Spallation device for producing neutrons

a technology of a spallation device and a neutron, which is applied in the direction of nuclear energy generation, nuclear reactors, electrical apparatus, etc., can solve the problems of limiting the performance of the spallation target, threatening confinement, and difficult if not impossibl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

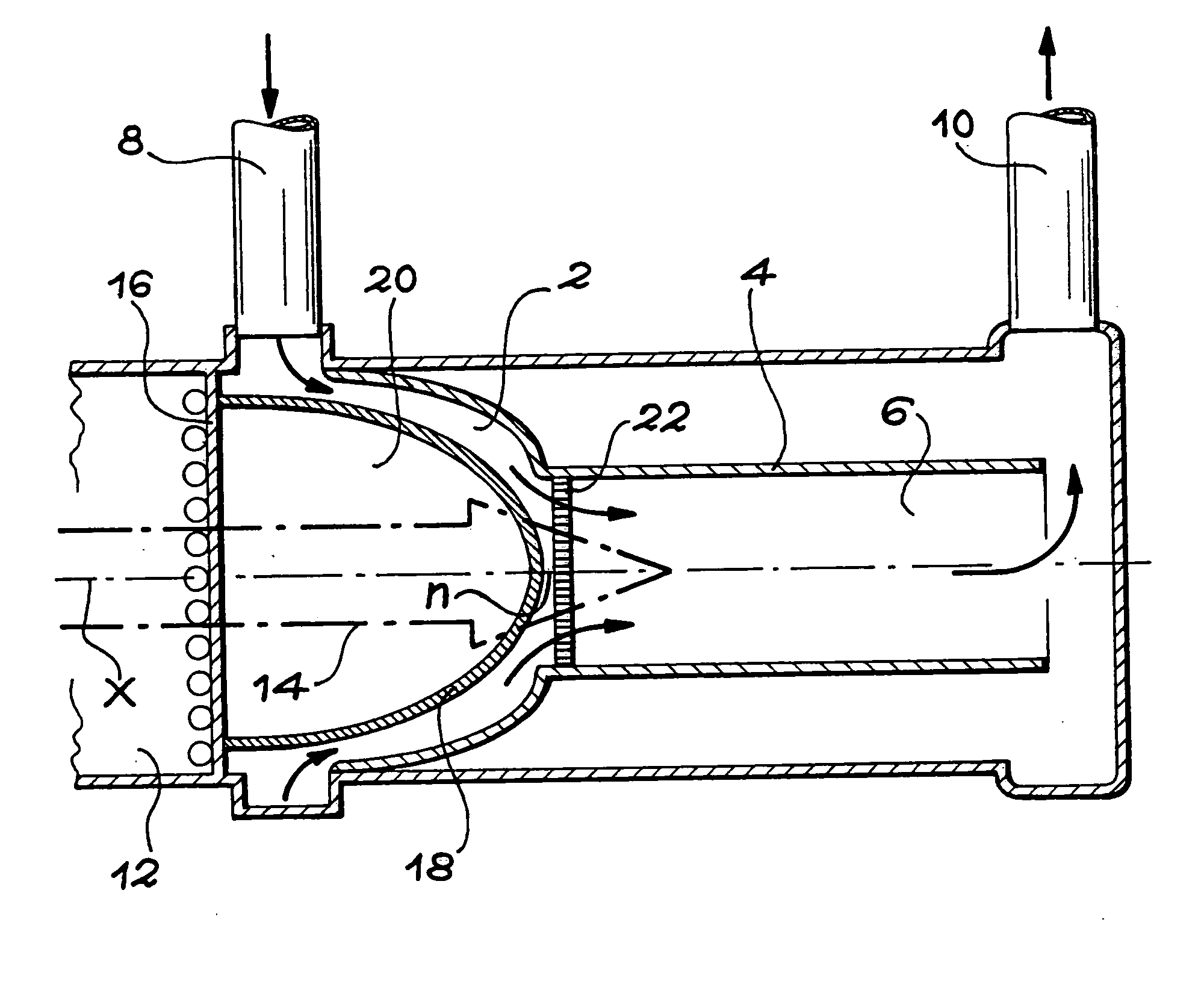

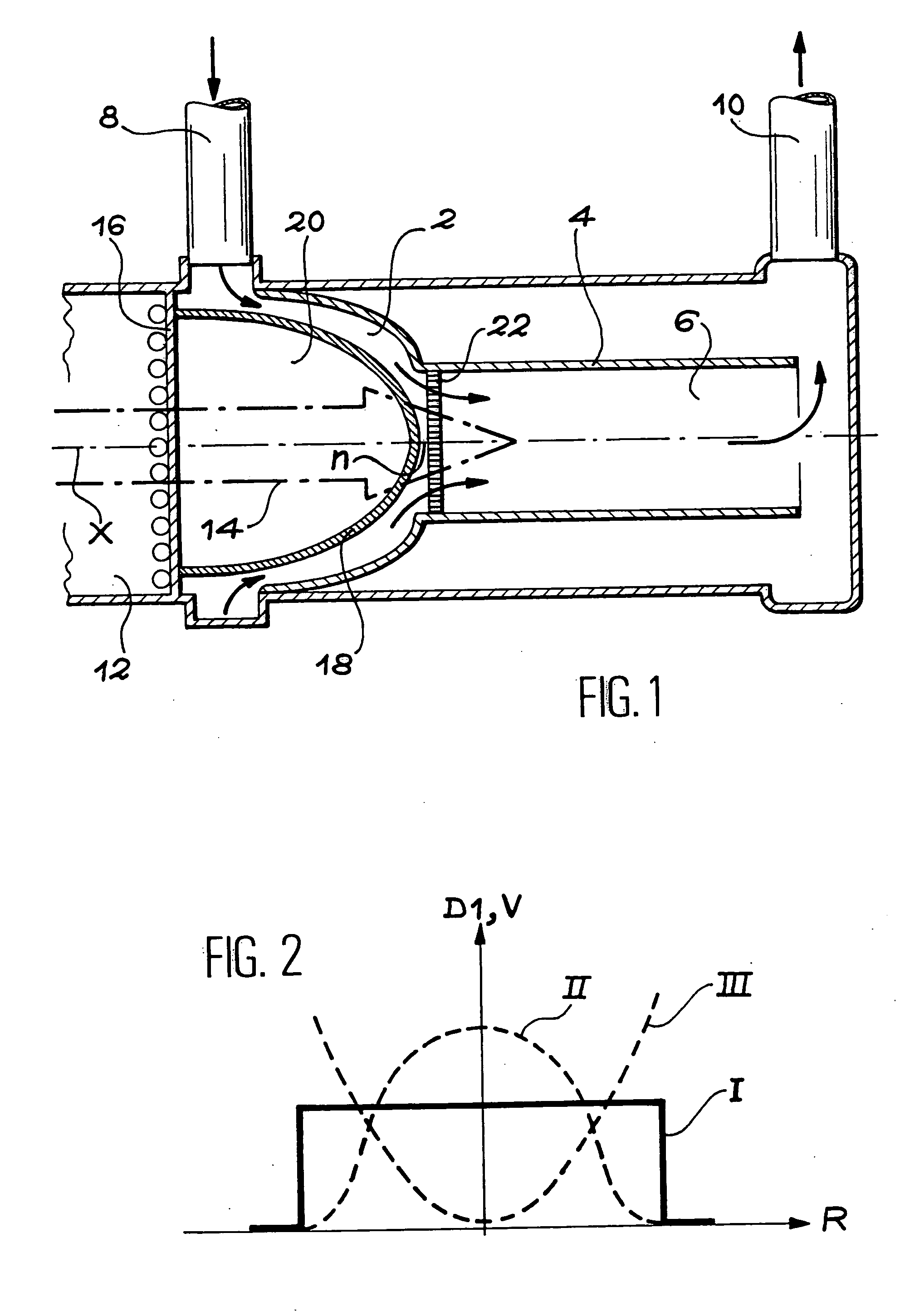

Embodiment Construction

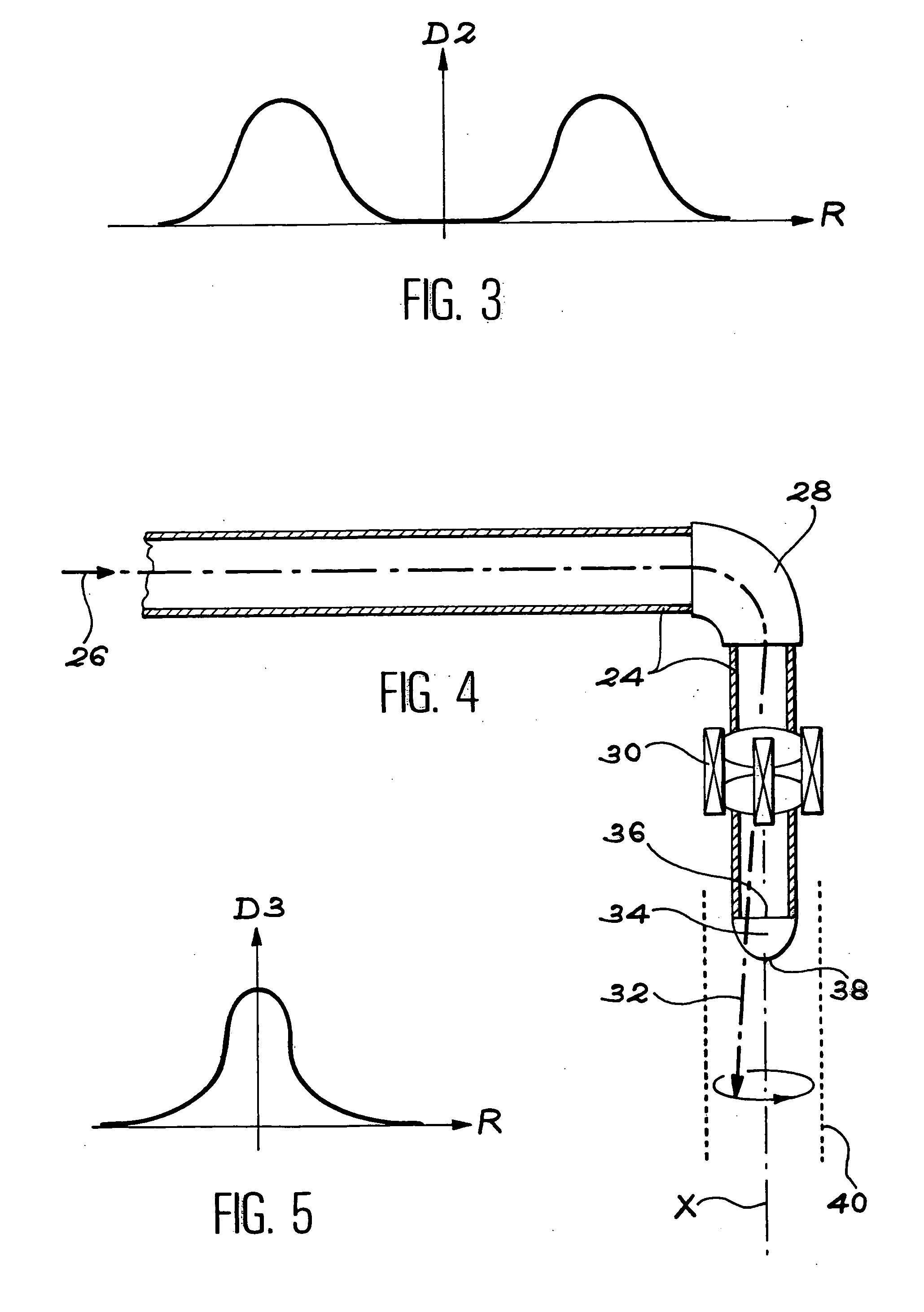

[0067] In the examples of the invention described below, a hollow particle beam also called an “annular particle beam” is used, in which the radial current density distribution is approximately gaussian. FIG. 3 diagrammatically illustrates variations of this density D2 as a function of the distance R from the hollow beam.

[0068] This is a means of solving the following two problems: [0069] limiting the current density gradient to avoid excessive internal mechanical stresses in key components of the spallation device, and particularly the leak tight partition, and the spallation target in the case of a solid target, and [0070] moving the peak power away from the axis of symmetry of the target to avoid cooling problems.

[0071] An annular distribution of the current density in the particle beam can be obtained using magnetic optical means that are placed on the input side of the leak tight partition.

[0072]FIG. 4 diagrammatically illustrates the generation of a hollow particle beam. FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com