Magnetic pattern forming method, magnetic pattern forming apparatus, magnetic disk, and magnetic recording apparatus

a magnetic pattern and forming method technology, applied in the direction of maintaining head carrier alignment, nanoinformatics, instruments, etc., can solve the problems of time-consuming one-by-one formation of irregularities, high cost, and difficulty in executing track position control with high accuracy and recording servo signals with high precision. , to achieve the effect of efficient forming a minute magnetic pattern, high precision and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

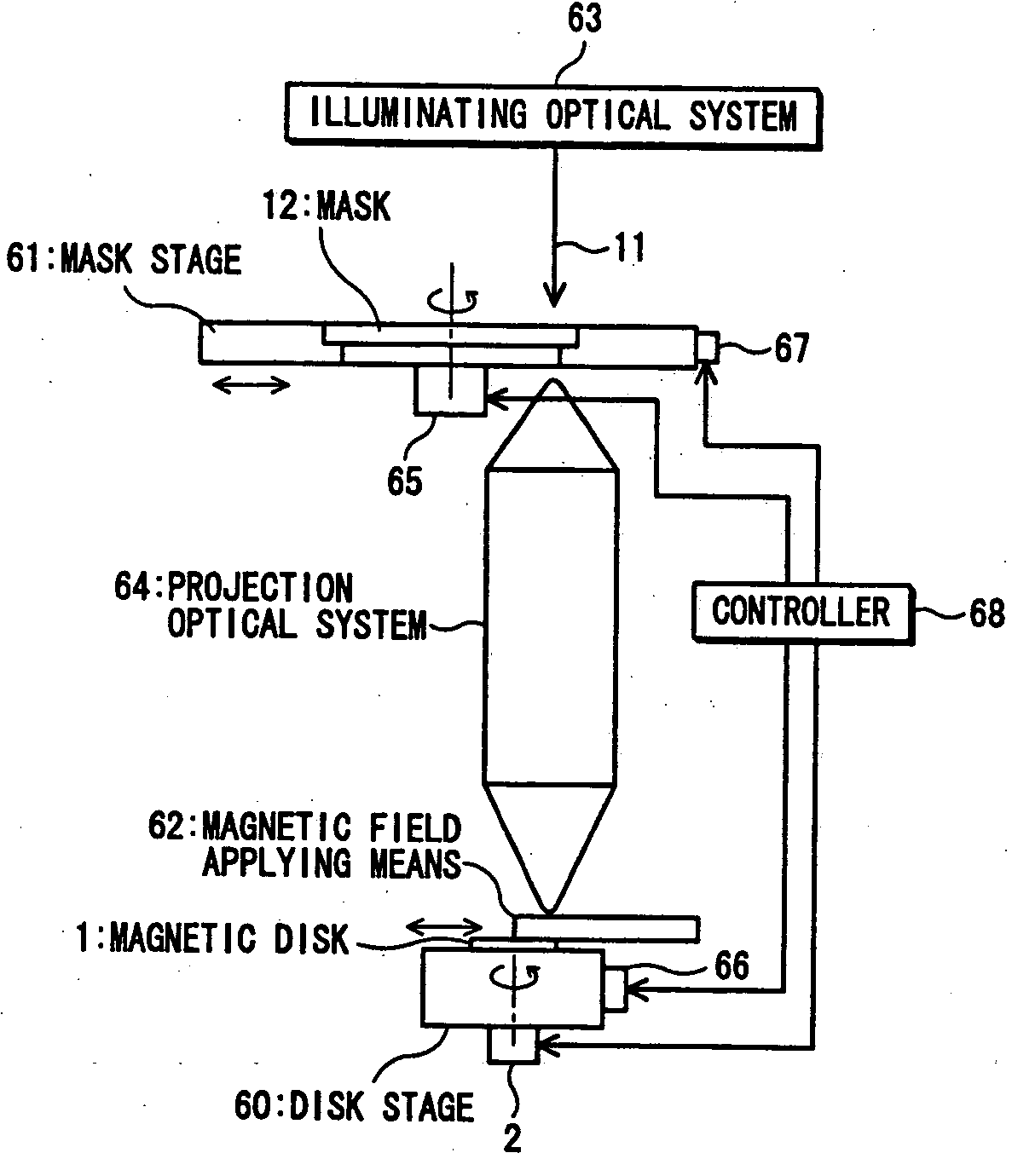

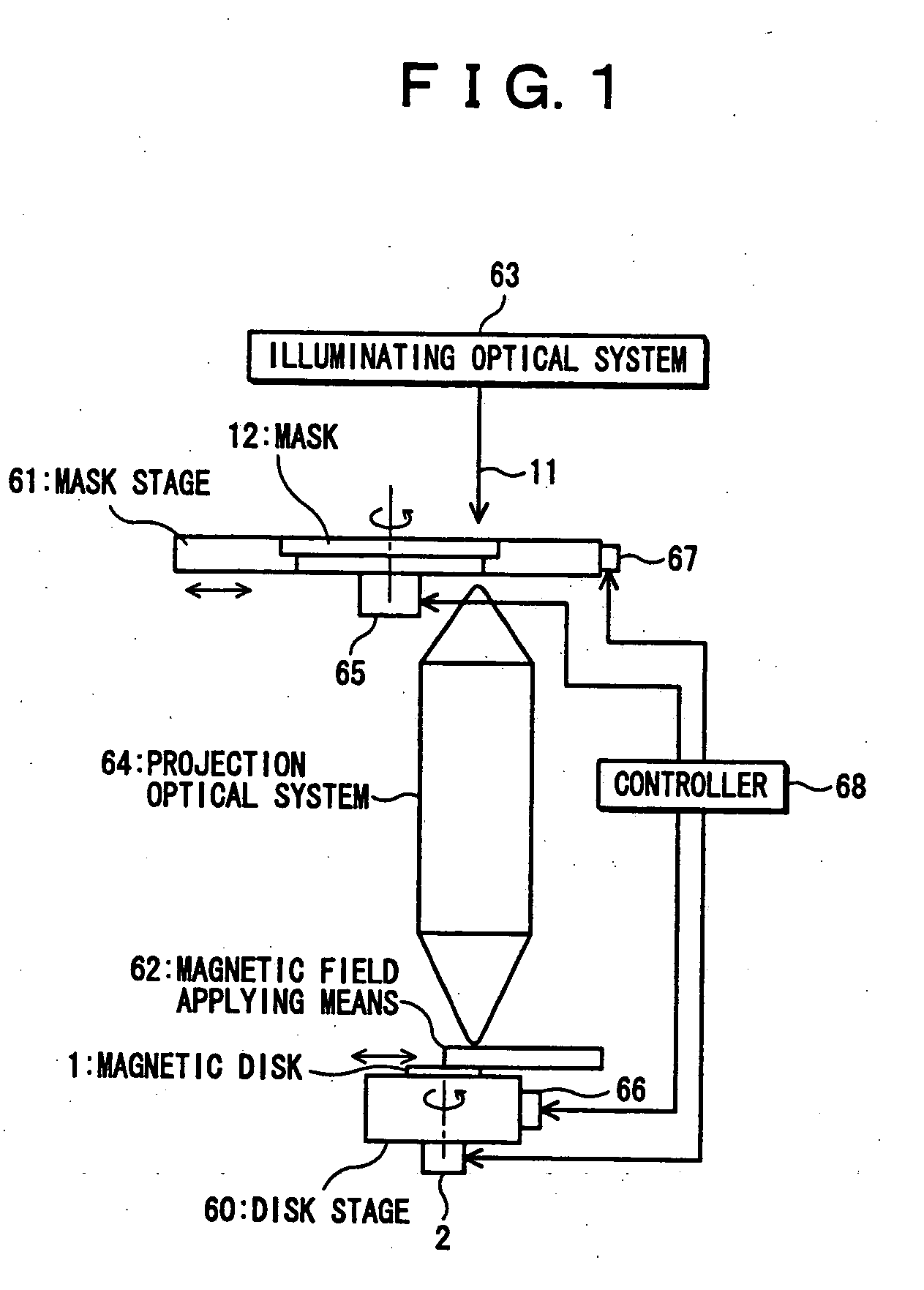

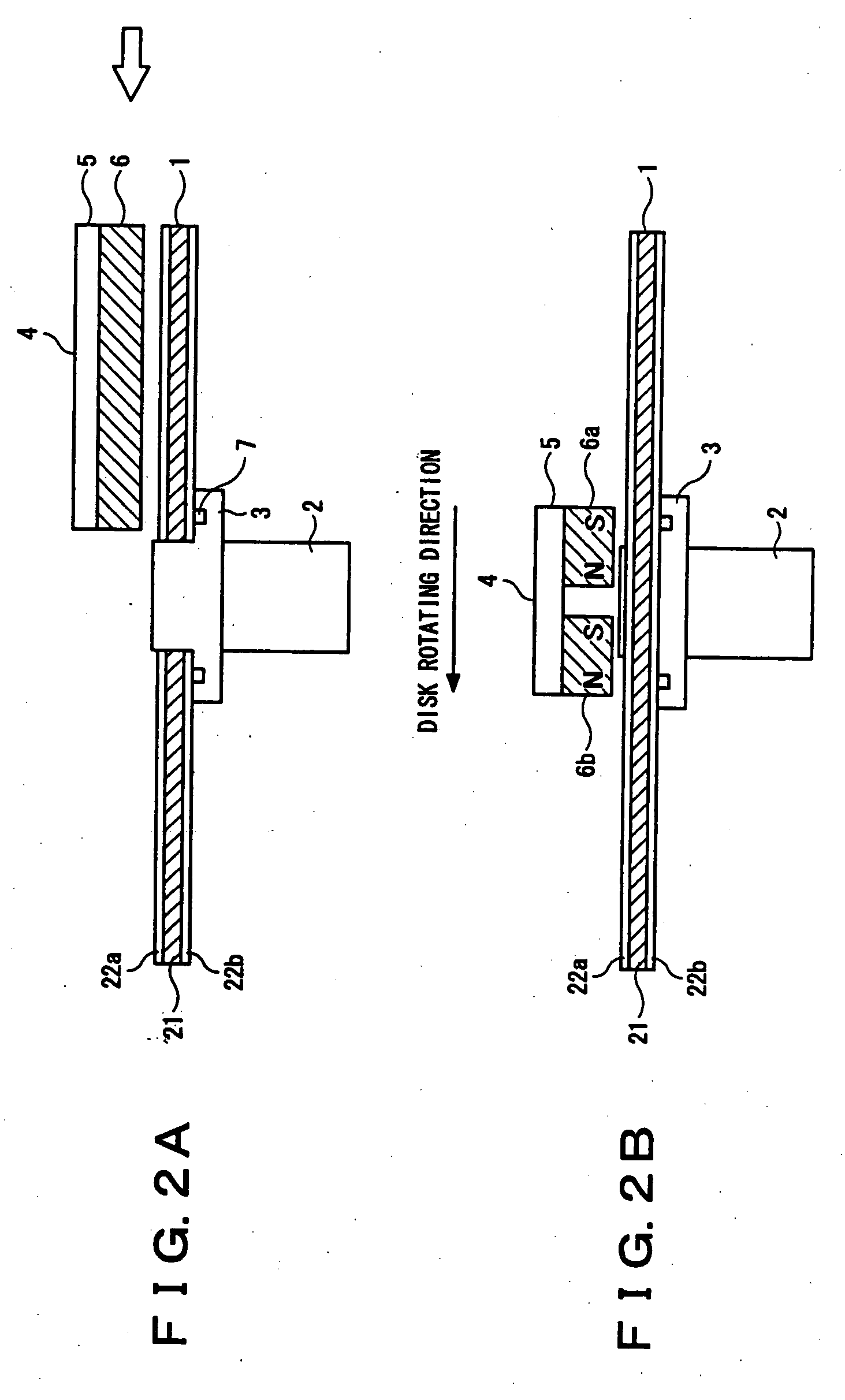

[0087] Referring to FIGS. 1 to 5, a description will be given hereinbelow of a magnetic pattern forming apparatus and method according to a first embodiment of the present invention.

[0088] Secondly, a description will be given of a magnetic disk on which a magnetic pattern is formed through the use of a magnetic pattern apparatus (method) according to this embodiment.

[0089] According to this embodiment, a magnetic disk is made as follows. That is, usually, a hard substrate is used as a substrate for a magnetic disk, for that there is a need to prevent it from vibrating even when a high-speed rotation takes place at fast recording / reproduction. To provide a sufficient rigidity against the vibration, in general, it is preferable that the thickness of the substrate is equal to or more than 0.3 mm. However, since a high thickness adversely affects the thickness reduction of a magnetic recording apparatus, preferably, it is less than or equal to 3 mm. For example, among the substrates,...

second embodiment

Description of Second Embodiment

[0325] Furthermore, referring to FIGS. 7, 8, 9A and 9B, a description will be given hereinbelow of a magnetic pattern forming apparatus and method, magnetic disk and magnetic recording apparatus according to a second embodiment of the present invention.

[0326] A difference of the magnetic pattern forming apparatus according to this embodiment from the above-described first embodiment is a construction for scanning with an energy beam in radial directions of a magnetic disk and a mask.

[0327] That is, in the above-described first embodiment, the illuminating optical system 63, the projection optical system. 64 and the magnetic field applying means 62 are set in fixed conditions and the disk stage 60 and the mask stage 61 are moved (operated for scanning) in a direction orthogonal to the energy beam 11 (the optical axis of a laser beam) given through the illuminating optical system 63 and the projection optical system 64, whereas in this embodiment, as ...

third embodiment

Description of Third Embodiment

[0361] Furthermore, referring to FIG. 10, a description will be given hereinbelow of a magnetic pattern forming apparatus and method, magnetic disk and magnetic recording apparatus according to a third embodiment of the present invention.

[0362] A difference of the magnetic pattern forming apparatus according to this embodiment from the apparatus according to the above-described first embodiment is a construction for making a scan with an energy beam in radial directions of a magnetic disk and a mask.

[0363] That is, in the above-described first embodiment, the illuminating optical system 63, the projection optical system 64 and the magnetic field applying means 62 are set in fixed conditions and the disk stage 60 and the mask stage 61 are moved (operated for scanning) in a direction orthogonal to the energy beam 11 (the optical axis of a laser beam) given through the illuminating optical system 63 and the projection optical system 64, whereas in this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap