Process for handling cargo and cargo handling facility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

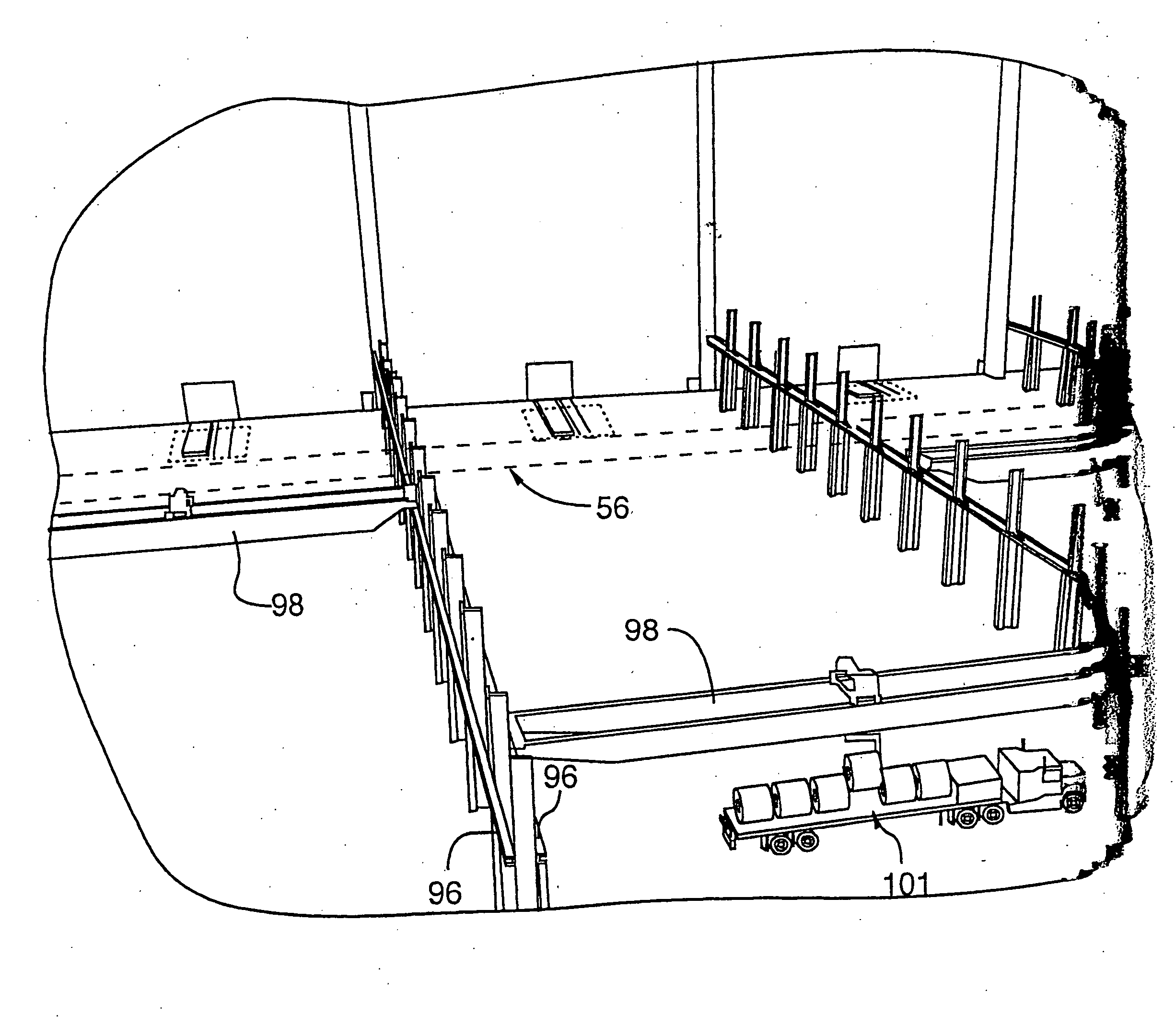

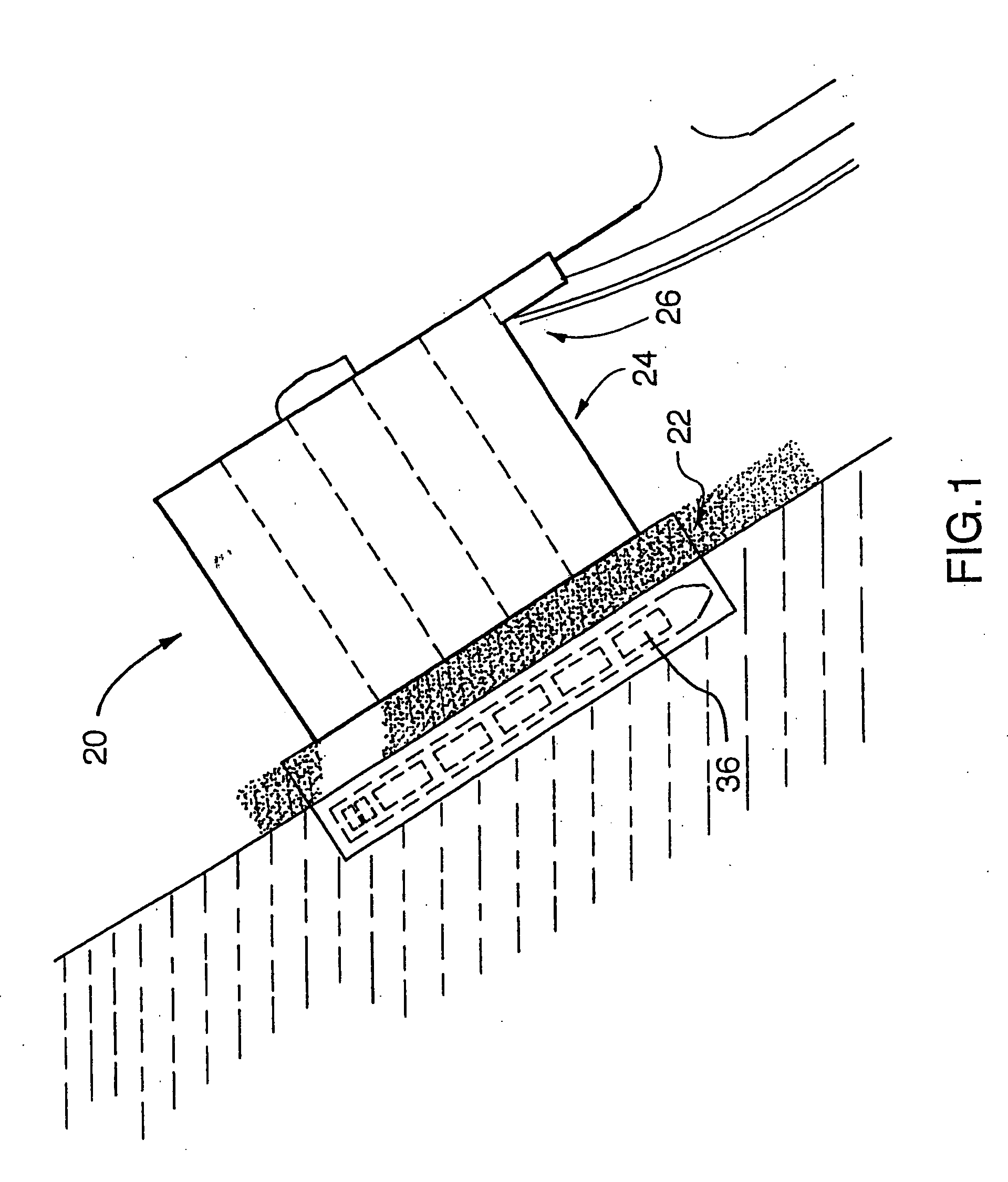

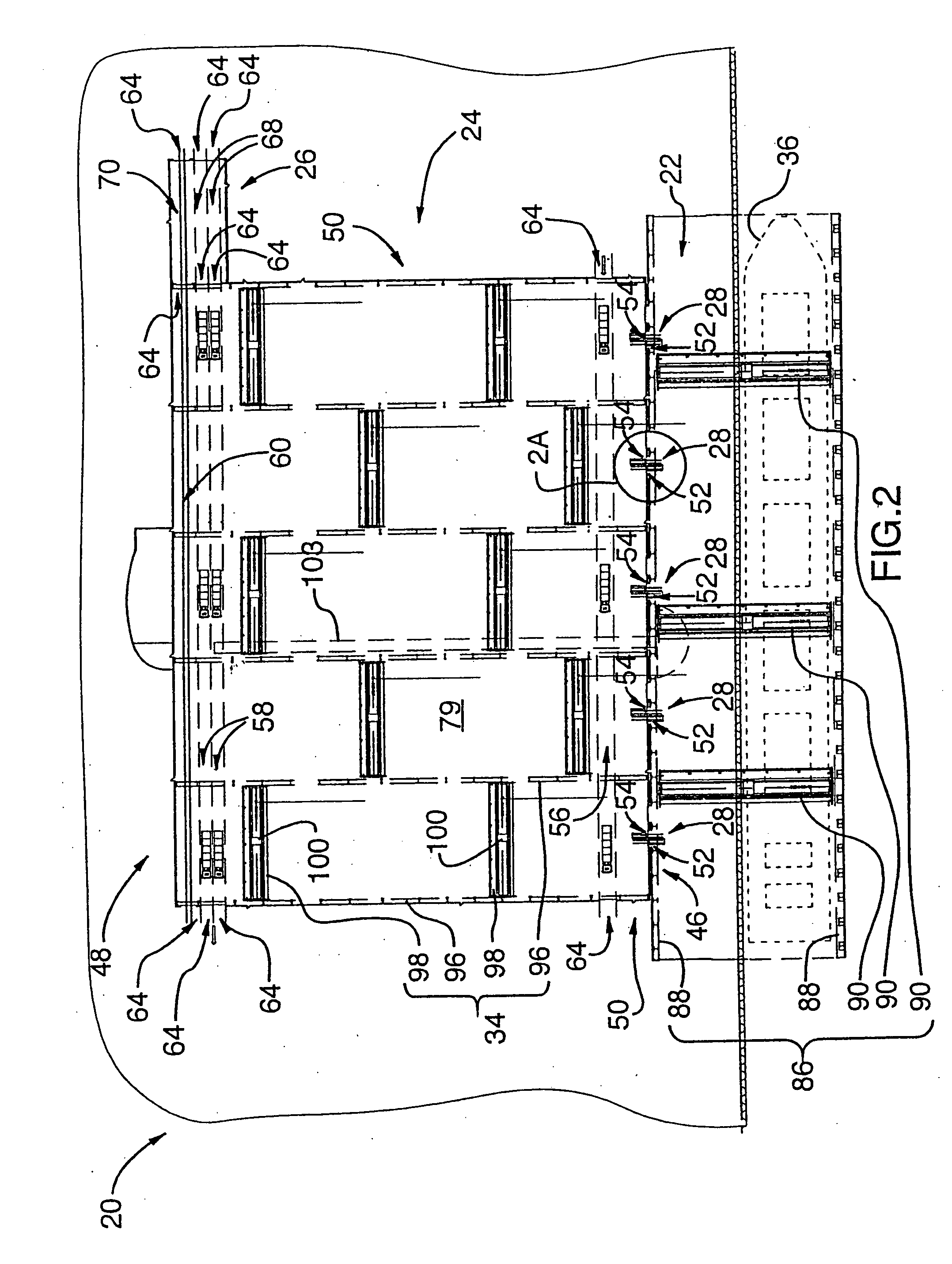

[0035] A process for handling cargo according to a preferred embodiment of the present invention will now be described with general reference to FIG. 1 through FIG. 12 of the drawings.

[0036] The process comprises the step of providing a cargo handling facility which is designated with general reference numeral 20 in FIG. 3, and will be understood to include, in the preferred embodiment illustrated: a wharf 22, a warehouse 24, a staging structure 26 and one or more cargo conveyance means 28, all as indicated in FIG. 2; a shelter 30, as indicated in FIG. 4; one or more overhead lifting means 32, as indicated in FIG. 5; and transport means 34, as indicated in FIG. 11.

[0037] In the preferred embodiment illustrated, the wharf 22 defines a marine berth of sufficient length to accommodate the docking of a marine vessel 42, said marine berth being shown in phantom outline in FIG. 1 and designated with general reference numeral 36. The wharf 22 preferably has defined thereon, substantially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com