System and method for dispensing a fluid to a liquid spraying device

a technology of liquid spraying device and fluid, which is applied in the direction of liquid/fluent solid measurement, container, volume measurement, etc., can solve the problems of solvents that are often hazardous to human health, affecting the quality of liquid spraying, etc., and achieves the effect of convenient use and inexpensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

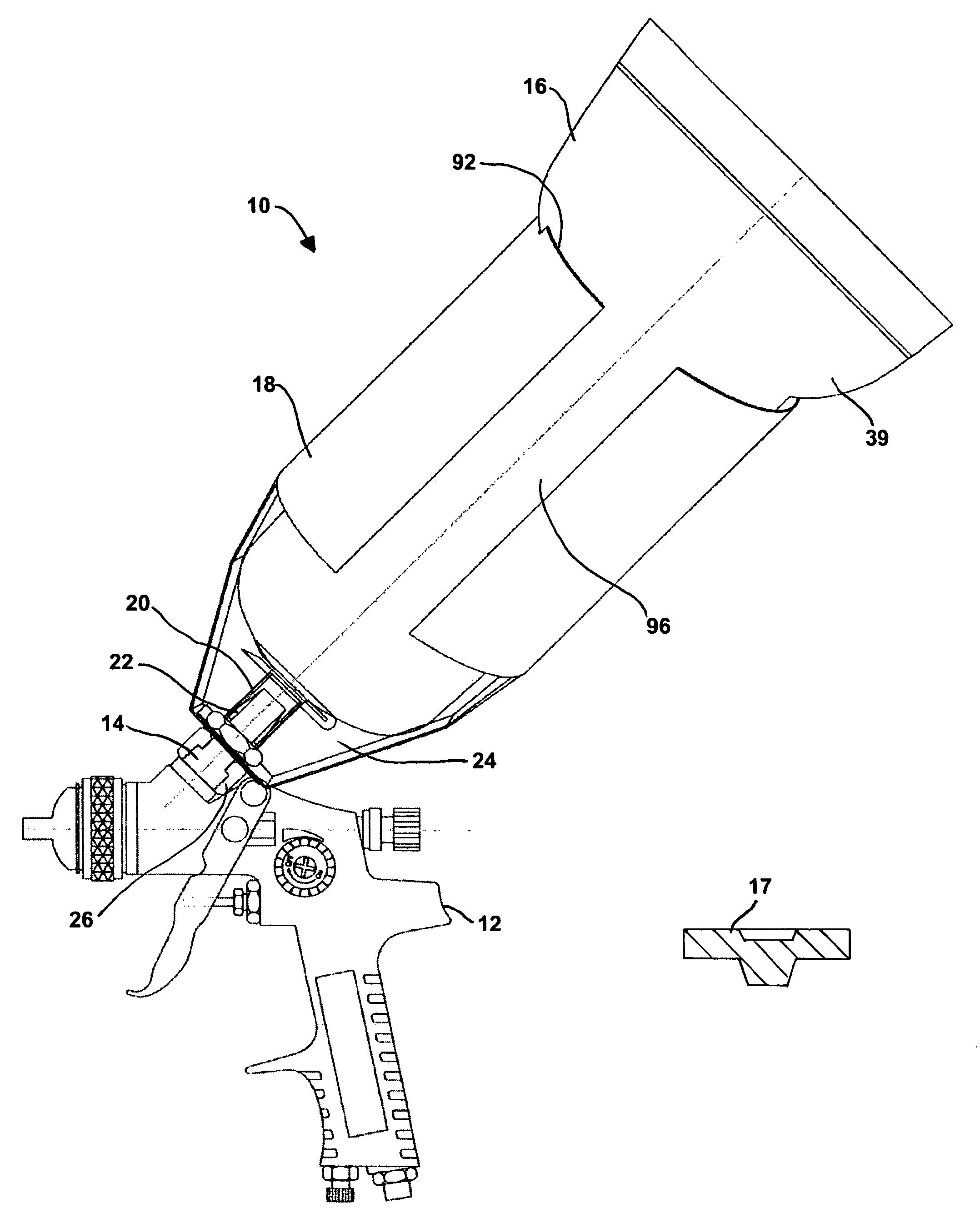

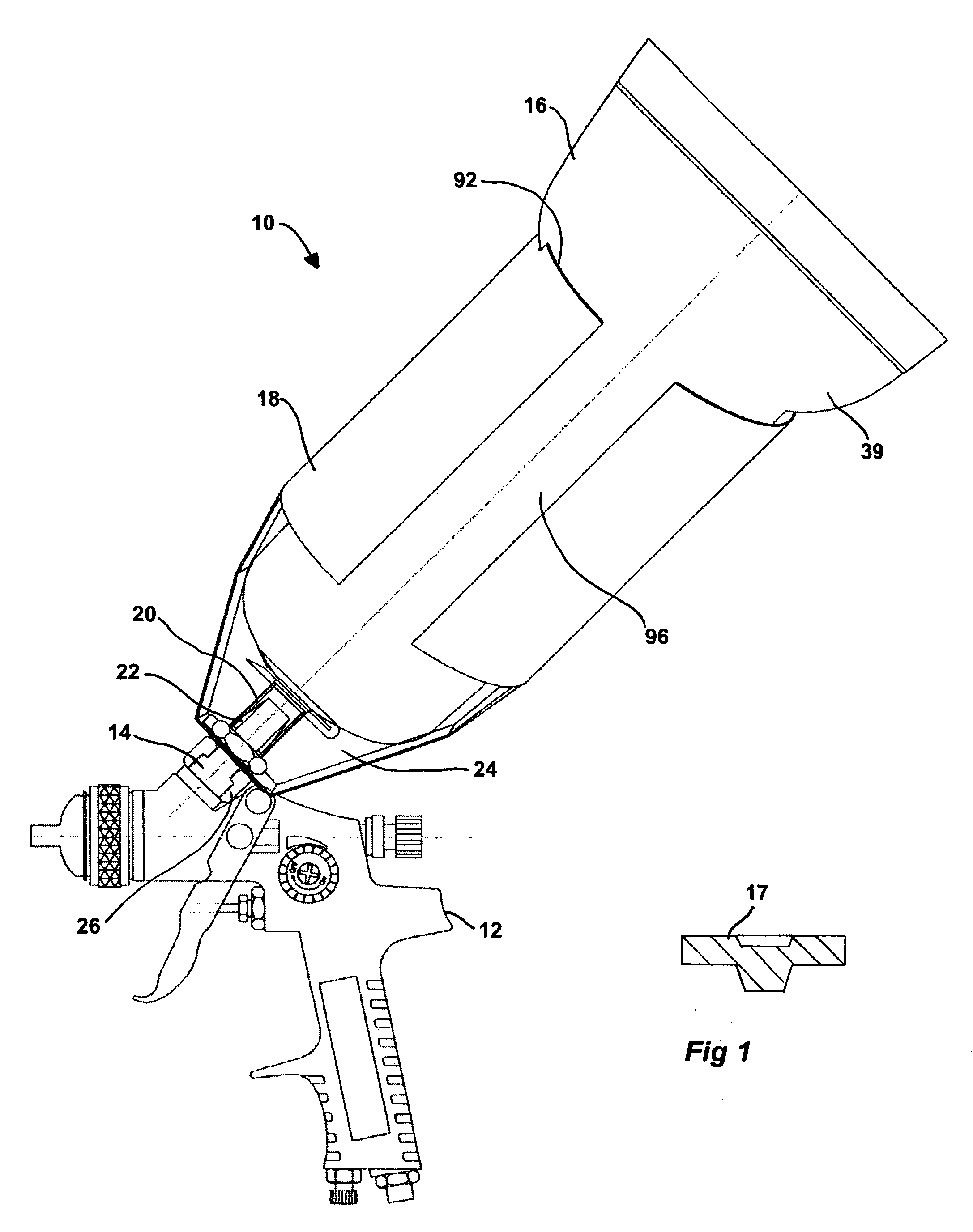

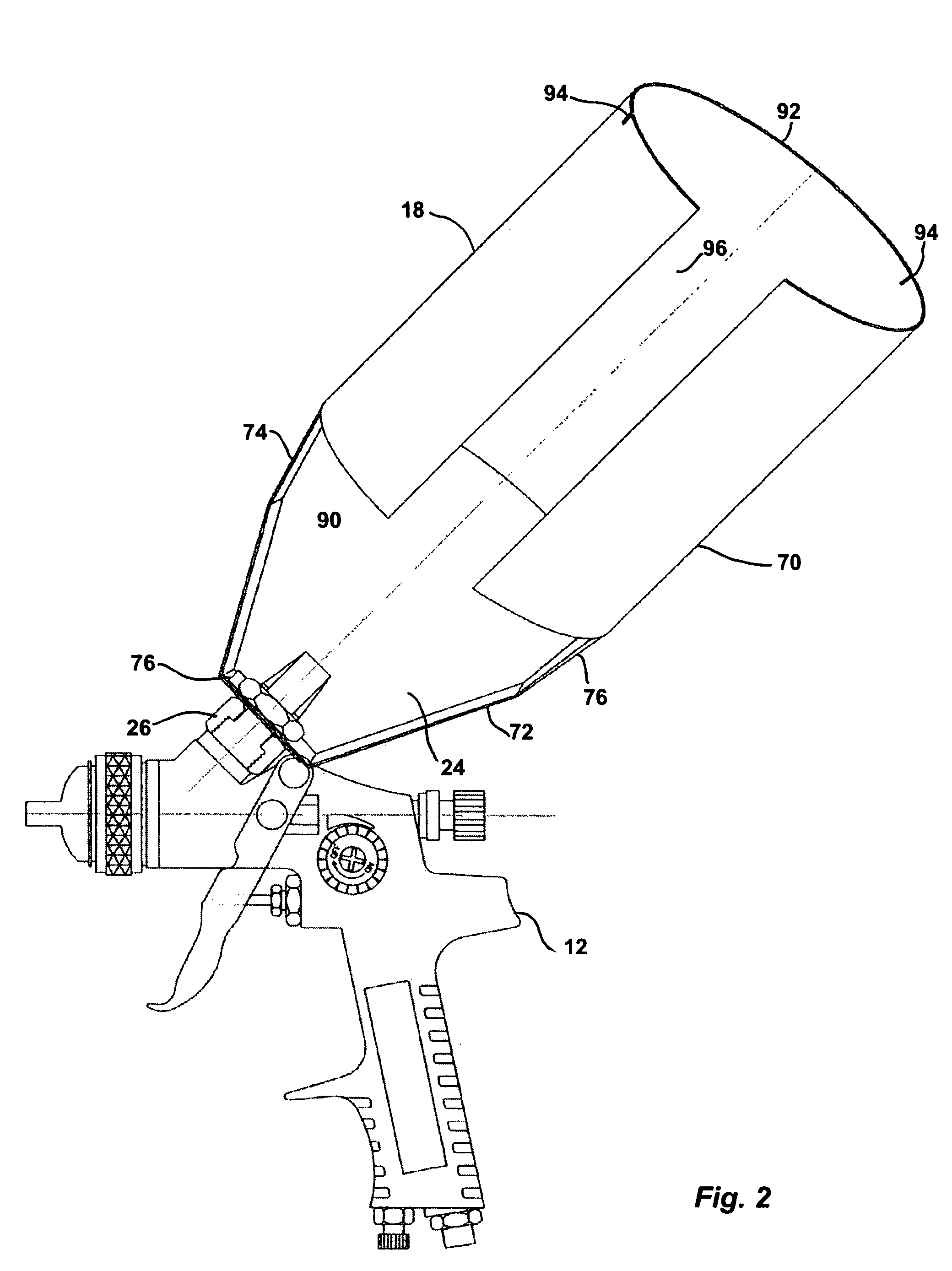

[0040]FIGS. 1 and 2 illustrate a system 10 for dispensing a fluid to a liquid spraying device 12. An example of a liquid spraying device is a spray paint gun. However, the reader skilled in the art will readily appreciate that any suitable liquid spraying device is usable in conjunction with the invention. The liquid spraying device 12 defines a fluid receiving aperture 14. The fluid receiving aperture 14 receives the fluid from the system 10.

[0041] The system 10 includes a substantially flexible bag 16 for containing the fluid to dispense. The bag 16 includes a dispensing portion 20 having an outlet 22 for dispensing the fluid.

[0042] The system 10 further includes a frame 18 for receiving the bag 16. The frame 18 is connectable to the liquid spraying device 12. The frame 18 includes a frame aperture 24 for allowing an intended user to connect the bag 16 to the liquid spraying device 12 further to the bag having 16 been filled with the fluid to dispense.

[0043] As better seen in F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com