Bollard and cable vehicle barrier

a cable vehicle and boltard technology, applied in roadway safety arrangements, roads, construction, etc., can solve the problems of slow activation of hydraulic actuators, difficulty and time-consuming after-sales repair, prior art devices are difficult and time-consuming to repair, etc., and achieve the effect of expanding the path width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

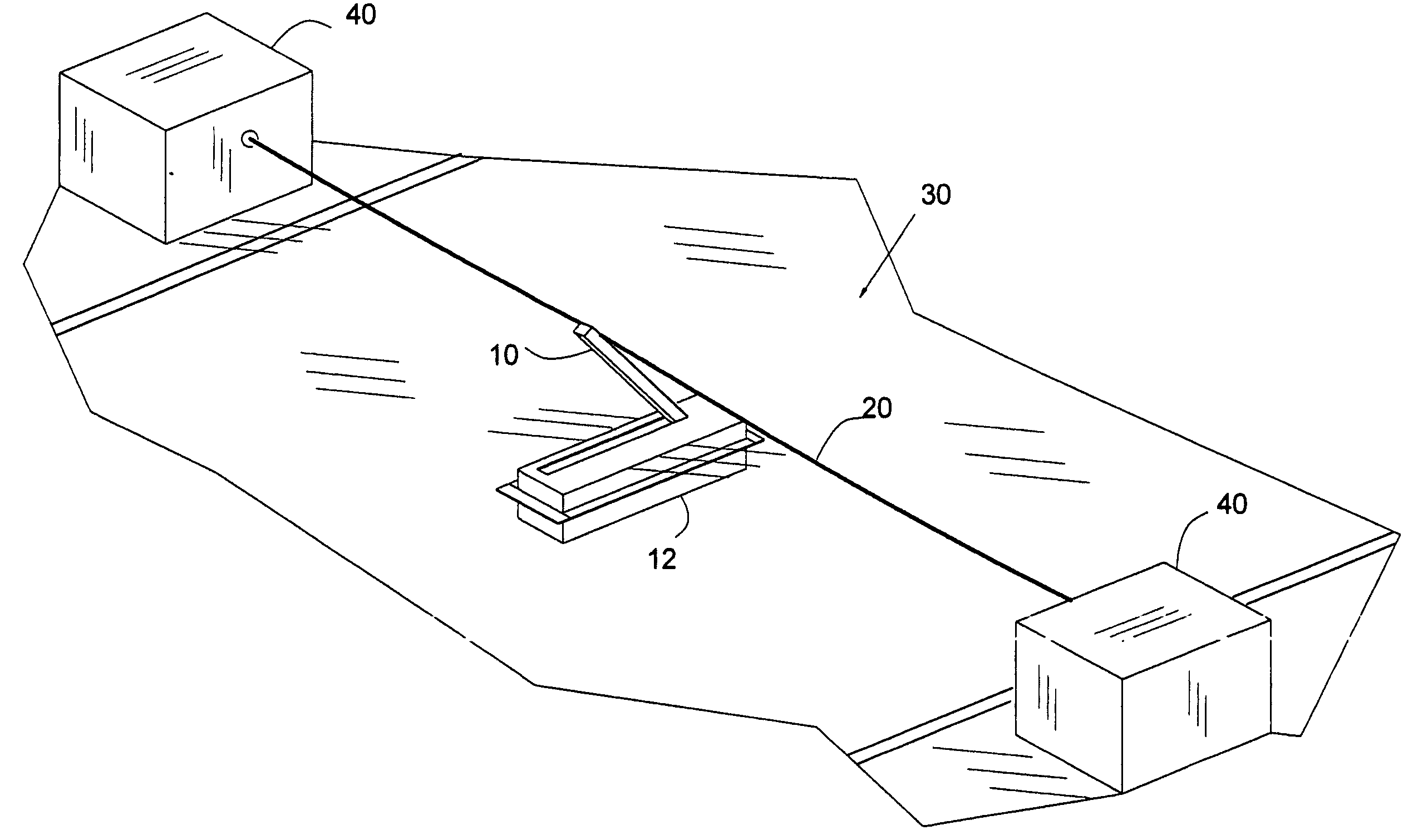

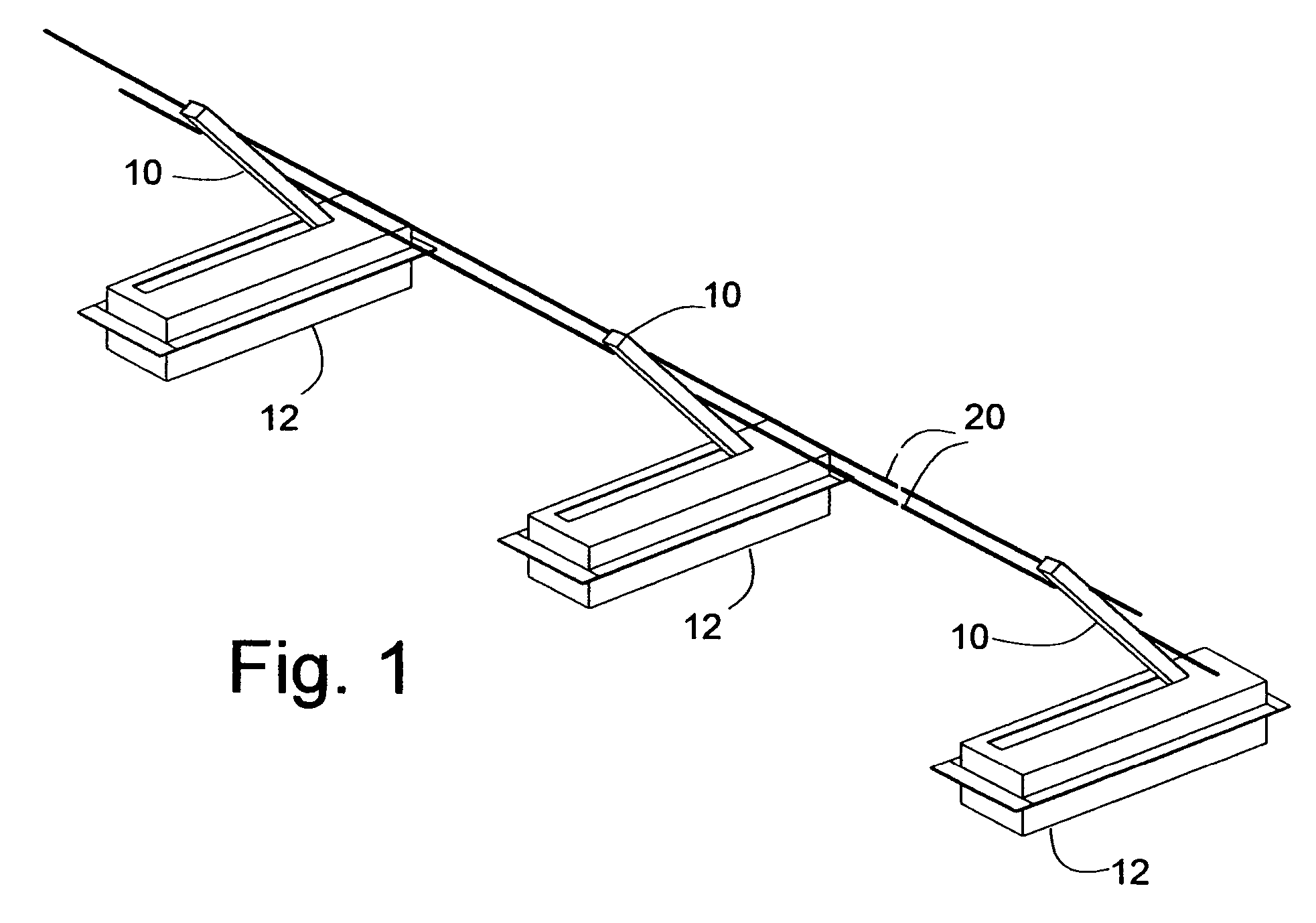

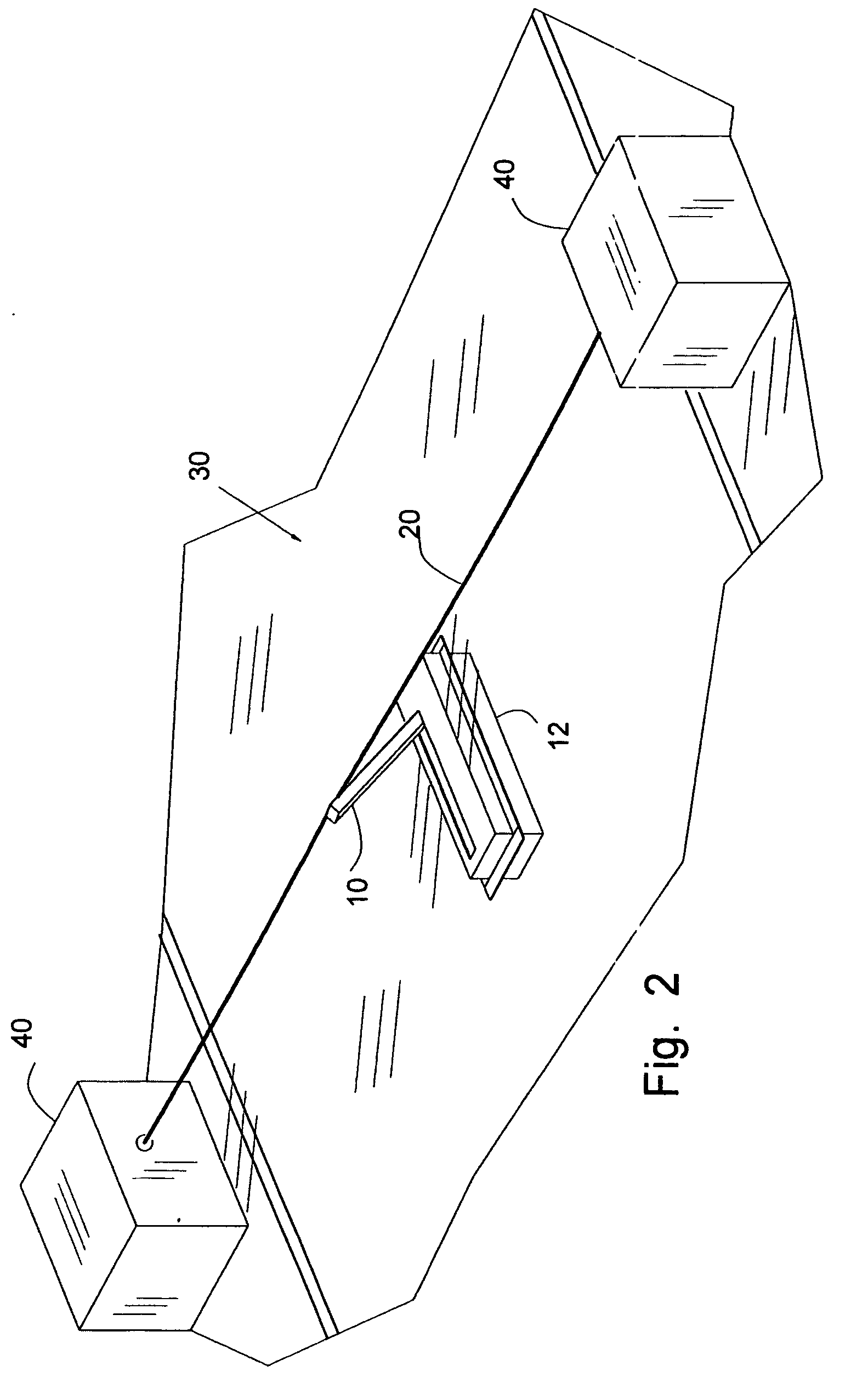

[0024] Referring now to the drawings and to FIG. 1 in particular, multiple bollards 10 are shown retaining and elevating barrier elements that have the form of two flexible steel cables 20. The condition shown is a raised condition, wherein cables 20 are elevated by the bollards 10 above respective bollard vaults 12. The vaults 12, in use, are buried into, and flush with, the surface of a vehicle path. In most cases, the vehicle path is formed of pavement directly on the ground.

[0025] In a stored or down condition, the bollards 10 are each received within, and flush to, the top of its respective bollard vault 12. In this condition, the cables 20 are flush to the vehicle path.

[0026] In operation, as a vehicle barrier, the bollards 10 are raised to place the cables 20 in the path of a vehicle. The cables 20 intercept the vehicle and prevent continued motion of the vehicle past the cables 20. The vehicle's energy is absorbed by the cables 20, bollards 10 and vaults 12. The vehicle fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com