Modular decking tile

a module and decking technology, applied in the field of modules, can solve the problems of large amount of timber required, high risk, and large platform area, and achieve the greatest degree of versatility in deck configuration, and reduce the risk of slipping on the upper surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

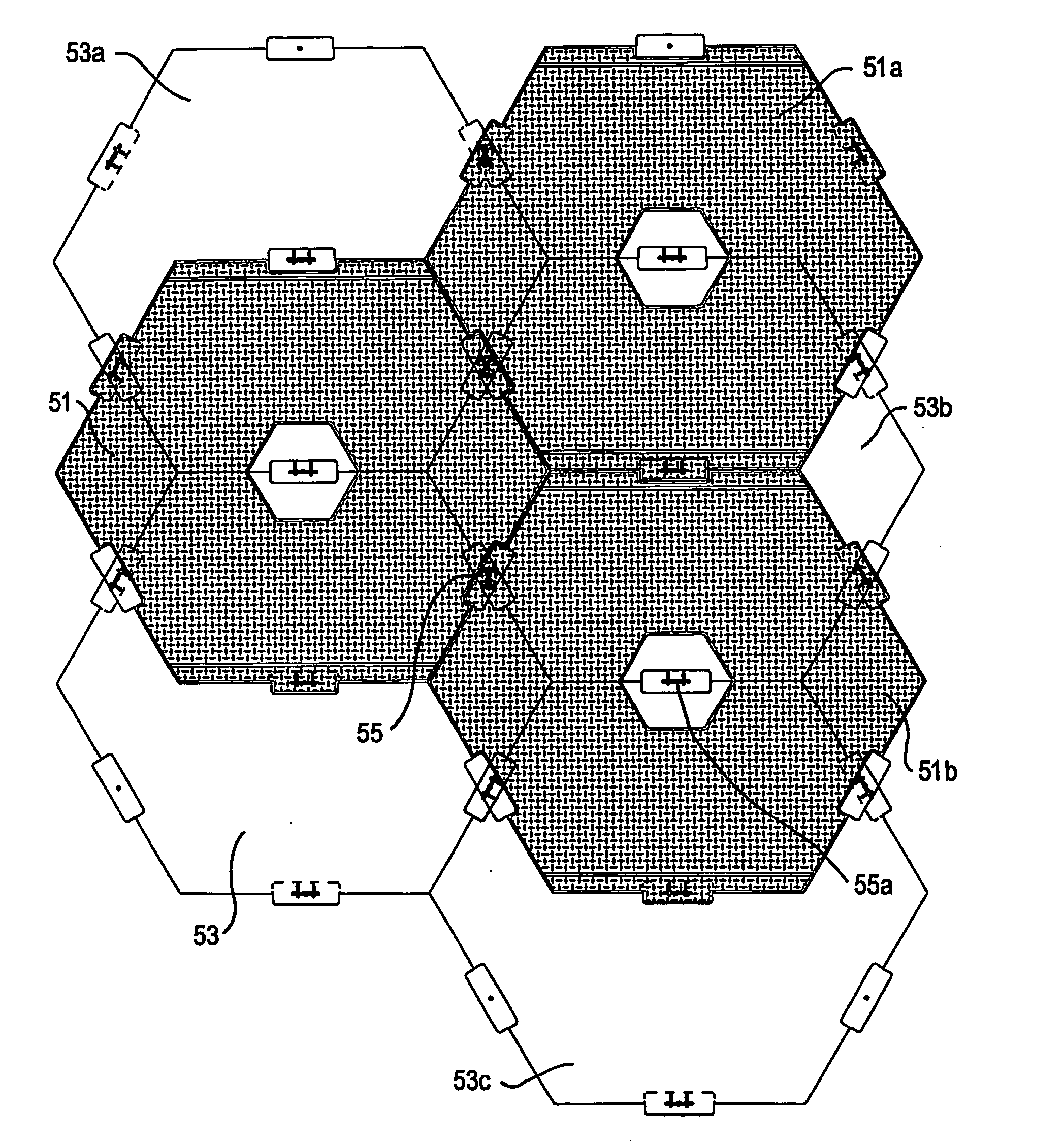

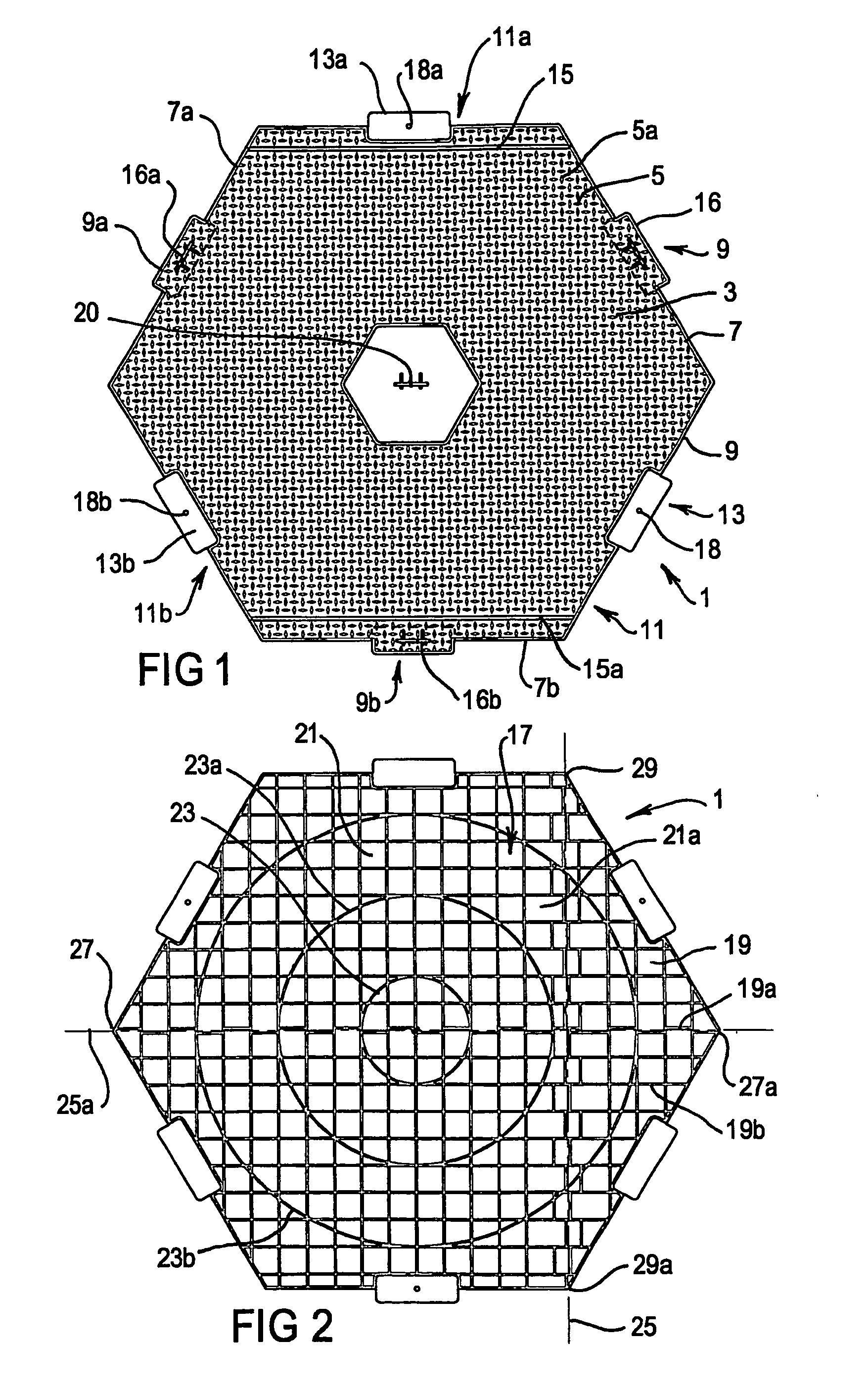

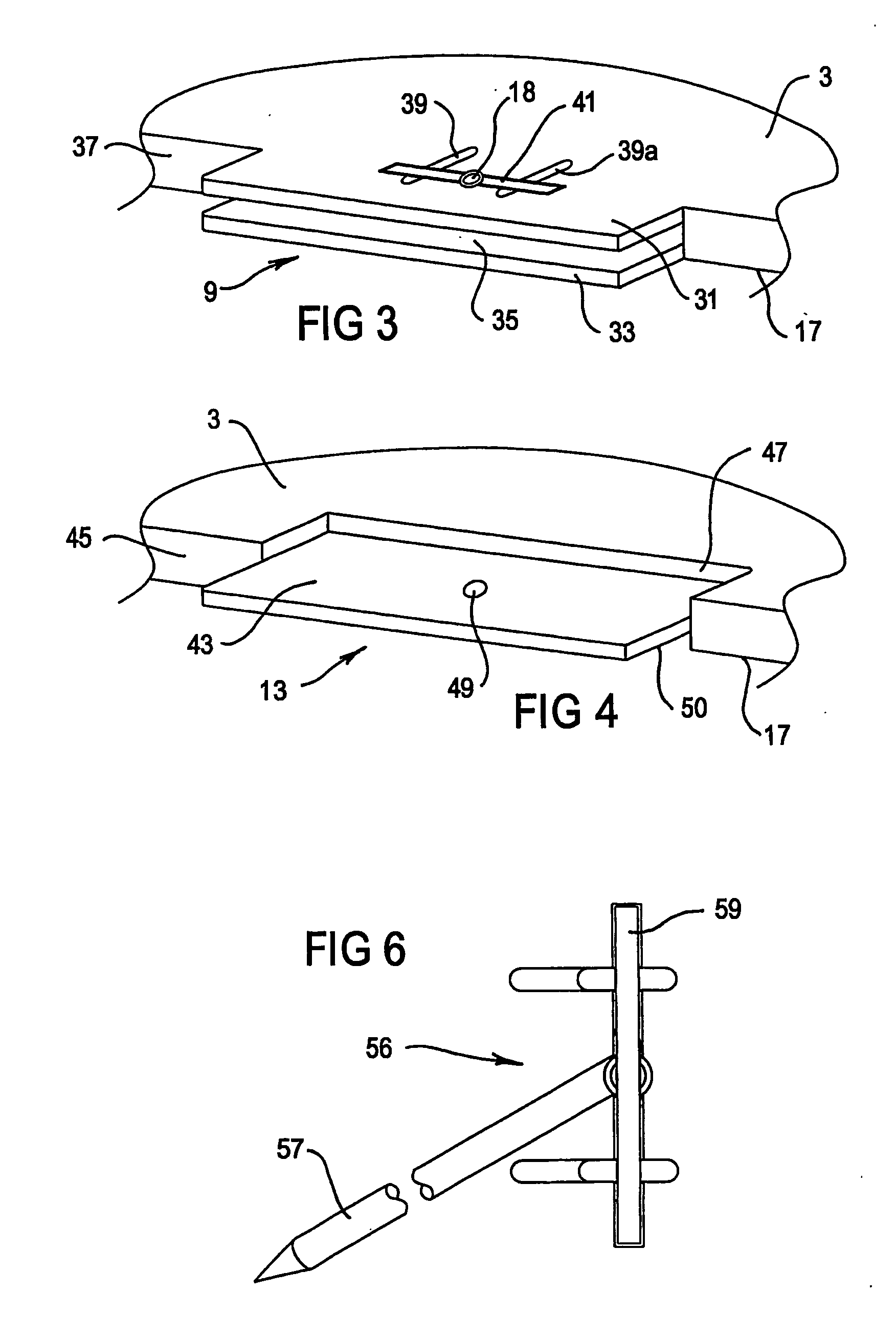

[0025] In FIG. 1, modular decking tile 1 has a planar hexagonal upper surface 3 bearing a pattern of raised friction lugs 5 to provide grip to upper surface 3. Lugs 5 are shown in a chequer plate configuration designed to ensure that wheels of vehicles or footwear of pedestrian traffic does not slip on upper surface 3, particularly when upper surface 3 is wet or muddy. The surface area of upper surface 3 may be up to approximately 3 m2 although smaller or larger versions may be made if desired. Peripheral edges 7, 7a and &7b each have a female connector portion 9, 9a and 9b typically shown in more detail in FIG. 3.

[0026] Peripheral edges 11, 11a and 11b each have male connector portions 13, 13a and 13b typically shown in more detail in FIG. 4.

[0027] Upper surface 3 has recessed lines 15 and 15a which are reduced slightly below the plane of upper surface 3. Recessed lines 15 and 15a may accommodate an adhesive marking tape (not shown) for clearly outlining desired areas of a deckin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com