Double-faced detecting devices for an electronic substrate

a detection device and electronic substrate technology, applied in the direction of measurement devices, printed circuit testing, instruments, etc., can solve the problems of only simulating data that is not precise, 80% of electronic substrates can be modified and detected by the conventional detection device, and the rest of the electronic substrates cannot be modified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

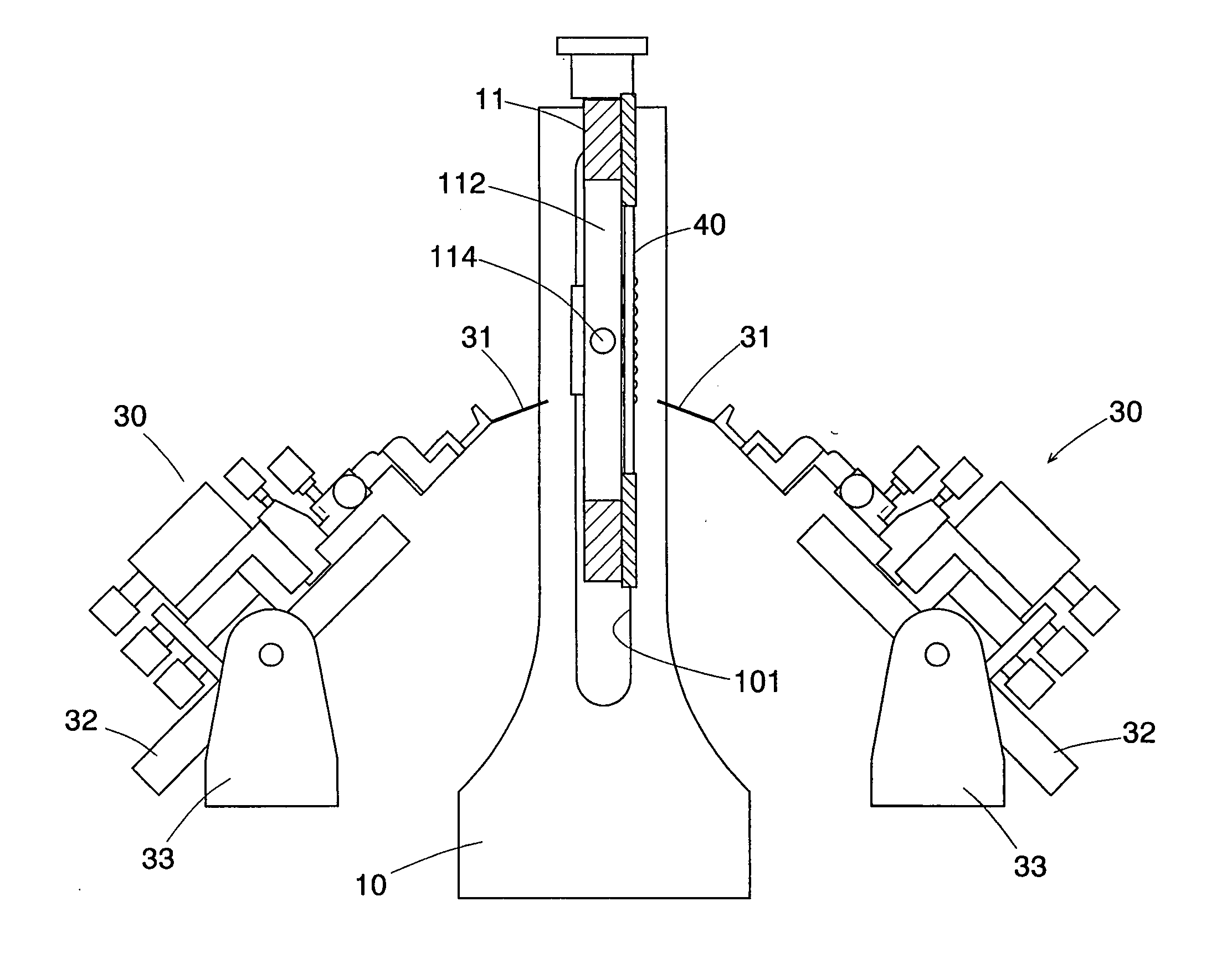

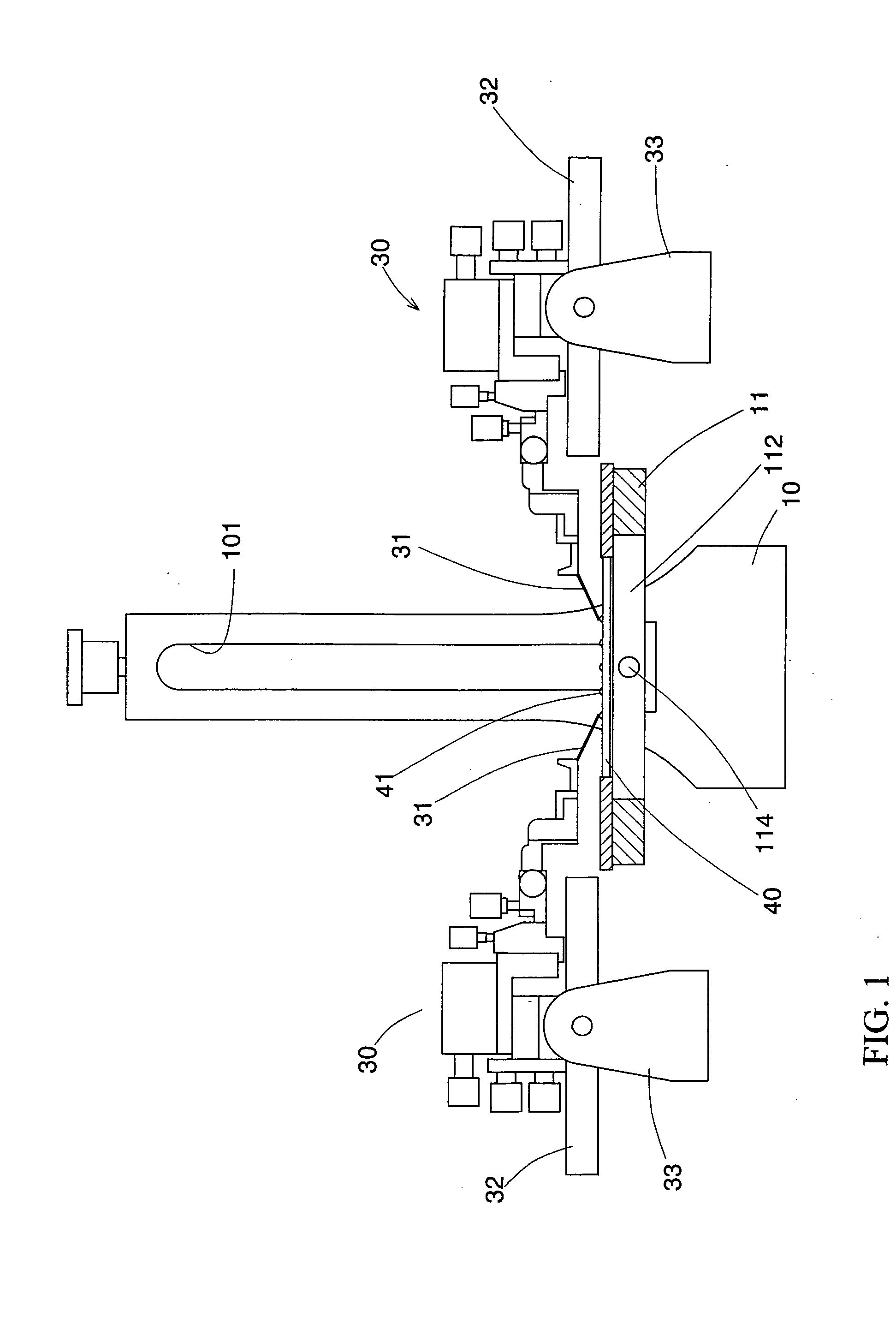

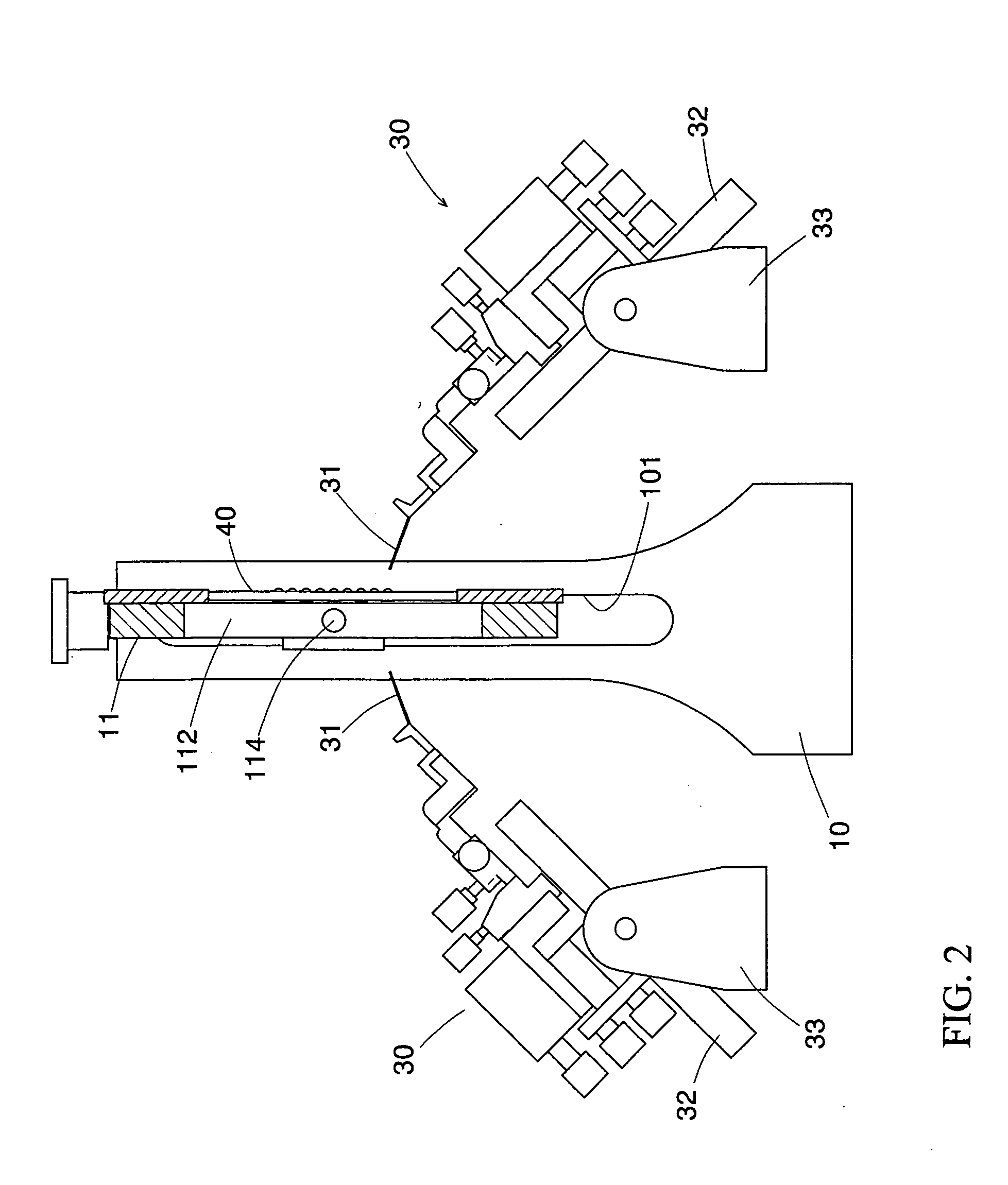

[0016] With reference to FIGS. 1 and 2, double-faced detecting devices for an electronic substrate 40 in accordance with the present invention comprises a base 10 with a substrate platform 11, two pivot bases 33, two probe-detecting machines 30 respectively mounted on the two pivot bases 33. Particularly, the electronic substrate 40 has a top face and a bottom face and multiple contacts 41 respectively arranged on the top and bottom faces.

[0017] The base 10 has an erecting post (not numbered) with a front face, an guiding groove 101 longitudinally defined in the front face of the erecting post, and the substrate platform 11 with a connecting rod 112 movably and rotatably attached to the erecting post via the guiding groove 101. The substrate platform 11 has a top face. A through hole 114 is defined in the substrate platform 11 and has a diameter smaller than that of the electronic substrate 40. Therefore, the electronic substrate 40 enables to be mounted on the top face of the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com