Spundbonding spin pack characterized by uniform polymer distribution and method of use

a polymer distribution and polymer technology, applied in the field of meltspinning apparatus and methods, can solve the problems of inadequate control, lack of robustness, inability to accept irregularities in nonwoven webs, etc., and achieve uniform physical and chemical properties, easy scaling, and greater uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention is directed generally to a spin pack for a meltspinning apparatus having improved polymer distribution in the machine direction. Although the filaments will be described herein as being formed using an exemplary meltspinning apparatus, it should be understood that modifications to the exemplary meltspinning apparatus described herein could be made without departing from the intended spirit and scope of the invention.

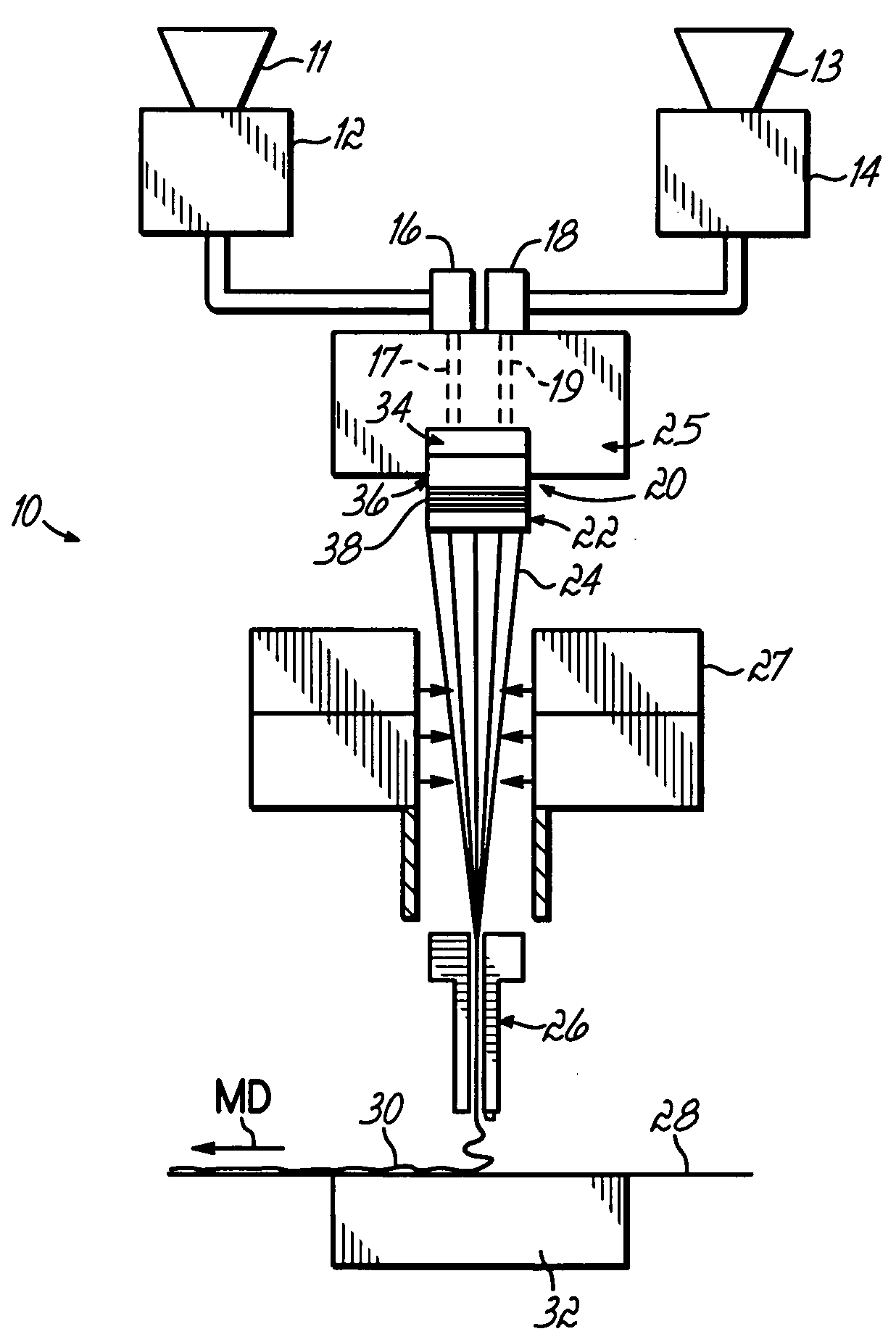

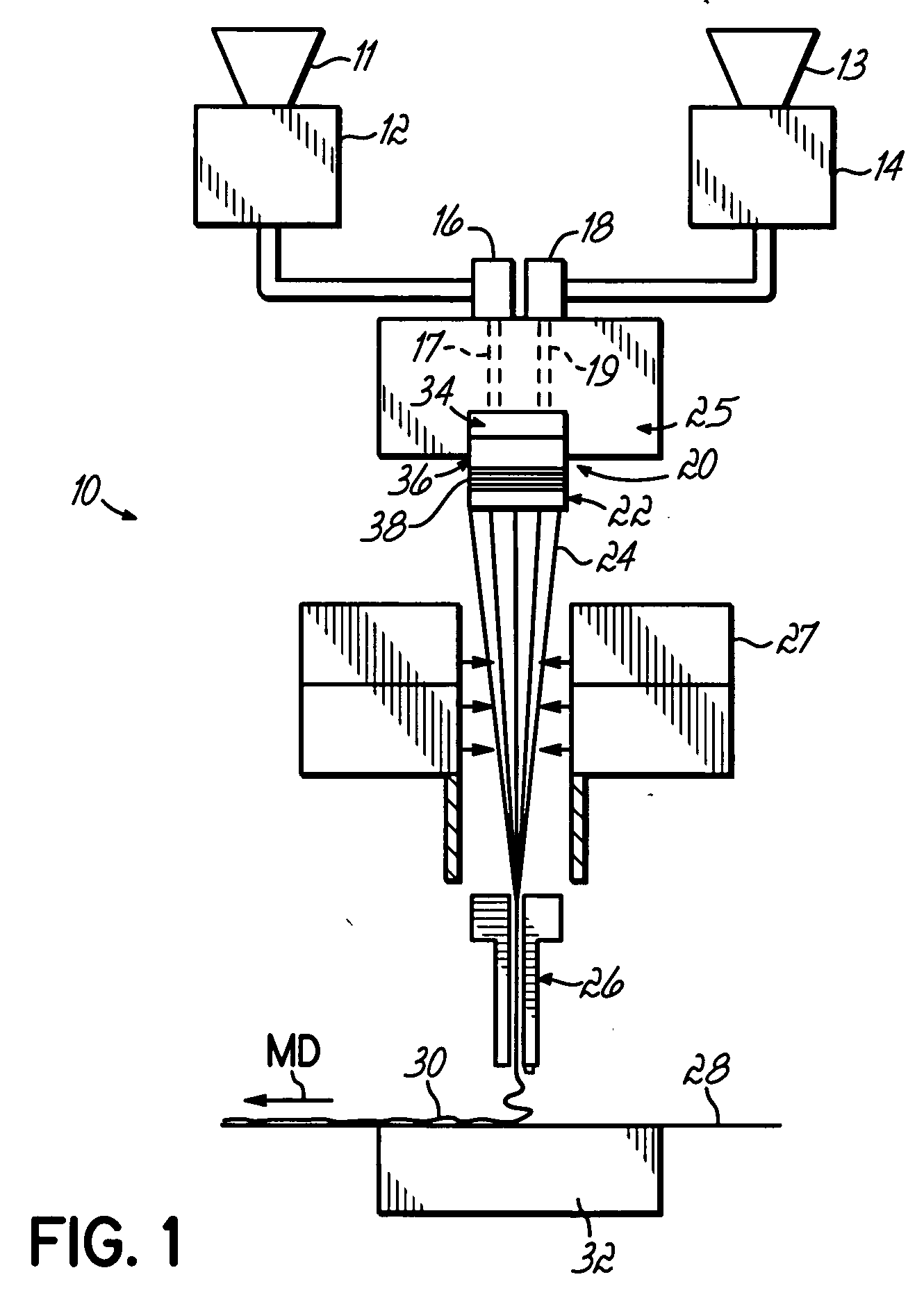

[0038] With reference to FIG. 1, a spunbonding apparatus 10 is equipped with an extruder 12 that converts a solid melt-processable thermoplastic polymer (Polymer A) into a molten state and transfers the molten polymer under pressure to metering pump(s) 16. A second solid melt-processable thermoplastic polymer (Polymer B) is converted by another extruder 14 into a molten state and transferred under pressure to metering pump(s) 18. Pellets of the solid thermoplastic polymers are placed in hoppers 11, 13 and fed to the corresponding one of extruders 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap