Liquid droplet discharge head and image forming apparatus

a technology of liquid droplet and image forming apparatus, which is applied in printing and other directions, can solve the problems of bleeding, color mixing, image quality decline, and particularly significant image degradation, and achieve the effects of preventing interference between adjacent dots, high-quality image recording, and preventing interferen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

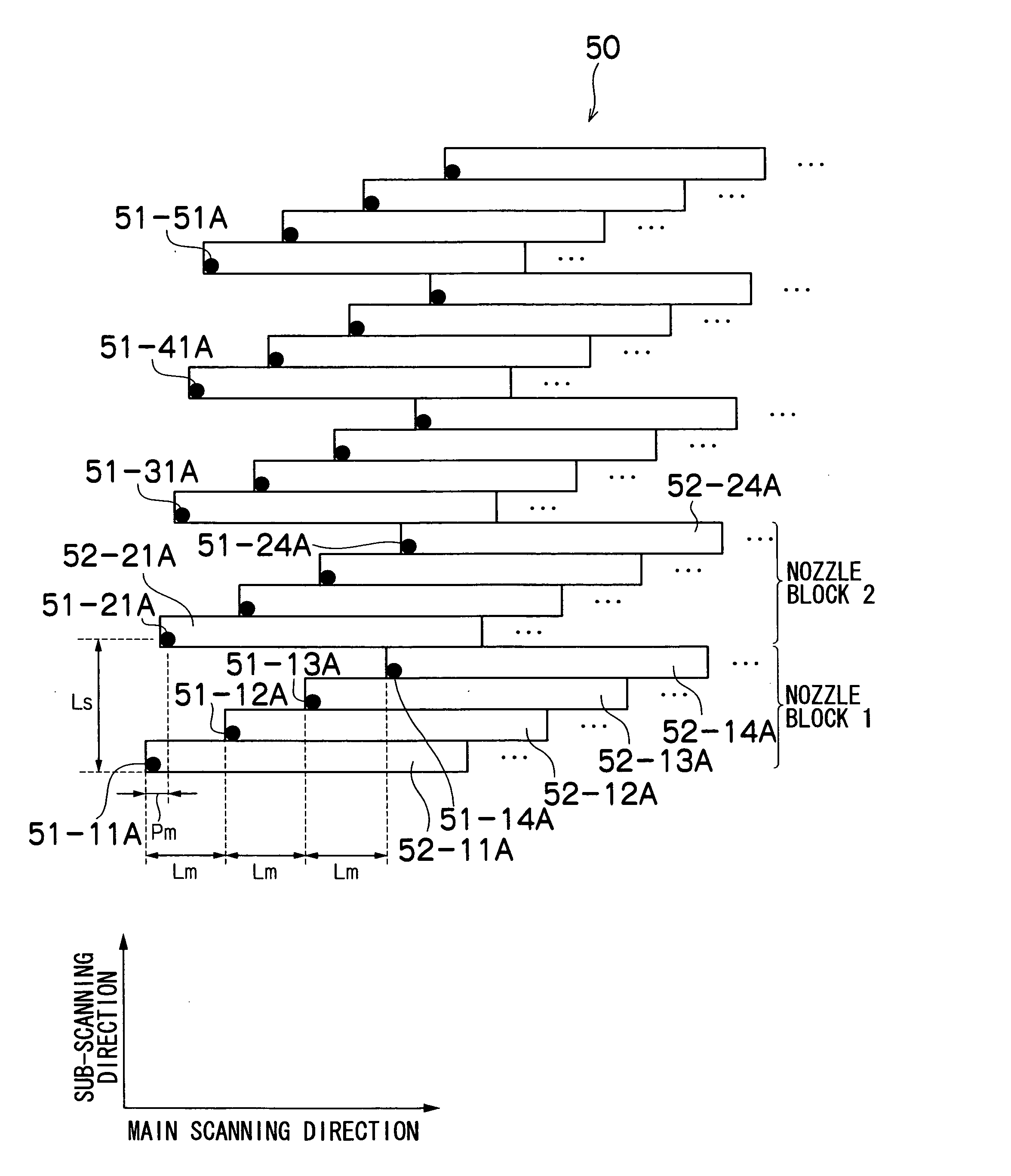

[0053] Below, a liquid droplet discharge head and an image forming apparatus according to the present invention are described in detail, with reference to the accompanying drawings.

[0054] In the liquid droplet discharge head according to the present invention, when arranging the nozzles in a two-dimensional matrix array, the nozzles are displaced with respect to each other as described in detail below, rather than simply arranging the nozzles in an oblique fashion as in the related art. Therefore, the time interval between the ejection of droplets which are discharged from different nozzles and overlap mutually on the recording medium is increased, thereby preventing landing interference between adjacent dots.

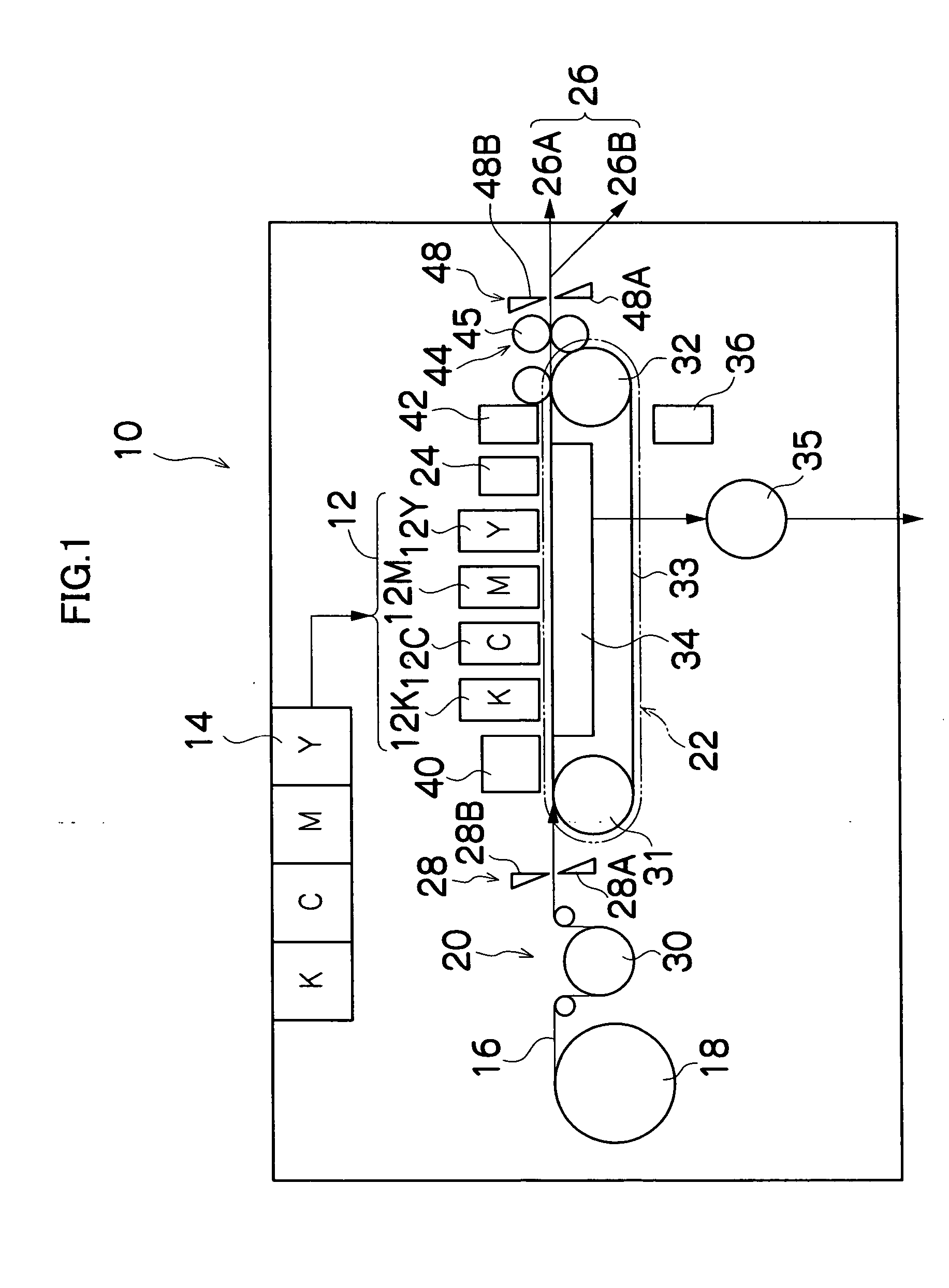

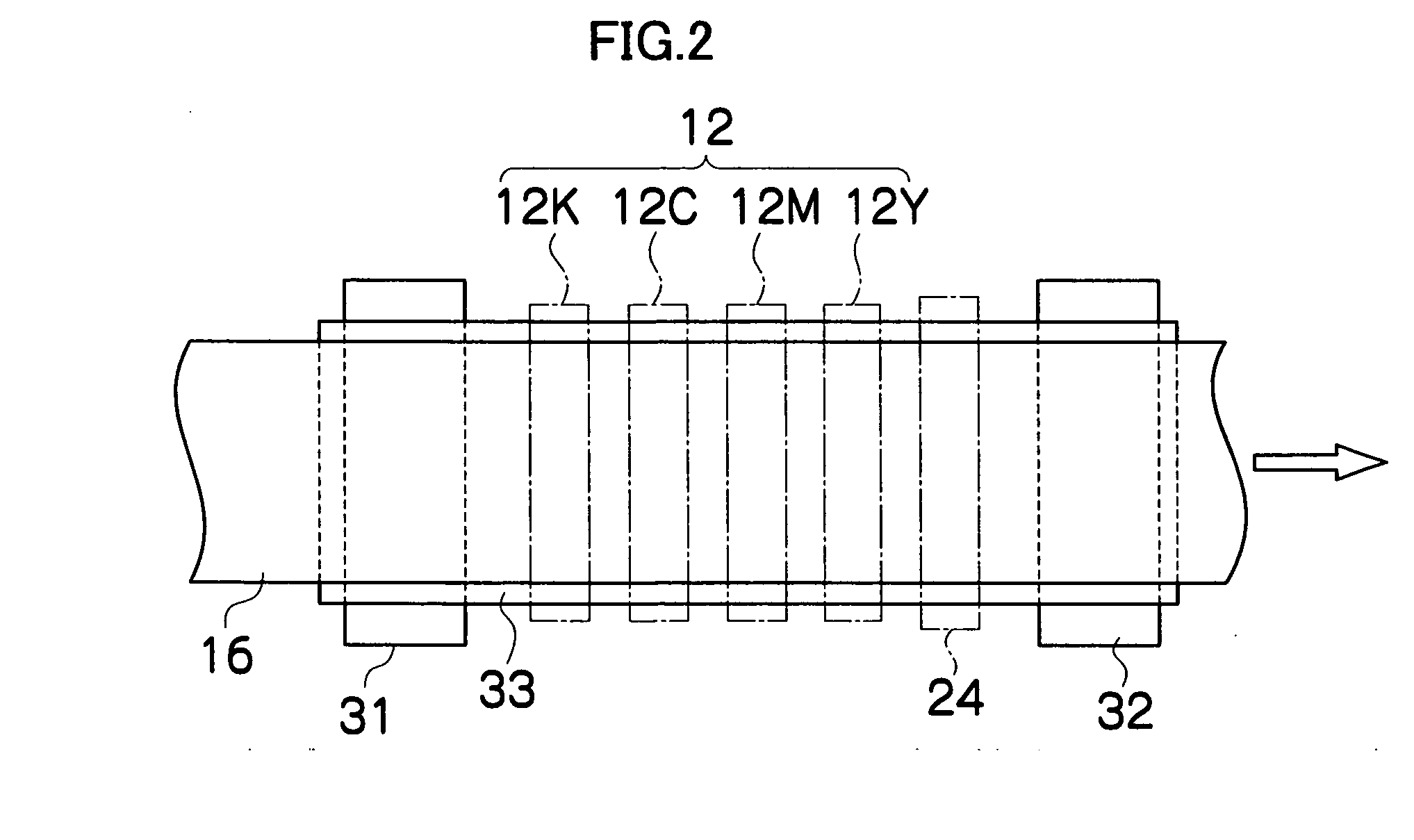

[0055]FIG. 1 is a general schematic drawing of an inkjet recording apparatus according to an embodiment of the present invention. As shown in FIG. 1, the inkjet recording apparatus 10 comprises: a printing unit 12 having a plurality of droplet discharge heads or print heads 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com