Ski core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

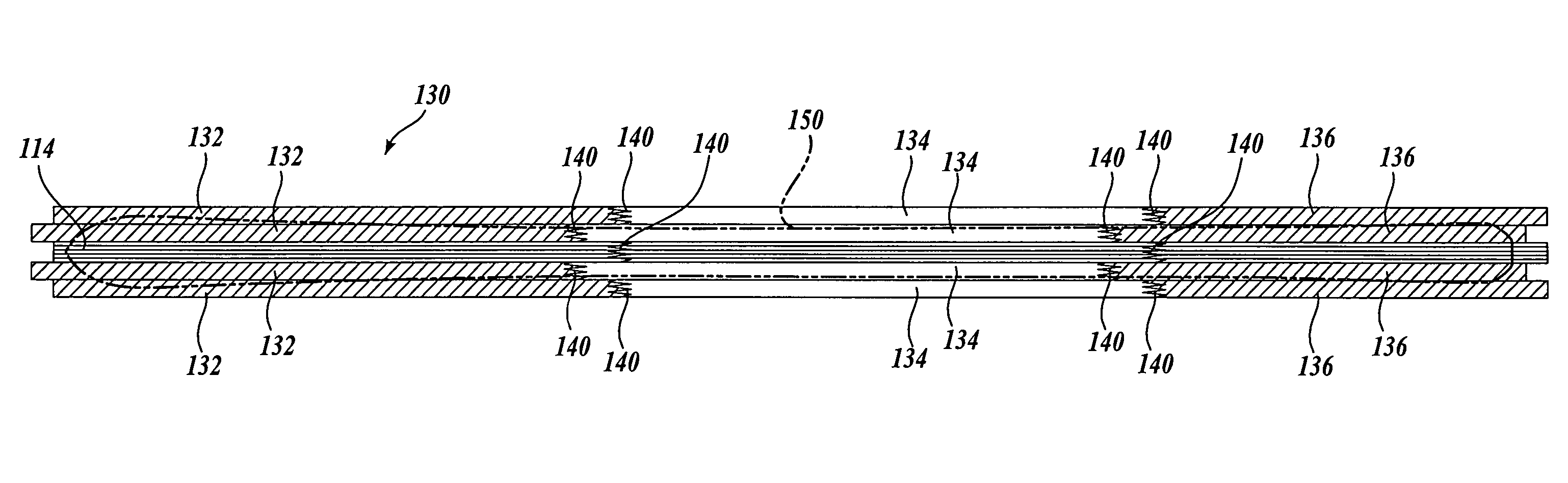

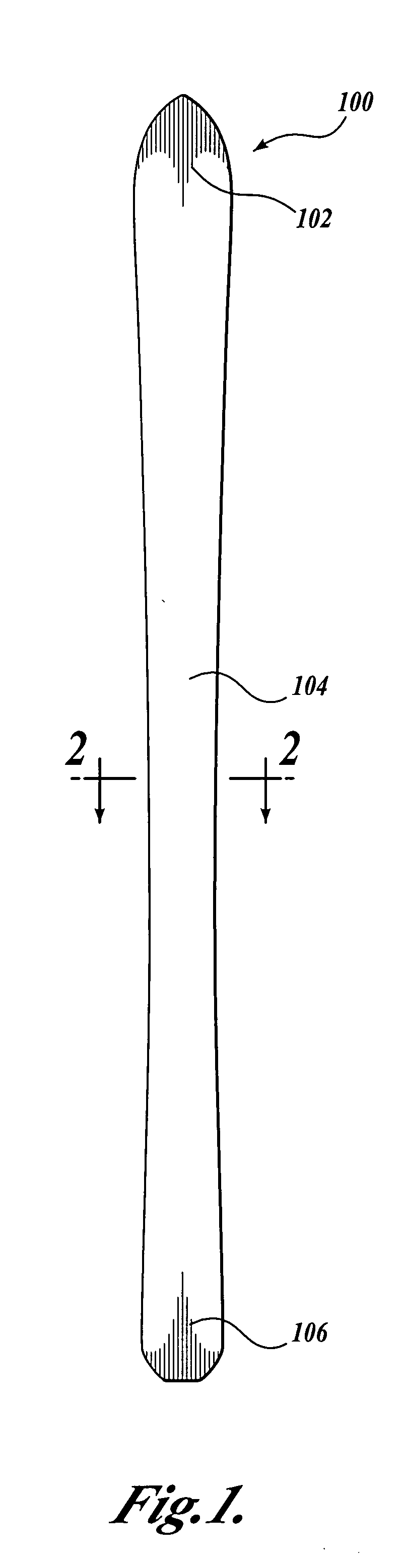

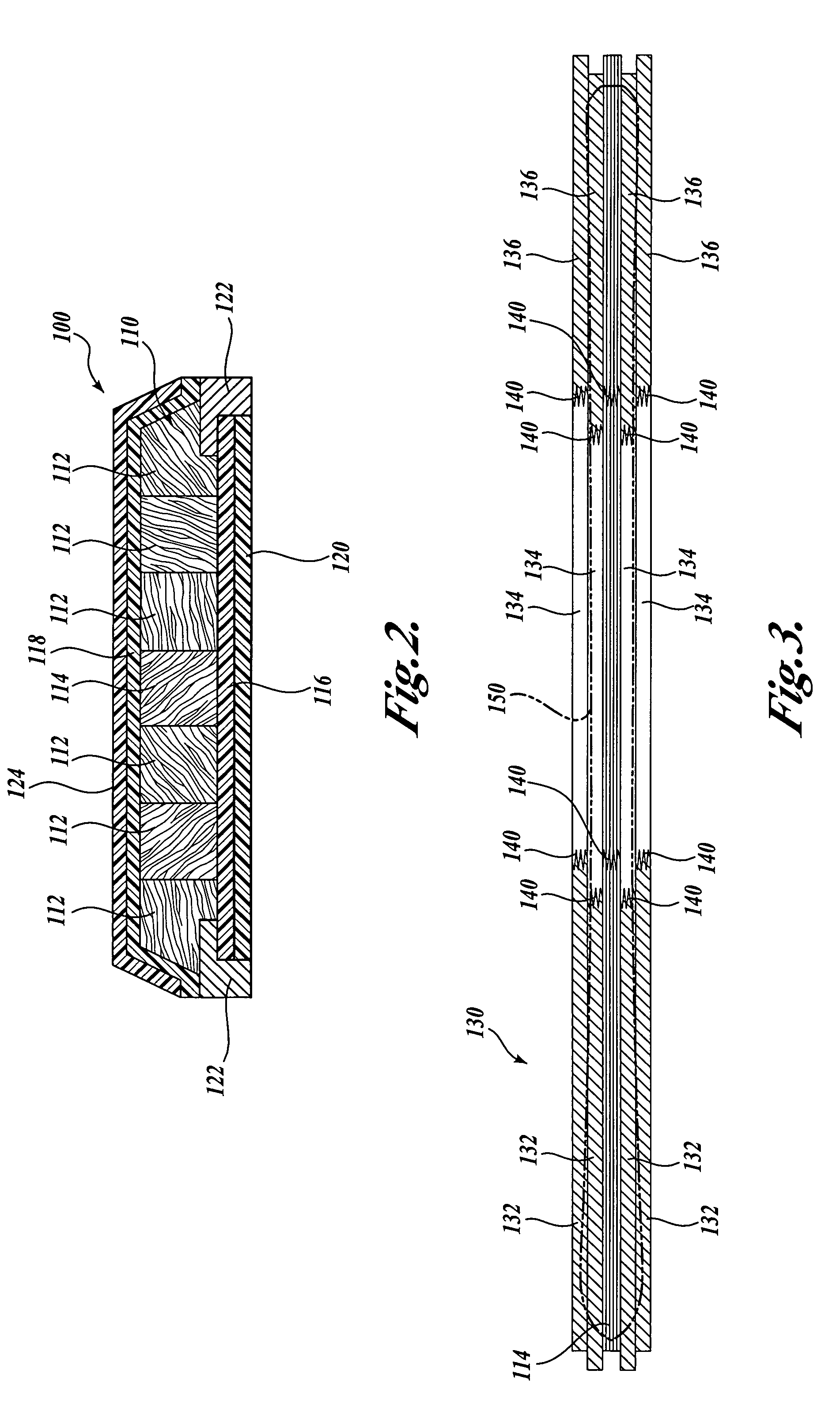

[0018] Refer now to the figures, wherein like numbers indicate like parts throughout the various figures. FIG. 1 shows a plan view of a snow ski 100 made in accordance with the present invention. The present invention provides a ski having a relatively low swing weight and is therefore particularly suited for snow skis used for backcountry skiing, such as cross-country and telemark skiing. It will be readily appreciated, however, that the present invention may also be utilized for all forms of skiing, including alpine skiing, snowboarding, and the like. The ski 100 shown in FIG. 1 includes a relatively wide front shovel section 102, a tapered waist section 104, and a relatively wide rearward heel section 106. The waist section 104 is adapted to receive a binding (not shown) for securing a user's boot to the ski 100. The tapered planform shown in FIG. 1 provides well-known performance advantages, particularly for turning. However, other planforms are also known and may alternatively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com