Formation of self-aligned contact plugs

a technology of contact plugs and plugs, which is applied in the direction of semiconductor/solid-state device manufacturing, basic electric elements, electric apparatus, etc., can solve the problems of etch selectivity, contact width and sidewall spacer thickness, and the difficulty of balancing the thickness of the polymer layer, and the difficulty of removing doped oxide relative to un-doped oxid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

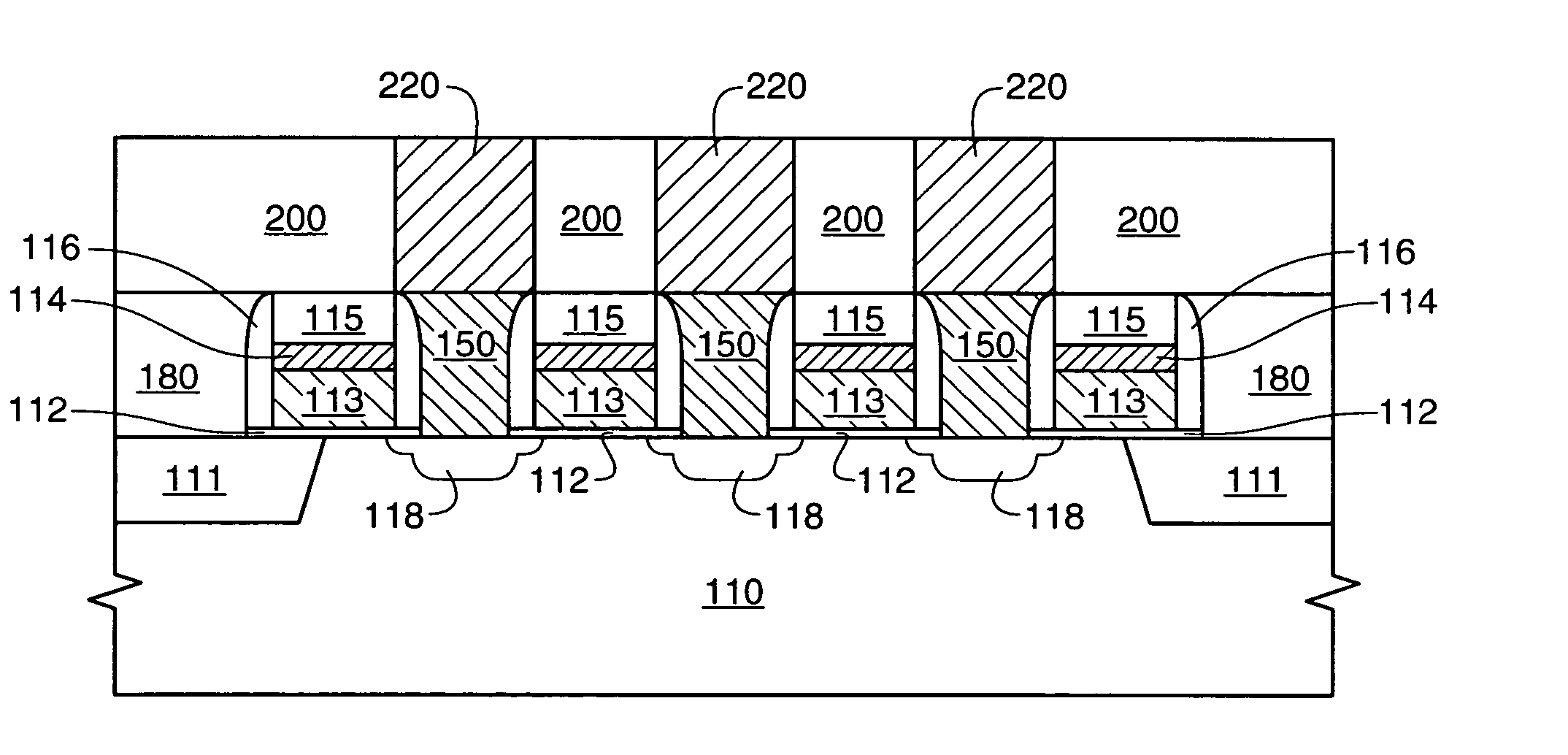

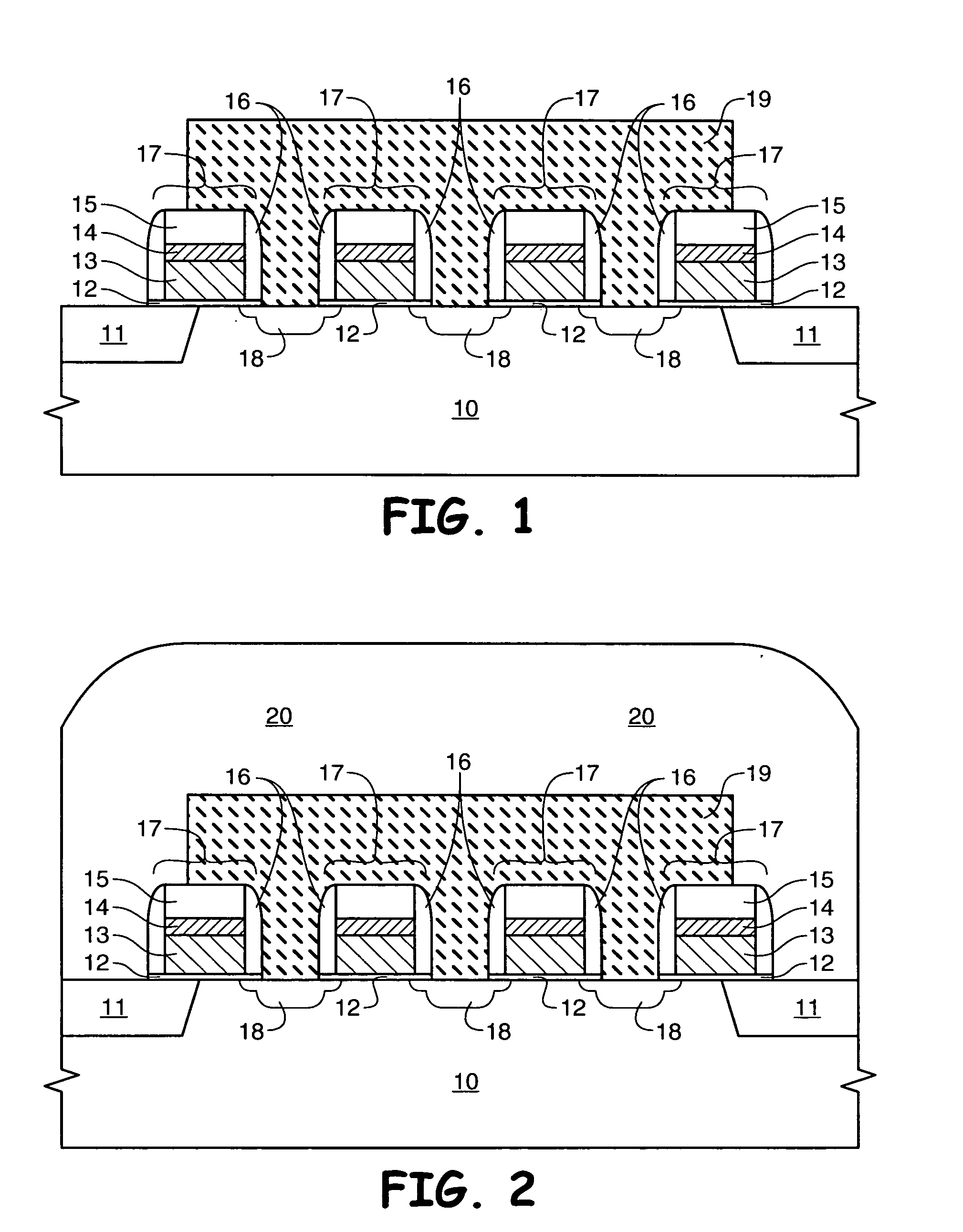

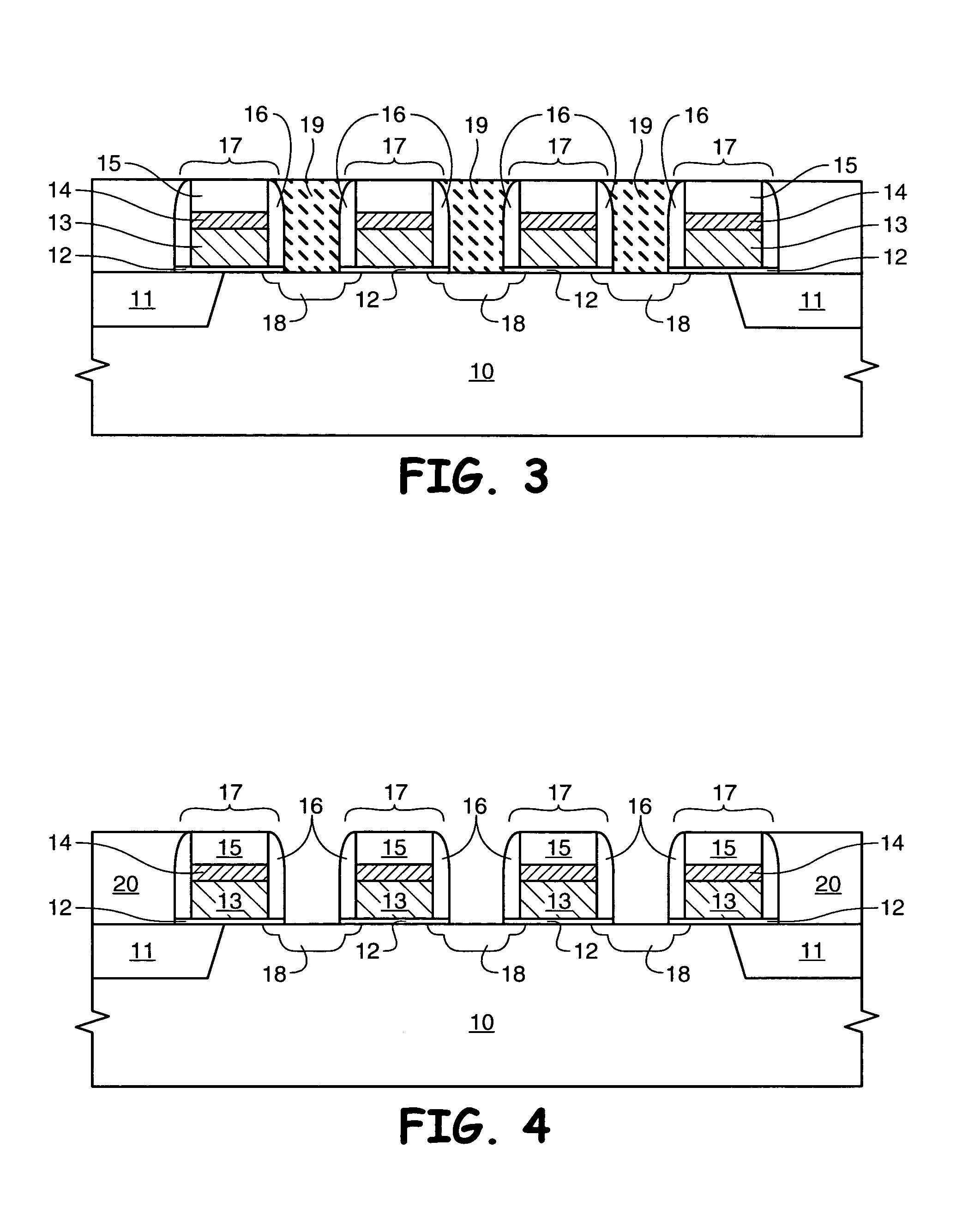

[0034] Embodiments of the present invention provide methods of forming transistor contacts without degrading sidewall spacers. In some embodiments either a photoresist or amorphous carbon material is used to fill a region between transistor gate stacks. The photoresist or amorphous carbon material can be removed to expose the source / drain contact area without substantial sacrificial removal of the sidewall spacer. That is, the photoresist or amorphous carbon material can be removed with greater selectivity to the spacer material than prior materials. For example, a dry develop process can be performed to remove the amorphous carbon material. It will be appreciated by those in the art with the benefit of the present disclosure that the present invention is not limited to photoresist or amorphous carbon material but can be implemented with other materials that can be removed without etching a sidewall spacer. For example, a filler material can be used that can be removed with a select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com