Swash plate type hydraulic pump or motor

a hydraulic pump and motor technology, applied in the direction of reciprocating piston engines, positive displacement liquid engines, positive displacement engines, etc., can solve the problems of complex hydraulic fluid passage and valve mechanism that switches the flow of hydraulic fluid in order to supply and discharge hydraulic fluid to and from the pistons disposed on both sides of the cylinder block, and the supply and discharge efficiency of hydraulic fluid is worsened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

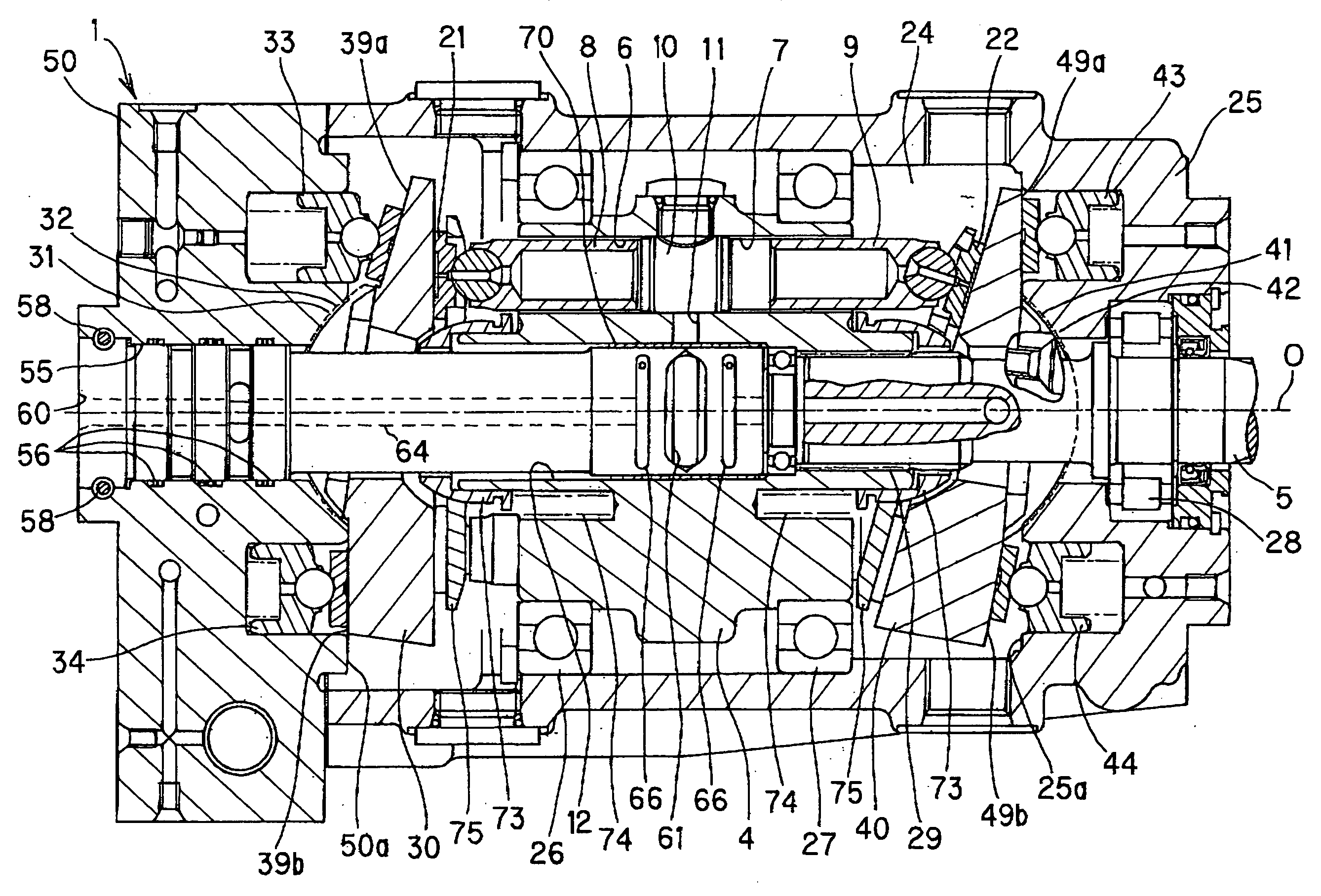

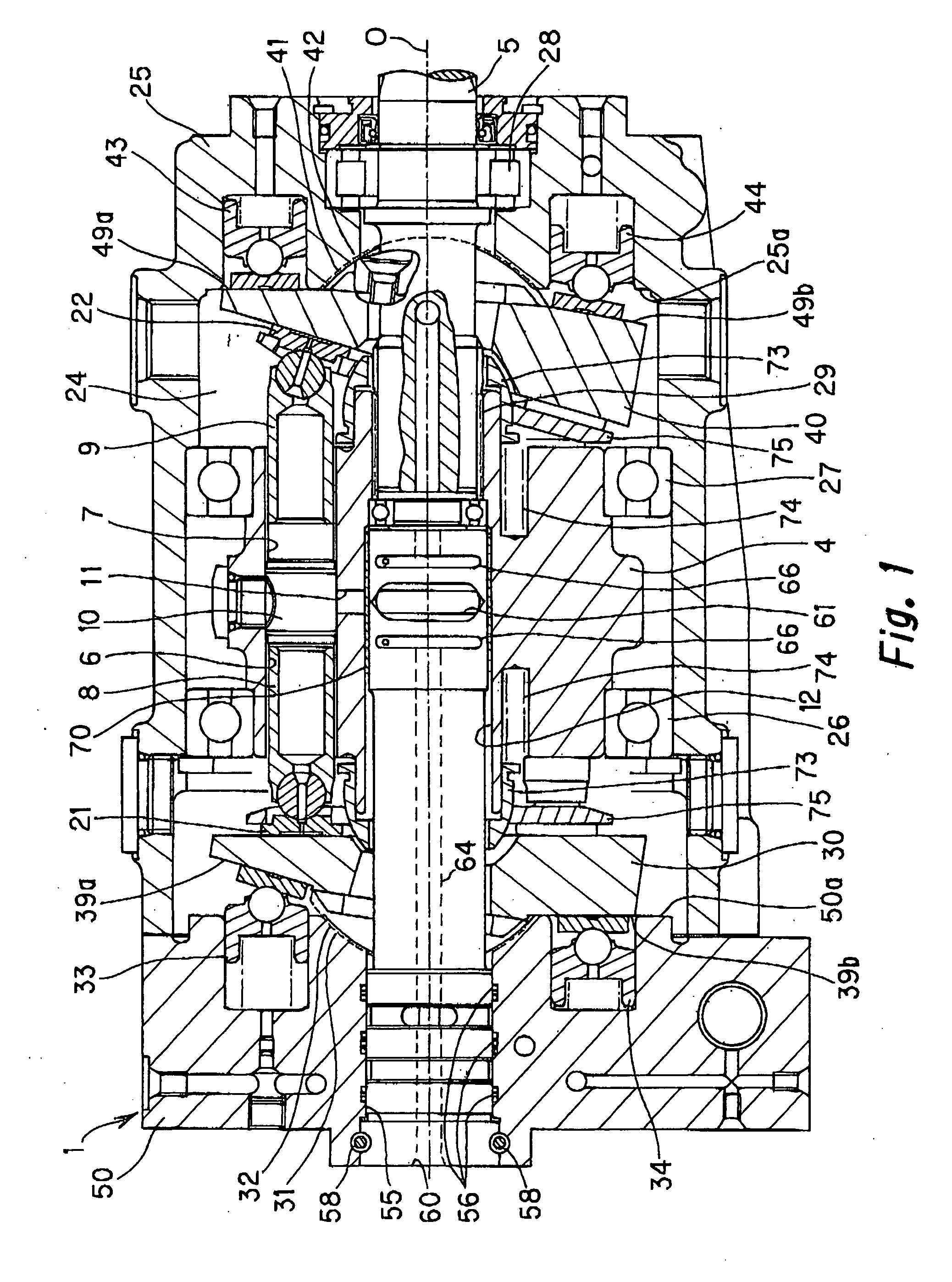

[0016] Embodiments of this invention applied to a hydraulic motor of an HST installed in an industrial vehicle or the like will be explained below based on the appended drawings.

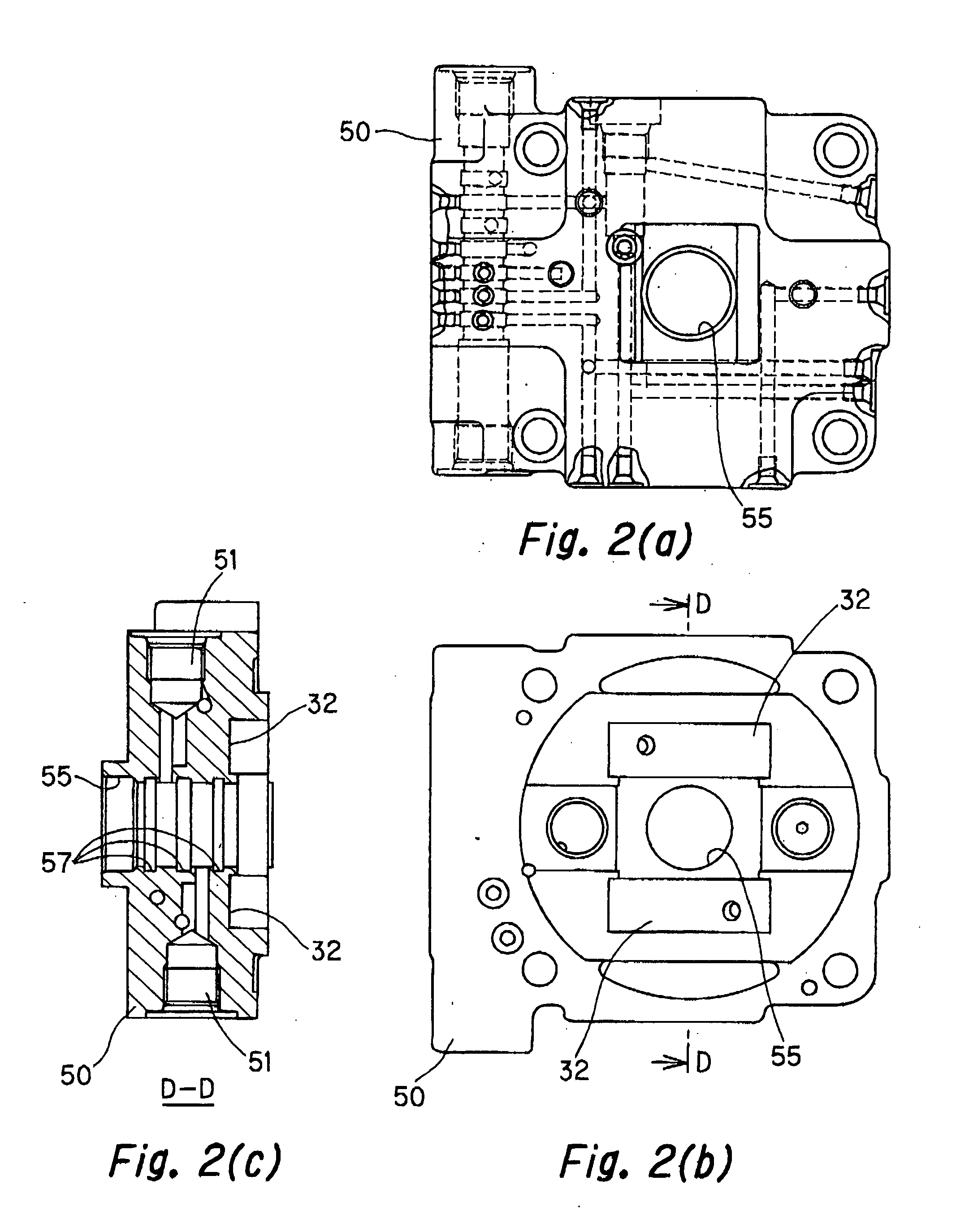

[0017] Referring to FIG. 1, a hydraulic motor 1 comprises a cylindrical case 25 and a port block 50 that is connected to the case 25. The hydraulic motor 1 is a swash plate type hydraulic pump or motor. A housing chamber 24 is provided in inner portions of the cylindrical case 25 and the port block 50. A cylinder block 4, a first swash plate 30, and a second swash plate 40 are housed in the housing chamber 24.

[0018] The cylinder block 4 is joined on an axis of a shaft 5 that is disposed in a center portion of the case 25, and the shaft 5 and the cylinder block 4 rotate integrally.

[0019] Consequently, a distal end portion of the shaft 5 is connected to an inner circumference of the cylinder block 4, through a spline 29. The shaft 5 is supported by the case 25, through a bearing 28, in an area where it pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com