Apparatus and methods for removing and installing a selected nozzle segment of a gas turbine in an axial direction

a gas turbine and axial direction technology, applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of laborious maintenance and testing operations, and the essentially non-removable nozzle segments are difficult to remove and install, so as to achieve the effect of easy removal and replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

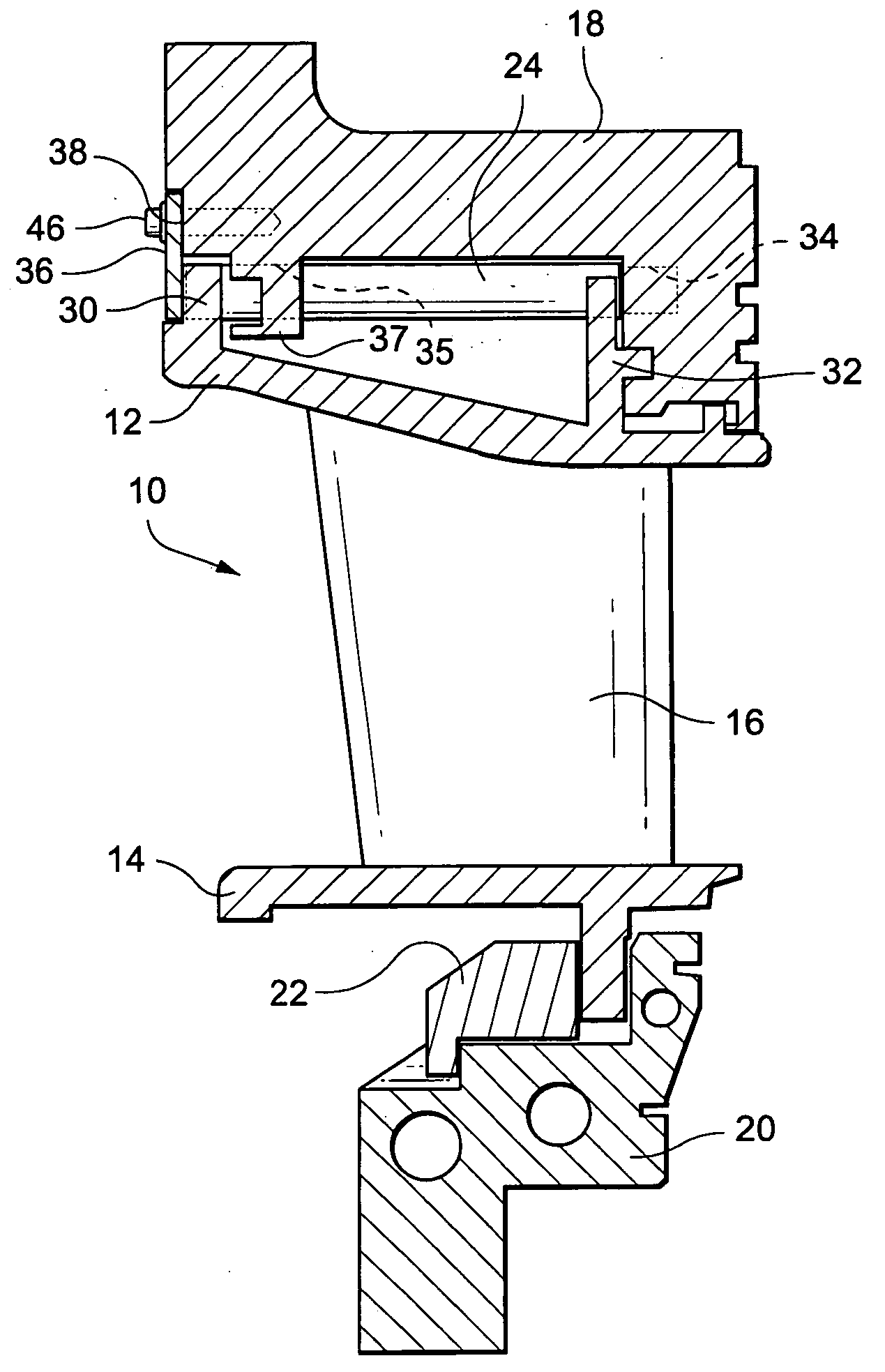

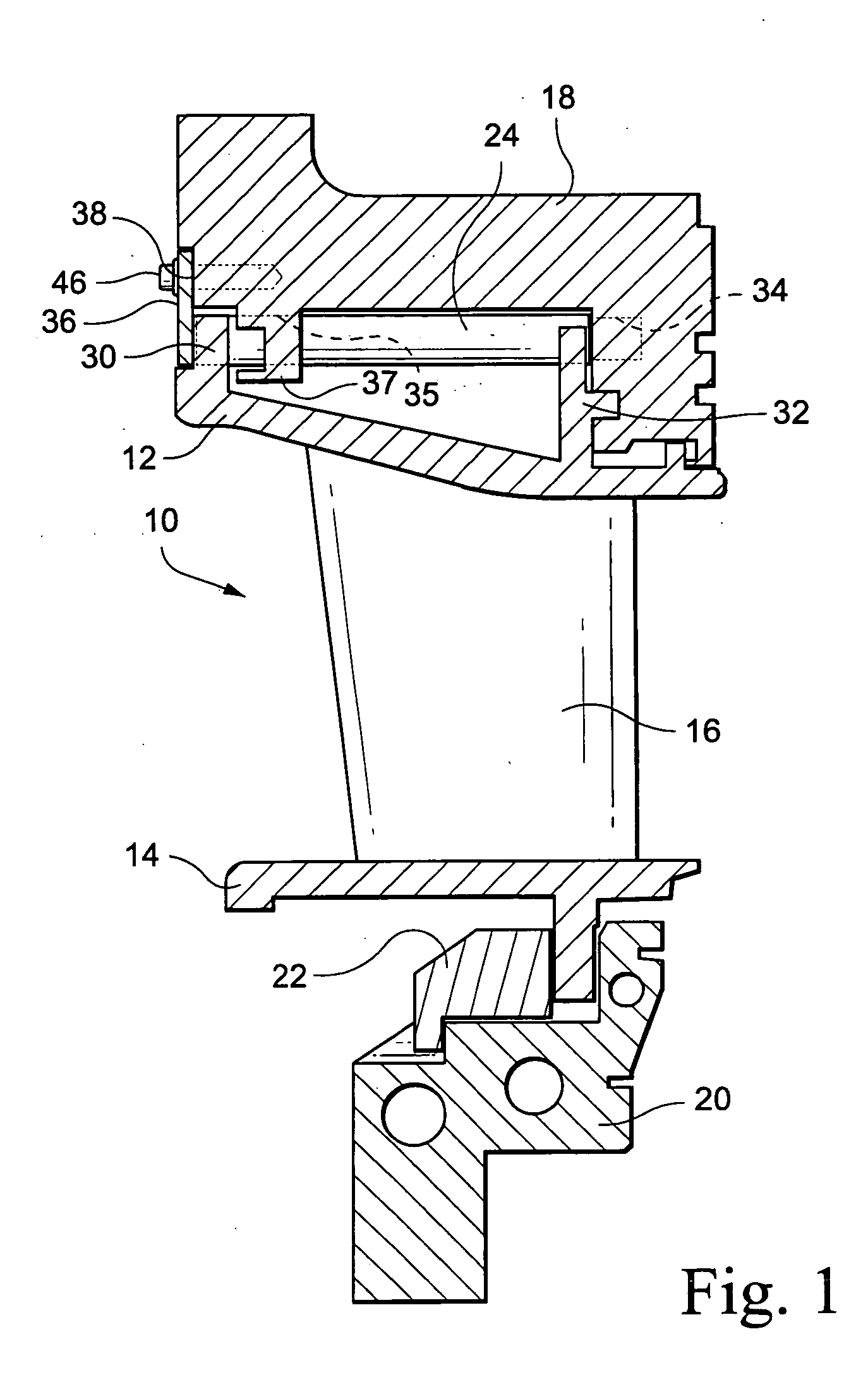

[0015] Referring to FIG. 1, there is illustrated a nozzle segment, generally designated 10, and including an outer band 12, an inner band 14 and one or more nozzle vanes 16 extending between the outer and inner bands. The outer bands 12 of the nozzle segments 10 are secured to an outer retention ring 18. The inner bands 14 are secured to an inner casing 20, by an annular array of inner diameter retention plates 22. The retention plates 22 are bolted to the casing 20 with bolts, not shown, extending in an axial direction, enabling removal of the inner diameter retention plates 22 in an axial forward direction.

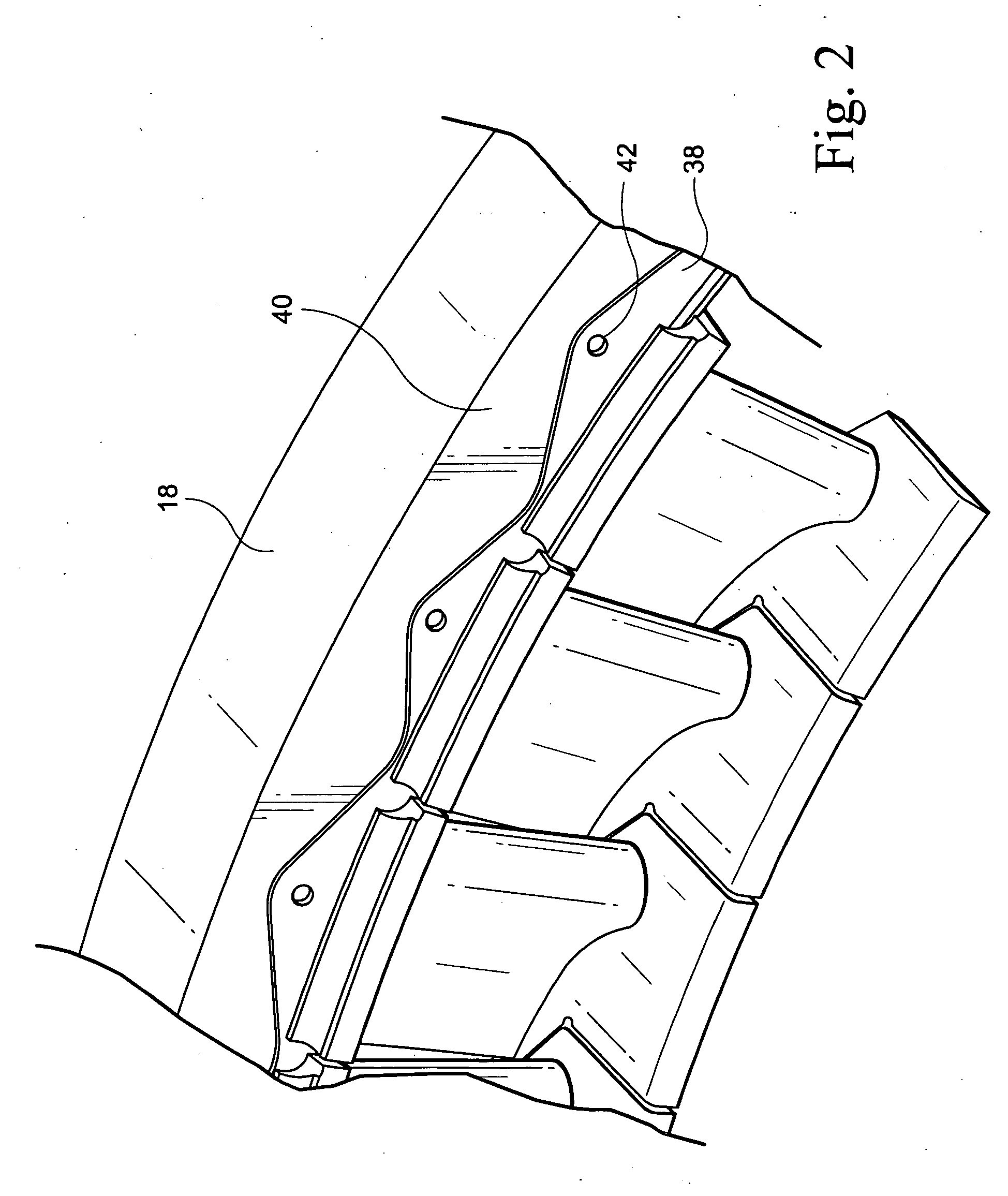

[0016] In accordance with a preferred aspect of the present invention, axially extending anti-rotation pins 24 are provided between the outer bands 12 and the outer retention ring 18, preferably one pin 24 per segment 10. Particularly, the outer band 12 includes a pair of radially outwardly extending flanges 30 and 32, respectively, axially spaced one from the other. Axially al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com