Masonry wall tension device and method for installing same

a technology of tension device and masonry wall, which is applied in the direction of walls, building components, structural elements, etc., can solve the problems of not strengthening adjacent units, masonry walls tend to vibrate back and forth, and the method of strengthening masonry walls suffers from various problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

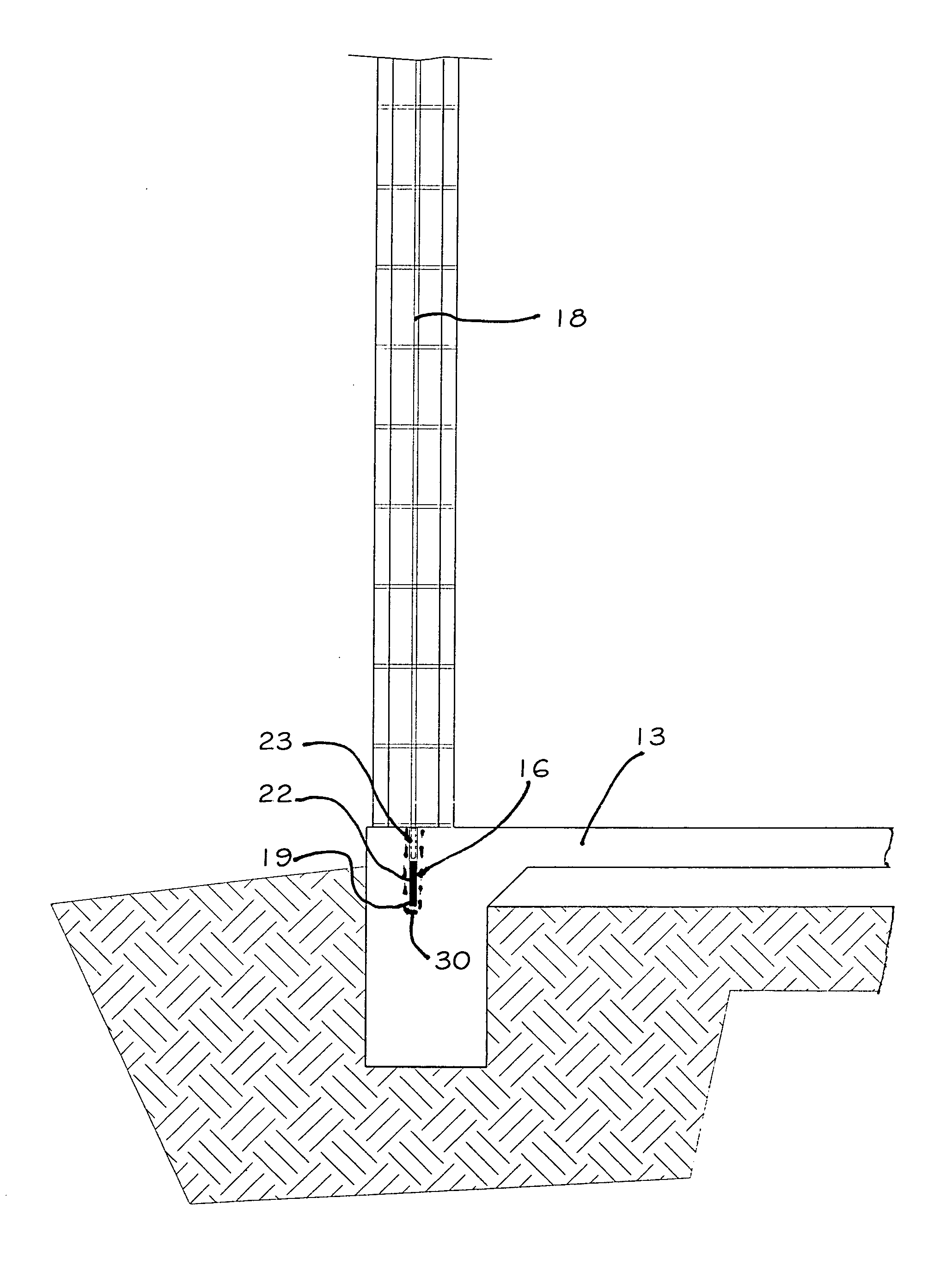

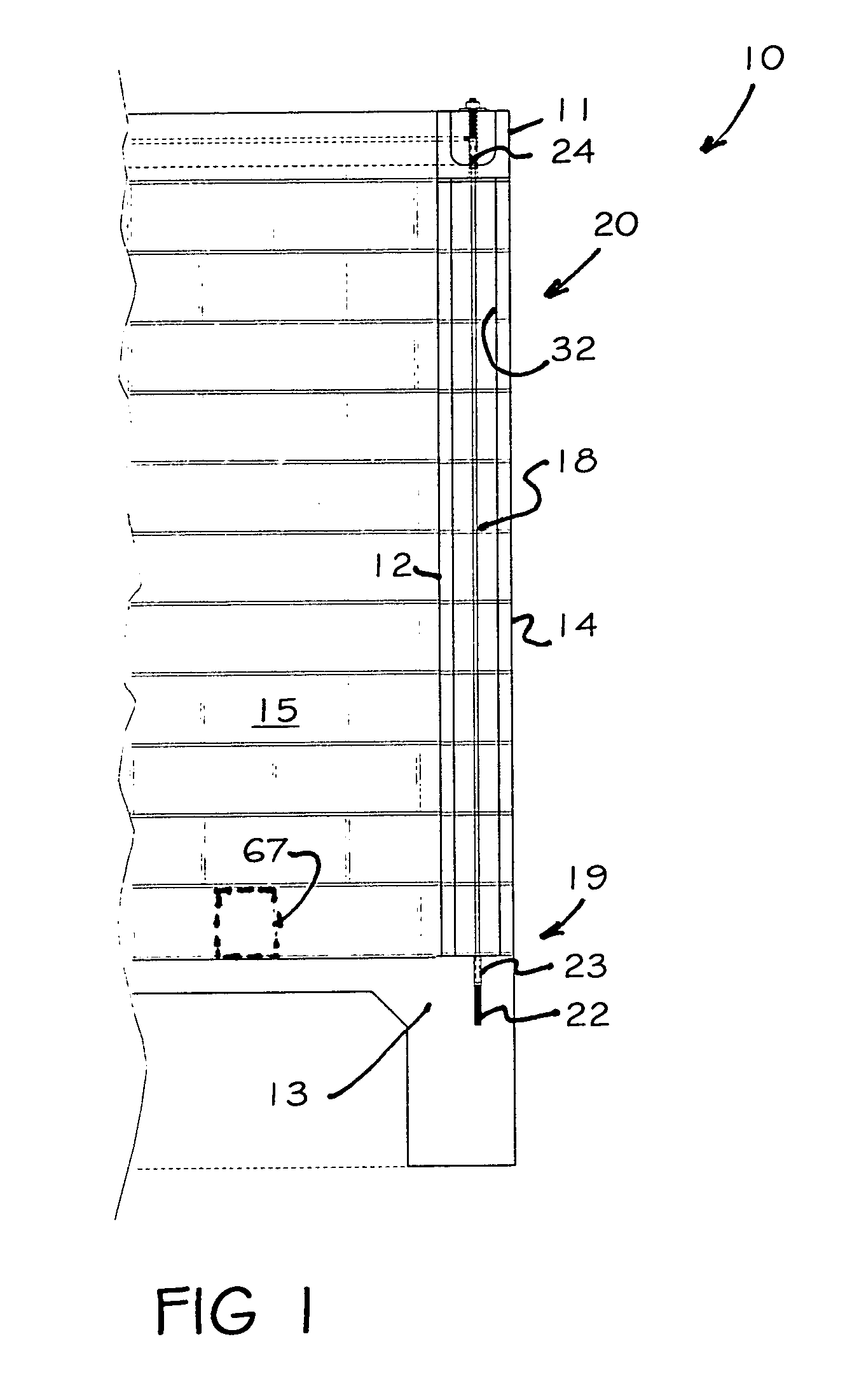

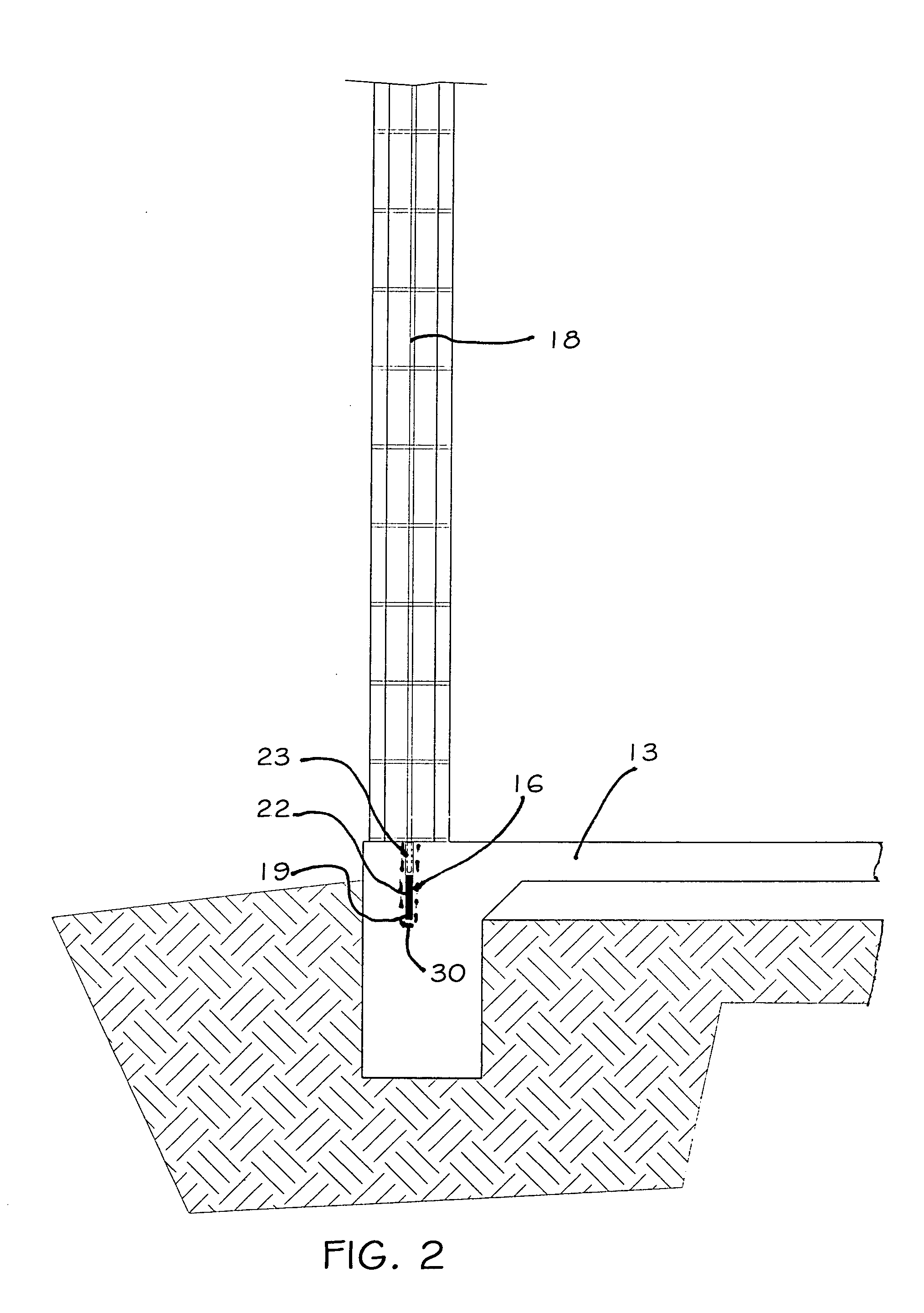

[0029] The present invention may be best understood by reference to the attached drawings wherein FIG. 1 shows the usage of the invention, and the remaining FIGS. Illustrate various embodiments of the tension device.

[0030] In FIG. 1 a partial section of a masonry building is shown at numeral 10. The building includes at least two masonry walls 12 supported on a concrete foundation 13. A continuous bond beam 11 is laid on top of the masonry walls 12 to strengthen the walls. Each of the masonry walls 12 includes a plurality of vertical hollow wall sections 14 having a number of hollow masonry units 15, laid over each other.

[0031]FIG. 1 shows a tensioning device, an elongated member 18, installed in a hollow masonry wall 12. The member 18 extends through and above the bond beam 11 located at the top of the masonry wall 12 and is secured to a foundation 13, by securing means such as epoxy resin adhesive. The member 18 ties the masonry wall 12 with the bond beam 11 and the concrete fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com