High capacity load decorative floor display rack

a technology for display racks and floor displays, which is applied to display racks, show hangers, and display shelves, etc., can solve the problems of inability to meet the needs of retail customers, the decorative covering itself may crack or shear under such loads, and the cost of sacrificing the aesthetics of display racks in order to increase the load bearing capacity of display racks, etc., to achieve high capacity load bearing, support vertical and horizontal loading, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

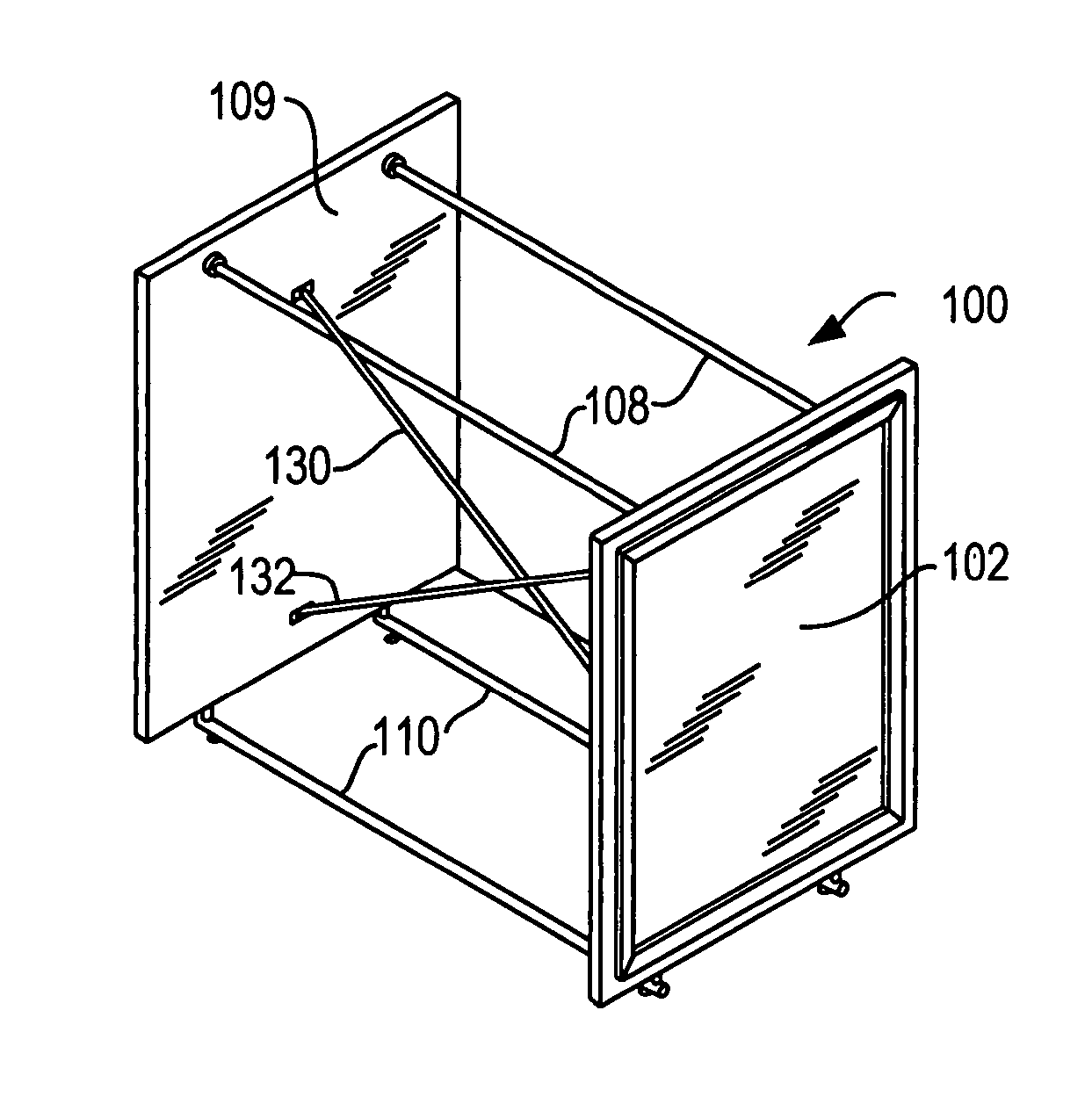

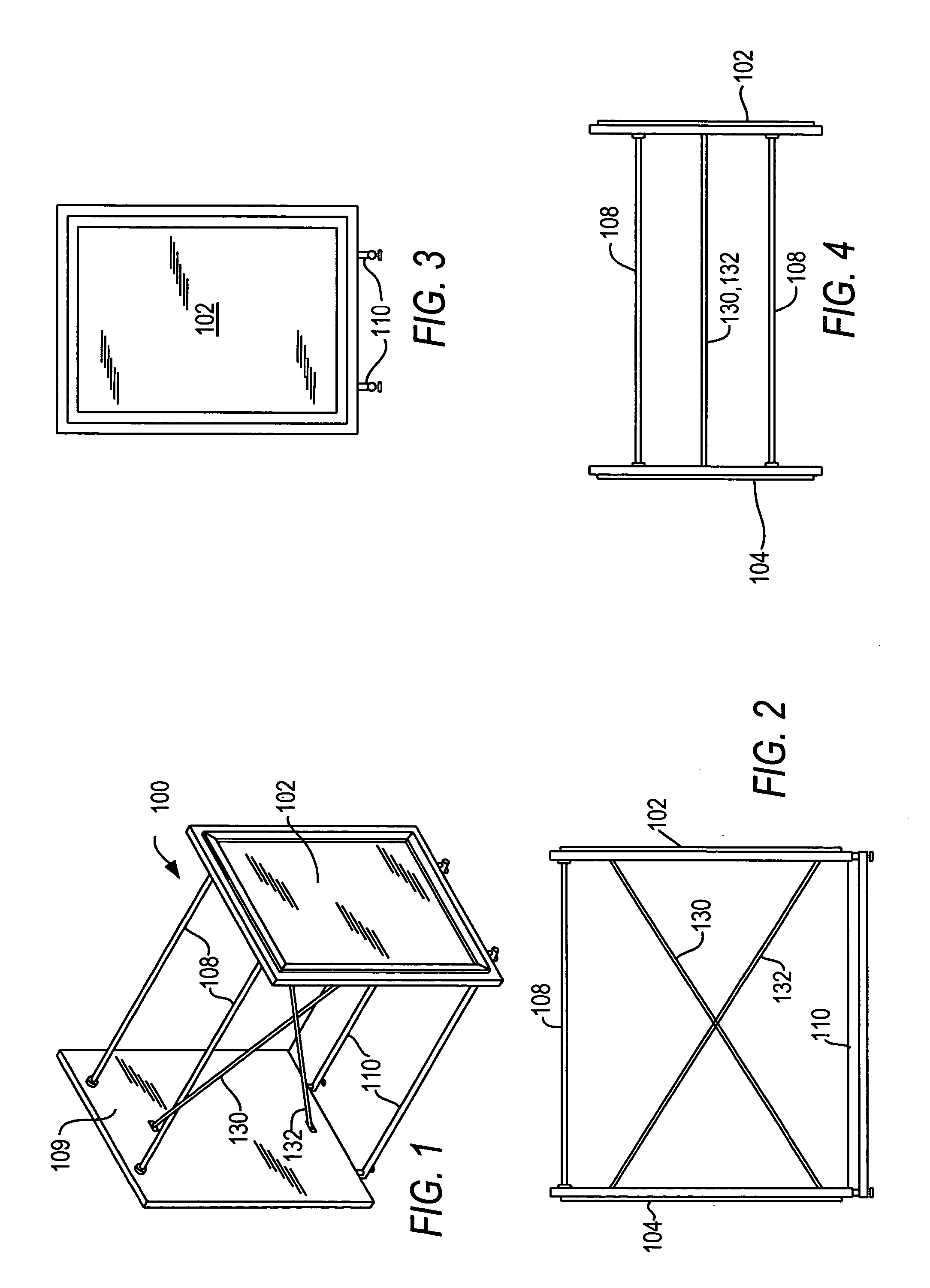

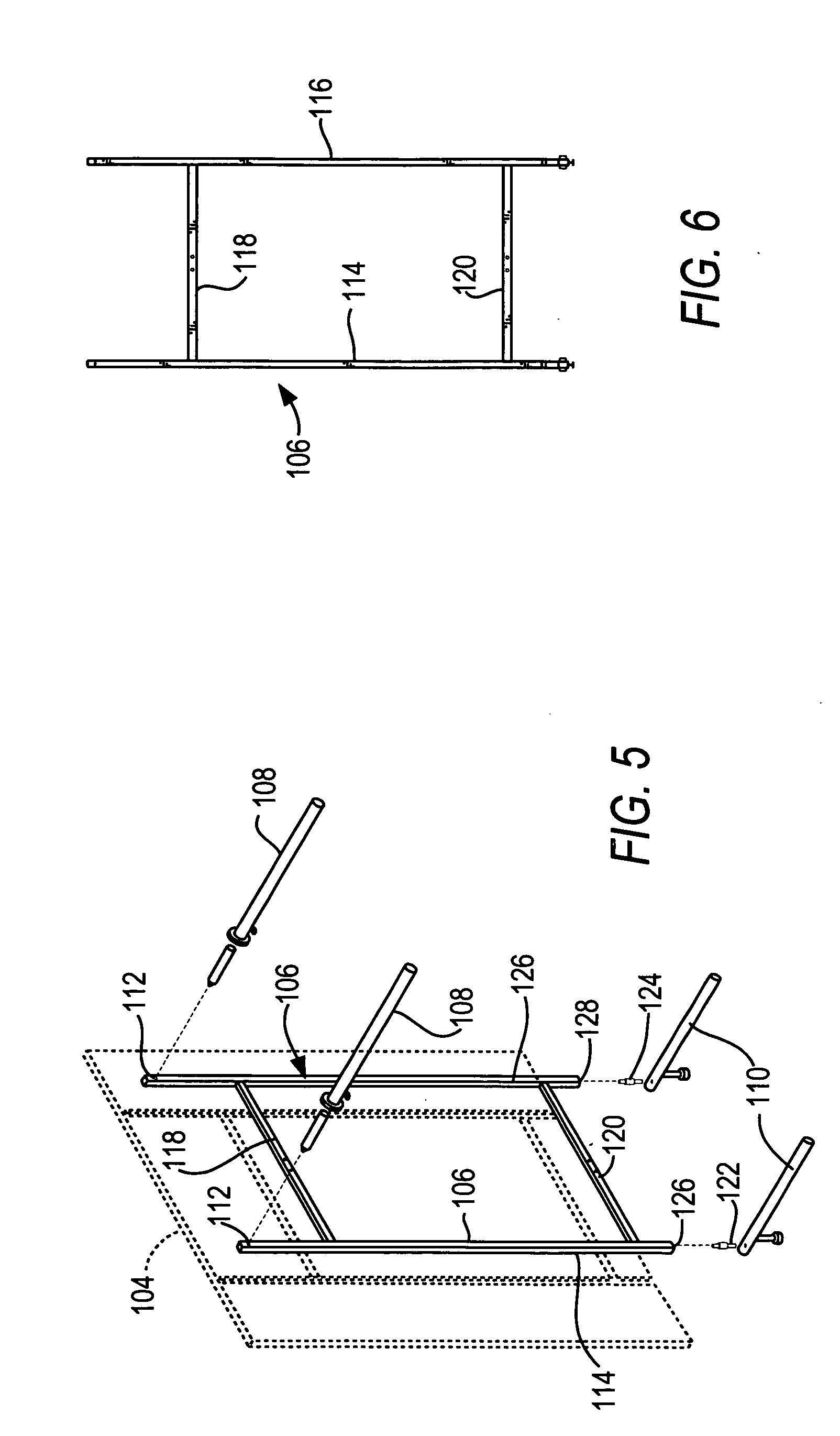

[0014] Referring now to the drawings in detail, and particularly to FIGS. 1-6, a presently preferred embodiment 100 of the floor display rack of the present invention is shown. As shown and preferred in FIG. 1, the floor display rack 100, which may be built to any desired hanging height, such as for example five feet, includes a pair of parallel decorative slab sides 102, 104, such as wooden slabs, a supporting steel crisscross framework 106 which is embedded or contained within each decorative slab 102, 104 (FIGS.>5-6), a pair of spaced apart horizontally extending steel hanging rods 108 structurally tied to the supporting framework 106 and the decorative slabs 102, and a horizontally extending steel base member 110 which is also structurally tied to the supporting framework 106. as shown and preferred, the hanging rods 108 structurally tie into horizontally extending mounting sockets 112 located in the supporting framework 106 in each of the decorative side slabs 102, 104, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com