Exhaust gas cleaning device

a cleaning device and exhaust gas technology, applied in the direction of exhaust treatment electric control, electrical control, separation process, etc., can solve the problems of excessive temperature rise of catalyst or catalyst carrier, excessive catalyst temperature rise, storage nox may be released, etc., to reduce the amount of nox slip and the rate of catalyst temperature rise. , the effect of gradual ris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

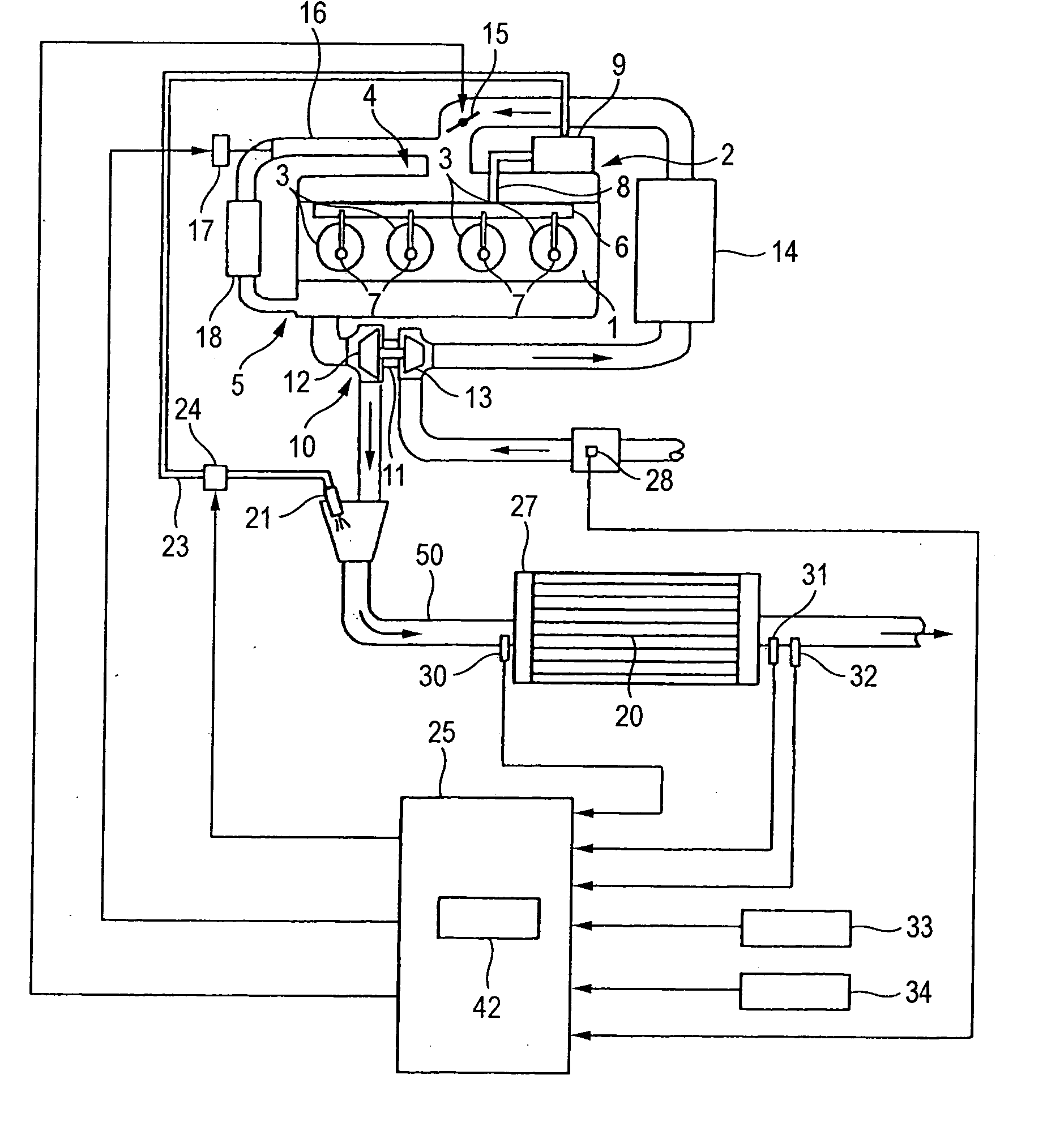

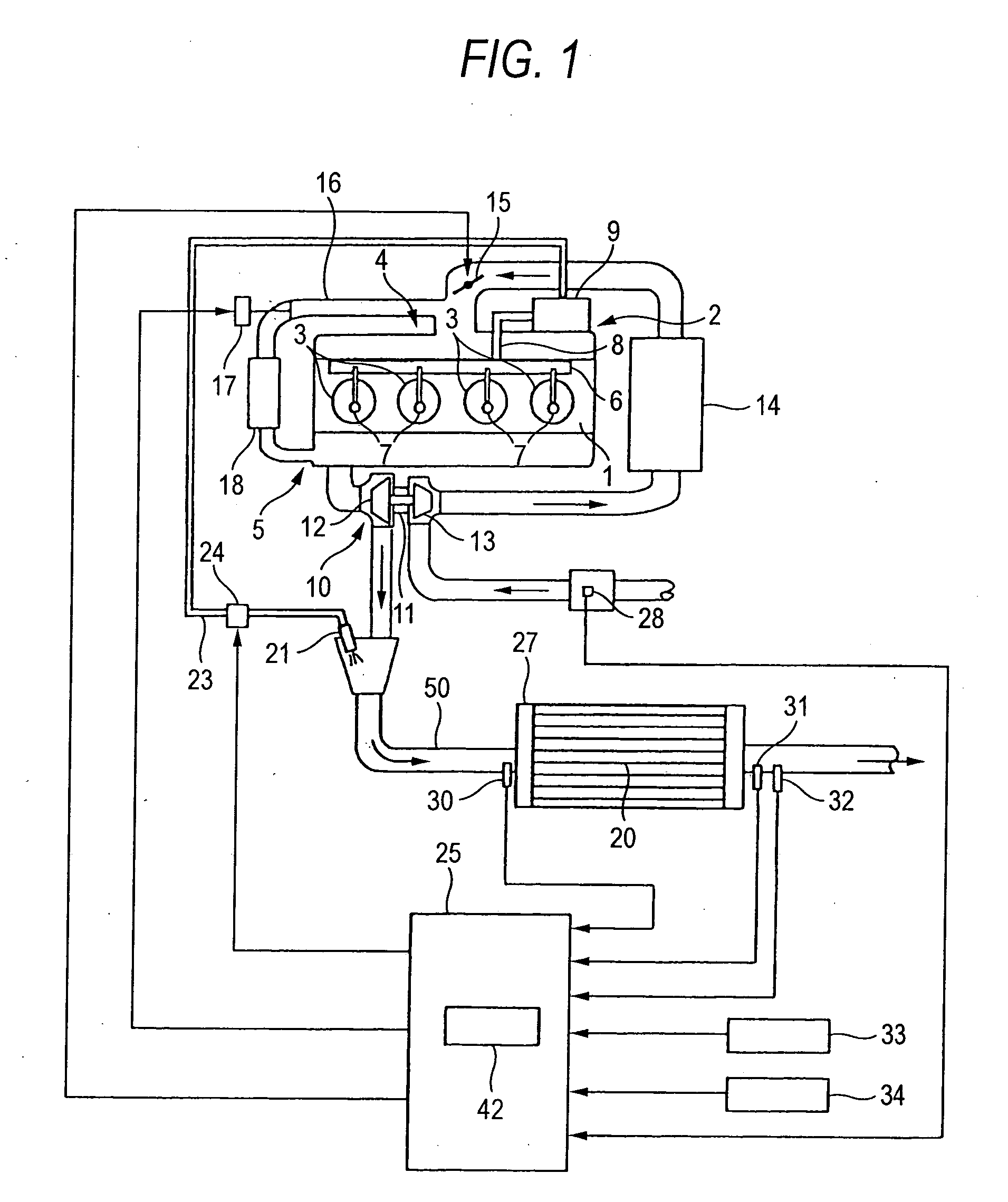

[0024]FIG. 1 shows an exhaust gas cleaning device, which is an embodiment of this invention. This exhaust gas cleaning device is applied to an internal combustion engine (referred to hereinafter as “engine”) 1. The engine 1 is a four-cylinder engine arranged with a fuel supply system 2, combustion chambers 3, an air intake system 4, an exhaust system 5, etc., as the principal parts. The fuel supply system 2 is equipped with a supply pump 9, a common rail 6, and injectors 7, which are the main injection unit and function as air-fuel ratio changing unit. The supply pump 9 is driven by the engine 1, applies high pressure to fuel pumped up from an unillustrated fuel tank, and supplies the fuel to the common rail 6 via an engine fuel passage 8. The common rail 6 functions as a pressure accumulating chamber that holds (accumulates the pressure of) the high-pressure fuel, supplied from the supply pump 9, at a predetermined pressure, and distributes the pressure-accumulated fuel among the i...

second embodiment

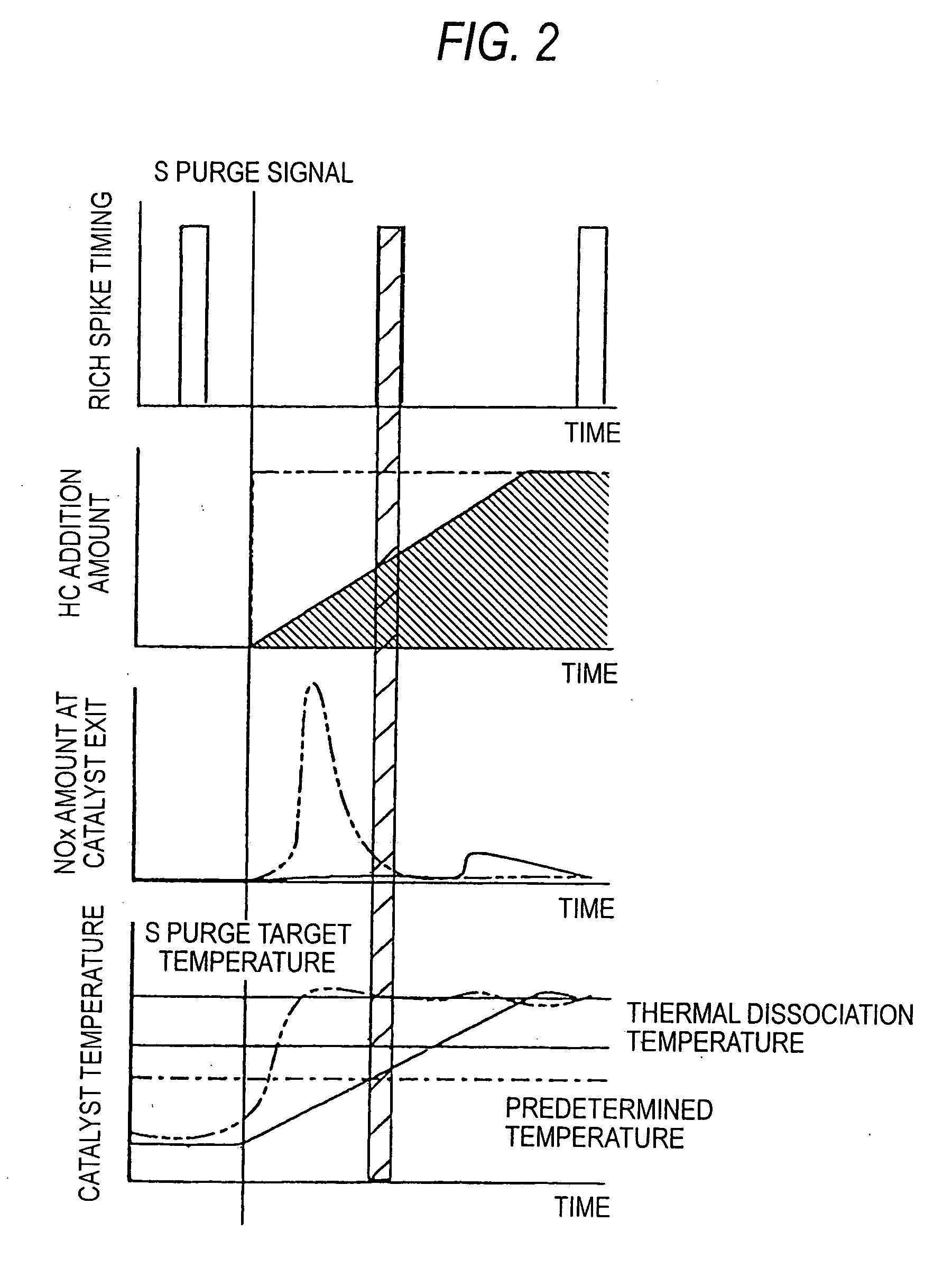

[0051] Newt, second embodiment of the invention will be described below. In this second embodiment, as shown in FIG. 4, in the S poisoning recovery control, a large amount of reducing components is supplied to the upstream side of the NOx catalyst in the exhaust system upon establishing the condition of maintaining the temperature of the NOx catalyst 20 at the S purge target temperature (600° C.) necessary for S poisoning recovery. However, though the large amount of reducing components supplied into the exhaust system exhibits the function of eliminating the SOx, etc., stored in the NOx catalyst 20 under the high-temperature condition, it also has the characteristic of raising the temperature of the NOx catalyst 20 further. Thus when the large amount of reducing components is supplied continuously to the upstream side of the NOx catalyst in the exhaust system, the NOx catalyst 20 may undergo excessive temperature rise, the stored NOx may become released due to thermal dissociation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com