Joint structure of building using thin and lightweight shaped-steel

a technology of lightweight shaped steel and joint structure, which is applied in the direction of joists, building roofs, girders, etc., can solve the problems of deteriorating living environment, inclination of buildings, lack of strength, etc., and achieves the effect of facilitating working efficiency and easy truss formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention will be described below with reference to the drawings.

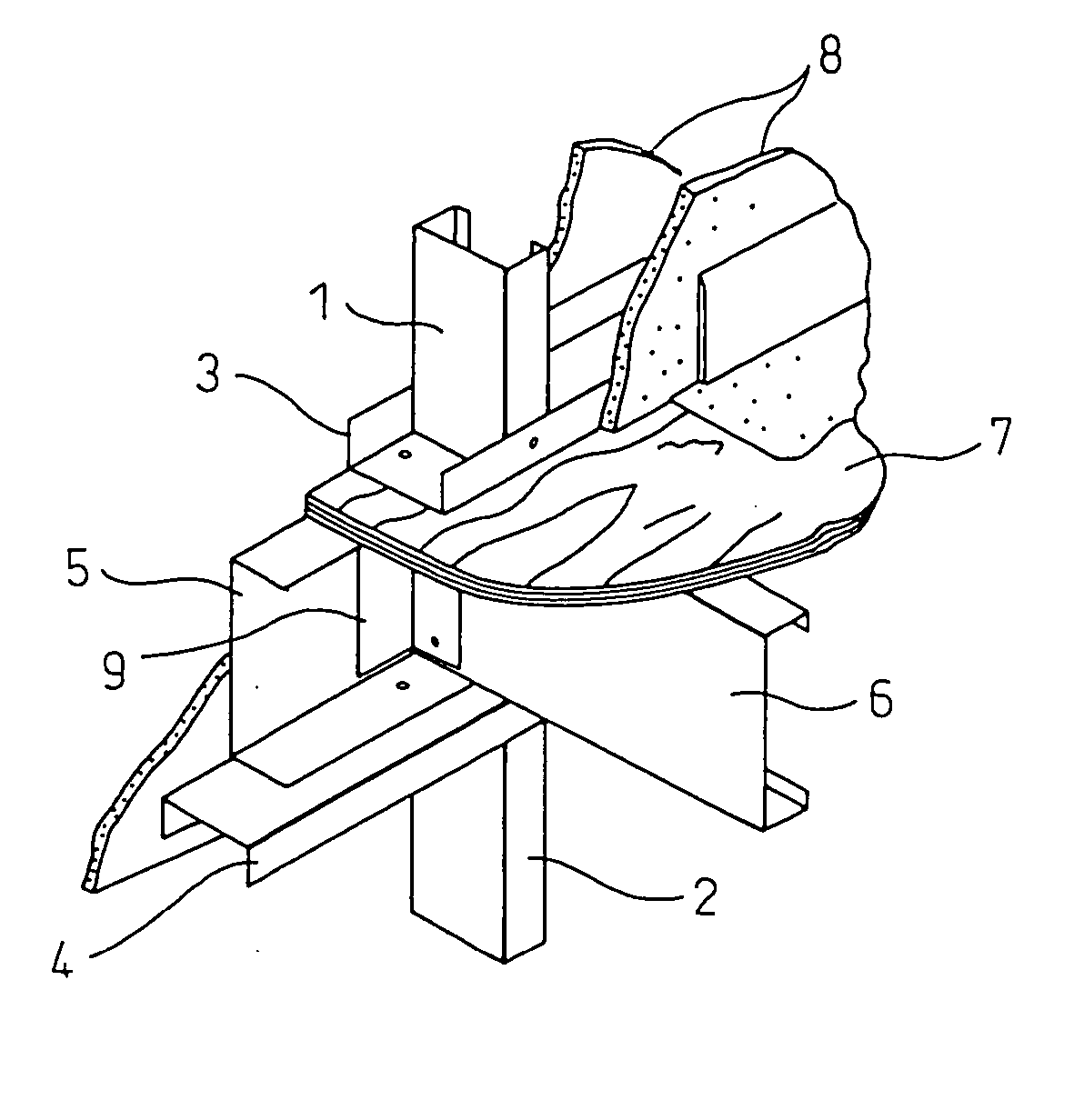

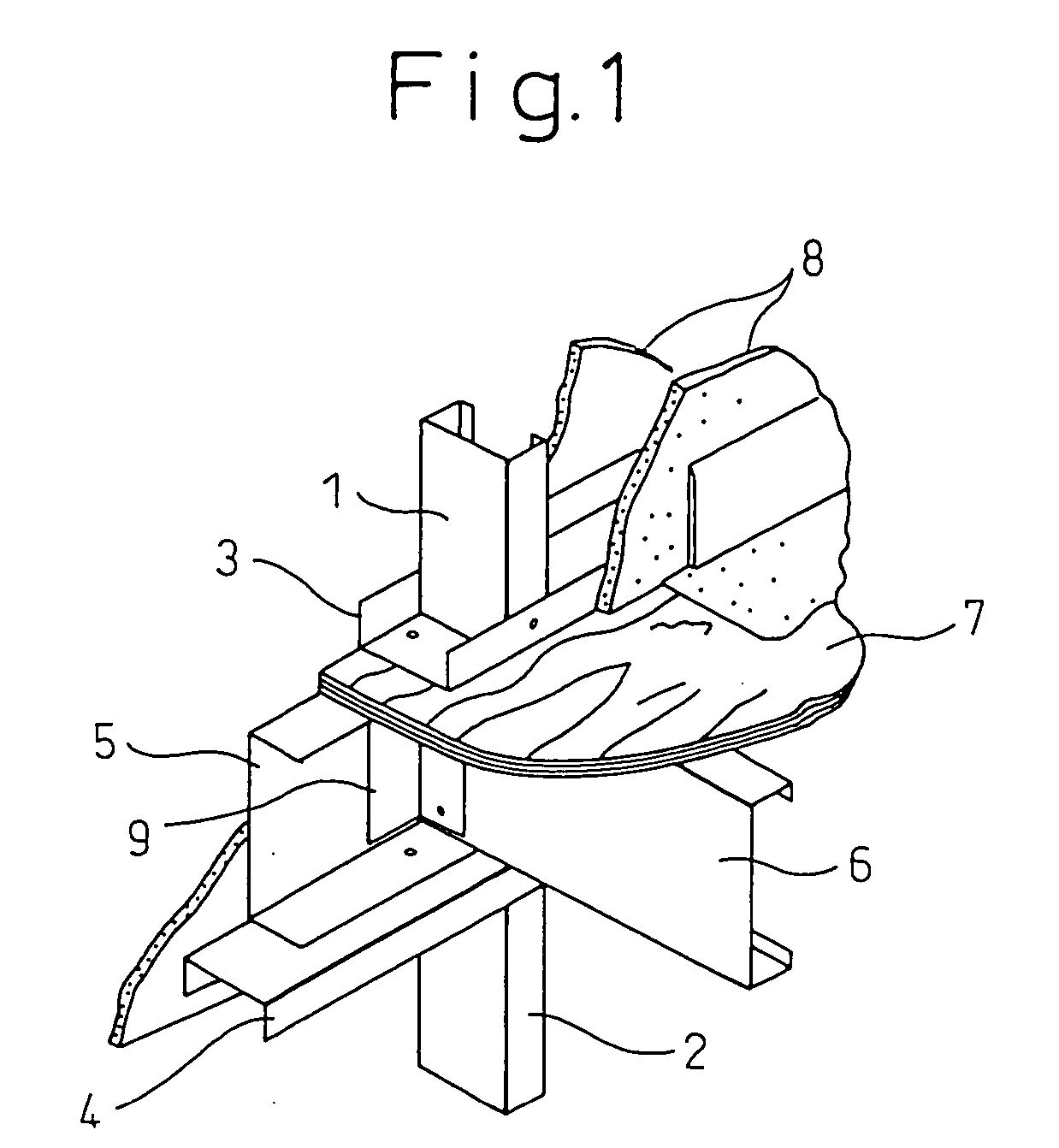

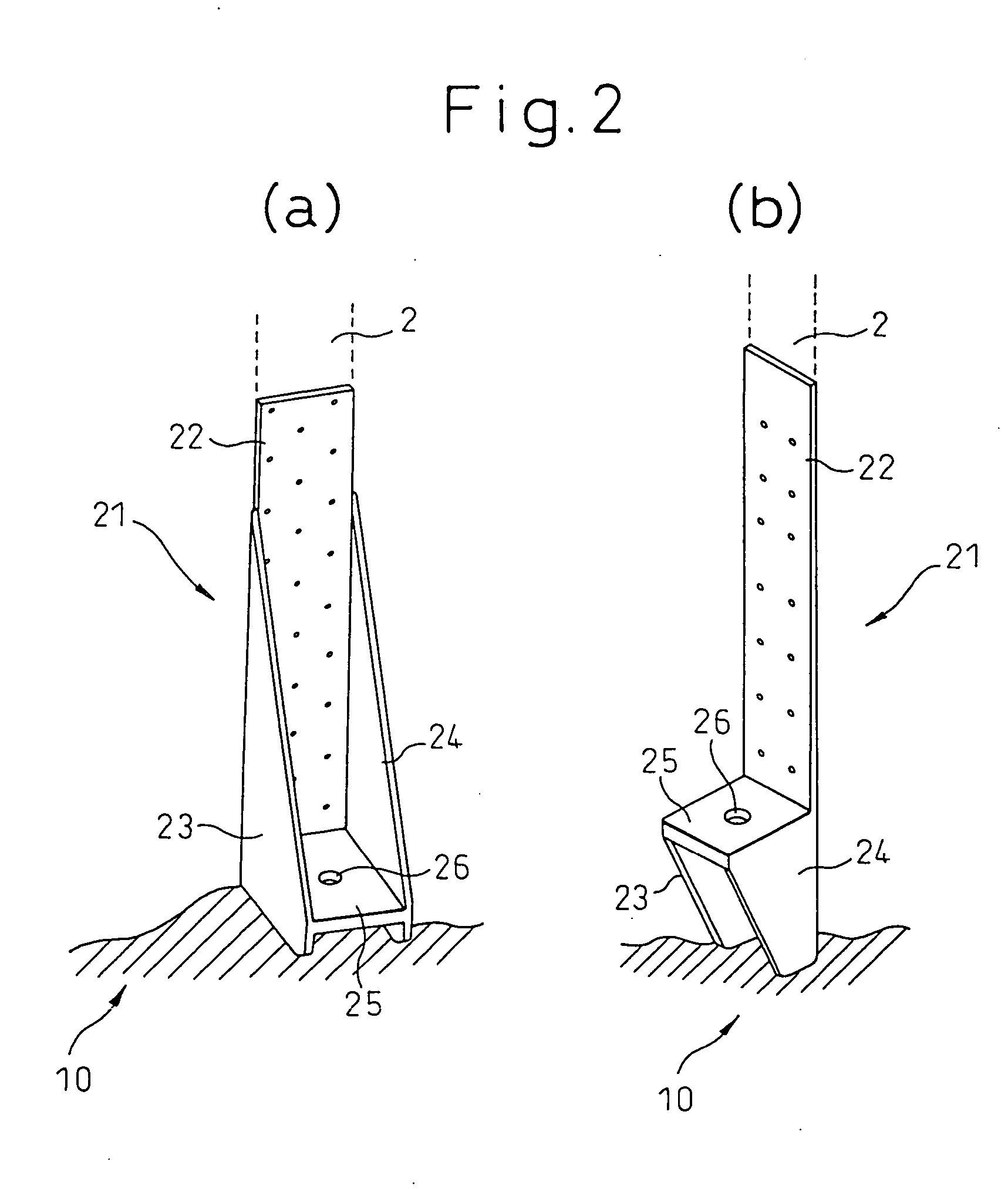

[0028] In FIG. 3, a joint structure according to the present invention, for fastening and joining the respective frame members with each other, is shown. In the drawing, a frame member 1 constitutes a pillar for an upper story and a frame member 2 constitutes a pillar for a lower story, and the ends of these frame members are orthogonally joined to tracks 3 and 4 to define a T-shape. Between the tracks 3 and 4, a sill 5 is disposed to be attached thereto, and another sill 6 is attached to the sill 5 and extends in the vertical direction. Directly above this sill 6, a floor 7 is placed. On the opposite sides of the sill 5, side wall members 8 are attached. Since the frame members 1 and 2 do not constitute an integral structure passing through the upper and lower stories but are assembled, a space exists between the both, in which the sills 5 and 6 are interposed. In this space, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com