Method and composition for car ramp concealing fiberglass artificial geological rock formation

a technology of artificial geological rock formation and car ramp, which is applied in the direction of construction, foundation engineering, etc., can solve the problems of compromising product quality, slow production rate, burdensome and time-consuming, etc., and achieve the effect of realizing natural rock characteristics and relatively rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

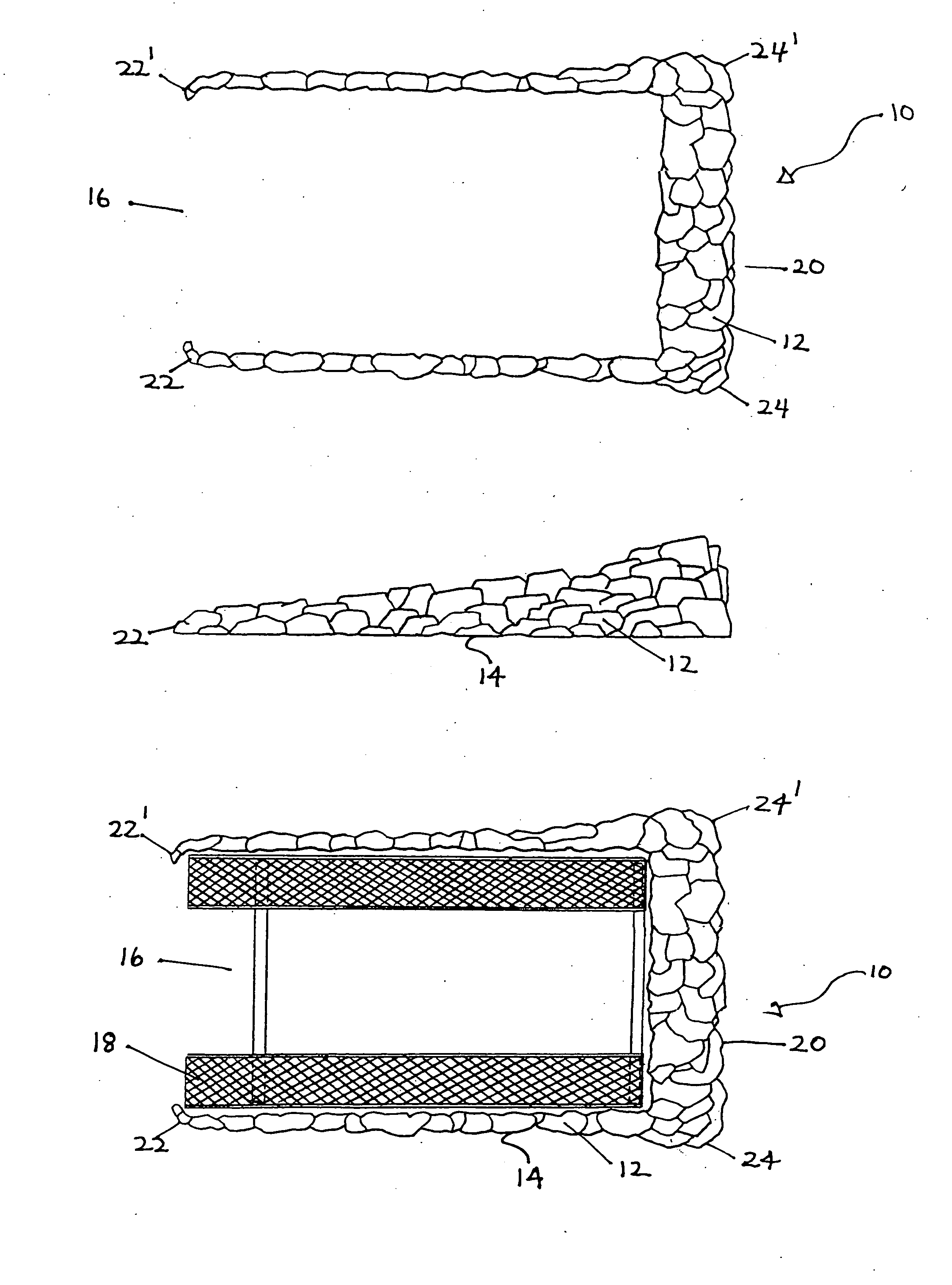

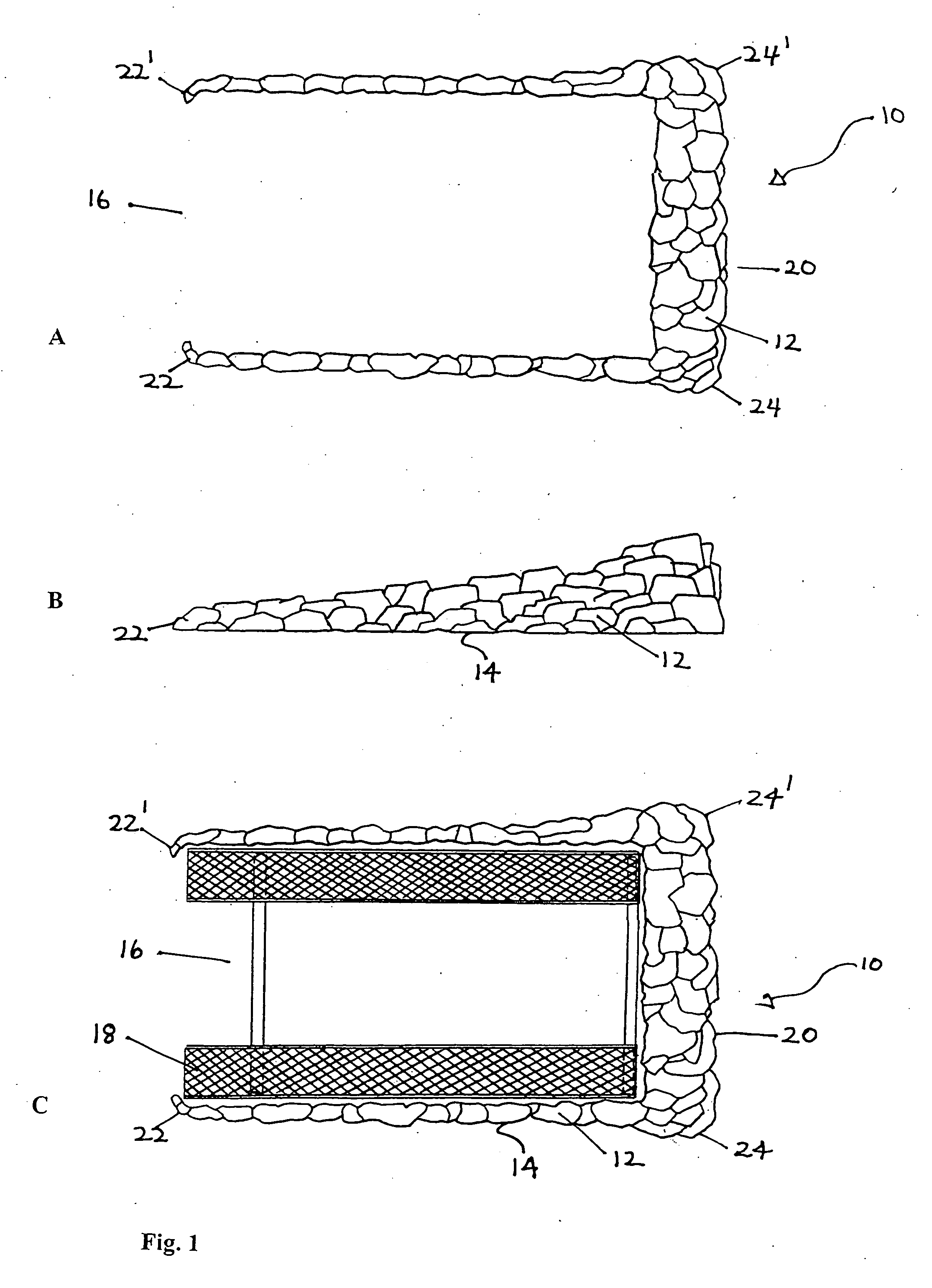

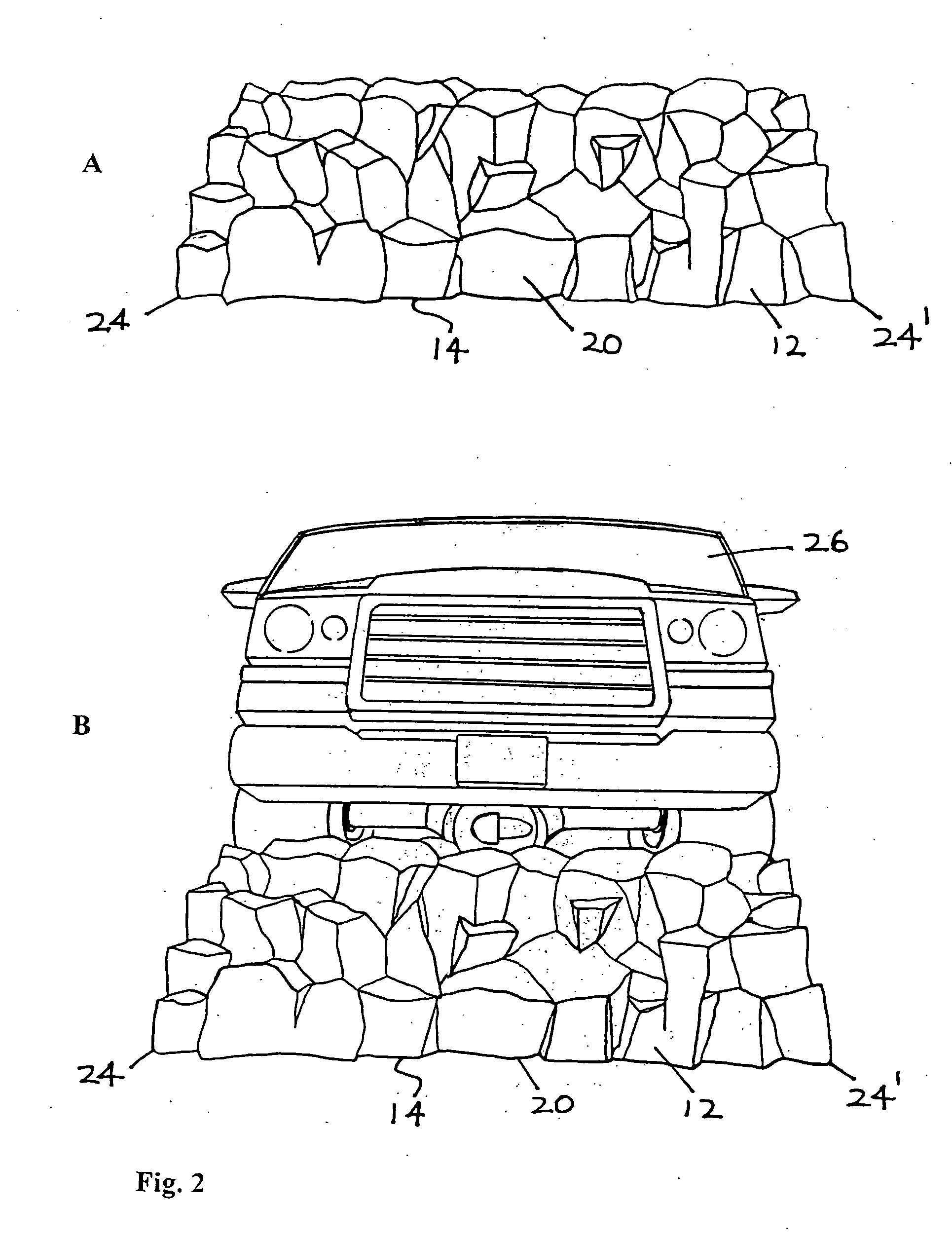

[0023] The present invention inheres, in pertinent part, with a method and composition for producing semi-unitary fiberglass composite artificial rock formations that can be used as facades for concealing car ramps. The artificial geological rock formation facades of the present invention can be used and therefore practiced with all manner of mold formation known in the art. In order to establish context, the following brief summary of basic rock mold production is provided below.

[0024] A synthetic rubber, such as silicone rubber or a flexible urethane rubber, can be utilized by applying the uncured liquid coating and thereafter curing the synthetic rubber to form the rubber mold. As an example, a flexible silicone rubber mold can be produced using 10 parts of silicone-forming compound with one part curing agent, such as General Electric RTV 630. This provides a liquid uncured rubber-forming material that is applied to the rock used as a model. After application of the liquid uncur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com