Flexible sleeve syringe and system

a flexible sleeve and syringe technology, applied in the field of syringes, can solve the problems of merely prolonging the onset of leakage, affecting the stability of the ptfe plunger, and affecting the stability of the sleeve, so as to achieve the effect of reducing the requirement of pumping force, superior resistance to leakage, and reducing the need for sleeve pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

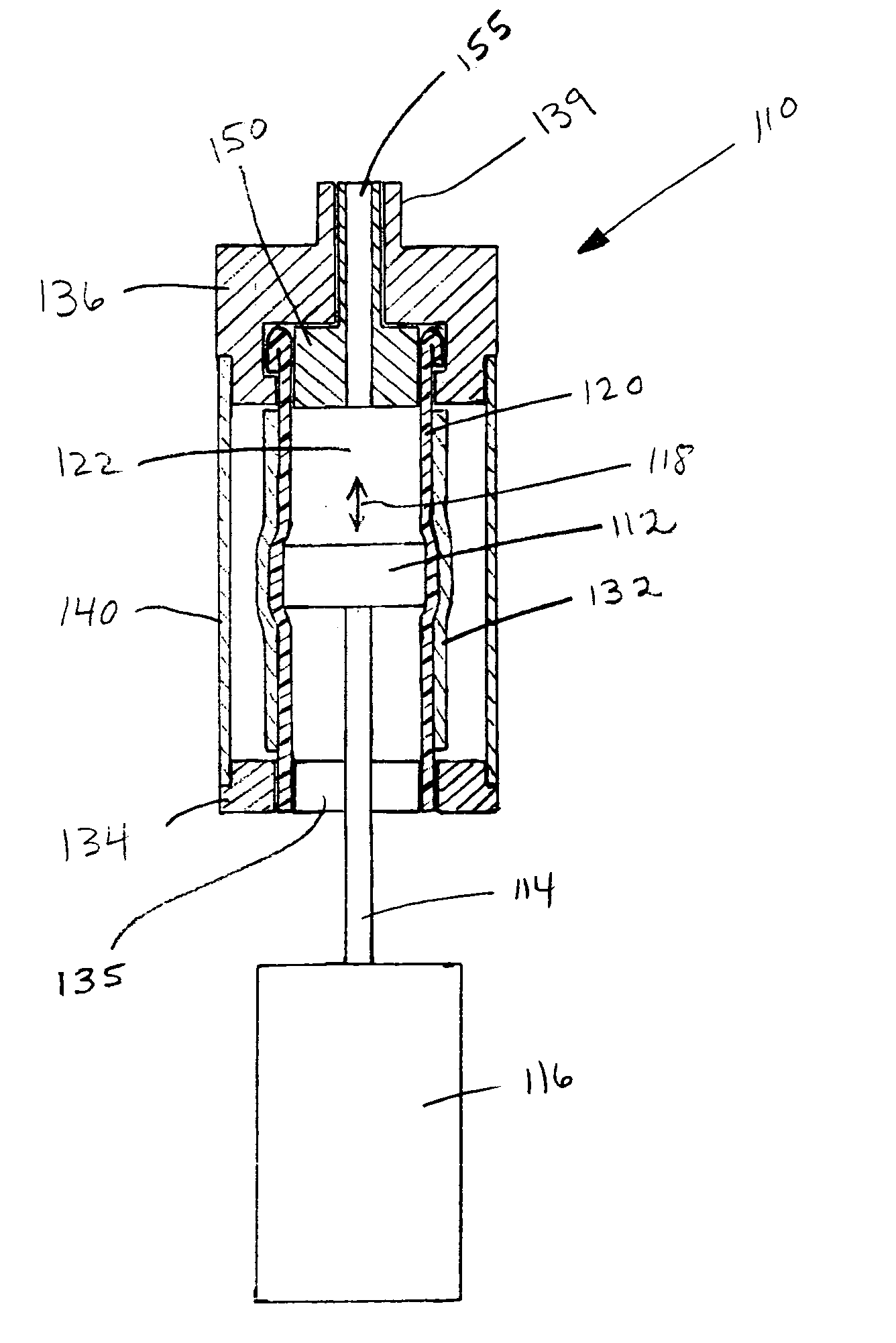

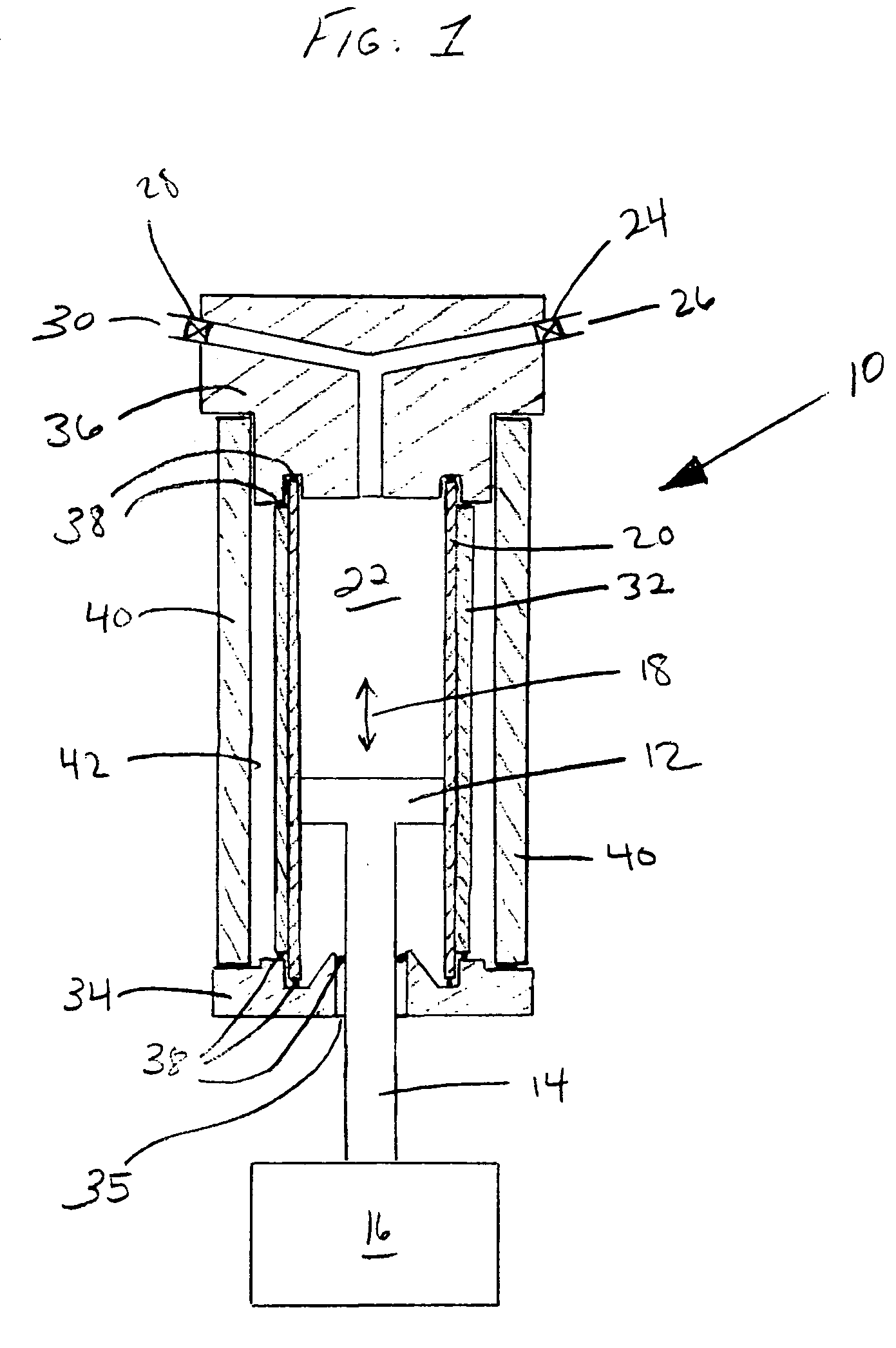

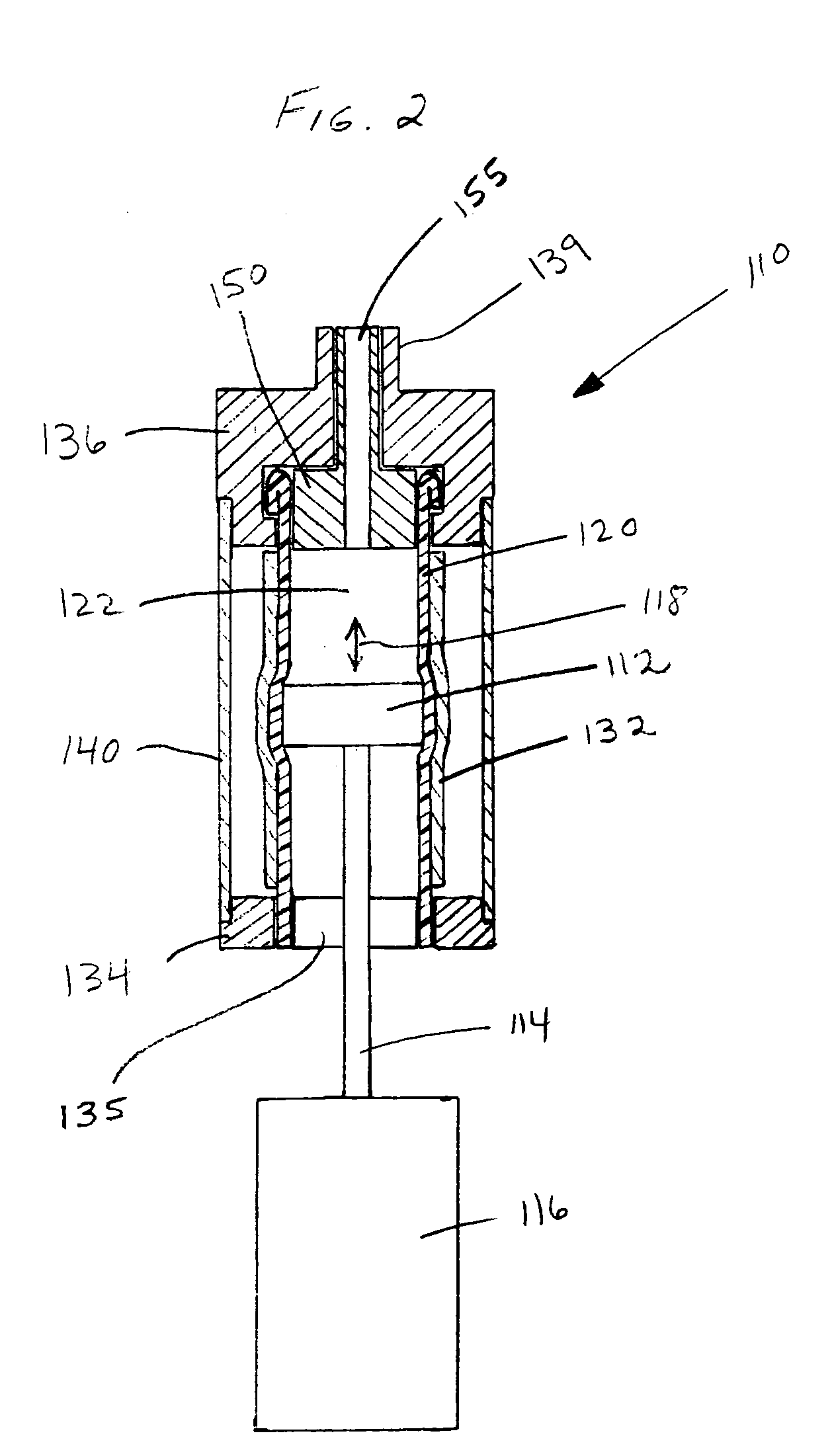

[0017] Embodiments of the present invention provides syringes and syringe systems which provide reduced friction between the plunger and the wall of the fluid chamber, reduced wear on components such as the plunger, and / or simplified manufacturing due to an ability to compensate for misalignment and less stringent tolerances. With respect to the reduced friction feature, embodiments of the present invention have lower pumping force requirements. Thus, for example, when a syringe according to an embodiment of the present invention is motor driven (i.e., a motor causes reciprocal movement of the plunger), less power is needed. In fact, this can allow a single motor to drive multiple syringes.

[0018] According to embodiments of the present invention, a syringe is provided comprising an elastic sleeve defining the fluid chamber of the syringe, and a plunger positioned within the elastic sleeve. The outer diameter of the plunger is oversized (i.e., greater than the inner diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wall thickness | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com