Unibody sanitary can with multiple storage compartments

a sanitary can and multiple storage compartment technology, applied in the field of containers, can solve the problems of food taste contamination, easy cracking, and inability to withstand the use of containers, and achieve the effect of facilitating stacking and shipping and preventing spillag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

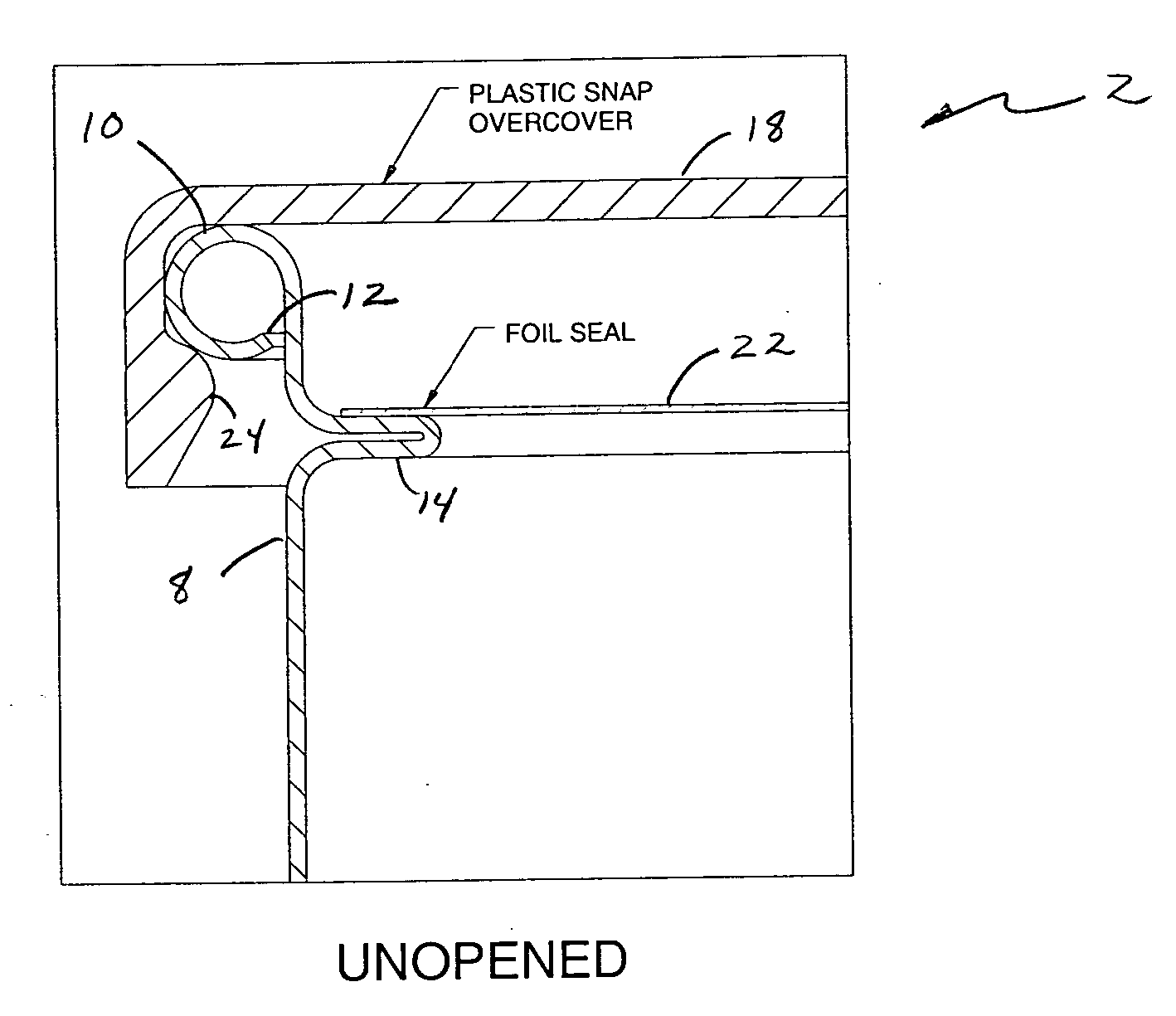

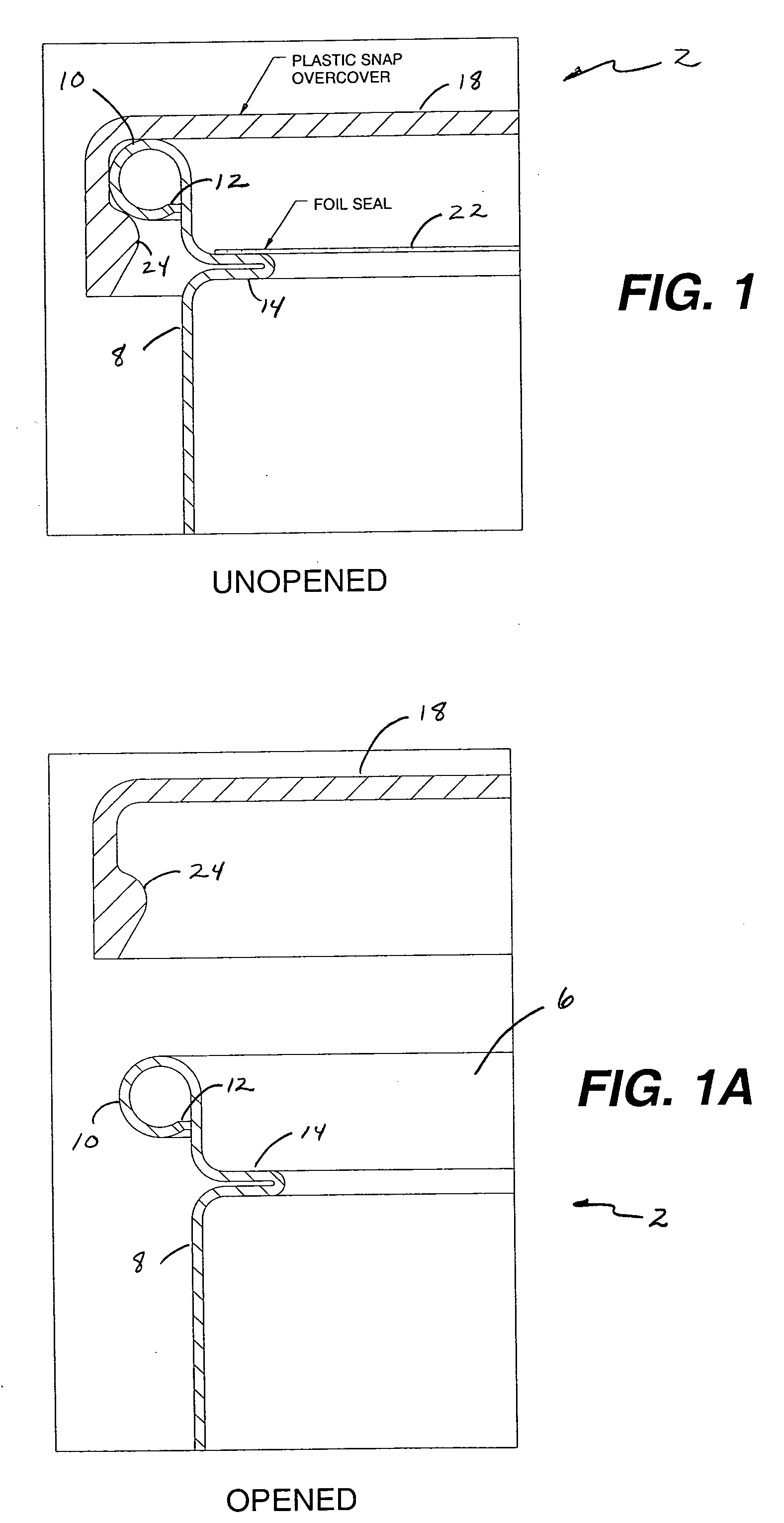

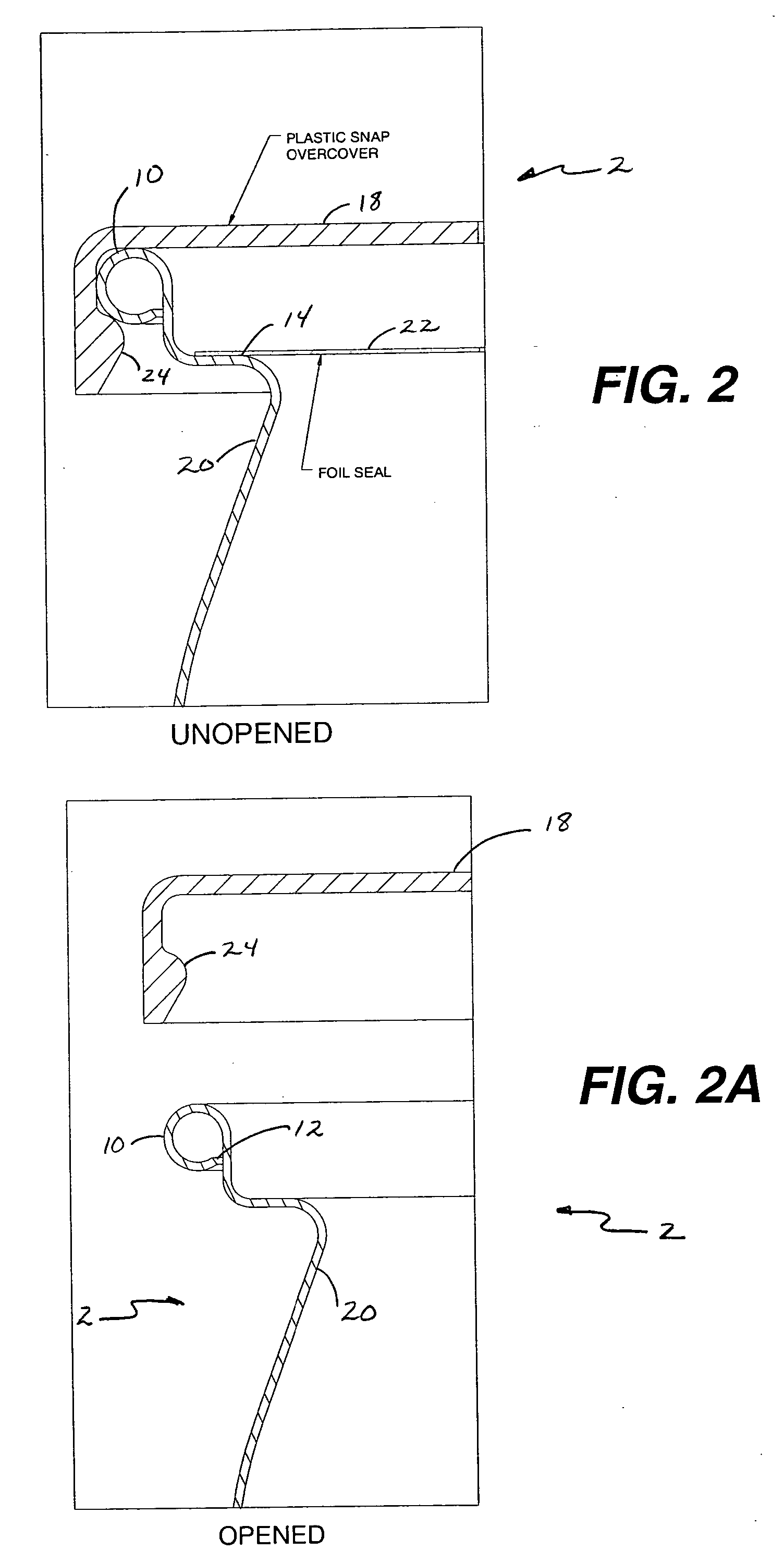

[0030] Referring now to the drawings, FIGS. 1-5A depict various embodiments of the present invention. More specifically, and referring now to FIG. 1, a container 2 is provided which is generally comprised of a container closed end 4 (not shown) a container open end 6, and a neck 8 positioned proximate to the container open end 6. Although the container 2 is generally comprised of a metallic material such as tin or aluminum, it is feasible that the container 2 could be comprised of plastics, styrofoam or other materials well known in the art. The neck 8 is integrally interconnected to a first inwardly extending ledge 14, and which is adapted to support a sealable membrane 22 such as a tin foil, aluminum foil, plastic, or other material which in one embodiment is substantially impermeable. The container open end 6 is further comprised of a peripheral cover hook 10 which has a peripheral cover hook leading edge 12. Preferably, the peripheral cover hook leading edge 12 is turned inwardl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com