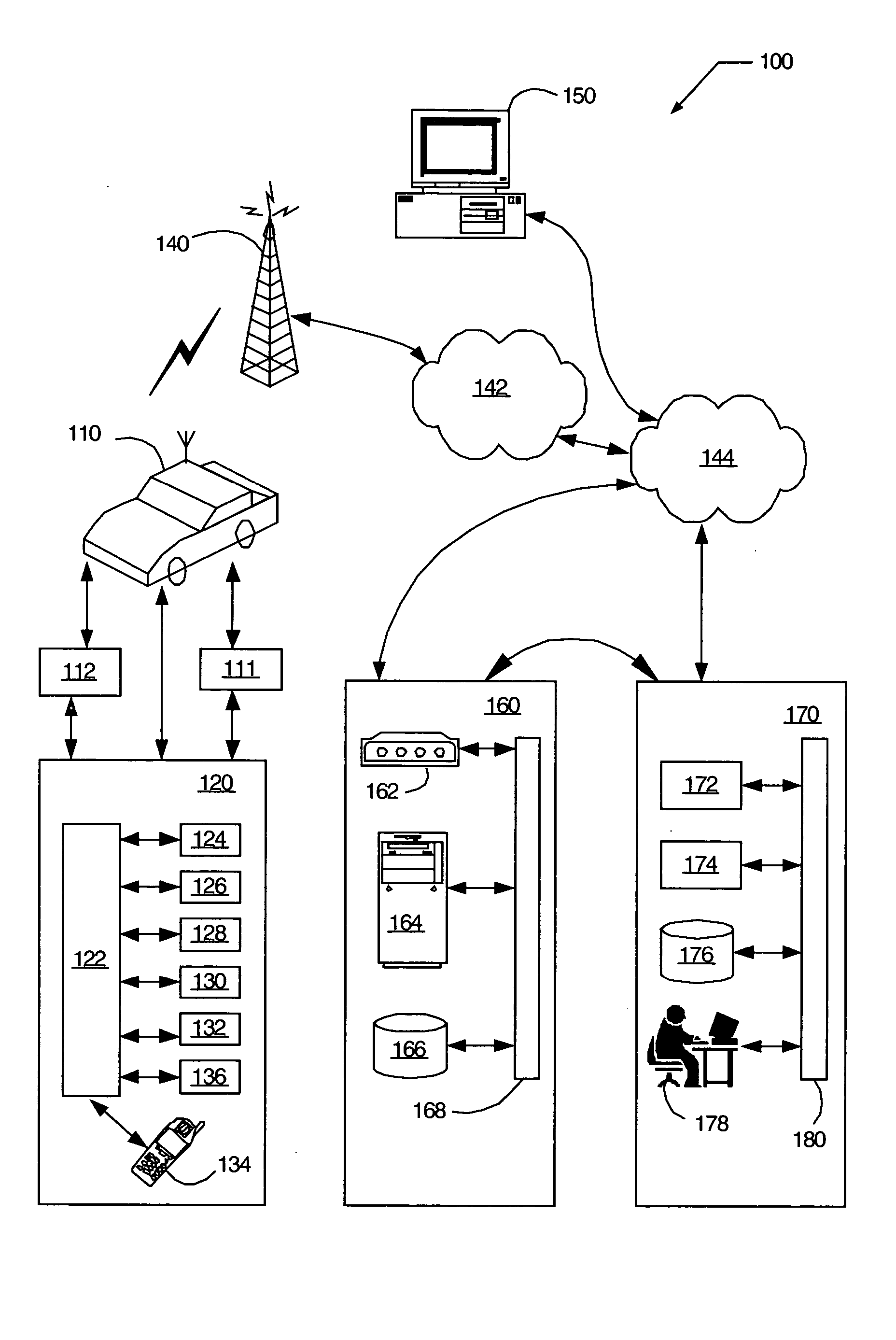

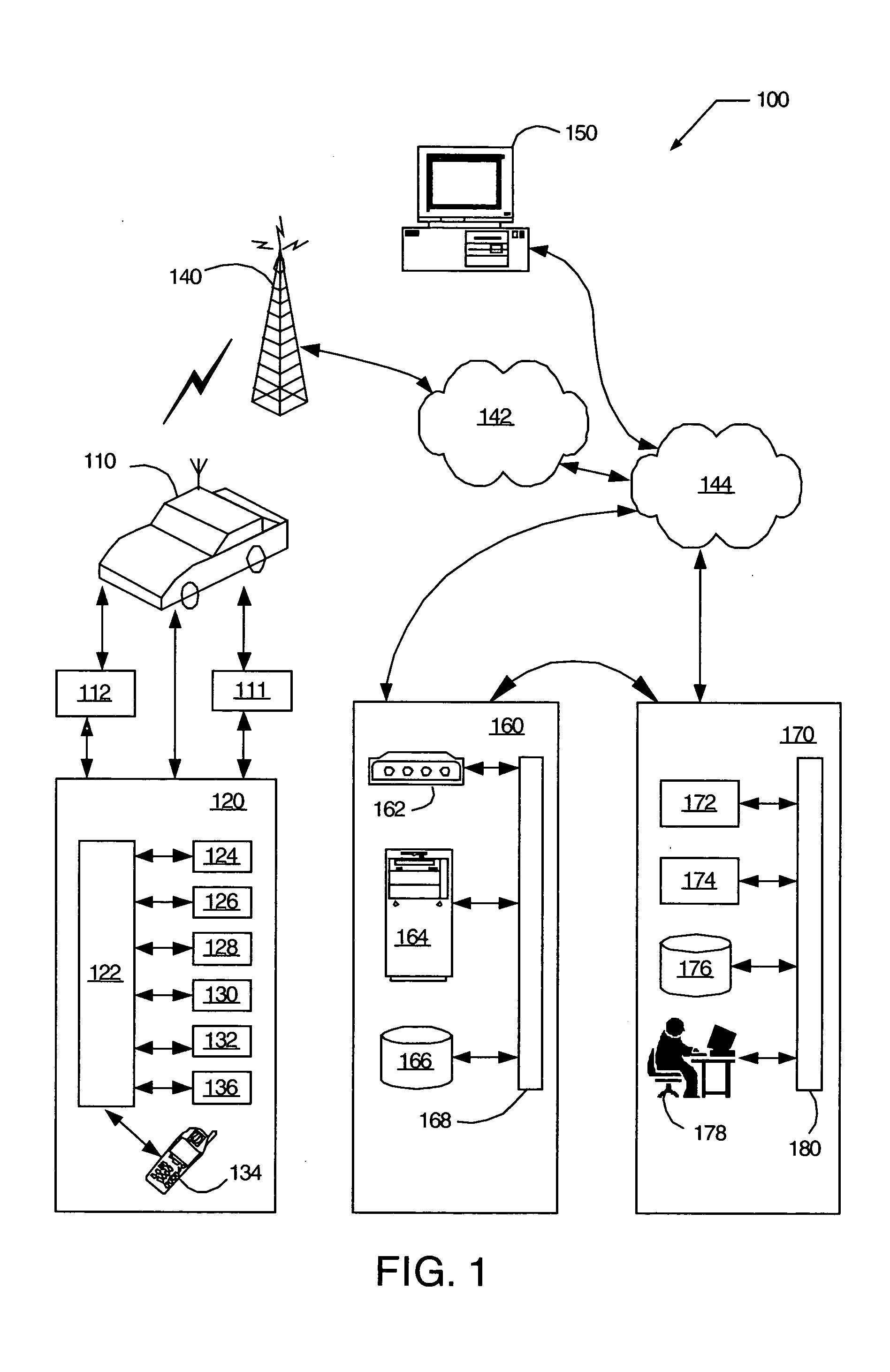

[0020]FIG. 1 is an illustrative operating environment for a captured test fleet in an embodiment of the present invention. In one embodiment, a captured test fleet is comprised of a set of identified vehicles monitored for vehicle or vehicle component behavior. FIG. 1 shows a captured test fleet vehicle communication system 100. Captured test fleet communication system 100 includes at least one captured test vehicle 110 (test vehicle, pilot vehicle, production vehicle) including vehicle communication bus 112 and telematics unit 120, one or more wireless carrier systems 140, one or more communication networks 142, one or more land networks 144, one or more client, personal or user computers 150, one or more web-hosting portals 160, and one or more call centers 170. In one embodiment, captured test vehicle 110 is implemented as a mobile vehicle equipped with suitable hardware and software for transmitting and receiving voice and data communications.

[0021] In one embodiment, telematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com