Mirror mount assembly with dual reflective surfaces

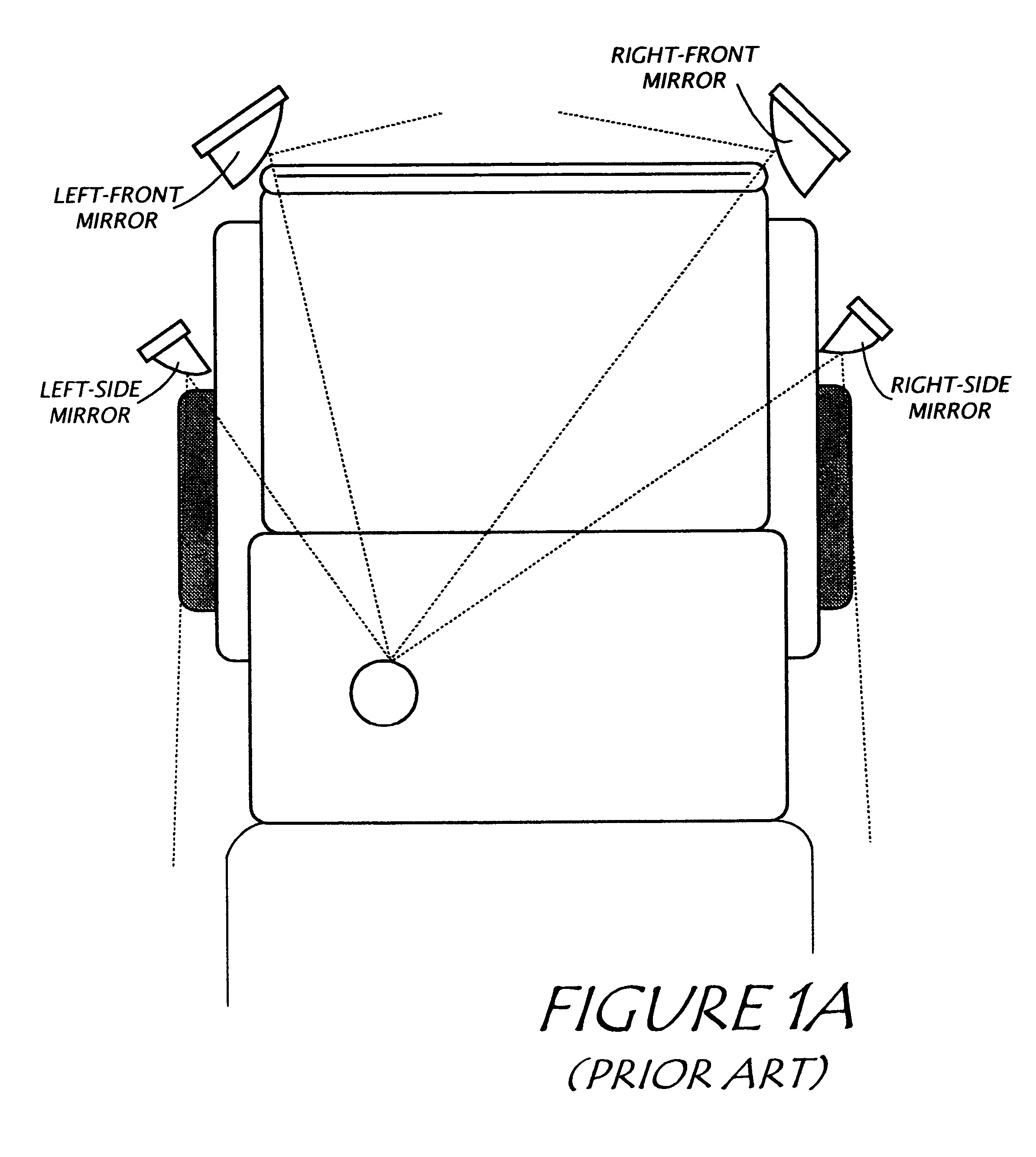

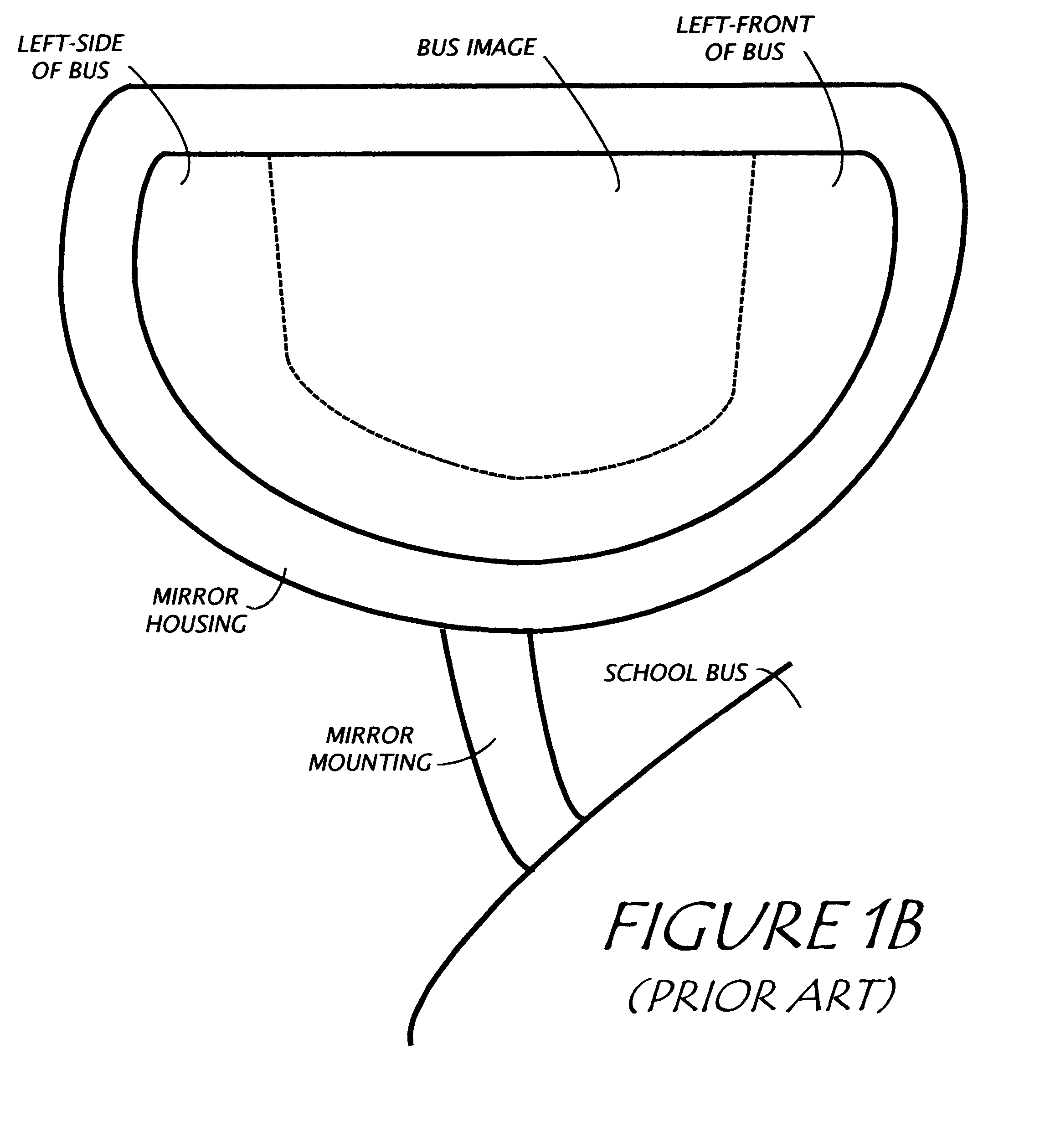

a mirror mount and mirror technology, applied in the direction of machine supports, other domestic objects, transportation and packaging, etc., can solve the problems of 25 schoolchildren being killed, and the blind spot behind the combination mirror is larger than the one behind i

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

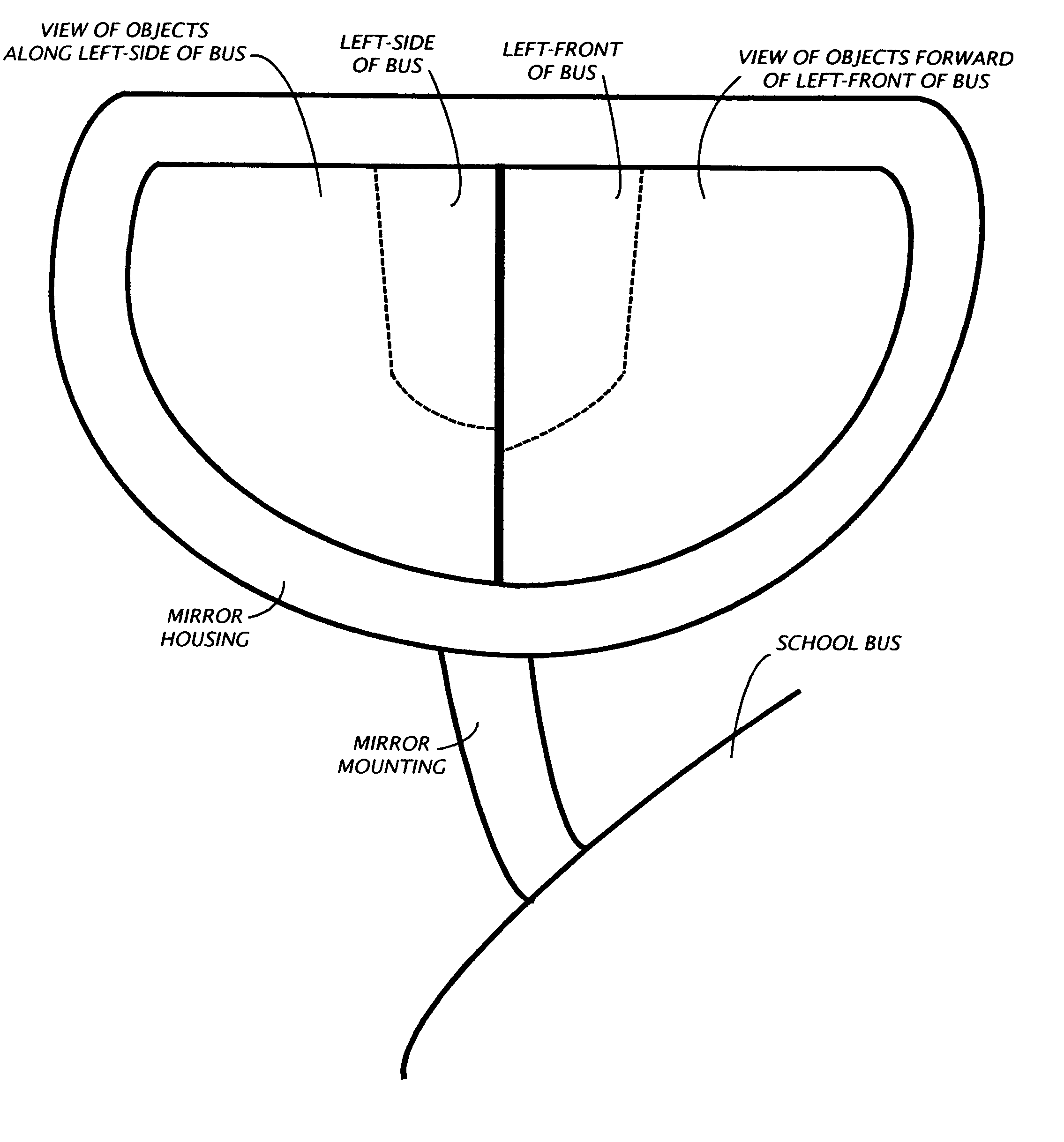

[0036] Referring now to the drawings with initial reference to FIGS. 1C and 2 which illustrate an environmental view of the preferred embodiment of the mirror mount assembly 10 of the present invention—a dual mirror mount assembly mounted onto a Type C school bus 12.

[0037] The mirror mount assembly 10 as shown comprises a mirror housing 20, and a pair of reflective surfaces (30 and 40) secured within the mirror housing 20. The front reflective surface 30 has a substantially convex shape. The front reflective surface 30 is primarily configured so that when the mirror mount assembly 10 is properly positioned, the front reflective surface 30 provides the school bus driver with an expanded field-of-view of objects disposed in a first zone. The side reflective surface 40 is separate and distinct from the front reflective surface 30 (alongside and below the school bus driver. The side reflective surface 40 also has a substantially convex shape. The side reflective surface 40 is primarily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com