Sealing bag with chuck

a technology of sealing bag and chuck, which is applied in the direction of flexible containers, sacks, packaging, etc., can solve the problems of slipping fingers, chuck cannot be opened well, and the opening edge part of the bag held in the fingers in the opening chuck easily slips, so as to prevent the fingers from slipping, the effect of deteriorating the holding properties of the fingers and enhancing the properties of the preventing fingers from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0046] First, a first embodiment of the sealing bag with the chuck according to the present invention will be described with reference to FIGS. 1 to 9.

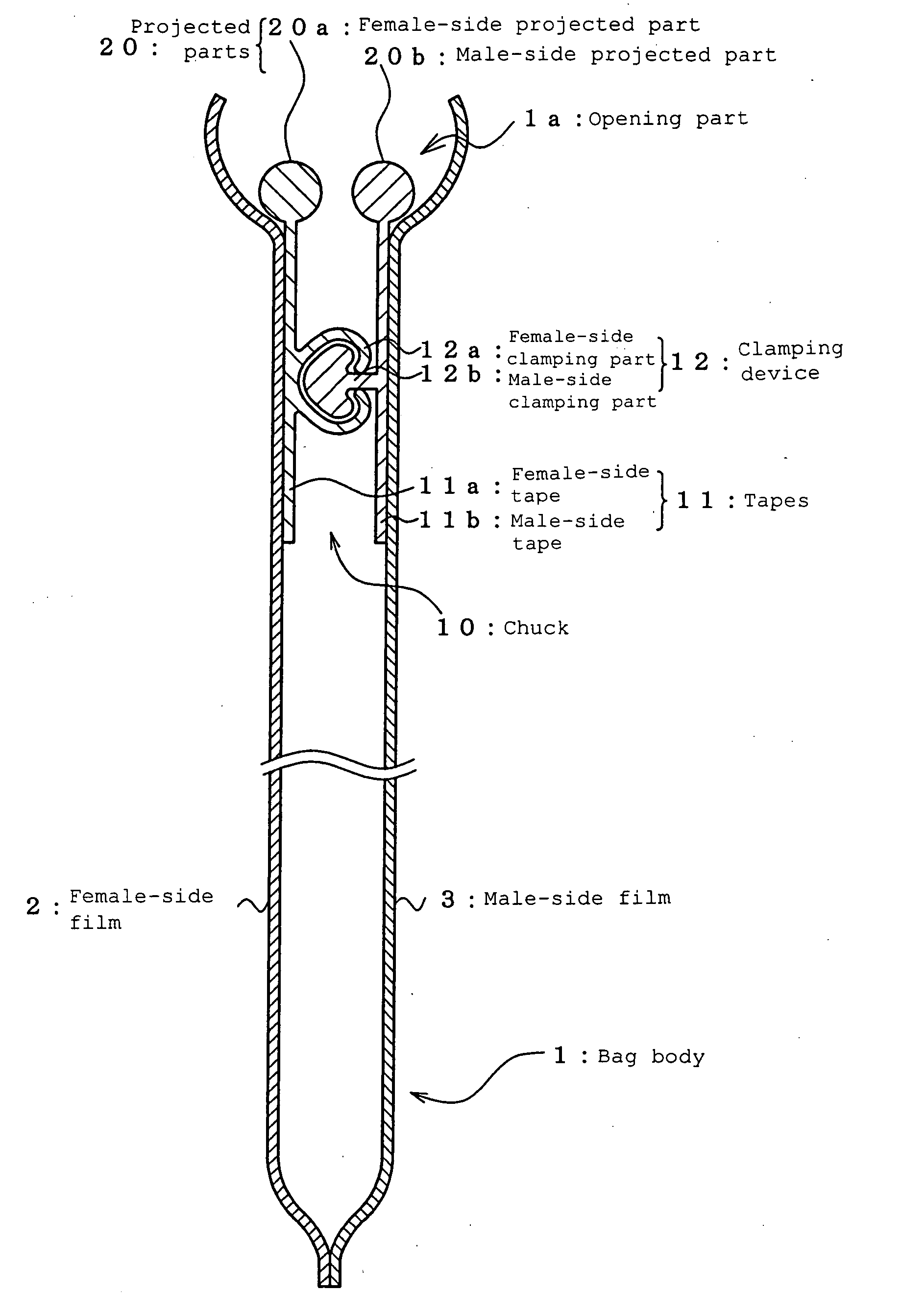

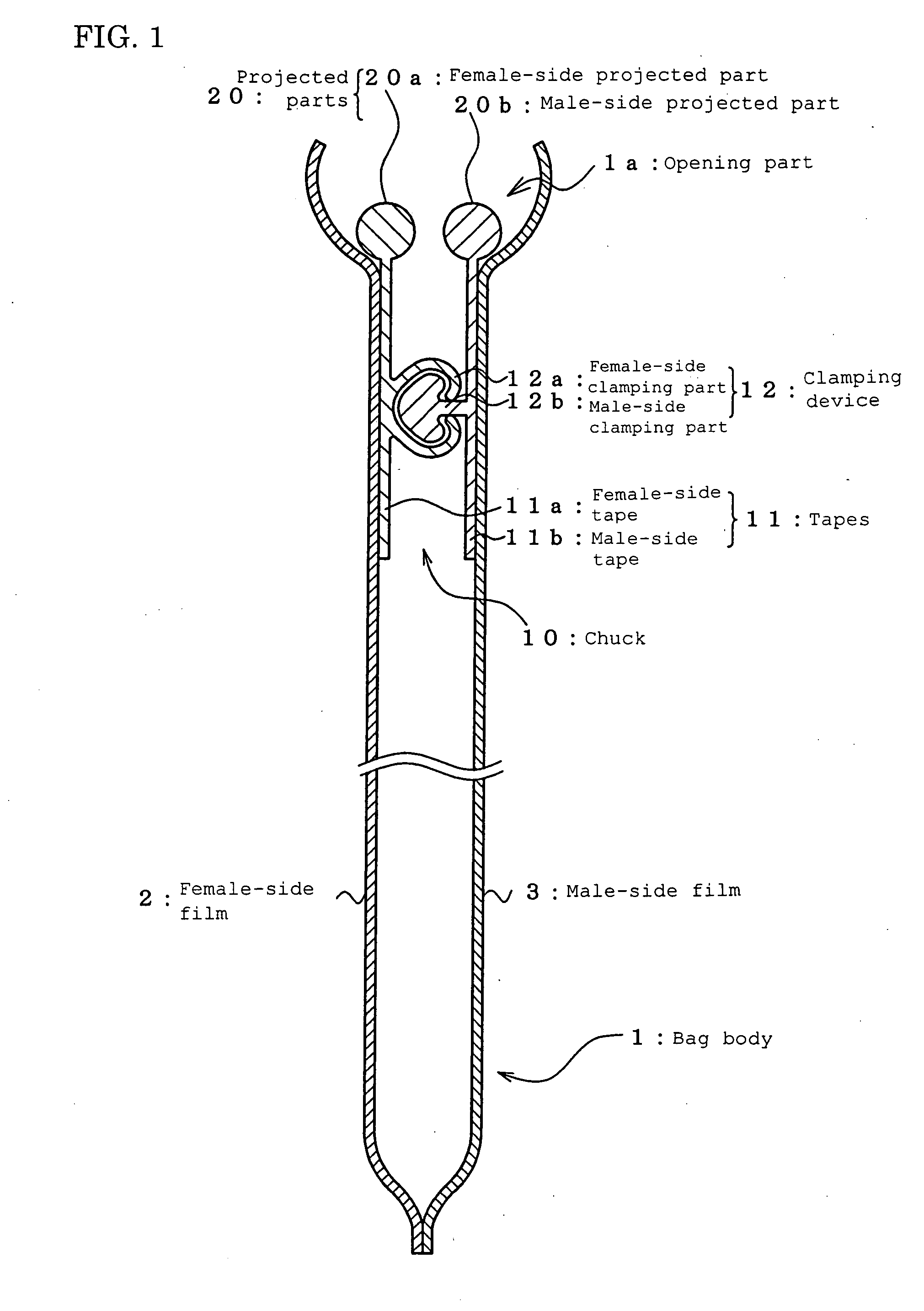

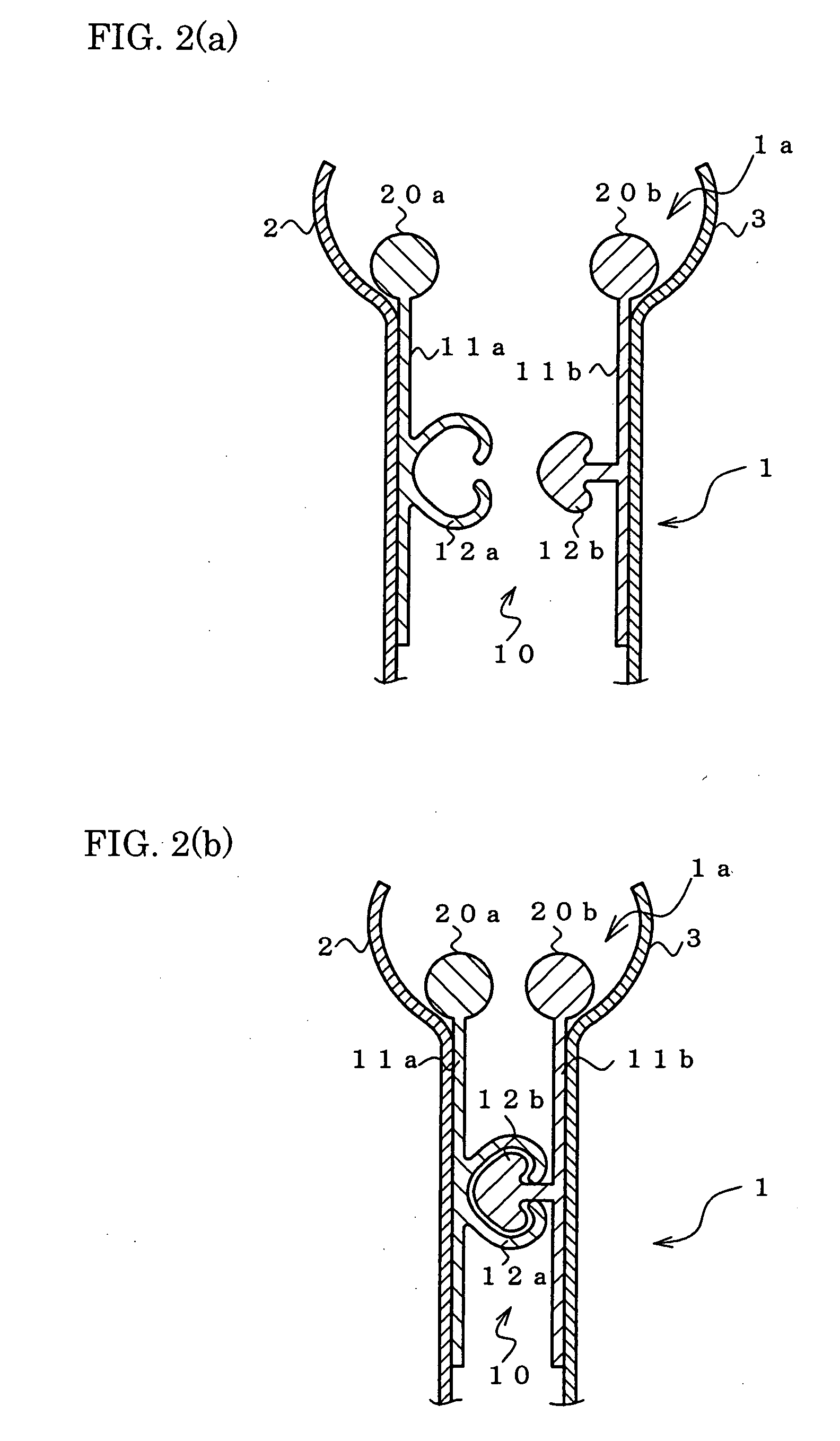

[0047]FIG. 1 is a side sectional view of an entire bag, schematically showing the sealing bag provided with the chuck according to the first embodiment of the present invention. FIG. 2 is similarly a side sectional view of a chuck part, schematically showing the sealing bag with the chuck according to the present embodiment, (a) shows a state in which the chuck is unclamped, and (b) shows a state in which the chuck is clamped. FIG. 3 shows the sealing bag with the chuck according to the present embodiment, (a) is a front view of the entire bag, and (b) is an enlarged view of a part shown by a two-dot chain line of (a). FIG. 4 is a side sectional view of the chuck part, for comparison of a size of a projected part in the present embodiment with that in a conventional sealing bag, (a) shows the first embodiment of the present invention...

second embodiment

[0083] Next, a second embodiment of the sealing bag with the chuck according to the present invention will be described with reference to FIG. 10. FIG. 10 is a side sectional view of the entire bag, schematically showing the sealing bag with the chuck according to the second embodiment of the present invention.

[0084] The sealing bag with the chuck according to the present embodiment shown in the same figure is a modification of the above-described first embodiment, and the projected parts 20 disposed opposite to each other in the same position in the bag body 1 in the first embodiment are disposed in different positions with respect to a depth direction of the bag body 1. The other constituting parts are similar to those of the first embodiment, similar constituting parts are denoted with the same reference numerals as those of the first embodiment, and detailed description thereof is omitted.

[0085] Concretely, as shown in FIG. 10, in the projected parts 20 according to the presen...

example 1

[0092] (1) A chuck (tapes and clamping devices) was formed by polypropylene.

[0093] (2) A projected part of a tape end part was formed into a round sectional shape, and a diameter of a circular sectional shape part of the projected part was set to 0.3 mm.

[0094] (3) The projected parts were formed in such a manner that the parts were disposed in the same position on male and female sides in accordance with the sealing bag described above in the first embodiment.

[0095] (4) A bag body was formed using a film obtained by laminating a biaxially stretched polypropylene film and a cast polypropylene film.

[0096] (5) Tape parts excluding projected parts on tape end parts are fused onto the film of the bag body, and the projected parts are prevented from being fused onto the bag body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com